Ensuring the longevity and optimal performance of your beloved angling apparatus is crucial for any enthusiast. Regular upkeep not only enhances functionality but also contributes to an enjoyable experience on the water. This guide aims to provide insightful steps to assist you in caring for your gear effectively.

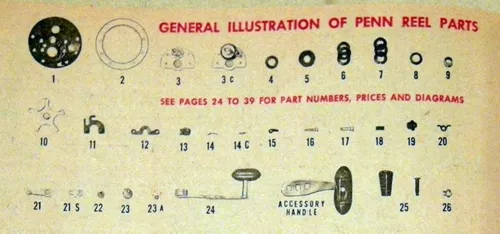

In the following sections, you will discover essential techniques for disassembling, cleaning, and reassembling your equipment. Understanding the intricacies of your apparatus will empower you to address common issues and prevent potential damage. Each component plays a significant role, and recognizing how they interact is key to successful maintenance.

Whether you’re a seasoned angler or just starting, knowing how to manage your equipment can make all the difference. With a bit of patience and attention to detail, you can ensure that your tackle remains in top condition, ready for your next adventure. Dive in to explore the valuable insights that will help you master the art of upkeep.

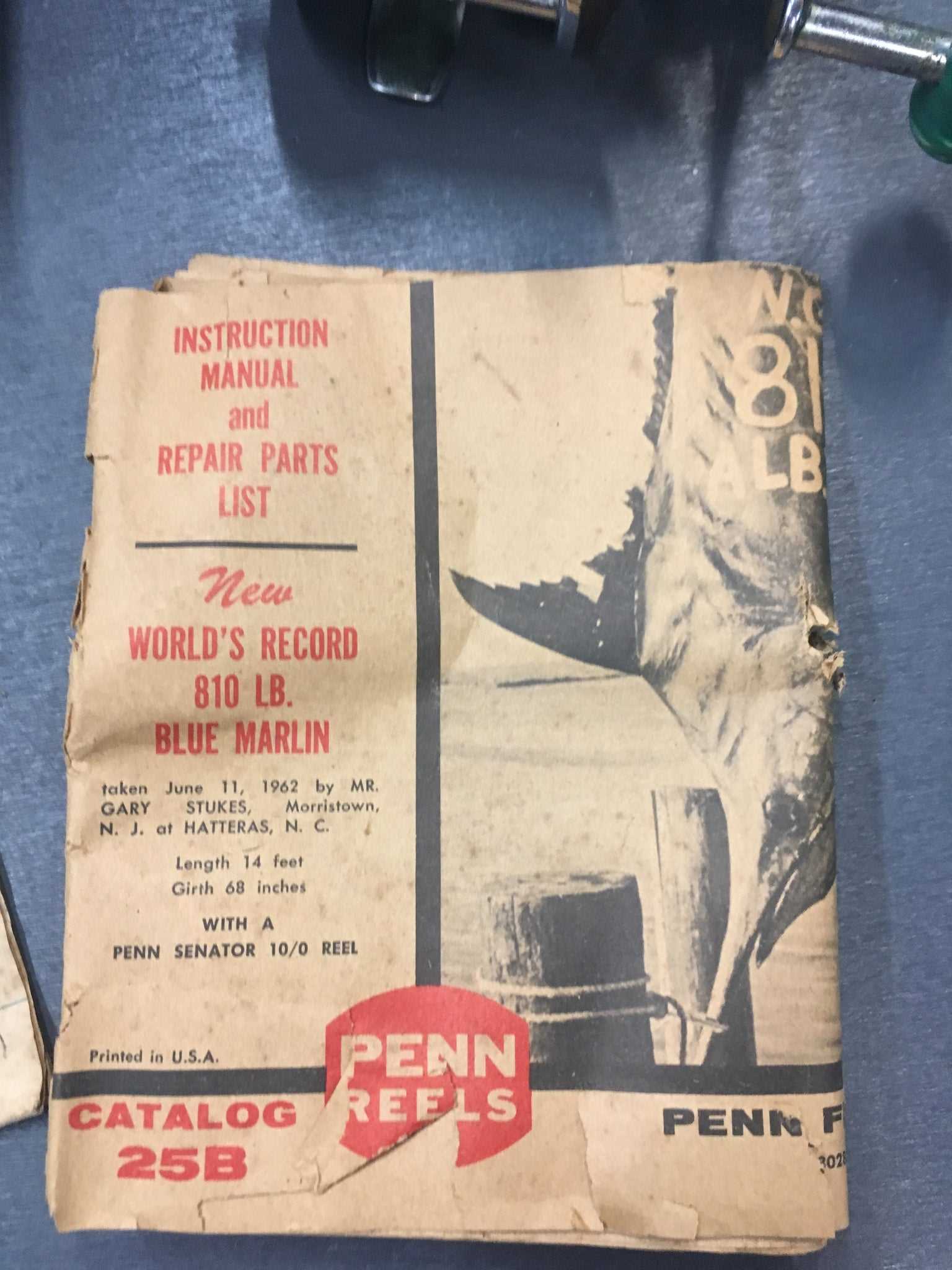

Penn Fishing Reel Repair Manual

This section provides essential guidance for maintaining and restoring your gear, ensuring optimal performance during your outdoor adventures. Understanding the components and their functions is crucial for effective upkeep.

To begin the process, follow these steps:

- Gather necessary tools:

- Screwdrivers (flathead and Phillips)

- Pliers

- Grease and lubricants

- Replacement parts

- Disassemble the unit carefully to avoid damage.

- Inspect each component for wear and tear.

- Clean parts using appropriate solvents.

- Lubricate moving parts to ensure smooth operation.

- Reassemble the unit, ensuring all pieces are correctly aligned.

Regular maintenance can significantly extend the lifespan of your equipment. Consider the following tips:

- Store your gear in a dry place to prevent corrosion.

- Avoid exposing the components to saltwater without rinsing them thoroughly afterward.

- Perform routine checks before and after use.

By following these guidelines, you can keep your equipment in peak condition and ready for any adventure.

Understanding Your Penn Fishing Reel

Every angler knows that a well-functioning tool is essential for a successful outing. Familiarity with the components and mechanics of your equipment can greatly enhance your experience and performance on the water. This section aims to provide insights into the various parts and their roles, ensuring you can make the most of your gear.

| Component | Description |

|---|---|

| Drag System | Regulates the tension on the line, allowing for controlled releases during a catch. |

| Handle | Used for reeling in the line; should be comfortable and ergonomic for extended use. |

| Spool | Holds the line and allows for smooth deployment and retrieval. |

| Gear Ratio | Affects the speed at which line is retrieved; higher ratios provide quicker retrieves. |

| Foot | Connects the unit to the rod, ensuring stability during operation. |

By understanding these elements, you can better appreciate the craftsmanship behind your device and enhance your skills in utilizing it effectively.

Common Issues with Fishing Reels

When engaging in angling, various mechanical challenges may arise that can hinder performance. Understanding these frequent problems is essential for ensuring an enjoyable experience on the water. Many issues can stem from wear and tear, improper maintenance, or environmental factors, impacting the efficiency of the device.

Frequent Problems

Here are some of the most typical complications encountered:

| Issue | Description |

|---|---|

| Line Jams | Snags and twists in the line can lead to frustrating interruptions during use. |

| Noise | Unusual sounds may indicate internal issues or lack of lubrication. |

| Stiffness | A lack of smooth operation often points to dirt accumulation or mechanical faults. |

| Drag Problems | Inconsistent drag settings can result in losing catch or difficulty managing tension. |

Preventive Measures

To mitigate these common issues, regular maintenance and proper usage techniques are crucial. Cleaning and lubricating moving parts can significantly enhance longevity and performance, making each outing more enjoyable.

Tools Needed for Reel Maintenance

To ensure optimal performance of your gear, a variety of instruments and supplies are essential. Proper upkeep not only extends the life of your equipment but also enhances your overall experience. Having the right tools on hand makes the process efficient and straightforward.

Essential Instruments

The following items are crucial for effective maintenance:

| Tool | Purpose |

|---|---|

| Screwdrivers | For loosening and tightening screws on the housing. |

| Wrenches | To adjust various components securely. |

| Grease | To lubricate moving parts, reducing friction. |

| Cleaning Cloth | For wiping down surfaces and removing debris. |

| Pliers | Useful for gripping and twisting components. |

Additional Supplies

In addition to the basic tools, consider having these items for thorough upkeep:

| Supply | Function |

|---|---|

| Oil | For fine lubrication of intricate mechanisms. |

| Brush | To clean small crevices and remove dirt. |

| Replacement Parts | To swap out worn or damaged components. |

| Storage Case | To keep tools organized and protected. |

Step-by-Step Disassembly Process

Understanding how to carefully dismantle your equipment is crucial for effective maintenance and troubleshooting. This process involves systematic removal of components to ensure each part is handled with care, allowing for thorough cleaning or replacement as needed. Following a structured approach not only simplifies the task but also helps prevent damage to delicate elements.

Preparation and Initial Steps

Before starting, gather necessary tools such as screwdrivers, pliers, and a clean workspace. Begin by removing any external covers or casings. Make sure to keep track of all screws and small parts by placing them in labeled containers. This will prevent misplacement and facilitate reassembly later.

Component Separation

Once the outer casing is removed, proceed to detach internal parts in a logical sequence. Start with the largest components and work your way to smaller ones. Take notes or photos during this process to document the arrangement of each element. This documentation will serve as a valuable reference when you are ready to reassemble everything.

Inspecting Internal Components

When maintaining precision mechanisms, a thorough examination of the internal parts is essential for optimal performance. Understanding the functionality and potential wear of these components can help in identifying issues and ensuring longevity. A careful inspection allows for the detection of subtle irregularities that may affect overall efficiency.

Identifying Wear and Damage

Begin by disassembling the unit carefully to access the internal elements. Look for signs of wear such as scratches, cracks, or corrosion on metal surfaces. Gears should mesh smoothly without any resistance, while bushings and bearings must rotate freely. Pay close attention to seals and gaskets for any signs of degradation, as these can lead to performance issues if not addressed.

Cleaning and Maintenance

Once the components are inspected, it’s vital to clean them thoroughly to remove any debris or buildup that could impair function. Use appropriate cleaning agents that won’t harm the materials. After cleaning, lubricate moving parts with suitable oils or greases to ensure smooth operation. Regular maintenance not only enhances functionality but also extends the life of the equipment.

Cleaning Techniques for Fishing Reels

Proper maintenance is essential for ensuring the longevity and performance of your equipment. Regularly removing dirt, salt, and grime not only keeps your gear in top shape but also enhances its functionality. This section outlines effective methods to clean and preserve your tools, ensuring they remain reliable during use.

Essential Supplies

Before you begin the cleaning process, gather the following materials:

| Item | Purpose |

|---|---|

| Soft Cloth | For wiping surfaces and removing debris |

| Brush | To reach tight spaces and dislodge particles |

| Warm Water | For soaking and rinsing components |

| Soap | To clean and break down oils |

| Lubricant | To ensure smooth operation after cleaning |

Step-by-Step Cleaning Process

Follow these steps to effectively clean your gear:

- Remove any line and tackle attached to your gear.

- Rinse the exterior with warm water to eliminate loose dirt.

- Apply a small amount of soap to your cloth and gently scrub all surfaces.

- Use a brush to clean intricate areas, ensuring no residue is left behind.

- Rinse thoroughly with warm water and dry with a clean cloth.

- Finally, apply a light coating of lubricant to moving parts for optimal performance.

Lubrication Guidelines for Optimal Performance

Proper maintenance is essential for enhancing the longevity and efficiency of any mechanical device. Regular application of the right substances can significantly improve functionality, reduce wear, and ensure smooth operation. Understanding how to apply lubricants effectively is crucial for achieving optimal results.

Types of Lubricants

Choosing the appropriate lubricant is vital for effective maintenance. Here are common types:

- Grease: Ideal for areas that require long-lasting protection and resist washout.

- Oil: Suitable for moving parts that need regular reapplication for optimal performance.

- Synthetic Lubricants: Offer superior performance in extreme conditions, providing excellent protection and longevity.

Application Tips

To maximize the benefits of lubrication, follow these guidelines:

- Clean all components thoroughly before applying any lubricant to remove dirt and old residue.

- Apply a small amount of lubricant to moving parts, ensuring not to over-saturate.

- Distribute the lubricant evenly to avoid uneven wear and tear.

- Regularly inspect and reapply lubricants as necessary, especially after extensive use.

By adhering to these guidelines, you can ensure that your equipment operates at peak performance, prolonging its life and enhancing your overall experience.

Reassembling Your Fishing Reel

Putting together your gear after maintenance can seem daunting, but with a systematic approach, it becomes a straightforward task. Understanding the components and their arrangement will help ensure everything functions smoothly. Follow the steps outlined below for a successful reassembly.

Essential Components

- Housing

- Handle

- Spool

- Drag System

- Gears

- Bearings

Step-by-Step Process

- Start by placing the main body on a clean, flat surface to prevent losing any parts.

- Insert the bearings into their designated slots, ensuring they are seated properly.

- Carefully align the gears, making sure they mesh smoothly without any resistance.

- Attach the drag system components in the correct order, referring to your notes or diagrams from the disassembly.

- Secure the spool in place and double-check that it spins freely.

- Finally, attach the handle, ensuring it is firmly in position.

After completing the assembly, perform a quick test to confirm that all functions operate correctly. Regular maintenance and proper reassembly will extend the life of your equipment and enhance your overall experience.

Troubleshooting Specific Problems

When it comes to addressing issues with your gear, understanding the common complications can significantly enhance your experience. Identifying specific symptoms can lead to efficient solutions, ensuring optimal performance and longevity of your equipment.

1. Unusual Noises: If you notice any strange sounds during operation, it often indicates a lack of lubrication or misalignment. Check the internal components for debris and apply appropriate grease to moving parts.

2. Drag Malfunction: If the drag system feels too tight or too loose, inspect the drag washers. Worn or damaged washers can affect functionality. Replacing these components may restore proper tension.

3. Difficulty in Casting: If casting becomes problematic, examine the line guide and spool for tangles or knots. Clearing these obstructions can improve casting distance and accuracy.

4. Handle Resistance: A stiff handle can be a sign of dirt accumulation or internal corrosion. Cleaning the handle assembly and applying a suitable lubricant can resolve this issue.

5. Wobbling or Vibration: If you experience wobbling during use, check for loose screws or misaligned parts. Tightening and realigning components can enhance stability and performance.

By systematically addressing these specific problems, users can ensure their equipment remains in peak condition, ready for any adventure.

When to Seek Professional Help

Understanding when to call in an expert can save you time, effort, and potential frustration. While some issues can be addressed independently, others may require specialized knowledge and tools. Recognizing the signs that indicate the need for professional assistance is crucial for maintaining the longevity of your equipment.

Signs You Should Consider Professional Assistance

- Persistent Malfunctions: If your device continues to malfunction despite your efforts to troubleshoot, it may be time to consult a professional.

- Unfamiliar Sounds: Unusual noises during operation can indicate deeper issues that require expert diagnosis.

- Complex Repairs: Tasks that involve intricate components or require specific tools are best left to trained technicians.

- Time Constraints: If you’re short on time and need a quick solution, seeking help can expedite the process.

Benefits of Consulting a Specialist

- Expert Knowledge: Professionals have the experience and training to handle various problems efficiently.

- Proper Tools: Access to specialized tools ensures that repairs are done correctly and safely.

- Warranty Considerations: Using a qualified technician can help preserve any existing warranties on your gear.

- Peace of Mind: Knowing your equipment is in capable hands can relieve stress and enhance your overall experience.

Preventive Care for Longevity

Maintaining your gear is essential for ensuring its durability and performance over time. Regular attention and proactive measures can significantly extend the lifespan of your equipment, allowing you to enjoy its benefits for years to come. This section explores various strategies to help you keep your apparatus in optimal condition, minimizing the likelihood of issues down the line.

Regular Cleaning

One of the simplest yet most effective ways to enhance longevity is through consistent cleaning. After each use, it’s crucial to remove any dirt, salt, or debris that may have accumulated. Using a soft cloth and freshwater can help preserve the integrity of the components, preventing corrosion and buildup that could hinder performance. Remember to pay attention to the smaller parts, as they often require detailed care.

Routine Lubrication

Lubrication plays a vital role in ensuring smooth operation and reducing friction among moving parts. Applying the appropriate lubricant at regular intervals can prevent wear and tear, enhancing the overall efficiency of your device. Be mindful to use products designed specifically for this purpose, as improper substances can cause damage rather than provide protection.

Upgrading Parts for Better Performance

Enhancing the components of your equipment can significantly elevate its overall functionality and longevity. By substituting standard parts with high-performance alternatives, you can achieve smoother operation, increased durability, and a more enjoyable experience. This approach not only maximizes efficiency but also allows for a personalized setup tailored to your specific needs.

Choosing Quality Materials

When considering upgrades, the quality of materials plays a crucial role. Opting for components made from premium materials such as carbon fiber or stainless steel can lead to improved strength and reduced wear. These materials often exhibit superior resistance to corrosion and fatigue, ensuring that your gear performs optimally under various conditions.

Upgrading Gear Ratios

Another effective way to enhance performance is by adjusting the gear ratios. Upgrading to a higher gear ratio can provide quicker retrieval speeds, making it easier to manage heavy loads. Conversely, a lower gear ratio can offer greater torque for tackling tougher challenges. Understanding your requirements will help in selecting the right configuration that suits your style.