In the realm of power tools, understanding the intricacies of upkeep is essential for ensuring longevity and optimal performance. This section delves into the fundamental aspects of maintaining your equipment, emphasizing the importance of regular checks and timely interventions to prevent breakdowns. Whether you are a professional tradesperson or a DIY enthusiast, having access to clear instructions can significantly enhance your experience.

By familiarizing yourself with the components and functionalities of your device, you empower yourself to tackle minor issues before they escalate. This guide provides insights into troubleshooting common challenges, equipping you with the knowledge needed to handle your tool effectively. With a focus on practical steps, it aims to foster a deeper understanding of your equipment, enabling seamless operation in various tasks.

Through detailed explanations and straightforward procedures, you will gain confidence in addressing maintenance tasks. The objective is to make the process accessible, ensuring that you can easily navigate through repairs and servicing. Embracing these practices will not only extend the lifespan of your equipment but also enhance your overall productivity and satisfaction.

Dewalt DCD780 Repair Manual

This section provides essential guidance for troubleshooting and fixing common issues encountered with a specific power tool model. The following information will help users understand the components, identify potential problems, and implement effective solutions to ensure optimal performance.

When addressing faults, it’s crucial to approach the situation methodically. Begin by gathering the necessary tools and reviewing the specifications for reference. The following table outlines typical issues and suggested remedies.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Tool not starting | Battery drained, faulty switch | Recharge battery, inspect and replace switch |

| Overheating | Dirt buildup, prolonged use | Clean vents, allow cooldown |

| Reduced power | Worn components, low charge | Replace worn parts, ensure full battery |

Following these guidelines will assist in maintaining the tool’s efficiency and longevity, ensuring it remains a reliable asset in any workshop.

Essential Tools for Repair

Having the right instruments is crucial for effective maintenance and troubleshooting of power devices. This section outlines the basic implements needed to ensure efficient operation and longevity of your equipment. Understanding each tool’s function can enhance your overall productivity.

Basic Hand Tools

- Screwdrivers: A variety of sizes and types, including Phillips and flathead, are necessary for removing screws.

- Pliers: Essential for gripping, twisting, and cutting wire or other materials.

- Wrenches: Adjustable and fixed wrenches help in loosening or tightening nuts and bolts.

- Cutters: Wire cutters or snips are useful for trimming cables and other components.

Power Tools

- Drills: A reliable drill can facilitate quick access to various components and make tasks easier.

- Multimeters: These devices are vital for testing electrical connections and diagnosing issues.

- Impact Drivers: Useful for driving screws with speed and precision, especially in tougher materials.

Common Issues and Troubleshooting

When using power tools, various challenges may arise that can affect performance and efficiency. Understanding these common problems is essential for effective maintenance and to ensure optimal functioning. This section outlines prevalent issues and provides guidance on how to address them effectively.

One frequent concern is the tool’s inability to start. This can stem from a drained battery or poor connection. Checking the battery charge and ensuring proper contact can often resolve this issue. Additionally, if the device operates intermittently, it may indicate a need for cleaning or inspection of internal components.

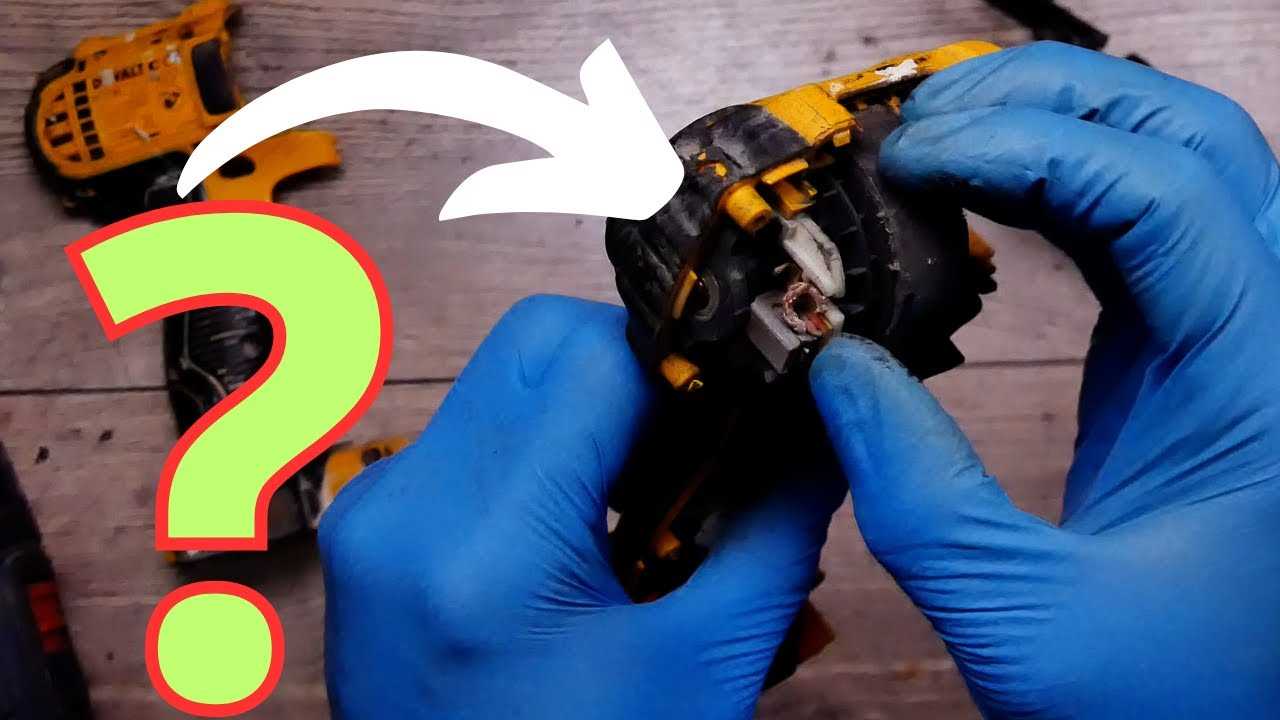

Another issue involves decreased power output, which might be caused by worn brushes or a malfunctioning motor. Regular inspection of these parts can help identify wear and prevent further damage. If overheating occurs, allowing the tool to cool down and ensuring proper ventilation during use are recommended steps.

Lastly, if there are unusual noises or vibrations, these could signify mechanical problems. Addressing any loose screws or components promptly can prevent escalation. Following these troubleshooting tips will help maintain tool reliability and longevity.

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to carefully dismantling the power tool for maintenance or inspection. Following these steps will help ensure that the process is efficient and minimizes the risk of damage to components. Understanding each phase of disassembly is crucial for successful reassembly and optimal performance.

Required Tools

Before beginning the disassembly process, gather the necessary tools to facilitate the task. This preparation will streamline the workflow and prevent interruptions.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove screws securing the outer casing |

| Pliers | For gripping and pulling components apart |

| Multimeter | To test electrical connections during reassembly |

Disassembly Steps

Follow these steps to dismantle the tool efficiently:

- Begin by disconnecting the power source to ensure safety.

- Remove the outer casing screws using the screwdriver.

- Gently pull apart the casing to expose internal components.

- Identify and disconnect wiring harnesses carefully to avoid damage.

- Remove additional components as necessary for thorough inspection.

Replacing the Battery Pack

When it comes to maintaining power tools, ensuring the longevity and efficiency of the energy source is crucial. Over time, battery packs may degrade, leading to diminished performance. This section provides guidance on how to successfully swap out an exhausted energy unit, restoring optimal functionality to your device.

Preparation is key before starting the replacement process. First, make sure the tool is turned off and disconnected from any power source. This will prevent accidental activation during the procedure. Gather the necessary tools, which typically include a compatible replacement pack and a screwdriver if required.

To begin, locate the release mechanism for the battery compartment. Depending on the design, this may involve pressing a button or sliding a latch. Once released, gently remove the old energy unit from the housing. Take a moment to inspect the compartment for any debris or damage that may need attention.

Next, take the new energy unit and align it properly with the compartment. Ensure that any connectors are positioned correctly to facilitate a secure fit. Push firmly until you hear a click or feel it lock into place. This signifies that the new unit is properly seated and ready for use.

Finally, after replacing the energy source, perform a brief test to ensure that the tool operates smoothly. Regular checks and timely replacements will help keep your power tools performing at their best.

Motor Maintenance and Care

Ensuring the longevity and optimal performance of an electric tool’s power source requires regular upkeep and attention. Proper maintenance can prevent malfunctions and extend the life of the device, making it essential for any user. This section outlines key practices to maintain and care for the motor effectively.

Regular cleaning is crucial for optimal functionality. Dust and debris can accumulate, leading to overheating and reduced efficiency. Here are some steps to keep the motor clean:

- Disconnect the tool from the power source before cleaning.

- Use a soft brush or compressed air to remove dust from vents and openings.

- Wipe the exterior with a damp cloth to eliminate grime.

Lubrication is another important aspect. Proper lubrication can reduce friction and wear on moving parts. Follow these guidelines:

- Consult the manufacturer’s specifications for recommended lubricants.

- Apply lubricant sparingly to bearings and other moving components.

- Avoid over-lubrication, which can attract dirt and debris.

Regular inspections are vital to identify potential issues early. Check for:

- Loose or damaged wiring connections.

- Signs of overheating or unusual noises during operation.

- Wear and tear on brushes and other components.

By following these maintenance practices, users can ensure their tools remain reliable and effective for years to come.

Switch Replacement Process

Replacing the actuator component in a power tool can significantly enhance its performance and functionality. This task requires careful attention to detail and a methodical approach to ensure a successful outcome. Below is a step-by-step guide to facilitate this process.

- Gather Necessary Tools:

- Screwdriver set

- Replacement actuator

- Safety goggles

- Wire cutters (if needed)

- Prepare the Workspace:

Ensure that your work area is clean and well-lit. Organize your tools and components for easy access.

- Remove the Housing:

Carefully unscrew and detach the outer casing to expose the internal components. Take note of the placement of screws to ensure proper reassembly.

- Disconnect the Old Actuator:

Locate the actuator and gently disconnect it from its wiring. If necessary, use wire cutters to detach any frayed connections.

- Install the New Actuator:

Connect the new actuator, ensuring that all wiring is secure and correctly positioned.

- Reassemble the Housing:

Carefully align the outer casing and reattach it with screws, making sure everything is securely fastened.

- Test the Device:

Once reassembled, power on the tool to verify that the new actuator functions properly.

Following these steps will help ensure a smooth transition when replacing the actuator component, ultimately improving the tool’s efficiency.

Understanding Wiring Diagrams

Wiring diagrams serve as essential tools for visualizing the connections and pathways within electrical systems. These illustrations depict the relationships between various components, enabling users to comprehend how electricity flows through a device. Grasping the layout of these diagrams is crucial for troubleshooting and maintaining functionality.

Key Elements of Wiring Diagrams

Typically, a wiring diagram includes symbols representing different components such as switches, batteries, and motors. Lines indicate the connections between these elements, often showing the flow of current. Familiarizing oneself with these symbols is fundamental for accurate interpretation and efficient repairs.

Importance of Accurate Interpretation

Understanding wiring diagrams not only aids in identifying faults but also assists in making informed modifications or upgrades. Accurate interpretation ensures that changes are implemented safely and effectively, preserving the integrity of the electrical system.

Reassembly Tips for Longevity

Ensuring the durability and efficient operation of your power tool requires careful attention during the reassembly process. Following specific guidelines can enhance performance and extend the lifespan of your equipment.

Here are key suggestions to keep in mind:

- Organize Components: Before beginning, arrange all parts systematically. This makes reassembly easier and helps avoid misplaced items.

- Inspect for Damage: Examine each component for wear or damage. Replacing any faulty pieces will prevent future issues.

- Use Appropriate Tools: Employ the correct tools to ensure parts fit together seamlessly. Using the wrong tools can cause damage.

- Follow a Methodical Order: Reassemble in the reverse order of disassembly. This helps maintain a clear structure and reduces the chance of missing steps.

- Apply Lubrication: When necessary, apply lubricant to moving parts to ensure smooth operation. This helps reduce friction and wear.

By adhering to these guidelines, you can significantly enhance the performance and longevity of your tool, ensuring it remains reliable for years to come.

Preventive Maintenance Strategies

Implementing regular upkeep practices is essential for ensuring optimal performance and longevity of power tools. By adhering to a consistent maintenance schedule, users can minimize the risk of unexpected failures and enhance operational efficiency. This approach not only preserves functionality but also contributes to safety during use.

Regular Inspections

Conducting systematic evaluations of equipment is crucial. Regularly checking for wear and tear, loose components, or signs of damage allows for early detection of potential issues. These inspections should focus on critical parts, ensuring they are in good condition and properly secured.

Cleaning and Lubrication

Keeping tools clean and well-lubricated is vital for maintaining performance. Dust and debris can hinder operation, while proper lubrication reduces friction and wear. Use appropriate cleaning agents and lubricants as specified by the manufacturer to ensure the best results.

Identifying Compatible Replacement Parts

When maintaining a power tool, selecting appropriate components is crucial for optimal performance. Understanding the specifications and compatibility of various parts can significantly extend the lifespan of your equipment. This section provides guidance on how to find suitable replacements to ensure your device operates efficiently.

To assist you in identifying the right parts, consider the following factors:

| Factor | Description |

|---|---|

| Model Number | Always refer to the model number when searching for replacements to ensure compatibility. |

| Specifications | Check voltage, amperage, and size specifications to match the original component’s requirements. |

| Manufacturer Recommendations | Consult the manufacturer’s guidelines for suggested parts to avoid mismatches. |

| Quality Standards | Opt for components that meet industry quality standards for reliability and durability. |

By following these guidelines, you can effectively identify and procure parts that will maintain the performance and safety of your equipment.

FAQs about DCD780 Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for a popular power tool model. Here, users can find answers to typical concerns that arise during usage, offering guidance and solutions to ensure optimal performance.

Common Issues and Solutions

Many users encounter specific challenges when operating this tool. Below are frequently asked questions and their corresponding solutions:

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| Tool won’t start | Dead battery | Charge the battery or replace it if necessary |

| Poor performance | Clogged ventilation | Clean the air vents and ensure proper airflow |

| Strange noises | Worn bearings | Inspect and replace bearings if needed |

Maintenance Tips

To prolong the lifespan of your equipment, consider these essential maintenance practices:

- Regularly check and clean the tool

- Store in a dry, secure location

- Inspect battery terminals for corrosion