In the world of machinery, the longevity and performance of engines are paramount. A thorough understanding of maintenance techniques is essential for ensuring optimal functionality and minimizing downtime. This section will delve into the critical aspects of engine upkeep, focusing on various strategies that can enhance reliability and efficiency.

Effective maintenance practices not only extend the life of equipment but also improve overall productivity. This guide will outline the essential procedures, including troubleshooting methods and routine checks that can be implemented to avoid common pitfalls. Understanding these practices is crucial for anyone involved in the operation and management of heavy machinery.

Furthermore, proper documentation plays a significant role in the maintenance process. Detailed records of service history and repairs can provide valuable insights and help in identifying recurring issues. By adopting a systematic approach, operators can ensure that their engines remain in peak condition, ready to meet the demands of any task.

Understanding Perkins 1104C 44T Engine

The engine in question is a crucial component widely recognized for its reliability and performance in various applications. Understanding its features and functionalities can significantly enhance operational efficiency and maintenance practices.

This power unit is designed to provide robust performance while maintaining efficiency. Key characteristics include:

- Compact design suitable for various machinery.

- Durable construction to withstand demanding conditions.

- Efficient fuel consumption for cost-effective operation.

Recognizing the engine’s specifications is essential for optimal usage. Some notable aspects include:

- Displacement and configuration that contribute to its power output.

- Advanced cooling systems that prevent overheating during extended use.

- Emission control technologies that adhere to environmental standards.

Regular maintenance is vital for prolonging the life of the engine. Essential maintenance practices involve:

- Routine checks of fluid levels and quality.

- Monitoring filter conditions and replacing them as needed.

- Inspecting belts and hoses for wear and tear.

By understanding the intricacies of this engine, operators can ensure longevity and peak performance, making it an invaluable asset in various industrial settings.

Common Issues with Perkins Engines

Engines of this type are known for their durability and efficiency, yet they can encounter various problems over time. Understanding these common issues can help in timely maintenance and improve overall performance. Below are some frequent challenges that users may face with these power units.

| Issue | Description | Possible Causes |

|---|---|---|

| Overheating | Excessive heat can lead to engine failure if not addressed promptly. | Low coolant levels, clogged radiators, or faulty thermostats. |

| Fuel System Problems | Inefficient fuel delivery can affect performance and fuel economy. | Dirty filters, contaminated fuel, or injector malfunctions. |

| Starting Difficulties | Challenges in ignition can prevent the engine from starting reliably. | Weak batteries, faulty starters, or issues with glow plugs. |

| Excessive Smoke | Abnormal exhaust emissions can indicate underlying issues. | Engine wear, poor fuel quality, or improper air intake. |

| Unusual Noises | Strange sounds may suggest mechanical problems. | Lack of lubrication, worn bearings, or damaged components. |

Identifying these issues early can significantly enhance the lifespan and reliability of the engine. Regular inspections and maintenance practices are essential in mitigating these common concerns.

Essential Tools for Engine Repair

When it comes to maintaining and fixing internal combustion units, having the right instruments is crucial for effective and safe work. Various tools are designed to assist technicians in diagnosing issues, disassembling components, and reassembling systems efficiently. Understanding the necessary equipment not only streamlines the process but also enhances precision in every task.

Basic Hand Tools

- Wrenches: A set of both adjustable and fixed wrenches are essential for loosening and tightening various bolts and nuts.

- Screwdrivers: A variety of flathead and Phillips screwdrivers in different sizes will accommodate various screws.

- Pliers: Needle-nose and slip-joint pliers provide grip and leverage for manipulating components.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing damage from over-tightening.

Diagnostic Instruments

- Multimeter: Essential for testing electrical systems and ensuring proper voltage levels.

- Compression Tester: Measures the pressure within the cylinders to assess engine health.

- OBD-II Scanner: A tool for reading trouble codes and monitoring engine performance.

Equipping yourself with these fundamental tools will set a solid foundation for tackling various tasks involved in engine maintenance and overhaul. Investing in quality instruments will enhance your capability to perform effective repairs and prolong the lifespan of the machinery.

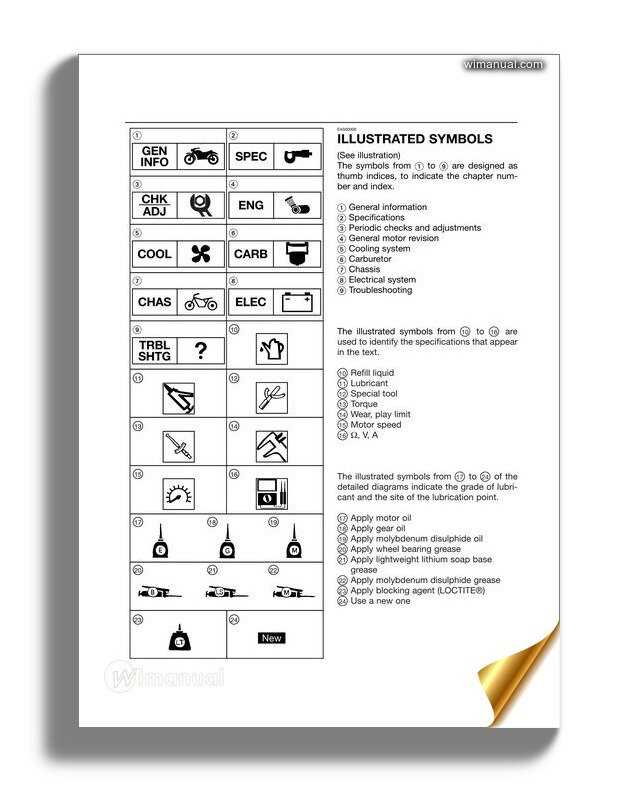

Step-by-Step Repair Procedures

This section provides a comprehensive guide to performing essential maintenance tasks on your engine. By following the outlined procedures, you can ensure optimal performance and longevity of the unit. Each step is designed to be clear and concise, making it accessible even for those with limited experience.

Preparation for Maintenance

Before starting any work, gather the necessary tools and safety equipment. Ensure that you have a clean workspace to avoid contamination. It’s crucial to review the operational manual for specific precautions and recommendations related to your particular engine type. Always disconnect the battery and allow the engine to cool to prevent any accidents during the process.

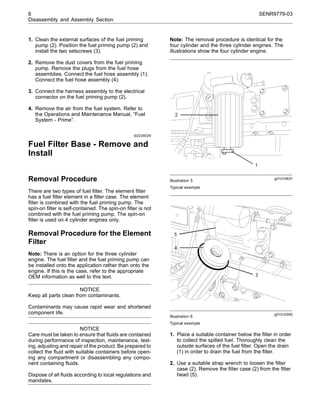

Disassembly and Inspection

Begin by removing the outer casing to access the internal components. Carefully document the position of each part to aid reassembly. Inspect all elements for signs of wear or damage. Pay special attention to gaskets and seals, as these are often the source of leaks. Replace any faulty components to maintain efficiency and reliability. Regular inspections can help prevent major issues down the line.

Once inspection and necessary replacements are complete, reassemble the engine, ensuring that all components are securely fastened. Follow the manufacturer’s torque specifications to avoid issues during operation.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of essential components. Implementing consistent care practices can significantly reduce the likelihood of unexpected failures and costly repairs.

Here are some essential tips to keep your equipment running smoothly:

| Maintenance Activity | Frequency | Benefits |

|---|---|---|

| Oil and Filter Change | Every 250 hours | Prevents engine wear and maintains efficiency |

| Air Filter Inspection | Monthly | Ensures proper airflow and optimal combustion |

| Coolant Level Check | Weekly | Prevents overheating and protects against corrosion |

| Belt and Hose Examination | Every 500 hours | Identifies wear and prevents system failures |

| Fuel System Maintenance | Quarterly | Ensures fuel cleanliness and enhances performance |

Following these guidelines will help maintain optimal functionality and ensure your equipment remains reliable over time. Regular attention to these tasks is key to preventing issues before they arise and maximizing productivity.

Replacing Engine Components Effectively

Maintaining optimal performance in an engine often requires the timely replacement of various parts. This process not only ensures longevity but also enhances the overall efficiency of the machinery. Understanding the nuances involved in this task can lead to better results and a smoother operation.

First, it is essential to identify the components that need attention. Regular inspections can help in detecting wear and tear early, preventing more significant issues down the line. Once the necessary parts are pinpointed, sourcing quality replacements becomes a priority. Utilizing reputable suppliers guarantees that the new components meet or exceed the original specifications.

When it comes to the actual replacement process, meticulousness is key. Preparing the workspace by gathering all required tools and ensuring cleanliness can streamline the procedure. Following manufacturer guidelines for disassembly and reassembly reduces the risk of mistakes. It is advisable to document the steps taken, providing a reference for future maintenance.

After installing new parts, conducting a thorough test is crucial. Monitoring performance helps to ensure that the changes made have positively impacted the operation. Additionally, keeping a detailed log of replacements and repairs can aid in tracking the engine’s health over time, leading to more informed maintenance decisions.

Diagnostic Techniques for Troubleshooting

Effective diagnostic techniques are essential for identifying and resolving issues in engine systems. A systematic approach allows technicians to isolate problems efficiently, ensuring minimal downtime and optimal performance. By employing various strategies and tools, one can pinpoint the root cause of malfunctions and implement appropriate solutions.

Common Diagnostic Methods

Several established methods are used to diagnose issues in engine systems. These techniques include visual inspections, performance testing, and electronic diagnostics. Each method provides valuable insights that contribute to a comprehensive understanding of the problem.

| Method | Description | Advantages |

|---|---|---|

| Visual Inspection | A thorough examination of components for wear, leaks, or damage. | Quick and cost-effective; often reveals obvious issues. |

| Performance Testing | Measuring engine performance against manufacturer specifications. | Helps identify discrepancies in operation and efficiency. |

| Electronic Diagnostics | Utilizing specialized tools to read fault codes from the engine’s computer. | Provides precise information on electronic system failures. |

Interpreting Results

After conducting diagnostic tests, interpreting the results accurately is crucial. Data gathered from various methods should be analyzed collectively to form a complete picture of the system’s health. Understanding the interplay between different components can reveal underlying issues that may not be immediately apparent.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. Proper precautions not only protect the technician but also safeguard the equipment and environment. Following established guidelines can greatly reduce the risk associated with hands-on tasks.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and ear protection to shield against potential hazards. Ensure that all tools are in good condition and suitable for the specific task at hand.

Additionally, it is essential to work in a well-ventilated area. This helps to dissipate harmful fumes and ensures a safe working environment. When dealing with heavy components, use the correct lifting techniques or mechanical aids to avoid strain or injury.

Moreover, always disconnect power sources and release any stored energy before beginning work. This step is critical to prevent unexpected starts or releases that could lead to serious accidents. Familiarize yourself with the layout of the equipment and identify any potential hazards.

Lastly, maintain a clean and organized workspace. This practice minimizes the risk of slips and falls and ensures that tools and materials are readily accessible. Regularly reviewing safety protocols can reinforce a culture of safety and vigilance.

Understanding Engine Specifications

Comprehending the characteristics of an engine is essential for optimizing its performance and longevity. These specifications provide critical insights into the capabilities and operational parameters of the power unit, enabling users to make informed decisions regarding maintenance, upgrades, and overall usage. Familiarity with these details is vital for both professionals and enthusiasts who seek to maximize efficiency and reliability.

Key Specifications to Consider

When examining an engine, several key specifications are paramount. Displacement, which indicates the total volume of all cylinders, plays a significant role in determining power output and fuel efficiency. Additionally, metrics such as horsepower and torque are crucial for understanding an engine’s performance potential. Other factors, like compression ratio and fuel type, also influence how well the engine operates under various conditions.

Importance of Adhering to Specifications

Staying within the outlined specifications is vital for ensuring optimal functionality and avoiding potential damage. Deviations can lead to inefficient operation, increased wear, and even catastrophic failure. Regularly consulting these specifications during maintenance and troubleshooting helps in preserving the engine’s health and extends its service life, ultimately leading to better performance and lower operating costs.

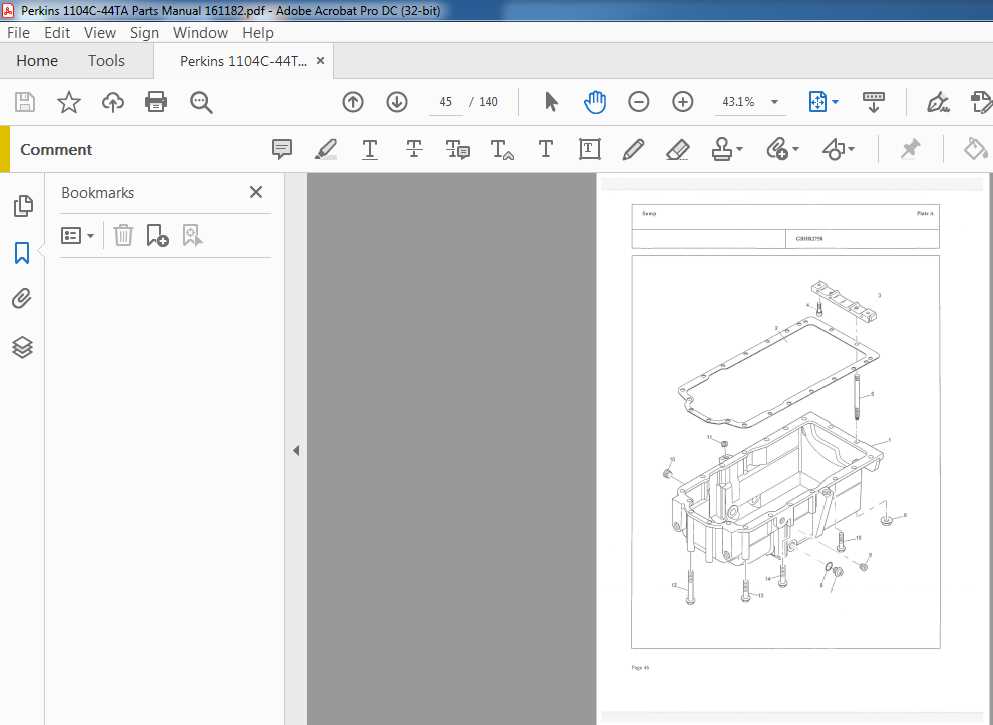

Parts and Components Overview

This section provides a comprehensive understanding of the various elements and assemblies that contribute to the efficient operation of the engine. Each component plays a crucial role in ensuring optimal performance, reliability, and longevity of the machinery.

The main sections include the engine block, which houses critical internal mechanisms, and the cylinder head, responsible for air and fuel intake. Additionally, the fuel injection system is highlighted for its role in delivering the right amount of fuel for combustion, while the cooling system maintains operational temperatures. Various sensors and electrical components are also integral for monitoring performance and enhancing efficiency.

Understanding these parts and their functions is essential for maintenance and troubleshooting, ensuring the engine operates smoothly and effectively over time.

Finding Replacement Parts Easily

Locating suitable components for machinery can be a daunting task, yet it is essential for maintaining optimal performance. Understanding the various avenues available for sourcing these items can streamline the process significantly.

Begin by exploring online marketplaces and specialized websites dedicated to machinery parts. These platforms often offer extensive catalogs and user reviews, enabling you to make informed decisions.

Local suppliers and distributors can also be invaluable resources. Establishing relationships with them might yield access to exclusive deals and prompt delivery options.

Additionally, networking with other professionals in the industry can provide insights into where to find hard-to-locate items, ensuring you have reliable sources at your disposal.

Finally, considering aftermarket alternatives can also expand your choices, often leading to cost savings without compromising quality.

FAQs about Engine Repairs

This section addresses common inquiries related to the maintenance and troubleshooting of diesel power units. Whether you are a seasoned technician or a novice, understanding these aspects can enhance your knowledge and efficiency in handling engine issues.

| Question | Answer |

|---|---|

| What are the signs that my engine needs attention? | Look for unusual noises, decreased performance, excessive smoke, or warning lights on the dashboard. |

| How often should I perform maintenance? | Regular checks every 250 hours of operation are recommended, along with annual inspections regardless of usage. |

| Can I perform repairs myself? | Yes, many repairs can be done by individuals with basic mechanical skills, but complex issues should be handled by professionals. |

| What tools do I need for basic maintenance? | A standard toolkit including wrenches, screwdrivers, pliers, and diagnostic tools will suffice for most tasks. |

| How can I extend the lifespan of my engine? | Regular servicing, using quality lubricants, and ensuring proper cooling can significantly enhance longevity. |