Ensuring the longevity and optimal performance of marine equipment is essential for any avid angler or boating enthusiast. Over time, wear and tear can affect various parts, making it necessary to understand how to properly address and resolve issues that may arise. In this section, we’ll explore key strategies and steps to help keep your setup functioning smoothly and efficiently.

For those encountering unexpected malfunctions or looking to enhance the reliability of their gear, having a thorough understanding of the internal mechanisms can make a substantial difference. From common adjustments to preventive upkeep, this guide delves into the practical knowledge needed for an effective approach to maintaining each component.

Additionally, we cover valuable insights into recognizing early signs of possible issues and handling basic fixes yourself. With the right approach, you can extend the life of your equipment, avoid unnecessary downtime, and stay prepared for every adventure on the water.

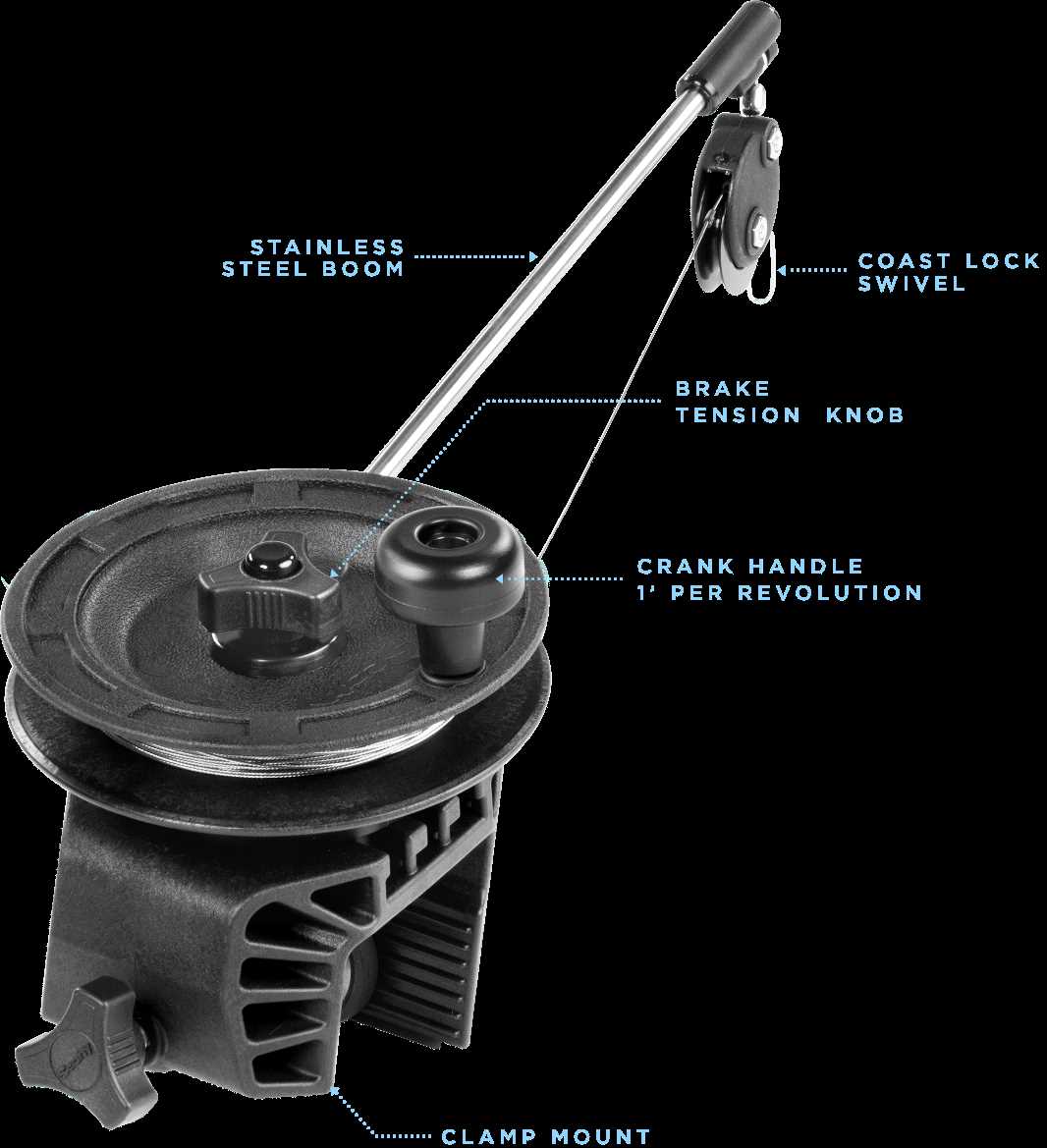

Overview of Scotty Downrigger Components

The system consists of several essential elements designed to optimize functionality and ease of use. Understanding these parts and how they work together is key to maintaining efficient operation and ensuring consistent performance.

- Base Mount: Provides stability and secures the entire unit to a surface, allowing smooth and secure installation for various settings.

- Crank Handle: Offers control over lowering and raising actions, making adjustments easy and precise.

- Spool and Line: Holds the cable or line in place, enabling depth control and steady positioning during operation.

- Boom: Extends outward to provide a steady reach, supporting the line and keeping it clear from the boat.

- Counter: Displays the depth level, allowing accurate adjustments to the line based on underwater conditions.

Each part contributes to the system’s functionality, ensuring a balanced and user-friendly experience.

Common Issues with Scotty Downriggers

Understanding and addressing frequent complications can ensure smooth operation and prolong the equipment’s lifespan. Below are typical problems that may arise and helpful tips for troubleshooting them.

Line Tension and Release Problems

One common challenge involves maintaining consistent line tension. Inconsistent line release can occur due to issues with the line’s setup or wear on the release mechanism. Regularly inspect all parts involved in line tension and ensure they are functioning optimally. Replacing worn components can often resolve this issue effectively.

Power and Motor Malfunctions

Power supply interruptions or motor faults can hinder the system’s overall functionality. Common causes include loose connections or battery-related issues. Ensure all electrical contacts are secure and check the power source. Addressing minor electrical problems promptly can prevent more significant damage.

Signs Your Downrigger Needs Repair

Understanding when your fishing equipment requires maintenance can save both time and trouble during trips. Recognizing early indicators of wear can help ensure consistent performance and reduce the likelihood of unexpected issues.

Unusual Sounds – If you hear grinding or squeaking noises when operating your device, this could signal internal parts are out of alignment or damaged. Addressing these sounds early on can prevent further complications.

Inconsistent Movement – A well-functioning device should lower and raise smoothly. If you notice any jerking, hesitation, or sudden stopping, this may indicate mechanical problems that require immediate attention.

Reduced Tension – A noticeable lack of tension might suggest issues with the cable or spool, which can hinder effective deployment. Regularly inspecting these parts helps maintain optimal function.

Visible Rust or Corrosion – Exposure to water can lead to rust, especially on metal components. If you spot any corrosion, it’s wise to address it promptly to prevent long-term damage and ensure smooth operation.

Essential Tools for Downrigger Maintenance

Proper upkeep of fishing equipment is key to ensuring smooth operation and extending the lifespan of the components. For regular servicing, having the right set of tools on hand allows you to address any issues effectively and keep your gear in prime condition. Here’s an overview of the most essential items that will make equipment care easier and more efficient.

Basic Hand Tools

Among the most crucial tools are basic hand tools like adjustable wrenches, screwdrivers, and pliers. These are invaluable for tasks such as adjusting tension, tightening fasteners, or replacing parts. Opting for tools with non-slip handles provides additional safety and comfort during maintenance.

Lubrication and Cleaning Supplies

High-quality lubrication is vital for smooth operation, reducing wear, and protecting metal surfaces. It’s beneficial to keep a multi-purpose lubricant along with specialized cleaners that remove dirt and prevent corrosion. Regular application will help to ensure that parts move freely and last longer.

How to Disassemble Scotty Downriggers

Disassembly of these fishing support devices requires careful attention to parts and a structured approach to ensure easy reassembly. By following the right steps, you can effectively access and inspect each internal mechanism, allowing for thorough maintenance and any needed fixes.

Step 1: Preparation and Safety

Before beginning, ensure you have a clear workspace and necessary tools on hand. Secure the equipment on a stable surface and, for your safety, disconnect any power sources if applicable. Familiarize yourself with each component’s location, as this will aid in reassembly.

Step 2: Removing the Housing

Start by unscrewing the outer casing to access internal sections. Use appropriate screwdrivers to prevent any stripping of screws. Carefully lift away the cover, taking note of how pieces fit together and positioning each removed part in a sequence for easy identification.

Step 3: Detaching the Spool Assembly

The spool mechanism is central to this device. Loosen it gently, allowing access to underlying parts. Handle the spool with care to avoid damage to line guides or other delicate elements. Lay it aside in a safe area.

Step 4: Accessing the Gear System

With the spool removed, the gear assembly is next. Gradually take out each gear, noting their order and orientation. Gears are essential for smooth operation, so consider marking them for reassembly purposes.

Completing these steps provides full access to each component, enabling a thorough examination and servicing as needed.

Troubleshooting Electrical Downrigger Problems

When dealing with electric fishing gear, understanding common issues can enhance your experience on the water. This section aims to provide insights into identifying and resolving electrical complications that may arise, ensuring a smoother operation and better performance.

Start by examining the power source and connections. Issues often stem from inadequate power supply or faulty wiring. Consider the following steps:

- Check the battery voltage to ensure it meets the required specifications.

- Inspect all wiring for signs of wear, fraying, or corrosion.

- Ensure all connections are secure and free of dirt or moisture.

If the device fails to operate despite proper connections, focus on the control mechanism:

- Test the switch to ensure it is functioning correctly.

- Examine the circuit breaker for any tripped settings that require resetting.

- Consider using a multimeter to check for continuity in the wiring.

In some cases, the mechanical components may be the source of the problem. Look for:

- Signs of physical damage or obstruction in moving parts.

- Lubrication issues that could cause increased friction and resistance.

- Wear and tear on gears that may affect performance.

By systematically addressing these areas, you can identify and rectify electrical difficulties, ensuring your fishing gear operates effectively.

Replacing Worn Parts in Downriggers

Maintaining optimal performance in fishing equipment requires attention to detail, particularly when it comes to replacing components that show signs of wear. Over time, various elements may become less effective due to frequent use or exposure to the elements. Addressing these issues promptly ensures longevity and reliability during your fishing trips.

Identifying Signs of Wear

Understanding when to replace parts is crucial. Common indicators include unusual noises, decreased functionality, or visible damage. Regular inspections can help detect these problems early, allowing for timely replacements. Look for frayed cables, corroded components, or any inconsistencies in operation, as these may significantly impact performance.

Steps for Effective Replacement

Once worn components are identified, it’s essential to follow a systematic approach for replacement. Start by gathering the necessary tools and replacement parts. Ensure that you follow the manufacturer’s specifications for each component. Carefully remove the damaged part, clean the area, and install the new piece, securing it properly. Testing the equipment after installation is vital to confirm that everything is functioning as intended.

Regular maintenance not only prolongs the lifespan of your equipment but also enhances your overall fishing experience. By staying proactive about replacing worn parts, you can ensure your gear remains in top condition, ready for your next adventure.

Cleaning and Lubricating Downrigger Parts

Maintaining the functionality and longevity of fishing equipment requires regular attention to cleanliness and proper lubrication of its components. Regular maintenance not only enhances performance but also prevents wear and tear, ensuring a smoother operation during use.

Importance of Regular Cleaning

Keeping equipment free of dirt, salt, and debris is crucial for optimal performance. These contaminants can lead to corrosion and damage, affecting the reliability of the system. Utilize a soft brush and warm, soapy water to gently clean all surfaces. Rinse thoroughly and dry completely before applying any lubricants.

Lubrication Techniques

Applying the right type of lubricant is essential for ensuring smooth movement of moving parts. Use a marine-grade lubricant that resists moisture and provides excellent protection against rust. Focus on areas such as gears, bearings, and any joints that require smooth operation. A light application is sufficient; avoid over-lubricating, as this can attract more dirt and debris.

Regular maintenance will extend the life of your equipment and improve its performance, making every fishing expedition more enjoyable. Remember to consult the manufacturer’s recommendations for specific products and maintenance intervals.

Adjusting Cable Tension on Scotty Models

Properly managing the tension of the cable is essential for the effective operation of fishing equipment. Adequate tension ensures smooth deployment and retrieval, preventing unnecessary wear and tear on components. This section provides guidance on achieving optimal tension settings for various models.

Start by ensuring the equipment is securely mounted. Check that all connections are firm and that the unit is stable before proceeding with adjustments. This will prevent any movement during the tuning process.

To adjust the tension, locate the adjustment mechanism. This may vary depending on the model, but typically involves a knob or lever. Turning it clockwise usually increases the tension, while turning it counterclockwise decreases it. Make small adjustments and test the operation after each change.

It’s crucial to test the cable during deployment. Observe how the cable interacts with the spool and make sure there are no signs of slipping or excessive strain. If the cable appears to be slack or overly tight, further adjustments may be necessary.

Regular maintenance of the cable and its tension not only enhances performance but also extends the lifespan of the entire system. Ensuring that tension is within recommended levels allows for a smoother and more efficient fishing experience.

Testing and Reassembling the Downrigger

Ensuring the proper functioning of your fishing equipment is crucial for a successful outing. This section covers the essential procedures for assessing the performance of your device and reassembling it correctly after maintenance. By following these steps, you can guarantee that all components work together seamlessly for optimal operation.

Assessing Performance

Start by examining the various parts for any signs of wear or damage. Check the motor function, cable integrity, and connection points. Utilize a multimeter to measure electrical components, ensuring they meet the required specifications. Conducting these checks will help identify any issues that need attention before reassembly.

Reassembly Process

Once testing is complete and any necessary repairs are made, it’s time to put everything back together. Begin with the base, ensuring all screws are tight and secure. Gradually add components, following the reverse order of disassembly. Pay close attention to alignments and connections to avoid any mishaps. After reassembly, perform a final test to confirm that the device operates smoothly and efficiently.