Keeping a classic roadster running smoothly requires a balance of care, understanding of its inner workings, and a well-informed approach to maintenance. For car enthusiasts, the ability to assess and address issues without constant reliance on professionals is invaluable. This guide provides an in-depth look at the essential steps for upkeep and effective troubleshooting, making complex tasks more accessible.

Understanding the details of system checks and regular tune-ups helps owners keep their vehicles in prime condition. From engine performance to the electrical setup, having a clear understanding of these components can dramatically improve efficiency and extend the lifespan of key parts. Routine tasks that may seem daunting are made approachable, allowing enthusiasts to enjoy hands-on care and improve their skills.

This guide also covers insights into common challenges that arise with a vintage model, offering effective strategies to address issues before they escalate. With clear explanations of each system’s function and common problem indicators, even intricate processes become manageable. Whether it’s preventive care or dealing with unexpected issues, this guide supports a confident approach to vehicle maintenance.

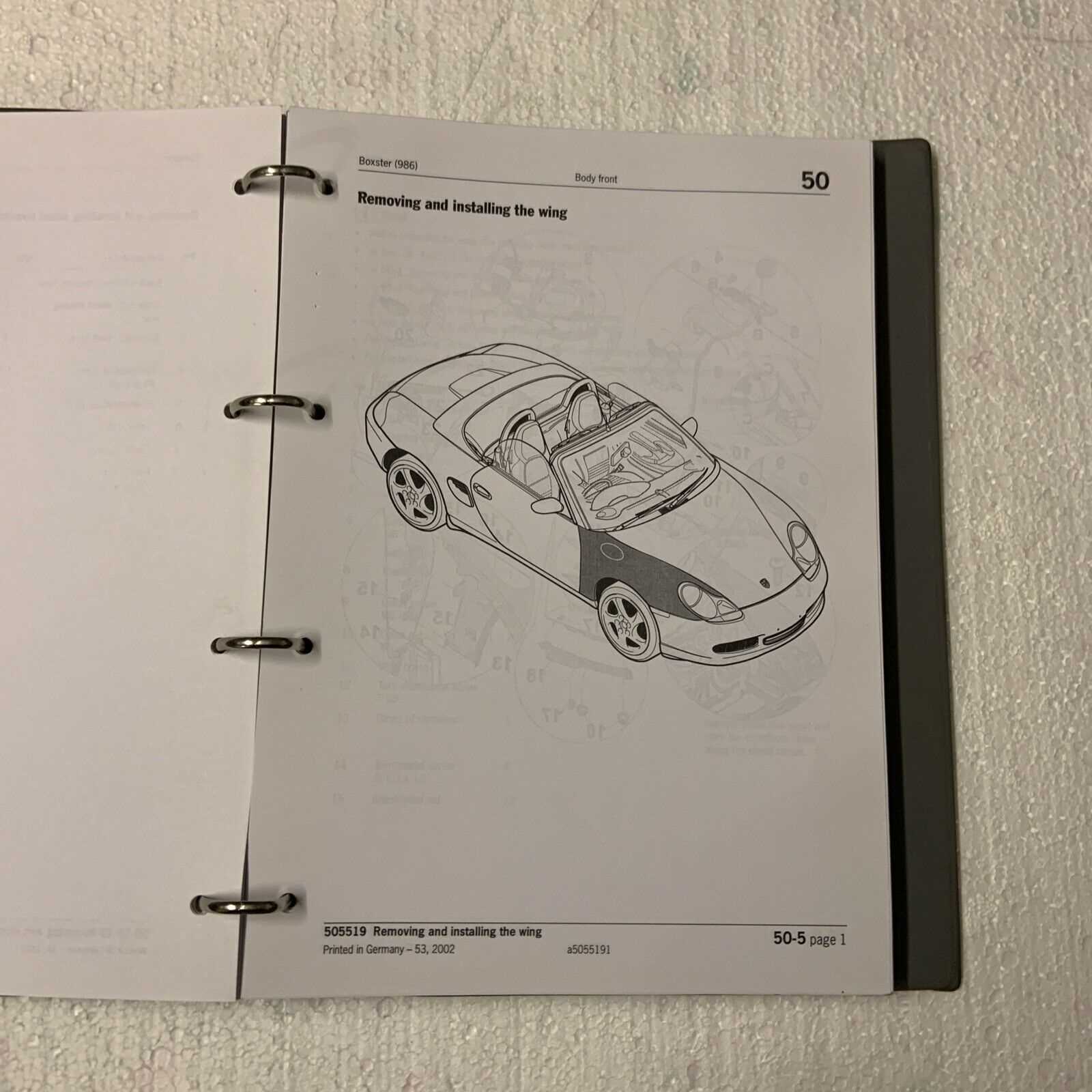

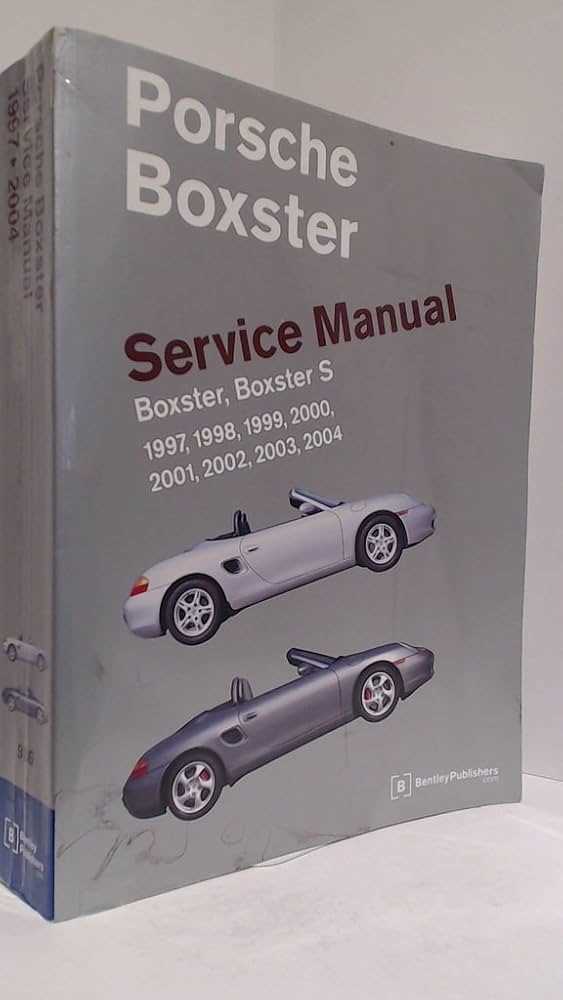

Porsche Boxster 986 Repair Manual

Understanding the intricacies of vehicle maintenance is essential for anyone aiming to preserve their automobile’s performance and longevity. This guide section provides insight into the fundamental systems and components, helping enthusiasts and owners navigate through routine care and specific technical adjustments.

With a focus on essential upkeep, we’ll cover common tasks that support engine efficiency, optimal handling, and overall system reliability. Whether it’s routine servicing or addressing unique mechanical nuances, these guidelines will assist in maintaining peak condition.

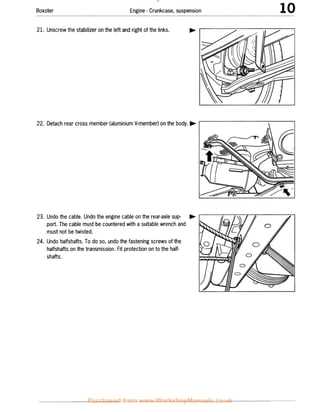

Detailed Systems Overview: Here, we explore key functional areas, including powertrain, suspension, and electrical systems. Each component has a specific role in ensuring smooth operation, and understanding these parts can simplify diagnostics and repairs, empowering users with hands-on knowledge to address challenges effectively.

Upkeep and Troubleshooting: Regular check-ups can prevent many issues. Simple, periodic inspections and minor adjustments can make a significant difference in preventing wear and extending the life of each part. Detailed explanations will help troubleshoot and correct common issues, making vehicle care more accessible to all levels of experience.

Common Issues and Solutions

Over time, certain mechanical and electronic components may develop wear or require maintenance. Recognizing frequent issues and addressing them promptly can extend the longevity and performance of the vehicle. Below is an overview of typical challenges along with recommended approaches to handle them efficiently.

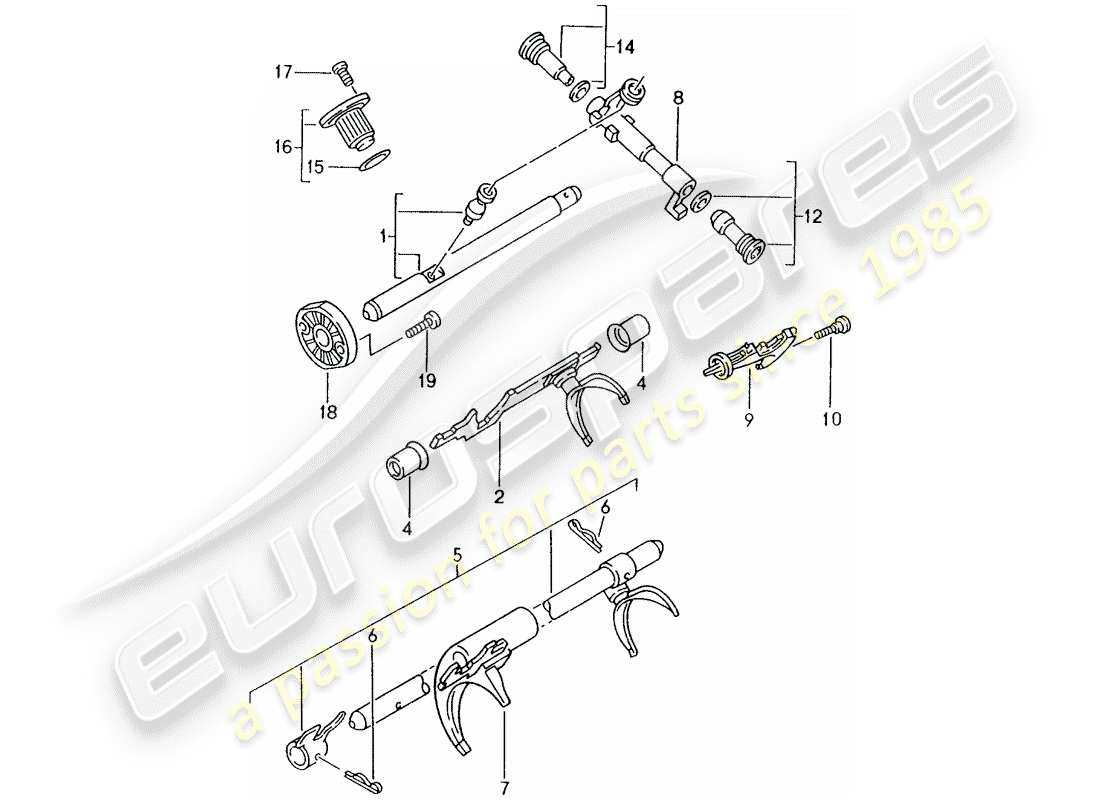

Engine and Transmission

The engine and transmission systems are complex and can sometimes exhibit signs of reduced performance, unusual sounds, or fluid leaks. These symptoms often point to the need for part replacements or lubrication adjustments. Regular checks and timely action can prevent more serious complications. Ensuring fluid levels are sufficient and using recommended products can significantly improve system durability.

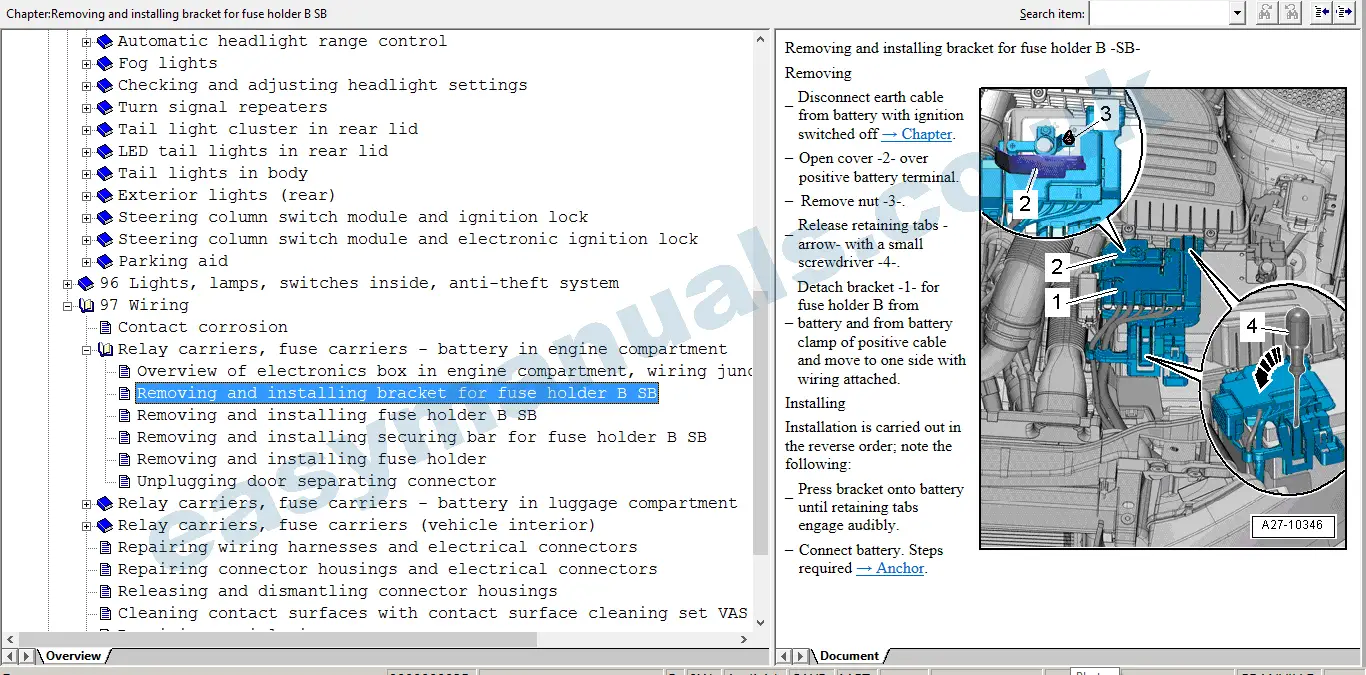

Electrical and Lighting

Electrical issues can manifest as flickering lights, intermittent gauge malfunctions, or non-responsive control buttons. These problems are often related to wiring connections, fuse conditions, or battery health. Periodic inspections of these electrical connections and the replacement of worn components will help maintain system reliability.

| Issue | Common Cause | Solution |

|---|---|---|

| Unusual Engine Noise | Insufficient lubrication or worn-out components | Check oil levels, replace any worn parts, and use the recommended oil type |

| Transmission Slippage | Low or degraded transmission fluid | Inspect fluid levels, add or replace with the correct fluid type |

| Flickering Dashboard Lights | Loose wiring or weak battery | Secure wiring connections and test battery charge; replace if

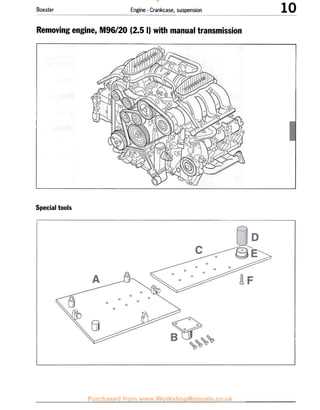

Essential Tools for DIY RepairsEvery enthusiast knows that successful maintenance begins with the right selection of tools. Having a well-prepared toolkit not only makes each task easier but also ensures precision, efficiency, and safety. Whether you’re handling routine upkeep or tackling more intricate tasks, a versatile and reliable tool set is key to achieving top-notch results in any home workshop setting. Basic Tools Every Workshop Needs

Starting with essential hand tools, items such as wrenches, screwdrivers, and pliers form the backbone of any toolkit. A sturdy socket set with a range of sizes is invaluable for various adjustments, while a reliable set of spanners adds flexibility. Additionally, having a quality torque wrench ensures each component is tightened to the correct specification, reducing the risk of over-tightening or damage. Specialized Tools for Enhanced Precision

Beyond basic items, some specialized equipment can greatly enhance accuracy and ease in more complex tasks. A digital multimeter helps in diagnosing electrical systems, while a sturdy jack and jack stands provide the stability needed for more in-depth inspections underneath. For those dealing with intricate components, picks, and pry tools are invaluable in accessing hard-to-reach areas without causing unnecessary wear. Equipping your workspace with these essential tools ensures not only effective and safe maintenance but also builds confidence in handling various technical challenges independently. Engine Maintenance Tips

Regular care and attention to the engine can significantly enhance its performance and longevity. Adopting consistent maintenance practices can prevent common issues and ensure that the engine runs smoothly and efficiently over time. Check Fluids Regularly: Maintaining optimal fluid levels is critical for engine health. Regularly inspect oil, coolant, and brake fluids, ensuring they are topped up and replaced as recommended. Fresh fluids help reduce friction, regulate temperature, and prevent corrosion. Replace Filters Timely: Air and fuel filters protect the engine by keeping contaminants out of sensitive areas. Replacing these filters at proper intervals promotes efficient combustion and reduces the risk of internal wear. Inspect Belts and Hoses: Belts and hoses are vital to various engine functions, including cooling and power delivery. Regular inspection for wear, cracks, or leaks ensures that these components don’t fail unexpectedly, which could lead to costly repairs. Monitor Spark Plugs and Ignition: Spark plugs play a crucial role in combustion efficiency. Inspecting and replacing them when necessary ensures better fuel economy and a smoother engine operation, while also minimizing emissions. Listen and Observe: Any unusual sounds, vibrations, or smells can be early signs of potential issues. Paying attention to these cues allows for timely intervention, reducing the risk of more serious damage and maintaining overall performance. Regular engine maintenance enhances reliability, improves fuel efficiency, and prolongs the life of the vehicle. These simple practices help maintain peak performance and prevent unforeseen breakdowns. Transmission Troubleshooting GuideMaintaining a well-functioning transmission is crucial for smooth and efficient vehicle operation. This section provides an overview of common transmission issues, offering insights into typical symptoms and potential causes. With a careful approach, these guidelines can help identify sources of shifting problems, unusual noises, or fluid leaks, ensuring each issue is addressed with appropriate solutions. Identifying Symptoms: Transmission problems often manifest in various forms. Recognizing early signs such as delayed gear engagement, slipping gears, or unusual vibrations can prevent more severe complications. Observing these symptoms can provide clues to specific underlying issues. Common Causes of Transmission Issues: Transmission troubles can stem from a range of factors, including fluid quality, mechanical wear, or sensor failures. Low or degraded transmission fluid is one of the primary causes, leading to overheating and poor performance. Mechanical wear in components such as clutch packs or gear synchronizers can also impair functionality, especially in older systems. Tip: Regularly check transmission fluid levels and condition. A low or discolored fluid level can indicate leaks or contamination, both of which warrant immediate attention. Diagnosing Unusual Sounds: Grinding, clunking, or whining sounds are often indicators of internal transmission issues. These sounds may result from worn bearings, misaligned gears, or insufficient lubrication. Investigating the source of the noise can reveal whether it’s linked to specific gears or occurs consistently, helping to narrow down the potential problem. Addressing Shifting Problems: Hard or erratic shifting can arise due to faulty sensors, solenoids, or software malfunctions. In automatic systems, these issues may relate to transmission control Electrical System Overview

The electrical framework of a modern sports automobile plays a crucial role in its overall performance and functionality. This intricate network ensures seamless communication between various components, facilitating critical operations such as lighting, starting the engine, and managing onboard electronics. Understanding this system is essential for effective diagnostics and maintenance. At the heart of this structure is the battery, which serves as the primary source of electrical energy. It not only powers the starter motor but also supports various electronic systems when the engine is off. The alternator takes over once the vehicle is running, recharging the battery and supplying power to the electrical systems, ensuring everything operates smoothly. Additionally, an array of fuses and relays safeguards the circuits by preventing overloads, while wiring harnesses distribute power and signals to different components. Each element within this setup is designed for efficiency and reliability, reflecting the high standards of engineering present in high-performance vehicles. Comprehending the electrical architecture is vital for identifying issues and implementing solutions. Regular inspections and tests can help maintain optimal functionality, ensuring that every electrical component performs as intended, thus enhancing the driving experience. Brakes and Suspension Care

Maintaining the braking and suspension systems of your vehicle is essential for ensuring safety, performance, and comfort during your driving experience. Proper care and timely interventions can significantly enhance the longevity and efficiency of these critical components. Regular inspections, fluid checks, and component replacements when necessary will help prevent unexpected failures and costly repairs. Begin by regularly inspecting brake pads and rotors for wear and tear. Look for any signs of uneven wear, which may indicate alignment issues or other underlying problems. Additionally, ensure that the brake fluid is at the correct level and free from contamination, as degraded fluid can compromise braking performance. The suspension system plays a vital role in maintaining stability and handling. Regularly check shock absorbers and struts for leaks or damage. Inspect bushings and joints for wear, as these components are crucial for providing a smooth ride and precise handling. Keep an eye on tire pressure and alignment, as improper settings can adversely affect suspension performance. Routine maintenance not only enhances safety but also contributes to the overall driving enjoyment. By addressing issues promptly and adhering to a maintenance schedule, you can ensure that your vehicle remains responsive and comfortable on the road. Cooling System Inspection

The cooling system is essential for maintaining optimal engine temperature and preventing overheating. Regular evaluation of this system ensures efficient operation and prolongs the life of the engine. This section outlines key aspects to consider when inspecting the cooling system, focusing on various components and their functionality. Key Components to Check

Inspection Process

By systematically evaluating these components and following the inspection process, potential issues can be identified early, helping to maintain the performance and longevity of the engine. Interior Restoration Techniques

Revitalizing the interior of a vehicle can significantly enhance its aesthetic appeal and overall comfort. Whether you’re aiming to refresh worn materials or restore functionality, a variety of techniques can be employed to achieve a professional finish. Consider the following methods for effective interior rejuvenation:

By implementing these strategies, you can breathe new life into the cabin environment, making it both visually appealing and comfortable for occupants. Exterior Paint and Bodywork

The exterior appearance of a vehicle significantly influences its overall aesthetic and value. Maintaining the paint and bodywork is essential for preserving the vehicle’s integrity and visual appeal. This section discusses various aspects of surface treatment, protective measures, and repair techniques to keep the exterior in prime condition. Surface Care and Maintenance

Regular maintenance is key to protecting the vehicle’s outer finish. Here are some essential tips:

Repair Techniques

In case of scratches, dents, or other imperfections, timely repairs can prevent further damage:

By following these maintenance and repair strategies, vehicle owners can ensure that the outer layer remains attractive and functional, reflecting the quality and care invested in their automobile. Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential for both the individual performing the work and the vehicle itself. Adhering to proper guidelines can help prevent accidents and ensure a smooth process, leading to successful outcomes. Here are some key safety measures to consider:

Additionally, following these practices can further enhance safety:

By prioritizing these safety precautions, individuals can significantly reduce the risks involved during maintenance activities. |