In the world of off-road vehicles, understanding the intricacies of maintenance is essential for longevity and performance. This resource serves as a vital tool for enthusiasts and owners alike, offering insights into the necessary procedures for upkeep and common issues that may arise. By equipping yourself with the right knowledge, you can ensure optimal functionality and enjoy every ride to the fullest.

Every vehicle requires attention to detail, and mastering the art of service can significantly enhance the overall experience. This guide will delve into the specific aspects of upkeep, from routine inspections to more complex repairs. Whether you are a novice or a seasoned rider, the information presented here will empower you to tackle various challenges effectively.

By following the structured approaches outlined, you can prevent minor problems from escalating into significant concerns. Familiarizing yourself with the components and their maintenance will not only save time and money but also instill confidence in your abilities as a caretaker of your machine. Prepare to embark on a journey of discovery and competence in the realm of all-terrain vehicle maintenance.

Understanding the Polaris Trailblazer 250

This section aims to provide an in-depth look into a specific all-terrain vehicle model, focusing on its design, features, and maintenance. Gaining a comprehensive understanding of this machine is essential for both potential buyers and current owners, as it enhances the overall riding experience and ensures longevity.

Key Features

One of the standout aspects of this model is its robust construction and reliable performance. Here are some noteworthy features:

| Feature | Description |

|---|---|

| Engine | Equipped with a powerful two-stroke engine, providing strong acceleration and excellent torque. |

| Suspension | Featuring an independent suspension system for improved handling and comfort on rough terrains. |

| Durability | Constructed with high-quality materials to withstand harsh conditions and heavy use. |

| Fuel Capacity | Designed with an ample fuel tank to extend riding time between refuels. |

Maintenance Considerations

Regular upkeep is crucial to maintain optimal performance. Important aspects to consider include:

- Checking fluid levels and changing them as needed.

- Inspecting the brakes and replacing worn components.

- Cleaning the air filter regularly to ensure efficient airflow.

Key Features of the Trailblazer 250

This section explores the distinctive characteristics of a well-regarded off-road vehicle, highlighting what makes it a popular choice among enthusiasts. The design emphasizes a balance between performance, durability, and user-friendly features, catering to both novice and experienced riders alike.

Robust Performance

Equipped with a powerful engine, this vehicle delivers impressive torque and acceleration, making it suitable for various terrains. The advanced suspension system ensures a smooth ride, absorbing shocks and bumps effectively. Whether navigating through rugged trails or cruising on flat surfaces, it provides an exhilarating experience.

User-Friendly Features

Incorporating intuitive controls and ergonomic seating, this model enhances rider comfort and control. The inclusion of storage options allows for easy transport of gear, while the straightforward maintenance requirements simplify upkeep. These thoughtful additions contribute to a seamless riding experience, making it accessible to a wide range of users.

Common Issues and Troubleshooting Tips

When it comes to outdoor vehicles, encountering problems is a common experience. Understanding the frequent issues and having a set of troubleshooting strategies can significantly enhance your ability to keep your machine in optimal condition. This section outlines typical challenges owners may face and offers practical solutions to resolve them effectively.

Starting Difficulties

One prevalent issue is difficulty starting the engine. This can be caused by several factors, including a drained battery, faulty ignition components, or fuel delivery problems. To troubleshoot, first, check the battery’s charge and connections. If the battery is in good condition, inspect the spark plug for wear and ensure that fuel is reaching the engine properly. Clean or replace components as necessary to restore functionality.

Overheating

Another common concern is overheating, which can lead to serious damage if not addressed promptly. This problem may stem from low coolant levels, a malfunctioning thermostat, or a blocked radiator. Start by checking the coolant reservoir and topping it up if needed. Ensure that the radiator is free from debris, and examine the thermostat for proper operation. Regular maintenance can prevent this issue from arising in the first place.

Essential Tools for Repairs

When it comes to maintaining and fixing your vehicle, having the right set of instruments is crucial for efficient and effective work. Each tool serves a specific purpose, ensuring that tasks can be completed with precision and care. Here, we outline the essential items that every enthusiast should have in their toolkit.

- Wrenches: A variety of wrenches, including adjustable and socket types, are necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are vital for handling different screws found throughout the vehicle.

- Pliers: A good set of pliers can help with gripping, twisting, and cutting wires and other materials.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Jack and Stands: Essential for lifting the vehicle safely, allowing access to the undercarriage for maintenance and inspections.

- Multimeter: Useful for diagnosing electrical issues, a multimeter measures voltage, current, and resistance.

- Shop Manual: While not a tool in the traditional sense, having a comprehensive guide is invaluable for troubleshooting and understanding specifications.

Equipping yourself with these instruments will not only make tasks easier but also enhance your ability to address any issues that may arise. By being prepared, you can ensure that your vehicle remains in top condition for all your adventures.

Maintenance Schedule for Optimal Performance

Ensuring peak functionality of your vehicle requires a systematic approach to maintenance. Regular check-ups and adherence to a well-structured timetable can significantly enhance longevity and reliability. Below is a comprehensive outline of essential maintenance tasks that should be performed periodically to keep your machine operating at its best.

- Daily Checks:

- Inspect fluid levels (oil, coolant, brake fluid).

- Examine tires for proper pressure and tread wear.

- Check lights and signals for functionality.

- Weekly Maintenance:

- Clean air filter and replace if necessary.

- Lubricate moving parts to prevent wear.

- Inspect battery connections and terminals for corrosion.

- Monthly Tasks:

- Change oil and replace oil filter.

- Examine brake system for wear and tear.

- Inspect drive belts and replace if frayed or cracked.

- Seasonal Checks:

- Flush and replace coolant before summer and winter.

- Inspect and clean spark plugs; replace if needed.

- Check suspension components and adjust as necessary.

Adhering to this maintenance schedule not only ensures optimal performance but also extends the lifespan of your vehicle. Regular attention to these areas can prevent costly repairs and enhance your overall riding experience.

Step-by-Step Repair Guide Overview

This section provides a comprehensive framework for addressing common mechanical issues, ensuring a systematic approach to maintenance and troubleshooting. By following a structured methodology, users can effectively diagnose problems and implement solutions with confidence.

The guide is divided into several key stages, each aimed at simplifying the process and enhancing understanding. Below is a summary of the main components involved in the overall procedure:

| Step | Description |

|---|---|

| 1 | Initial Assessment: Gather information on the symptoms and history of the vehicle to pinpoint potential issues. |

| 2 | Tools Preparation: Identify and organize necessary tools and materials needed for the task. |

| 3 | Disassembly: Carefully remove components to access the area requiring attention, taking care to document the process. |

| 4 | Inspection: Thoroughly examine parts for wear, damage, or malfunction to determine required repairs. |

| 5 | Replacement: Substitute any faulty parts with new or refurbished components, ensuring proper fit and function. |

| 6 | Reassembly: Put everything back together, following the documentation from the disassembly phase. |

| 7 | Final Checks: Conduct tests to ensure the vehicle operates correctly and efficiently before returning it to service. |

By adhering to this structured approach, individuals can improve their technical skills and ensure a thorough resolution of issues, leading to enhanced performance and longevity of their vehicles.

Engine Components and Their Functions

The engine is the heart of any vehicle, comprising various components that work in harmony to generate power and ensure optimal performance. Each part plays a specific role in the overall functionality, contributing to efficiency, reliability, and responsiveness. Understanding these elements is crucial for maintaining and enhancing the vehicle’s operation.

The cylinder block serves as the main structure of the engine, housing the cylinders where combustion occurs. Within these cylinders, pistons move up and down, converting the energy produced from fuel combustion into mechanical energy. The crankshaft, connected to the pistons, transforms this linear motion into rotational energy, driving the wheels.

Atop the cylinder block is the cylinder head, which contains the intake and exhaust valves. These valves control the flow of air and fuel into the cylinders and the expulsion of exhaust gases. The camshaft operates the valves in synchronization with the pistons, ensuring efficient engine timing.

Additionally, the fuel system includes components such as the fuel pump and injectors, delivering the necessary fuel mixture to the combustion chamber. The ignition system, consisting of spark plugs and ignition coils, ignites the air-fuel mixture, initiating the combustion process. Together, these components ensure that the engine operates smoothly and effectively, providing the necessary power for movement.

Lastly, the cooling and lubrication systems play vital roles in maintaining optimal operating temperatures and reducing friction among moving parts. The coolant circulates through the engine to dissipate heat, while oil lubricates the components, preventing wear and tear. Understanding these elements is essential for effective maintenance and performance enhancement.

Electrical System Diagnostics Explained

Understanding the intricacies of an electrical system is crucial for maintaining optimal performance and safety in any vehicle. This section delves into the methodologies and tools used to assess electrical components, ensuring reliability and functionality. By identifying issues early, one can prevent further complications and enhance the longevity of the system.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical malfunctions is the first step in effective diagnostics. Here are some typical indicators:

- Dim or flickering lights

- Unresponsive electronic components

- Frequent blown fuses

- Intermittent power failures

Diagnostic Tools and Techniques

Several tools and techniques can aid in the evaluation of an electrical system:

- Multimeter: Essential for measuring voltage, current, and resistance.

- Scan Tool: Provides access to error codes and real-time data from electronic control units.

- Battery Tester: Checks the health and charge level of the battery.

- Circuit Tester: Used to determine if electricity is flowing through a circuit.

By employing these methods, one can accurately pinpoint issues, ensuring that the electrical system operates efficiently and effectively.

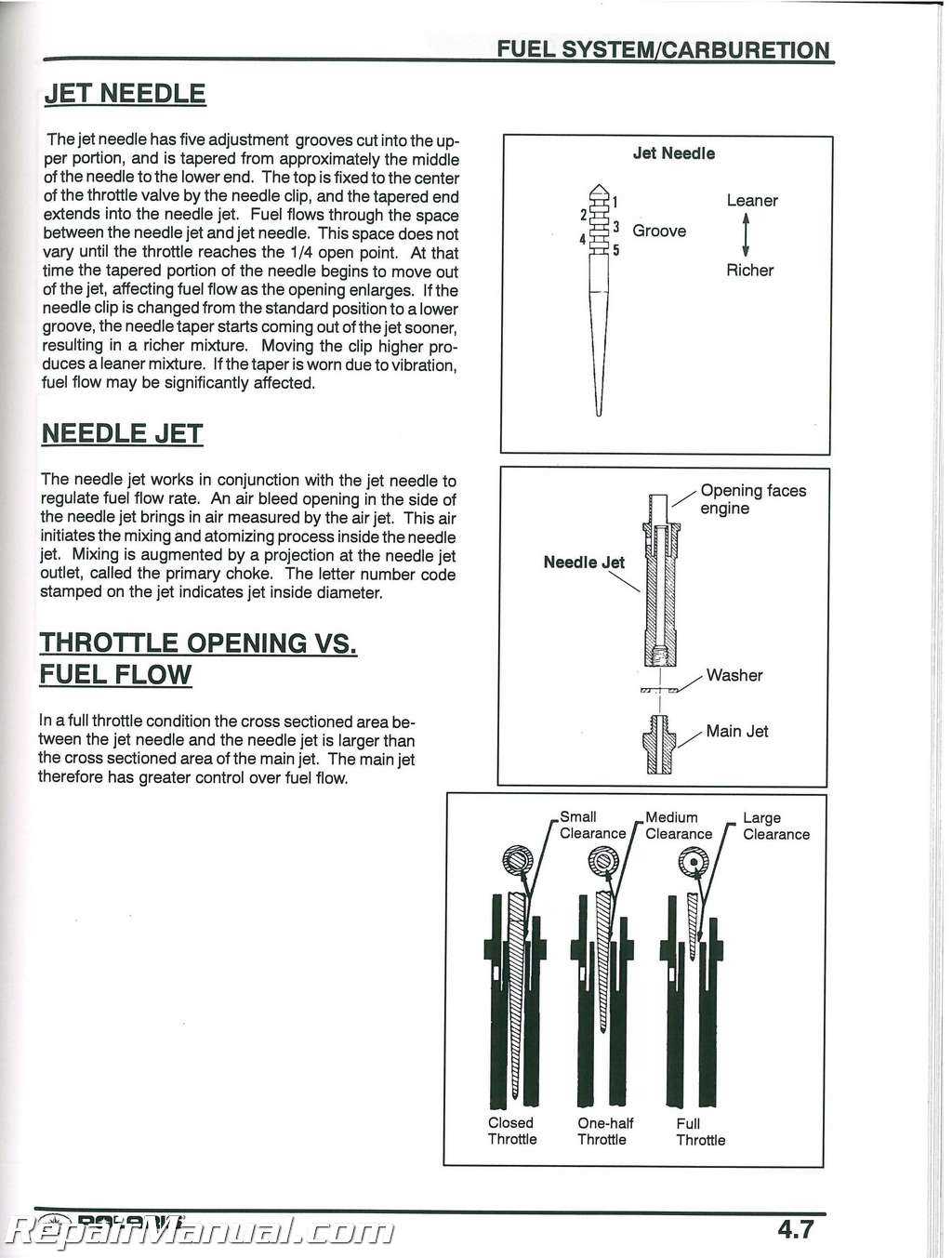

Fuel System Troubleshooting Techniques

Identifying issues within the fuel delivery system is essential for optimal performance. This segment offers systematic approaches to diagnosing common problems related to fuel flow and mixture, ensuring efficient operation and longevity of your vehicle.

Common Symptoms of Fuel System Issues

- Engine stalling or poor acceleration

- Difficulty starting the engine

- Unusual engine noises

- Decreased fuel efficiency

- Fuel leaks or odors

Troubleshooting Steps

- Visual Inspection: Begin with a thorough examination of the fuel lines, connections, and components for any signs of wear, damage, or leaks.

- Check Fuel Filter: A clogged filter can restrict fuel flow. Replace it if necessary.

- Test Fuel Pump: Ensure the fuel pump is functioning correctly by listening for operation sounds or measuring fuel pressure.

- Inspect Fuel Injectors: Clean or replace injectors that show signs of blockage or malfunction.

- Examine Air-Fuel Mixture: Adjust the mixture settings if the engine is running rich or lean.

Implementing these techniques will help pinpoint fuel system complications and guide you toward effective resolutions, ultimately enhancing your vehicle’s performance.

Suspension and Steering Maintenance Tips

Proper upkeep of your vehicle’s suspension and steering systems is essential for ensuring smooth operation and enhancing overall performance. Regular attention to these components not only improves handling and comfort but also extends the lifespan of critical parts. This section provides useful guidance on how to maintain these systems effectively.

Start by regularly inspecting the suspension components for signs of wear or damage. Check for leaks in shock absorbers and ensure that bushings and joints are not cracked or deteriorating. Keeping these parts in good condition will prevent more significant issues down the road.

Lubrication is key to maintaining smooth operation. Apply appropriate grease to pivot points and moving parts as specified by the manufacturer. This reduces friction and prevents premature wear, contributing to a more responsive ride.

Alignment is another critical aspect. Periodically assess the alignment of the wheels, as improper alignment can lead to uneven tire wear and affect handling. If you notice any pulling to one side or uneven tire wear, consider having a professional alignment performed.

Lastly, don’t overlook the importance of tire condition and pressure. Regularly check tire pressure and tread depth, as these factors significantly impact steering responsiveness and overall safety. Keeping tires properly inflated and well-maintained will enhance your vehicle’s handling and ride quality.

Brake System Repair Procedures

The braking mechanism is crucial for ensuring safety and control in any vehicle. Proper maintenance and timely servicing of this system are essential to prevent potential failures and enhance performance. This section outlines the necessary steps and considerations for addressing issues within the braking assembly.

Inspection and Diagnosis

Begin by performing a thorough assessment of the braking components. Check for signs of wear, such as worn brake pads or damaged rotors. Inspect the hydraulic lines for leaks and ensure that the fluid level is adequate. A visual examination can often reveal underlying problems, while a more detailed analysis may be required if symptoms persist.

Replacement and Adjustment

If any components are found to be defective, they must be replaced. Remove the old parts carefully and install the new ones according to the specifications provided by the manufacturer. Adjustments may also be necessary to ensure proper alignment and function. After installation, it’s crucial to bleed the braking system to eliminate air pockets that could hinder performance. Regular checks and timely adjustments will significantly prolong the lifespan of the braking system.

Preparing for Seasonal Storage

When the time comes to put away your vehicle for the off-season, proper preparation is essential to ensure its longevity and functionality. A thorough approach to seasonal storage can prevent potential damage and ensure that your machine is ready for action when needed. Taking a few key steps can safeguard components and maintain performance during the downtime.

Cleaning the exterior and undercarriage is the first step in the process. Dirt and debris can hold moisture, leading to corrosion and wear over time. Use a gentle wash to remove grime, and pay attention to any areas that may collect water.

Next, fuel stabilization is crucial. Adding a fuel stabilizer to the gas tank helps prevent the fuel from deteriorating, which can lead to engine problems when it’s time to start again. Run the engine for a few minutes after adding the stabilizer to ensure it circulates through the fuel system.

Another important aspect is battery maintenance. Disconnect the battery and store it in a cool, dry place. Check the charge level and consider using a trickle charger to maintain its condition during storage. This simple step can prevent starting issues when you are ready to use the vehicle again.

Finally, don’t forget to cover your vehicle. A high-quality cover protects it from dust, moisture, and pests. Ensure the cover is breathable to prevent condensation buildup underneath, which can lead to mold or mildew.

By following these guidelines, you can ensure that your machine remains in optimal condition and is ready for the next adventure when the season changes.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on vehicles is essential to protect both the individual performing the task and the equipment itself. By adhering to specific guidelines, one can minimize risks associated with potential hazards, thereby promoting a secure working environment.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes gloves to safeguard against sharp edges and chemical exposure, as well as goggles to shield the eyes from debris. Additionally, ear protection may be necessary when working with loud machinery.

Workspace Organization

Maintaining an organized workspace can significantly reduce accidents. Ensure tools are neatly stored and readily accessible, and always keep the area free from clutter. Proper lighting is also essential; it enhances visibility, making it easier to identify potential dangers and carry out tasks efficiently.