Owning a compact ATV brings both excitement and the need for attentive upkeep. Young riders and enthusiasts often rely on these robust machines for exploration, and ensuring smooth functionality enhances every ride. Regular care and well-guided steps can keep these vehicles in optimal condition, helping to prevent unexpected breakdowns or safety issues. In this section, we’ll delve into essential practices and guidelines to maintain such a four-wheeler.

Each ATV has unique attributes, and understanding its components can help owners extend its life and boost performance. From basic check-ups to more thorough inspections, adopting a proactive approach to upkeep can help detect and address minor issues before they escalate. This guide offers practical advice to assist owners with essential care tips, empowering them to confidently handle minor issues and foster a deeper connection with their vehicle.

For those passionate about exploring rough terrains or simply enjoying recreational rides, knowing how to maintain a compact ATV is invaluable. In the following sections, you’ll find a blend of insights and steps focused on sustaining reliability and safety, all designed to help you become adept in handling maintenance tasks with ease.

Polaris Sportsman 90 Repair Guide

Understanding how to keep an all-terrain vehicle running smoothly is essential for enthusiasts and owners alike. This section provides insights into diagnosing common issues and maintaining critical components, enabling a longer lifespan and optimal performance for your ride. From engine upkeep to electrical checks, exploring these practices will help you ensure reliable use in diverse environments.

| Component | Issue | Solution |

|---|---|---|

| Engine | Starting difficulties | Check spark plug condition and fuel levels. Replace faulty parts as needed. |

| Brakes | Reduced response | Inspect brake pads and fluid levels. Adjust or replace to restore full function. |

| Battery | Low power | Verify connections and charge. Replace battery if power drops significantly. |

| Suspension | Uneven handling | Check for wear on shocks and springs. Replacing worn parts may improve stability. |

Essential Tools for Maintenance

Having the right set of tools is crucial for keeping your vehicle in top condition. Regular maintenance requires specific equipment designed to assist with a variety of tasks, from simple adjustments to more involved procedures. Choosing quality tools tailored to these needs ensures smoother, safer upkeep and extends the overall lifespan of your ride.

Socket Set: A high-quality socket set is fundamental for reaching bolts and screws in various tight spaces. Ensure it includes a range of sizes to cover diverse maintenance requirements.

Torque Wrench: This tool is indispensable for tasks where accuracy matters. Properly securing components with a torque wrench helps avoid both under-tightening and over-tightening, which can lead to damage.

Multi-bit Screwdriver: With interchangeable bits, this tool adds versatility, making it ideal for multiple types of screws encountered during maintenance.

Pliers: A robust pair of pliers allows for better grip and control, essential for tasks involving wires, cables, or small parts. Needle-nose pliers, in particular, are useful for accessing narrow spaces.

Oil Drain Pan: For any oil-related work, an oil drain pan is essential. It keeps your workspace clean, capturing used oil and making disposal simpler and more environmentally friendly.

Work Light: Good lighting is crucial, especially for work in low-light conditions. A portable work light provides the visibility needed to tackle hard-to-see areas safely.

With these tools on hand, routine maintenance and more intricate adjustments become more manageable, helping to ensure reliable and safe operation over time.

Checking and Adjusting the Carburetor

Ensuring the proper function of the carburetor is essential for maintaining smooth performance and efficiency. When the carburetor is accurately adjusted, the engine receives the ideal fuel mixture, which promotes steady operation and reduces unnecessary fuel consumption. Regular assessment and fine-tuning help avoid issues and keep the engine responsive under varying conditions.

Step 1: Initial Inspection

Start by examining the carburetor’s components for any signs of wear or clogging. Inspect the idle and main jets to ensure they are clean and free from debris. Any blockages here can cause irregular fuel delivery, affecting overall engine function. If needed, use a carburetor cleaner to remove residue, but take care not to damage any delicate parts during cleaning.

Step 2: Fine-Tuning the Mixture

After inspection, begin adjusting the air-fuel mixture screw. This screw controls the balance of air and fuel entering the engine. Turning it clockwise typically leans out the mixture, while counterclockwise enriches it. Adjust gradually, listening to the engine’s idle speed and ensuring it runs smoothly without sputtering. A balanced mixture prevents excessive fuel use and supports consistent engine output.

Final Check: Once adjustments are complete, test the engine by gently revving to observe any irregularities in response. A properly tuned carburetor should deliver smooth acceleration without hesitation or surging. Recheck settings periodically to maintain optimum engine health.

Understanding the Electrical System

The electrical system in any motorized vehicle plays a crucial role in powering essential components, ensuring smooth performance, and maintaining rider safety. This network includes a series of connections, circuits, and devices that work together to manage power flow throughout the machine.

Understanding this setup is essential for diagnosing and resolving issues that may arise. The wiring, battery, and control switches are integral parts, each playing specific roles that support engine performance, lighting, and other key functions. Familiarity with these elements allows for efficient troubleshooting and enhances overall knowledge of the machine’s operation.

Key Components include the power source, ignition system, and various wiring circuits that deliver electricity to the necessary parts. By understanding how these elements interact, users can more effectively maintain or adjust the system, ensuring it remains reliable over time.

Steps for Replacing the Brake Pads

Brake pads wear down over time, and replacing them is essential for maintaining safe and efficient braking performance. The process is straightforward, but having a clear sequence of steps can ensure a smooth replacement.

| Step | Description | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Loosen the wheel bolts slightly while the vehicle is still on the ground. This will make it easier to remove them fully after lifting. | ||||||||||||||||||||

| 2 | Lift the vehicle carefully using a jack and secure it with jack stands for stability. Ensure the vehicle is stable before proceeding. | ||||||||||||||||||||

| 3 | Remove the bolts and take off the wheel to access the brake assembly. Set the wheel aside in a safe place. | ||||||||||||||||||||

| 4 | Locate the brake caliper and remove the bolts securing it. Gently lift the caliper away, avoiding tension on the brake line. | ||||||||||||||||||||

| 5 | Slide out the old brake pads and inspect the caliper area for dust or debris, which can be cleaned with a brush or brake cleaner. | ||||||||||||||||||||

| 6 | Insert the new pads into the caliper, ensuring they are properly aligned and seated for optimal function. | ||||||||||||||||||||

| 7 | Reattach the caliper over the brake assembly and secure it with the bolts. Double-check all connections for tightness. | ||||||||||||||||||||

| 8 | Reinstall the wheel, tighten the bo

How to Change the Oil ProperlyChanging the lubricant in your vehicle is essential for maintaining optimal performance and extending its lifespan. Regular oil changes help keep the engine clean and ensure that all moving parts are properly lubricated. This process is straightforward and can be accomplished with some basic tools and attention to detail. Step 1: Start by gathering the necessary supplies, including fresh oil, an oil filter, a drain pan, and a wrench. It’s important to use the correct type of oil for your engine, so refer to the specifications provided for your vehicle. Step 2: Warm up the engine for a few minutes to thin the oil, making it easier to drain. Once warm, turn off the engine and ensure the vehicle is on a flat surface. Use a jack if necessary to raise the vehicle and secure it with jack stands. Step 3: Locate the oil drain plug, typically found at the lowest point of the oil pan. Place the drain pan underneath and carefully remove the plug, allowing the old oil to completely drain out. Be cautious, as the oil may be hot. Step 4: After the old oil has drained, replace the drain plug and tighten it securely. Next, remove the old oil filter, which can usually be done with your hands or an oil filter wrench. Make sure to clean the area around the filter mounting point to prevent any debris from entering the engine. Step 5: Install the new oil filter by applying a small amount of fresh oil to the gasket. This ensures a proper seal. Screw the new filter into place, making sure it is snug but not overly tight. Step 6: Finally, add the fresh oil through the oil filler cap. Check the owner’s guidelines for the correct amount and type. Once filled, start the engine and let it run for a minute, then check for any leaks around the drain plug and filter. Shut off the engine and check the oil level with the dipstick, adding more oil if necessary. By following these steps, you can ensure that your vehicle runs smoothly and efficiently, keeping it in prime condition for many adventures ahead. Inspecting and Replacing the Air Filter

Maintaining optimal airflow is crucial for the efficiency of any vehicle’s engine. A clean air filter ensures that the engine receives the necessary amount of clean air, which is vital for performance and longevity. Regular checks and timely replacements can prevent potential issues that may arise from restricted airflow. Signs of a Clogged FilterBefore replacing the air filter, it’s important to identify signs that indicate it may be clogged. Common indicators include:

Steps to Replace the FilterWhen it’s time to replace the air filter, follow these steps for a smooth process:

Troubleshooting Common Engine IssuesIdentifying and addressing engine problems is crucial for maintaining optimal performance and longevity of your vehicle. This section outlines typical issues that may arise, along with effective strategies to diagnose and rectify them. Understanding these common faults can enhance your ability to troubleshoot effectively. Engine Won’t Start

If the engine fails to ignite, several factors could be at play. Check the fuel level to ensure there is adequate supply. A malfunctioning ignition system or battery may also prevent the engine from starting. Additionally, examine the starter motor for any signs of damage. Unusual Noises During OperationStrange sounds coming from the engine can indicate underlying problems. Listen for knocking, popping, or grinding noises, which may suggest issues with internal components. It is essential to investigate these noises promptly to avoid further damage. Battery Maintenance and Replacement TipsProper care and timely replacement of power sources are essential for ensuring optimal performance of your vehicle. Regular maintenance helps extend the lifespan of the battery and prevents unexpected failures. Understanding the basics of upkeep and when to change the power unit can save you time and effort in the long run. Regular Inspection: Frequently check the power source for any signs of corrosion, leakage, or physical damage. Cleaning the terminals and ensuring a secure connection can help maintain efficient operation. Charge Management: Ensure the battery is adequately charged, especially if the vehicle is not used regularly. Using a smart charger can help maintain optimal charge levels without overcharging. Storage Conditions: When storing the vehicle for extended periods, remove the battery and keep it in a cool, dry place. Extreme temperatures can affect the battery’s performance and lifespan. Replacement Indicators: If you notice sluggish starting or dimming lights, it may be time to consider a new power source. Refer to the specifications to choose a compatible replacement that meets the required standards. Professional Assistance: If you are uncertain about maintaining or replacing the battery, seek help from a qualified technician. They can provide guidance and ensure proper installation. Replacing the Drive Belt SafelyWhen it comes to maintaining your vehicle’s performance, one of the essential tasks is changing the drive belt. This component plays a crucial role in transferring power from the engine to the wheels, making its proper function vital for smooth operation. Understanding the process and safety measures involved in replacing this part can help ensure a successful maintenance task. Before starting the replacement, gather the necessary tools and equipment. Ensure the vehicle is parked on a flat surface and the engine is turned off. Wear appropriate safety gear, such as gloves and goggles, to protect yourself from potential injuries. It’s important to follow the correct procedure to prevent any damage to the system. Begin by removing any covers or components that obstruct access to the drive belt. Carefully inspect the old belt for signs of wear, such as cracks or fraying, which may indicate it needs replacement. When installing the new belt, ensure it is properly aligned and tensioned according to the manufacturer’s specifications to avoid any operational issues. Once the new belt is in place, reassemble any removed components, and double-check that everything is secure. After completing the installation, start the engine and observe the operation to confirm that the new belt is functioning correctly. Regular maintenance and timely replacement of this vital part can enhance the longevity and performance of your vehicle. Adjusting Suspension for a Smooth RideFine-tuning the suspension system is essential for enhancing overall comfort and handling. Proper adjustments can greatly improve the riding experience, allowing for better control over varied terrains. Understanding how to set the suspension can lead to a smoother, more enjoyable journey. To achieve optimal performance, consider the following parameters that can influence the effectiveness of your suspension:

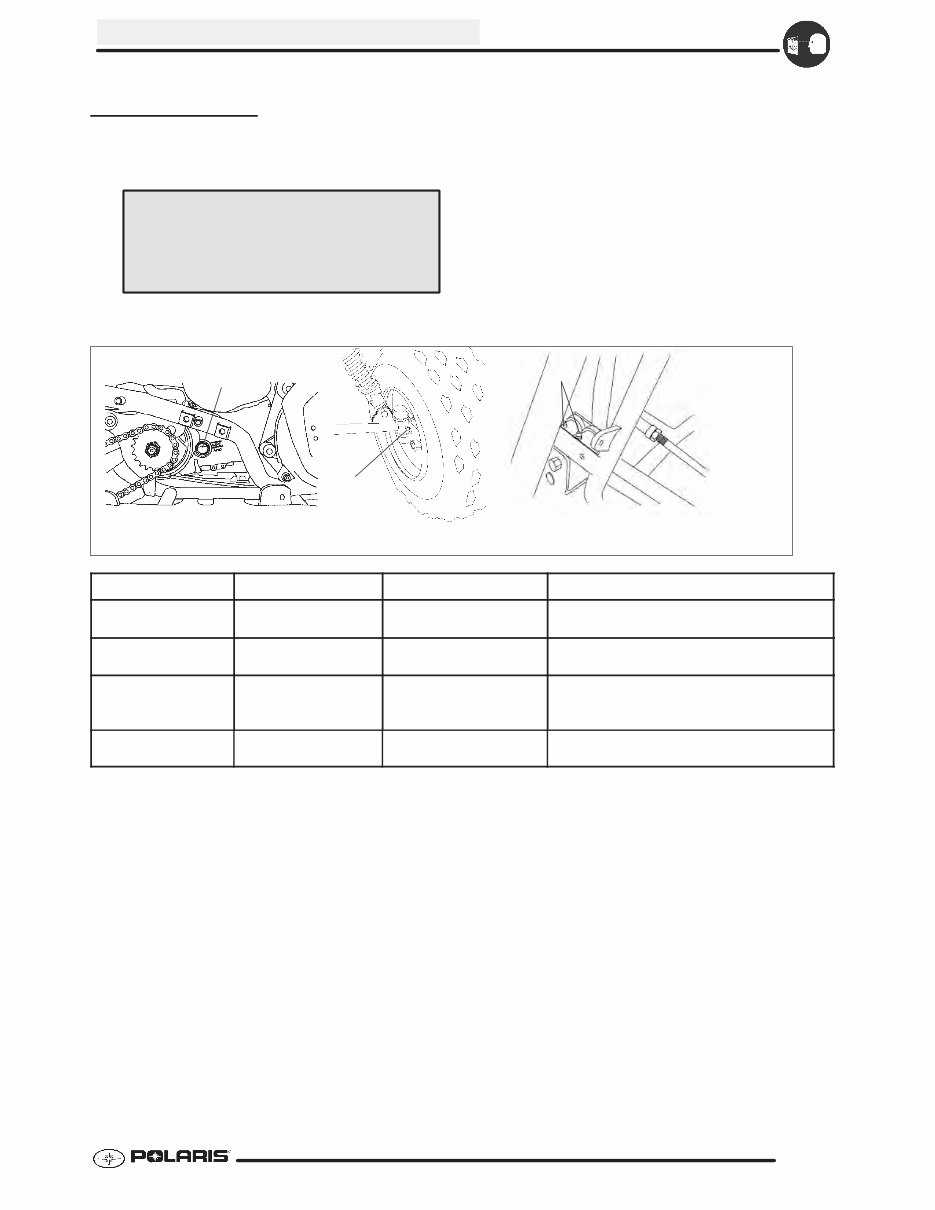

By methodically adjusting these factors, riders can enhance their experience significantly, ensuring a smooth and controlled ride across diverse landscapes. Inspecting Tires and Wheels for DamageRegular examination of the tires and wheels is essential to ensure optimal performance and safety of your vehicle. Any signs of wear or injury can significantly impact handling and stability. It is crucial to familiarize yourself with what to look for during these inspections. Begin by checking the tires for any visible cracks, punctures, or bulges. These imperfections can lead to air loss and ultimately cause a tire failure. Ensure that the tread depth is adequate, as insufficient tread can reduce traction and increase the risk of accidents. A simple way to gauge this is by using a tread depth gauge or even the penny test, where you insert a penny into the tread; if you can see the top of Lincoln’s head, it’s time for a replacement. Next, examine the wheels for any dents, cracks, or corrosion. Damage to the wheels can lead to improper sealing of the tires, which may cause air leaks. Additionally, make sure that the lug nuts are tight and secure, as loose lug nuts can lead to wheel detachment while driving. Lastly, ensure that both the tires and wheels are clean and free from debris. Dirt and grime can hide damage and contribute to wear over time. Regular cleaning will not only help you identify potential issues but will also enhance the overall appearance of your vehicle. Ensuring Proper Chain TensionMaintaining the correct tension in a drive system is essential for optimal performance and longevity of the vehicle. Properly adjusted tension helps to prevent excessive wear on components and reduces the risk of unexpected breakdowns. Regular checks and adjustments should be part of the maintenance routine to ensure smooth operation and safety during use. Signs of Incorrect TensionIndicators of improper tension include unusual noise during operation, excessive vibrations, or slippage during acceleration. A chain that is too tight may cause strain on the engine, while one that is too loose can lead to disengagement or increased wear. Regular inspection will help identify these issues early. Adjustment ProceduresTo achieve the right tension, begin by loosening the adjustment bolts. Next, gently pull the chain to ensure it is snug but not overly tight. Refer to the specifications for ideal tension levels, typically measured by the amount of vertical play in the chain. Once the desired tension is achieved, securely tighten the adjustment bolts and recheck the alignment to ensure everything is in place. |