Maintaining outdoor power equipment is crucial for ensuring optimal performance and longevity. This section provides valuable insights into the intricacies of servicing specific engine types, focusing on common issues and practical solutions. Understanding the essential components and their functions lays the foundation for effective troubleshooting.

Comprehensive knowledge about various mechanical systems empowers users to tackle challenges confidently. From identifying common faults to implementing preventative measures, this guide aims to enhance your proficiency in managing engine upkeep. Detailed instructions and tips will facilitate a smoother maintenance process, allowing you to keep your machinery running efficiently.

By utilizing this resource, you will gain access to structured information that simplifies complex tasks. Whether you are a novice or an experienced technician, the outlined strategies will assist in honing your skills. Emphasizing the importance of routine checks and repairs, this guide serves as a roadmap for achieving reliable operation.

Understanding Briggs and Stratton Manuals

The documentation provided by engine manufacturers serves as an essential resource for users, offering valuable insights into maintenance, troubleshooting, and operation. These guides are designed to assist owners in achieving optimal performance and longevity from their equipment.

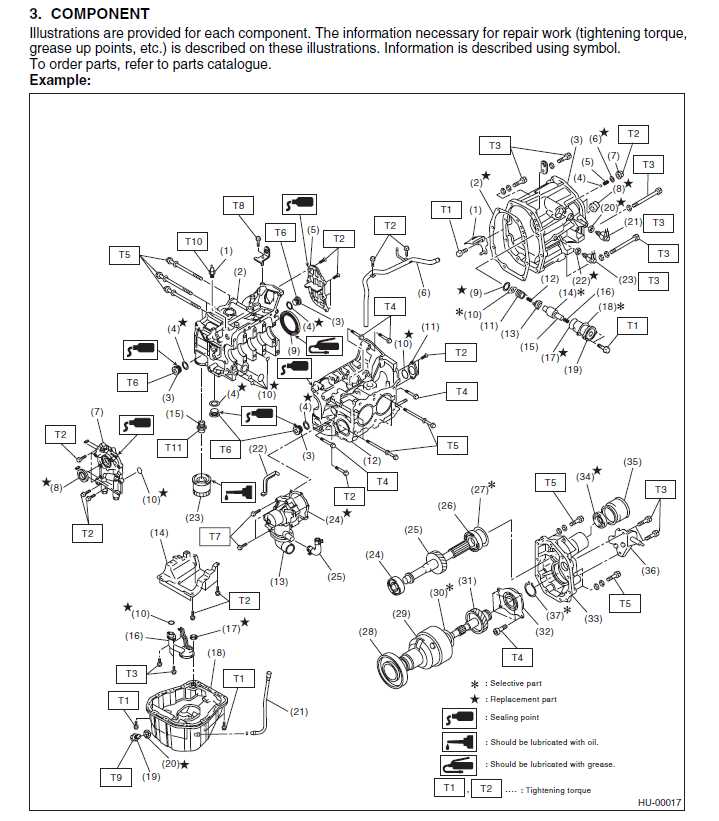

Such resources typically include detailed illustrations, step-by-step instructions, and specifications tailored to various models. Familiarizing oneself with these documents can greatly enhance the ability to identify issues and perform necessary adjustments or replacements.

Furthermore, a comprehensive guide often covers safety precautions, operational guidelines, and periodic maintenance recommendations. Utilizing these materials effectively ensures that users can maximize the efficiency and reliability of their machinery.

Common Issues in Small Engines

Small engines are often reliable, but they can encounter a variety of problems that hinder their performance. Understanding these typical issues can help in diagnosing faults and ensuring smooth operation. Here, we explore frequent challenges faced by these power units, offering insights into potential causes and solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Hard Starting | Old fuel, clogged filters, or worn spark plugs | Replace fuel, clean or change filters, and inspect spark plugs |

| Overheating | Low oil levels, blocked air vents, or a dirty cooling system | Add oil, clear air vents, and clean cooling fins |

| Loss of Power | Dirty carburetor, air filter blockage, or fuel line issues | Clean carburetor, replace air filter, and check fuel lines |

| Unusual Noises | Lack of lubrication, damaged components, or loose parts | Ensure adequate lubrication, replace damaged parts, and tighten loose fittings |

| Excessive Smoke | Overfilled oil, burning oil, or a malfunctioning fuel system | Drain excess oil, check for leaks, and inspect fuel components |

Tools Needed for Effective Repairs

Ensuring a successful maintenance task requires the right set of instruments. Having the appropriate equipment not only facilitates the repair process but also enhances efficiency and safety. Below are essential tools that will aid in achieving effective results during the service of small engines.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for various fastening tasks.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating components.

- Torque Wrench: This tool ensures that bolts are tightened to the correct specifications, preventing damage.

- Cleaning Supplies: Brushes and cleaning solvents help maintain parts and remove debris.

Additional specialized instruments may also be beneficial, depending on the specific task at hand:

- Multimeter: For testing electrical components and ensuring proper function.

- Feeler Gauge: Useful for checking clearances and adjustments in engine components.

- Impact Wrench: Aids in loosening stubborn fasteners quickly.

Equipping yourself with these essential tools will significantly enhance your ability to perform effective maintenance and prolong the lifespan of the equipment.

Step-by-Step Troubleshooting Techniques

Effective troubleshooting is essential for diagnosing issues and restoring functionality. This guide presents a systematic approach to identify and resolve common problems encountered in small engines. By following these techniques, you can streamline the process and enhance your problem-solving skills.

1. Initial Assessment

Begin by gathering information about the symptoms and conditions leading to the malfunction. Document any unusual sounds, performance drops, or visual signs of wear. This foundational step helps narrow down potential causes.

- Check for fuel supply issues.

- Inspect for signs of physical damage.

- Evaluate electrical connections for integrity.

2. Systematic Testing

Implement a logical testing sequence to isolate the problem. Use appropriate tools to measure parameters and verify component functionality. This organized approach ensures thorough examination without overlooking crucial aspects.

- Test the battery voltage and connections.

- Examine the ignition system for faults.

- Inspect the carburetor and air filter for blockages.

- Evaluate the exhaust system for obstructions.

By adhering to these techniques, you can effectively troubleshoot and address various issues, leading to a more efficient repair process.

Maintenance Practices for Longevity

Regular upkeep is essential for maximizing the lifespan and efficiency of any mechanical equipment. By adhering to a consistent maintenance schedule, users can ensure optimal performance and minimize the risk of unexpected breakdowns. This section outlines key practices that contribute to prolonged functionality.

Essential Upkeep Activities

Implementing a routine that includes specific tasks can significantly enhance reliability. Here are some critical activities to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 25 hours | Replace old oil to ensure smooth operation and prevent engine wear. |

| Filter Inspection | Every 50 hours | Check air and fuel filters for clogs; replace if necessary to maintain airflow and fuel efficiency. |

| Spark Plug Replacement | Every 100 hours | Change spark plugs to improve ignition and engine performance. |

Additional Considerations

Incorporating environmental factors into maintenance routines can further enhance equipment durability. Ensure that the unit is stored in a dry, clean area and that debris is regularly removed from vents and surfaces. Additionally, inspecting components for wear and tear on a periodic basis can help in identifying potential issues before they escalate.

Replacing Engine Components Safely

Ensuring the secure replacement of engine parts is essential for maintaining optimal performance and longevity. This process involves a series of precautions and best practices that should be followed to avoid accidents and ensure effective repairs.

Preparation and Safety Gear

Before starting any replacement task, it is crucial to gather the necessary tools and materials. Equally important is the use of appropriate personal protective equipment (PPE), including gloves, safety goggles, and a dust mask. These items help minimize the risk of injury while handling engine components.

Step-by-Step Replacement Process

Follow these steps to safely replace engine parts:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidental starts. |

| 2 | Carefully remove the damaged component, noting the arrangement of any attached parts. |

| 3 | Install the new part, ensuring it is aligned correctly and secured properly. |

| 4 | Reconnect any components that were detached during the replacement. |

| 5 | Test the engine to ensure the new part functions correctly. |

By adhering to these guidelines, individuals can ensure that component replacements are conducted safely and effectively, ultimately prolonging the life of the engine. Always refer to the manufacturer’s instructions for specific details regarding your equipment.

Fuel Systems: Repair and Optimization

This section delves into the intricacies of fuel delivery mechanisms, focusing on enhancing performance and addressing common issues. A well-functioning fuel system is essential for optimal engine operation, as it ensures proper combustion and efficiency.

Diagnosis of Common Issues

Identifying malfunctions in the fuel delivery system is the first step toward resolution. Symptoms such as difficulty starting, stalling, or reduced power may indicate problems with the fuel lines, filter, or carburetor. Regular inspections can help in pinpointing these concerns early.

Maintenance Practices

Regular cleaning of fuel components is crucial. This includes flushing the fuel lines, replacing filters, and ensuring that the carburetor is free of debris. Utilizing high-quality fuel can also prevent sediment buildup and enhance the longevity of the system.

Optimization Techniques

To maximize efficiency, consider adjusting the carburetor settings for optimal air-fuel mixture. This fine-tuning can lead to improved throttle response and fuel economy. Additionally, employing additives designed for cleaning fuel systems can help maintain peak performance.

Conclusion

Understanding and maintaining the fuel system is vital for ensuring reliable engine performance. By diagnosing issues promptly and implementing regular maintenance, users can optimize their machinery’s efficiency and extend its operational lifespan.

Electrical System Diagnostics and Fixes

Diagnosing and resolving issues within the electrical framework of small engines is essential for optimal performance. A systematic approach to troubleshooting can help identify common problems such as faulty connections, defective components, or irregular voltage levels.

Step 1: Visual Inspection

Begin with a thorough examination of the wiring and connections. Look for signs of wear, fraying, or corrosion. Ensure that all connections are secure and free of debris. This initial check can often reveal obvious issues that require immediate attention.

Step 2: Testing Voltage

Utilize a multimeter to measure voltage at critical points within the system. Start by checking the battery voltage to confirm it is within the specified range. Then, proceed to inspect the voltage output of the alternator or coil, ensuring it meets the manufacturer’s recommendations.

Step 3: Component Evaluation

If voltage readings are outside acceptable limits, further investigation of specific components is necessary. Inspect switches, relays, and fuses for functionality. Replace any defective parts to restore proper operation.

Step 4: Continuity Testing

Perform continuity tests on wires and connections using a multimeter. This step helps identify any breaks in the circuit that could impede electrical flow. Repair or replace any sections of wire that exhibit continuity issues.

Conclusion

Systematic diagnostics and timely fixes are crucial for maintaining the reliability of the electrical system in small engines. Regular maintenance and proactive checks can prevent future complications and ensure smooth operation.

Preventive Measures to Avoid Failures

To ensure optimal performance and longevity of small engine systems, it is essential to implement a series of precautionary steps. These practices not only enhance reliability but also significantly reduce the likelihood of operational disruptions.

Regular Maintenance: Routine inspections and servicing are crucial. Check for wear and tear on components, replace filters, and ensure that lubricants are at appropriate levels. Timely intervention can prevent minor issues from escalating into major failures.

Proper Storage: When not in use, store equipment in a dry and sheltered environment. This helps protect it from environmental factors that could cause corrosion or damage. Additionally, draining fuel and stabilizing the system can prevent fuel-related complications.

Use Quality Fuel: Always use high-quality fuel to minimize the risk of clogging and engine damage. Avoid using fuel that contains excessive ethanol, as it can lead to issues within the fuel system.

Check Electrical Connections: Regularly inspect all electrical connections and wiring for signs of wear or corrosion. Ensuring a secure and clean connection is vital for reliable operation and can prevent electrical failures.

By adopting these strategies, users can significantly enhance the reliability and efficiency of their engines, ensuring smooth operation and minimizing the risk of unexpected failures.

Understanding Engine Specifications and Features

This section aims to illuminate the essential characteristics and attributes of small engines, which are crucial for optimal performance and longevity. A comprehensive understanding of these specifications can significantly enhance the efficiency of operation and maintenance, ensuring that users can effectively manage their equipment.

Key Specifications

Among the most vital specifications are displacement, power output, and torque. Displacement refers to the total volume of all cylinders, indicating the engine’s size and potential power. Power output measures the engine’s ability to perform work over time, often expressed in horsepower. Torque, on the other hand, reflects the engine’s rotational force, crucial for applications requiring substantial pulling power.

Notable Features

In addition to basic specifications, several features can enhance the overall functionality of an engine. Fuel efficiency is a critical consideration, impacting operational costs and environmental impact. Starting mechanism options, such as recoil or electric start, determine user convenience. Lastly, the maintenance accessibility can vary significantly, influencing the ease of servicing and repairs, thereby affecting long-term reliability.

Best Practices for Seasonal Maintenance

Regular upkeep is essential for ensuring the longevity and efficiency of outdoor equipment. Adopting a seasonal maintenance routine helps in preventing unexpected breakdowns and enhances performance. This section outlines key practices to keep your machinery in optimal condition throughout the year.

1. Clean and Inspect

Before each season begins, thoroughly clean the equipment to remove dirt, debris, and any buildup that could hinder operation. Check for any visible damage or wear on components, and replace parts as necessary to maintain peak functionality.

2. Change Fluids

Regularly replacing oils and fuels is vital. Use the recommended type of lubricant and ensure that the fuel is fresh. This practice not only enhances performance but also helps in preventing corrosion and other issues.

3. Sharpen and Adjust Blades

If your equipment includes cutting elements, ensure that they are sharp and correctly adjusted. Dull blades can lead to poor performance and unnecessary strain on the engine. Regular sharpening promotes cleaner cuts and more efficient operation.

4. Store Properly

At the end of each season, store equipment in a dry and sheltered location. Use protective covers to guard against dust and moisture. Additionally, consider draining fuel if the machinery will not be used for an extended period to prevent stale fuel issues.

5. Follow Manufacturer Guidelines

Always refer to the manufacturer’s recommendations for maintenance tasks and intervals. Adhering to these guidelines ensures that you are using the equipment safely and effectively, ultimately extending its lifespan.

Frequently Asked Questions on Repairs

This section aims to address common inquiries related to maintenance and troubleshooting. Whether you are dealing with engine issues or component replacements, the following questions provide clarity on the most prevalent concerns faced by users.

1. What should I do if the engine won’t start?

If the engine fails to start, check the fuel level, ensure the battery is charged, and inspect the ignition system for faults. A clogged air filter can also prevent proper airflow.

2. How can I improve engine performance?

Regular maintenance, including oil changes, air filter replacements, and spark plug inspections, is crucial for optimal engine efficiency. Consider using high-quality fuel to enhance performance.

3. What are the signs of a failing spark plug?

Symptoms of a malfunctioning spark plug may include difficulty starting, rough idling, and decreased power. Regular inspections can help identify wear and prevent larger issues.

4. How often should I perform maintenance?

Routine checks and servicing should be conducted according to the manufacturer’s guidelines. Typically, this includes seasonal checks and servicing after a specific number of operating hours.

5. What tools are necessary for basic maintenance?

Essential tools include wrenches, screwdrivers, pliers, and a spark plug socket. A multimeter can also be beneficial for electrical diagnostics.