Ensuring the longevity and performance of your two-wheeled vehicle is essential for any enthusiast. This section will explore various techniques and strategies to keep your machine in optimal condition, focusing on essential care practices and troubleshooting common issues. With the right knowledge, you can enhance your riding experience and maintain the value of your investment.

From basic upkeep to addressing specific challenges, understanding the intricacies of your vehicle will empower you as an owner. By delving into the core elements of vehicle care, you can develop a deeper connection with your ride and enhance its reliability. This guide aims to provide valuable insights and practical tips to navigate the maintenance process effectively.

Pit Bike Repair Manual

Maintaining small off-road vehicles requires careful attention and knowledge of their components. This section provides essential guidance for ensuring optimal performance and longevity of these machines.

Understanding the Fundamentals is crucial. Familiarizing oneself with various parts and their functions can significantly aid in troubleshooting and maintenance tasks. Regular checks on the engine, brakes, and tires will prevent unexpected issues.

Common Challenges may include starting difficulties, unusual noises, or handling problems. Identifying these symptoms early can lead to simpler fixes and better riding experiences. A systematic approach to diagnosing issues often proves effective.

Implementing a routine inspection schedule will greatly enhance the reliability of the vehicle. Documentation of maintenance history can also provide valuable insights into recurring problems, allowing for more efficient solutions in the future.

Essential Tools for Maintenance

Regular upkeep of your two-wheeled vehicle is crucial for optimal performance and longevity. Having the right equipment at your disposal not only simplifies the process but also enhances your ability to troubleshoot and resolve issues efficiently. Here are some key tools every enthusiast should consider for their maintenance toolkit.

Basic Hand Tools

A variety of hand tools are fundamental for performing routine tasks. These tools help in adjusting, tightening, and replacing parts with ease. Below is a list of essential hand tools:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening nuts and bolts. |

| Screwdrivers | Essential for handling screws of various sizes and types. |

| Pliers | Useful for gripping and bending materials as needed. |

| Socket Set | Provides versatility for different fastener sizes. |

Specialized Maintenance Tools

In addition to basic hand tools, certain specialized equipment can greatly assist in specific maintenance tasks. These tools are designed to address unique challenges:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Chain Tool | Facilitates chain removal and installation. |

| Feeler Gauge | Measures gaps and spaces for precise adjustments. |

| Oil Filter Wrench | Assists in removing and replacing oil filters. |

Common Issues and Troubleshooting

Addressing frequent challenges and finding effective solutions is crucial for maintaining optimal performance. This section explores typical problems encountered and provides practical tips for resolution.

- Engine Won’t Start:

- Check fuel levels and ensure the fuel is fresh.

- Inspect the ignition system for faults.

- Verify the battery charge and connections.

- Unusual Noises:

- Listen for any grinding or knocking sounds.

- Check for loose parts or debris in the engine.

- Inspect the chain and sprockets for wear.

- Overheating:

- Ensure coolant levels are adequate.

- Check for blockages in the cooling system.

- Examine the radiator and hoses for leaks.

- Handling Issues:

- Inspect tire pressure and tread for wear.

- Check suspension settings and adjustments.

- Ensure all components are securely attached.

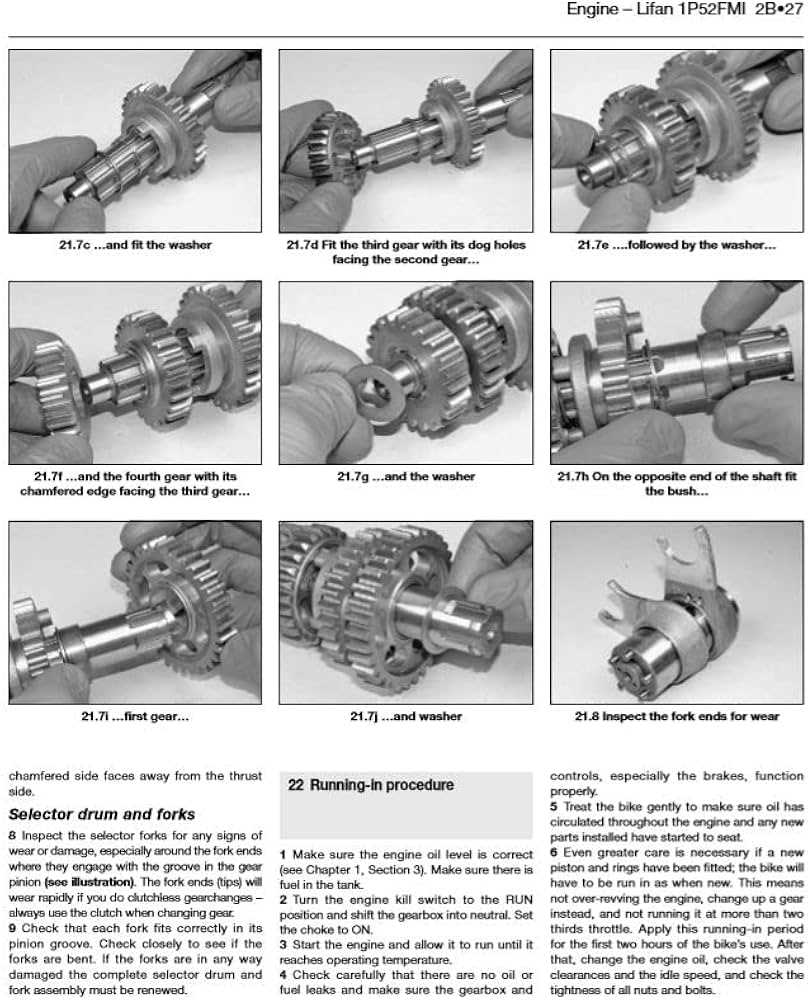

Step-by-Step Engine Repair Guide

This section provides a comprehensive approach to addressing common issues encountered in small engine maintenance. Understanding the fundamentals of the engine’s components is essential for effective troubleshooting and resolution of problems.

1. Preparation: Begin by gathering all necessary tools and materials. Ensure that you have a clean workspace to facilitate the process.

2. Inspection: Carefully examine the engine for visible signs of damage or wear. Check for leaks, cracks, or unusual noises during operation.

3. Disassembly: Follow a systematic approach to disassemble the engine components. Take notes or pictures to remember the arrangement of parts.

4. Cleaning: Remove any dirt or debris from the components. Use appropriate cleaning solutions to ensure that all parts are free of contaminants.

5. Replacement: Identify any worn or damaged parts that need to be replaced. Choose high-quality replacements to ensure optimal performance.

6. Reassembly: Carefully reassemble the engine, following the notes or pictures taken during disassembly. Make sure each component is securely fastened.

7. Testing: Once reassembled, conduct a test run to verify that the engine operates smoothly. Listen for any irregular sounds and observe performance.

8. Final Adjustments: Make any necessary adjustments based on the test results to optimize the engine’s functionality.

Changing Tires Like a Pro

Switching out wheels is an essential skill for any enthusiast looking to maintain optimal performance. Whether you’re preparing for a race or ensuring safe rides, mastering this task can enhance your experience and prolong the life of your vehicle.

Tools You Will Need

- Wrench set

- Tire levers

- Air pump or compressor

- New tires

- Lubricant (optional)

Step-by-Step Guide

- Start by loosening the bolts on the current wheels.

- Carefully lift the vehicle and remove the existing tires.

- Use tire levers to detach the old tires from the rims.

- Inspect the rims for any damage before installing the new tires.

- Apply lubricant to the beads of the new tires for easier installation.

- Mount the new tires onto the rims, ensuring they fit snugly.

- Inflate the tires to the recommended pressure.

- Reattach the wheels, tightening the bolts securely.

Following these steps will help you execute tire changes efficiently, enhancing both safety and performance during your rides.

Cleaning and Maintaining Air Filters

Proper care of air filters is essential for optimal performance and longevity of your engine. Regular cleaning ensures that airflow remains unobstructed, which directly impacts efficiency and power output.

Steps for Cleaning Air Filters:

- Remove the filter from its housing carefully, taking note of how it is positioned.

- Inspect for any signs of damage or excessive dirt buildup.

- Clean the filter using compressed air or a specialized cleaning solution, depending on the material.

- Dry the filter completely before reinstallation to prevent moisture-related issues.

- Reinstall the filter securely, ensuring it fits snugly in place.

Regular maintenance of air filters not only prolongs their life but also enhances the overall performance of your machine.

Understanding the Electrical System

The electrical system of any vehicle plays a crucial role in ensuring optimal performance and functionality. This section will delve into the various components that constitute this system, highlighting their significance and how they interact with each other. A solid understanding of this network is essential for maintaining efficient operation.

Key Components of the System

At the heart of the electrical framework are several integral parts, including the battery, wiring harness, and ignition system. The battery stores energy, while the wiring harness facilitates the distribution of electricity throughout the vehicle. The ignition system is responsible for starting the engine and ensuring it runs smoothly.

Common Issues and Solutions

Electrical malfunctions can lead to significant performance problems. Typical issues include faulty connections, damaged wiring, or a depleted battery. Regular inspections and timely repairs are vital for preventing breakdowns and ensuring longevity. Identifying and addressing these challenges promptly can enhance the overall efficiency of the vehicle.

Brake System Maintenance Tips

Ensuring the optimal functionality of your braking components is essential for safety and performance. Regular upkeep not only extends the lifespan of these elements but also enhances your overall riding experience. Here are some key practices to keep in mind.

Routine Checks

- Inspect brake pads for wear and tear, replacing them when necessary.

- Examine brake fluid levels and top up as needed to maintain pressure.

- Check brake lines for any signs of damage or leaks.

Cleaning and Lubrication

- Clean brake components with appropriate solutions to remove dirt and debris.

- Lubricate moving parts lightly to ensure smooth operation.

- Avoid over-lubrication, as this can lead to reduced braking efficiency.

Adjusting Suspension for Performance

Optimizing the suspension system is crucial for enhancing overall performance. Proper adjustments can significantly impact handling, stability, and rider comfort. This section explores key aspects of tuning suspension to achieve the desired feel and responsiveness.

Understanding Suspension Components

Before making adjustments, it’s essential to grasp the function of each component. The main elements include springs, dampers, and preload settings. Each part plays a vital role in how the vehicle responds to various terrains and riding styles.

Steps for Effective Adjustment

Start by checking the current settings and making note of any issues. Fine-tuning the preload can help achieve the right sag for the rider’s weight. Next, adjusting the compression and rebound damping will improve the ride’s overall quality. Regular evaluations and tweaks based on personal preferences and riding conditions are key to maintaining optimal performance.

Fuel System Care and Upgrades

Maintaining and enhancing the fuel system is crucial for optimal performance and longevity of any small engine. Proper attention ensures that fuel delivery is efficient and prevents common issues that can arise over time.

Regular Cleaning: It’s important to keep the fuel tank, lines, and filters clean. Contaminants can lead to clogs, affecting performance. Use a suitable cleaner to remove debris and sediment.

Fuel Quality: Always use high-quality fuel to minimize deposits and engine knocking. Consider adding a fuel stabilizer to extend the life of the fuel, especially if the engine will not be used for an extended period.

Upgrading Components: Replacing standard components with high-performance alternatives can significantly enhance fuel flow and efficiency. Look for upgraded fuel pumps, injectors, or carburetors that match your engine’s specifications.

Monitoring Performance: Regularly check for any signs of fuel leaks or performance drops. Keeping an eye on the engine’s responsiveness can help identify potential issues before they escalate.

Keeping the Chain in Shape

Maintaining the flexibility and functionality of the drive system is essential for optimal performance. Regular attention to the chain can prevent unnecessary wear and ensure a smooth ride.

Begin by inspecting the chain for any signs of damage, such as kinks or rust. A clean chain is crucial; use a suitable degreaser to remove grime, followed by a gentle scrub with a brush. After cleaning, apply a high-quality lubricant specifically designed for chains to reduce friction and extend lifespan.

It’s important to check the tension regularly. An overly tight or loose chain can lead to performance issues and premature wear. Adjust the tension according to the manufacturer’s specifications to maintain balance and efficiency.

Lastly, keep an eye on the sprockets. Worn or damaged sprockets can adversely affect the chain’s operation. Replace them as necessary to ensure everything operates smoothly and efficiently.

Safety Precautions During Repairs

Ensuring a safe environment is crucial when undertaking maintenance tasks on any vehicle. Adhering to safety measures not only protects the individual performing the work but also extends the lifespan of the machine. This section outlines essential guidelines to follow during maintenance activities.

Essential Guidelines

- Always wear appropriate protective gear, including gloves and goggles.

- Ensure the work area is well-ventilated to avoid inhaling harmful fumes.

- Disconnect the battery or power source to prevent accidental starts.

- Keep tools organized and within reach to minimize hazards.

Proper Work Environment

- Choose a clean and dry workspace to avoid slipping or falling.

- Avoid clutter and ensure all materials are properly stored when not in use.

- Have a fire extinguisher readily available in case of emergencies.

- Stay hydrated and take regular breaks to maintain focus and prevent fatigue.

Upgrading Components for Better Performance

Enhancing various elements of your vehicle can significantly improve its overall functionality and responsiveness. By focusing on key parts, you can achieve a more thrilling riding experience and increased efficiency, making every ride more enjoyable.

Key Areas for Improvement

Consider prioritizing areas such as the suspension system, braking mechanisms, and exhaust components. Upgrading these aspects can lead to better handling, increased safety, and enhanced power delivery.

Choosing the Right Upgrades

When selecting new components, it’s essential to ensure compatibility and quality. Investing in reputable brands often leads to greater durability and performance. Don’t hesitate to consult experts or enthusiasts for recommendations to make informed choices.