In the world of textile arts, maintaining the functionality of your stitching device is crucial. This section will explore essential techniques and guidelines to help you effectively troubleshoot and enhance the performance of your machine.

Understanding the inner workings of your device can significantly extend its lifespan and ensure consistent quality in your projects. From simple adjustments to more intricate procedures, the information provided here aims to empower you with the knowledge needed to address common issues.

With proper care and attention, your machine can continue to serve you well for years. This guide will equip you with the tools and insights necessary for successful maintenance and repair.

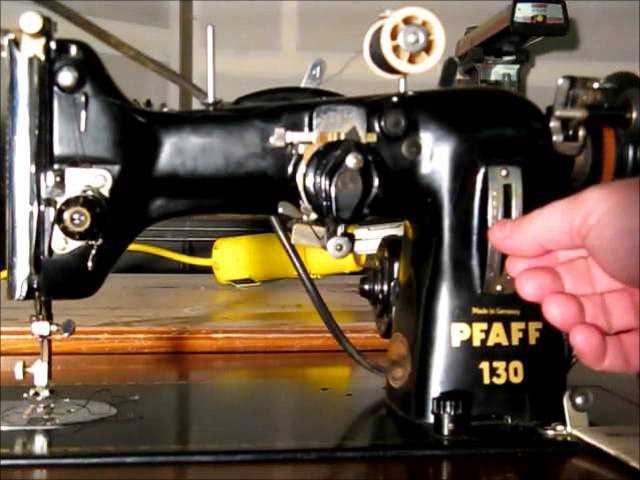

This section provides a comprehensive overview of a notable sewing machine model that has gained popularity among enthusiasts and professionals alike. The design and functionality of this device cater to a wide range of sewing tasks, making it a versatile choice for various projects.

Key Features

The machine boasts several important characteristics that enhance its usability. Below is a summary of these features:

| Feature | Description |

|---|---|

| Stitch Options | A variety of stitch types for different sewing needs. |

| Speed Control | Adjustable settings to manage sewing speed effectively. |

| Durability | Constructed with high-quality materials for longevity. |

Usability and Maintenance

Understanding how to operate and maintain this sewing device is crucial for ensuring optimal performance. Regular upkeep helps in preserving its functionality and extending its lifespan.

Common Issues with Pfaff 130

When operating a classic sewing machine, several typical challenges may arise that affect performance and efficiency. Understanding these common problems can aid users in identifying issues quickly and maintaining optimal functionality.

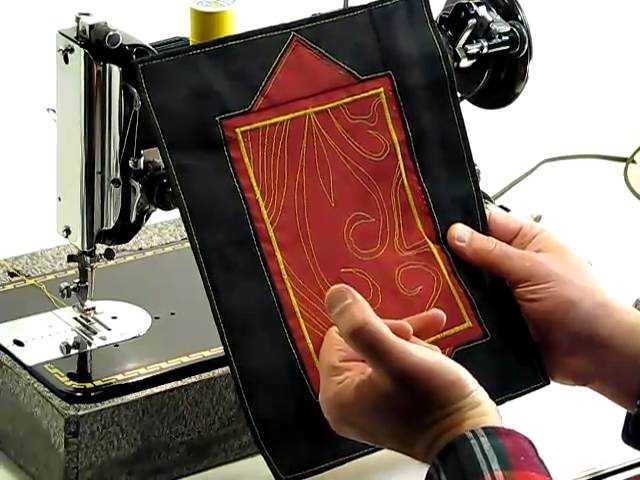

Stitch Quality Problems

One frequent concern involves the quality of the stitches produced. Inconsistent tension or improper threading can lead to loose stitches or thread bunching beneath the fabric. Regularly checking the tension settings and ensuring correct threading can significantly improve stitch integrity.

Feed Mechanism Malfunctions

Another prevalent issue is related to the fabric feeding mechanism. If the material does not move smoothly through the machine, it may be due to dirty feed dogs or misalignment. Cleaning the feed dogs and adjusting their position can restore proper movement and enhance the sewing experience.

Tools Needed for Repair

To effectively address mechanical issues, it is essential to gather the appropriate instruments. Having the right equipment on hand facilitates a smoother process and enhances the likelihood of achieving optimal functionality.

Key items for this task include a variety of screwdrivers to handle different types of screws. Additionally, pliers are crucial for gripping and bending components as needed. A wrench set is also important for loosening or tightening nuts and bolts securely.

Moreover, utilizing a seam ripper can assist in carefully removing stitches without damaging the surrounding fabric. For precision work, a magnifying glass can help inspect small details. Lastly, having a reliable work surface will provide a stable area to organize tools and components during the process.

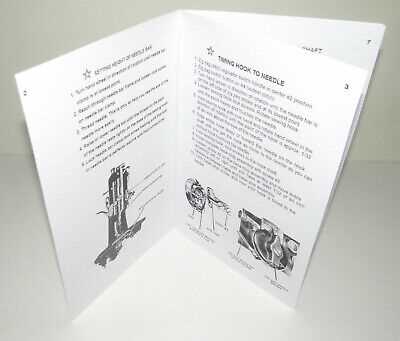

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered with sewing machines. By following the outlined steps, users can systematically diagnose problems and implement effective solutions to restore functionality.

Identifying Common Issues

Implementing Solutions

How to Replace Parts

Replacing components in your sewing device is essential for maintaining its performance and longevity. Understanding the basic procedures can help you efficiently handle the task, ensuring that each part functions optimally. Proper attention to detail during the replacement process will enhance your machine’s overall efficiency.

Identifying the Component to Change

Before starting the replacement process, it’s crucial to identify which part requires attention. Referencing the manufacturer’s specifications or consulting with experienced users can provide valuable insights. Keep in mind the specific function of each component and how it contributes to the overall operation of your machine.

Steps for Successful Replacement

Begin by gathering the necessary tools and a suitable replacement part. Ensure the machine is unplugged to prevent any accidents. Carefully disassemble the unit, noting the arrangement of components to aid reassembly. When installing the new part, align it precisely as per the guidelines to avoid any operational issues. Once completed, reassemble the unit and perform a test to confirm functionality.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your sewing equipment. Regular attention to details can prevent wear and tear, ensuring smooth operation and consistent performance over time.

1. Regular Cleaning: Dust and lint accumulation can lead to mechanical issues. It’s important to clean the machine after each use, focusing on the feed dogs and bobbin area. Use a soft brush or cloth to remove debris.

2. Lubrication: Periodic lubrication of moving parts is crucial. Refer to the guidelines for the specific lubricant recommended for your machine. Applying oil to designated points can significantly enhance functionality.

3. Tension Adjustments: Regularly check and adjust the thread tension to maintain consistent stitch quality. This helps prevent skipped stitches and thread breakage, contributing to the overall efficiency of the machine.

4. Needle Care: Using the correct needle type for your fabric and replacing it regularly will help avoid unnecessary strain on the machine. Dull or damaged needles can lead to skipped stitches and fabric snags.

5. Storage: When not in use, store the equipment in a protective cover to shield it from dust and potential damage. This simple step can help preserve its condition and functionality.

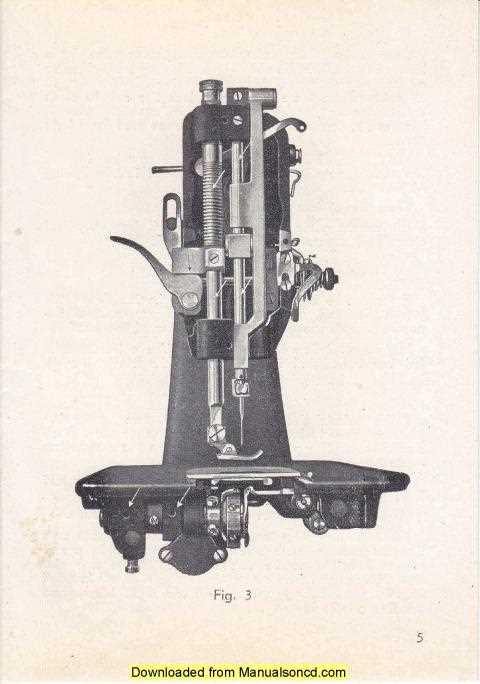

Understanding the Sewing Mechanism

The sewing mechanism is a vital component in textile creation, providing the necessary functions for stitching fabrics together. This intricate system combines various parts that work in harmony to produce consistent and high-quality results. A thorough understanding of this mechanism is essential for effective operation and maintenance.

Key Components of the Mechanism

- Needle: The primary tool that penetrates the fabric to create stitches.

- Bobbin: A small spool that holds the lower thread, crucial for forming stitches.

- Feed Dogs: These components move the fabric through the machine during sewing.

- Presser Foot: This part holds the fabric in place as it is stitched.

- Tension Discs: They control the thread tension, affecting stitch quality.

How the Mechanism Functions

The process begins with the needle descending through the fabric, creating a hole. Simultaneously, the bobbin rotates to catch the upper thread, forming a loop. As the needle rises, the feed dogs pull the fabric forward, preparing for the next stitch. This cycle repeats, allowing for continuous sewing.

Understanding these components and their functions is crucial for anyone looking to maintain or enhance their sewing experience. Proper knowledge can lead to better performance and longevity of the sewing equipment.

Adjusting Tension for Optimal Performance

Proper adjustment of thread tension is essential for achieving flawless stitching and overall functionality of your sewing machine. Balancing the upper and lower threads ensures that the fabric is fed smoothly, preventing issues such as puckering or thread breakage. Understanding how to fine-tune this setting can significantly enhance your sewing experience.

Understanding Tension Mechanics

The mechanism that controls thread tension plays a crucial role in stitch quality. Each fabric type and thread weight may require different tension levels. To determine the optimal setting, it is beneficial to conduct a few test stitches on a scrap piece of the same material you plan to work with. This trial-and-error approach allows for precise calibration.

Steps to Adjust Tension

Begin by loosening or tightening the tension dial, depending on your initial assessment. A good starting point is to refer to the manufacturer’s guidelines regarding recommended settings. Observe the results and make further adjustments as necessary. Always remember that consistency in tension leads to professional-looking seams, making this adjustment a vital aspect of sewing.

Cleaning and Lubrication Procedures

Maintaining your sewing machine is essential for optimal performance and longevity. Regular cleaning and appropriate lubrication ensure that all moving parts function smoothly, preventing wear and tear that could lead to malfunctions.

Cleaning involves removing lint, dust, and debris from various components. Begin by unplugging the machine and taking off the needle and presser foot. Use a small brush or a vacuum attachment to gently clean around the bobbin case and feed dogs. Pay special attention to the areas that collect threads and fabric particles, as these can hinder the machine’s operation.

Lubrication is equally important. After cleaning, apply a few drops of suitable oil to the designated points as indicated in the manufacturer’s guidelines. This helps reduce friction between moving parts, ensuring a smooth sewing experience. Be cautious not to over-lubricate, as excess oil can attract dust and lead to buildup.

By regularly performing these tasks, you will enhance the efficiency and lifespan of your equipment, allowing for enjoyable and trouble-free sewing projects.

When to Seek Professional Help

Identifying the right moment to consult an expert can significantly impact the longevity and performance of your equipment. While many minor issues can be addressed with basic troubleshooting, certain situations demand the skills of a trained technician.

Signs That Indicate Professional Assistance

- Persistent problems despite attempted fixes

- Unusual noises or vibrations during operation

- Parts not functioning as intended or misalignments

- Visible damage or wear that may affect performance

Benefits of Expert Intervention

- Access to specialized knowledge and tools

- Ensured safety during complex repairs

- Potentially reduced long-term costs by preventing further damage

- Expert guidance on maintenance practices to extend lifespan

Resources for Further Assistance

When facing challenges with your sewing apparatus, seeking additional support can be invaluable. There are various avenues available that can provide you with guidance and solutions tailored to your specific needs.

Online forums and communities dedicated to textile machinery enthusiasts often serve as excellent platforms for sharing experiences and troubleshooting advice. Engaging with fellow users can yield practical tips and innovative techniques that enhance your understanding.

Moreover, numerous instructional videos and tutorials are accessible on various streaming platforms. These resources can visually demonstrate the processes, making it easier to follow along and implement necessary adjustments or maintenance tasks.

Additionally, consulting with local sewing machine retailers or service centers can offer professional insights. These experts possess a wealth of knowledge and can assist in addressing any complex issues you may encounter.

Finally, manuals or guides, often available in digital format, can serve as helpful references. They typically contain detailed information about the device’s features, functions, and maintenance requirements, aiding you in achieving optimal performance.