In the realm of aquatic vessels, understanding the intricacies of upkeep is essential for ensuring longevity and optimal performance. This section delves into the fundamental aspects of maintaining such vehicles, emphasizing the importance of regular checks and timely interventions. Knowledge in this area empowers enthusiasts to tackle challenges effectively and confidently.

Equipping yourself with the right insights can significantly enhance your experience on the water. From troubleshooting common issues to implementing preventative measures, the information provided will serve as a valuable resource for both novice and experienced users alike. It is crucial to familiarize yourself with the various components and systems that contribute to the overall functionality of your craft.

Furthermore, staying informed about best practices can prevent costly repairs and extend the lifespan of your vessel. With a commitment to diligent maintenance and a proactive approach, you can ensure a safe and enjoyable experience on the water.

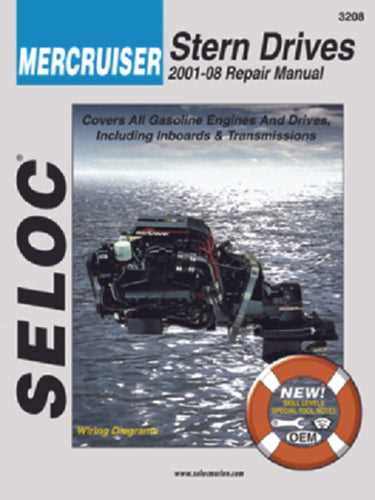

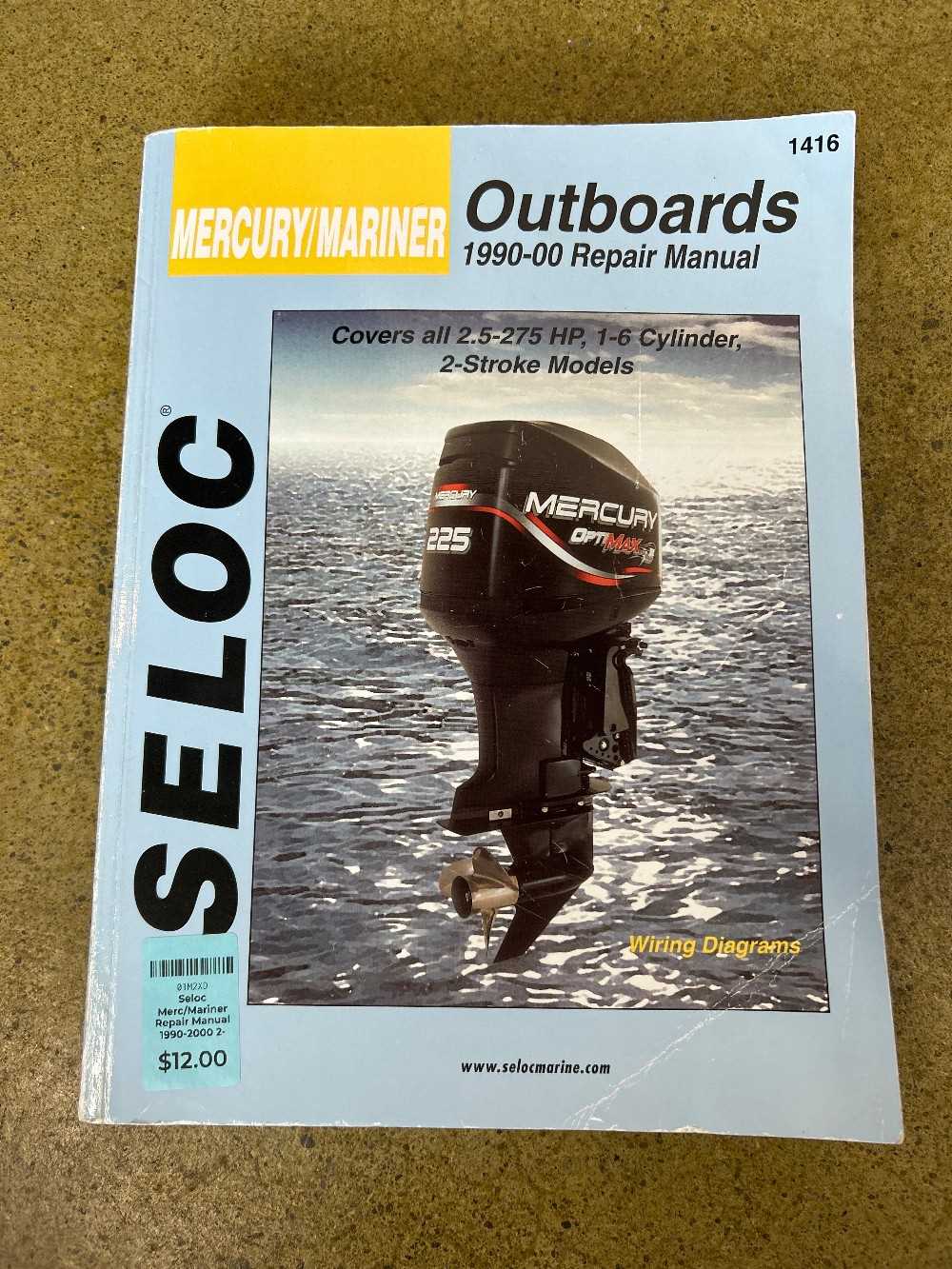

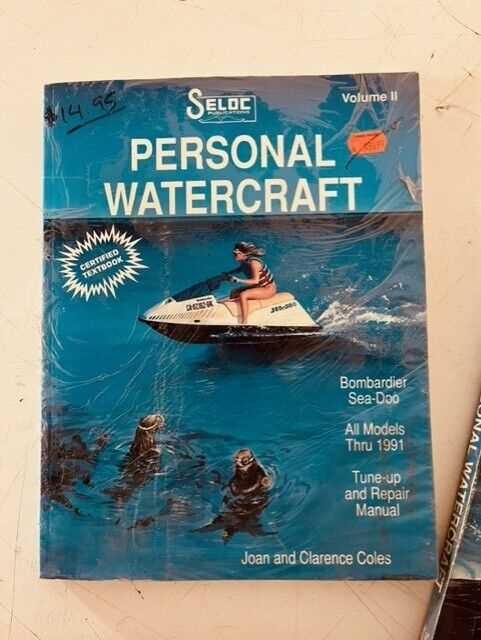

This section provides a comprehensive overview of a valuable resource designed to assist individuals in the maintenance and troubleshooting of watercraft. The guide offers essential insights into various components, enabling users to efficiently address issues and enhance performance.

Key Features

The resource is characterized by its user-friendly structure, allowing for easy navigation through different topics. It typically includes diagrams, detailed instructions, and troubleshooting tips, making it accessible for both novice and experienced users.

Benefits of Using the Guide

Utilizing this resource can lead to significant improvements in vessel upkeep. Users can expect increased reliability and safety, as well as potential cost savings by performing maintenance tasks independently.

| Section | Description |

|---|---|

| Introduction | A brief overview of the resource’s purpose and importance. |

| Component Breakdown | Detailed descriptions of various parts and systems. |

| Troubleshooting Tips | Common issues and solutions for quick reference. |

| Maintenance Schedules | Recommended routines for optimal performance. |

| Safety Precautions | Essential safety information for handling equipment. |

| Parts Identification | Guidelines for recognizing specific components. |

| Wiring Diagrams | Visual representations to aid in understanding electrical systems. |

| FAQs | Answers to common questions regarding vessel maintenance. |

| Glossary | Definitions of technical terms used throughout the guide. |

| Resource Index | An organized index for quick reference to topics. |

| Conclusion | A summary of the resource’s benefits and final thoughts. |

Key Features and Benefits

This section highlights the essential characteristics and advantages of the reference guide, providing valuable insights for users seeking to enhance their knowledge and skills in the relevant field. The resource is designed to facilitate understanding and support effective problem-solving.

Comprehensive Information

- Detailed instructions for various tasks

- Illustrations that enhance comprehension

- Step-by-step processes to simplify complex repairs

User-Friendly Format

- Organized layout for quick navigation

- Accessible language for all skill levels

- Easy-to-follow diagrams that aid in execution

Overall, this guide equips individuals with the necessary tools to address issues confidently and efficiently, ultimately improving the overall experience and outcome of the task at hand.

Understanding Marine Engine Types

Engines designed for aquatic vessels play a crucial role in determining performance and efficiency. They come in various forms, each tailored to specific applications and environmental conditions. Recognizing the different categories can significantly enhance the overall experience and functionality of any watercraft.

Two primary types dominate the landscape: inboard and outboard engines. Inboard engines are installed within the hull and are typically more powerful, suitable for larger vessels. Conversely, outboard engines are mounted externally and offer versatility, making them ideal for smaller crafts. Each type has distinct advantages, such as weight distribution and ease of maintenance.

Furthermore, engines can be categorized based on their power source. Traditional internal combustion engines remain prevalent, while alternatives like electric motors are gaining traction for their eco-friendly attributes. Understanding these distinctions not only aids in selecting the right engine but also impacts fuel efficiency and environmental considerations.

Maintenance Guidelines for Marine Crafts

Regular upkeep is essential for ensuring the longevity and performance of aquatic vessels. Following systematic procedures not only enhances safety but also preserves functionality over time.

Routine Checks

- Inspect all exterior surfaces for signs of wear or damage.

- Check the integrity of fasteners and fittings to prevent leaks.

- Test electrical systems to ensure proper operation.

Seasonal Preparation

- Clean the hull thoroughly to remove debris and algae.

- Apply protective coatings to prevent corrosion.

- Store equipment properly during off-seasons to avoid deterioration.

Troubleshooting Common Engine Issues

Addressing frequent engine problems is essential for maintaining optimal performance and reliability. Identifying the root causes of these issues can save time and resources while ensuring smooth operation. This section outlines key aspects to consider when diagnosing typical malfunctions.

Unresponsive Engine: If the engine fails to start, check the battery for adequate charge and ensure all connections are secure. A malfunctioning ignition system could also be the culprit, requiring inspection of spark plugs and wires.

Overheating: Overheating can stem from various sources, such as insufficient coolant or a failing thermostat. It’s crucial to monitor coolant levels regularly and inspect hoses for leaks. Additionally, ensuring that the cooling system is free from debris can help maintain proper temperatures.

Poor Performance: A noticeable drop in performance may indicate issues with fuel delivery or air intake. Verify that the fuel filter is clean and that the fuel pump is functioning properly. Similarly, inspect the air filter for blockages that could restrict airflow.

Unusual Noises: Strange sounds from the engine can signal underlying problems. Knocking or tapping noises may suggest issues with internal components, while excessive vibration could indicate misalignment or loose parts. Immediate investigation is recommended to prevent further damage.

Regular checks and a proactive approach to these common challenges can significantly enhance the longevity and efficiency of your engine.

Parts and Tools Needed for Repairs

Ensuring a successful maintenance process requires a thorough understanding of the components and instruments necessary for the task at hand. Having the right supplies on hand not only facilitates smoother execution but also enhances the overall efficiency of the work being undertaken.

Essential Components

Before embarking on any task, it is crucial to gather the appropriate parts. This may include gaskets, seals, and various fasteners specific to the equipment. Identifying the exact components needed ensures that downtime is minimized and that the job can be completed without unnecessary delays.

Required Instruments

Equipping oneself with the right tools is equally important. Commonly used instruments might consist of wrenches, screwdrivers, and specialized gauges. Investing in quality tools not only improves the precision of your work but also contributes to a safer working environment. Regularly checking the condition of these tools can prevent complications during repairs.

Safety Precautions When Repairing

Ensuring a secure environment during maintenance activities is crucial for both personal safety and the integrity of the equipment. By adhering to essential guidelines, one can minimize risks and enhance the efficiency of the tasks at hand.

Personal Protective Equipment

Utilizing appropriate personal protective gear is vital. This includes wearing gloves, goggles, and sturdy footwear to shield against potential hazards. The right equipment not only protects against injuries but also promotes a more confident working atmosphere.

Proper Workspace Management

Maintaining an organized workspace is equally important. Ensure that tools are stored safely and that the area is free of clutter. An orderly environment reduces the likelihood of accidents and facilitates smoother operations, allowing for a focused approach to the task.

Detailed Repair Procedures Explained

This section aims to provide an in-depth understanding of the processes involved in restoring equipment. The following procedures will guide you through various methods and techniques that ensure efficient and effective maintenance. Emphasis will be placed on clarity and precision to facilitate successful outcomes.

Essential Steps to Follow

- Begin by assessing the current condition of the equipment.

- Gather all necessary tools and materials required for the task.

- Carefully follow the outlined steps to avoid common pitfalls.

Common Techniques for Efficient Restoration

- Inspection: Examine all components for wear and tear.

- Disassembly: Carefully take apart the unit, noting the order of components.

- Cleaning: Remove dirt and debris to ensure optimal functionality.

- Replacement: Swap out any damaged parts with new ones.

- Reassembly: Put the unit back together, following the initial disassembly order.

- Testing: Run a series of tests to confirm everything operates smoothly.

Tips for Efficient Engine Maintenance

Regular upkeep of your power unit is crucial for ensuring longevity and optimal performance. By adopting a systematic approach, you can minimize downtime and enhance reliability.

Establish a Routine Schedule

Creating a consistent maintenance timetable allows for thorough inspections and timely interventions. Regularly checking fluid levels, filters, and belts can prevent minor issues from escalating into significant problems.

Utilize Quality Components

Investing in high-quality parts and fluids is essential for maintaining peak performance. Using premium lubricants and filters can significantly improve efficiency and reduce wear. Additionally, following manufacturer recommendations for specifications ensures compatibility and effectiveness.

Frequently Asked Questions

This section addresses common inquiries and concerns related to maintenance and troubleshooting for watercraft. Here, you will find answers to some of the most prevalent issues faced by users, providing clarity and guidance.

Understanding the nuances of equipment care is essential for optimal performance. Users often wonder about routine maintenance tasks and how to identify potential problems before they escalate. This information aims to assist enthusiasts in enhancing their knowledge and confidence.

Additionally, questions about specific components and their functions frequently arise. Whether you are looking for advice on best practices or need assistance with specific scenarios, this resource is designed to offer comprehensive support.