In the realm of outdoor machinery, understanding the intricacies of small power units is essential for optimal performance. Proper maintenance ensures longevity and efficiency, allowing users to enjoy seamless operation throughout the seasons. This guide focuses on the essential techniques and practices required to keep these vital engines functioning at their best.

From troubleshooting common issues to executing necessary adjustments, having access to comprehensive instructions is invaluable. This resource aims to provide clear insights into various aspects of upkeep, empowering users with the knowledge to address challenges effectively. Whether you are a seasoned technician or a novice enthusiast, familiarizing yourself with these principles can lead to significant improvements in functionality.

By investing time in learning about engine upkeep, individuals can not only save on costly repairs but also enhance their overall experience with machinery. Understanding the mechanics behind these power units cultivates confidence and skill, ultimately fostering a more sustainable approach to equipment ownership. Explore the essential topics outlined in this guide to become well-versed in the art of engine maintenance.

Comprehensive Guide to Briggs and Stratton

This section provides an in-depth exploration of essential knowledge related to small engine maintenance and troubleshooting. Understanding the intricacies of these power units can significantly enhance their longevity and performance.

Key aspects to consider include:

- Maintenance: Regular checks and servicing can prevent potential issues.

- Tuning: Proper adjustments can optimize engine performance.

- Common Issues: Identifying frequent problems aids in quicker resolution.

Furthermore, becoming familiar with available resources can empower users to tackle various challenges effectively. Comprehensive guides, detailed instructions, and troubleshooting tips can transform the maintenance experience into a manageable task.

Engaging with community forums and expert advice is beneficial for enhancing skills and knowledge. Networking with other enthusiasts fosters an environment of learning and support.

Understanding Single Cylinder Engines

This section explores the fundamentals of engines characterized by their singular combustion chamber. These power units are widely utilized in various applications due to their simplicity and efficiency. Understanding their design and functionality is essential for effective maintenance and troubleshooting.

Key Features of These Engines

Engines with a solitary combustion chamber exhibit several notable characteristics:

- Compact design ideal for small machinery

- Lightweight, promoting ease of use and transport

- Cost-effective, making them accessible for various users

- Relatively straightforward operation and maintenance

Common Applications

These engines find their use in a multitude of settings:

- Lawn care equipment, such as mowers and trimmers

- Portable generators for electricity supply

- Small vehicles like go-karts and ATVs

- Power tools, including chainsaws and blowers

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments at hand is crucial for achieving optimal outcomes. A well-equipped toolkit not only streamlines the process but also enhances safety and efficiency. Familiarity with essential devices can significantly improve one’s ability to troubleshoot and address various mechanical challenges.

Wrenches are fundamental for loosening and tightening nuts and bolts, while screwdrivers come in handy for assembling and disassembling components. Additionally, pliers can provide the necessary grip for handling small parts. It is also beneficial to have a socket set for reaching tight spaces and a multimeter to check electrical connections and diagnose issues.

Furthermore, a workbench offers a stable surface for performing tasks, and a toolbox helps keep all instruments organized. Safety gear, such as gloves and safety glasses, should not be overlooked to protect oneself during any mechanical undertaking. Investing in quality tools can lead to more efficient maintenance experiences and prolonged equipment life.

Common Issues and Solutions

This section addresses frequent challenges encountered with small engine models and provides practical solutions to enhance performance and longevity. Understanding these common problems can significantly simplify maintenance and troubleshooting processes.

Difficulty Starting: One prevalent issue is the engine’s reluctance to start. This may be due to a drained fuel supply or a clogged air filter. Ensure proper fuel levels and replace any obstructed filters to improve ignition.

Unusual Noises: Odd sounds during operation often indicate mechanical issues. Inspecting components for wear and tear or loose fittings can help identify the source. Tighten any loose parts and consider replacing worn components to restore smooth functionality.

Overheating: Engines may overheat due to inadequate lubrication or debris blocking the cooling fins. Regularly checking oil levels and cleaning the cooling system can prevent overheating. Keep the engine well-oiled and clear from obstructions to maintain optimal temperature.

Reduced Power Output: If performance decreases, it could stem from a dirty spark plug or fuel system issues. Cleaning or replacing the spark plug and ensuring a steady fuel flow can enhance efficiency. Regular maintenance of these parts can significantly improve engine performance.

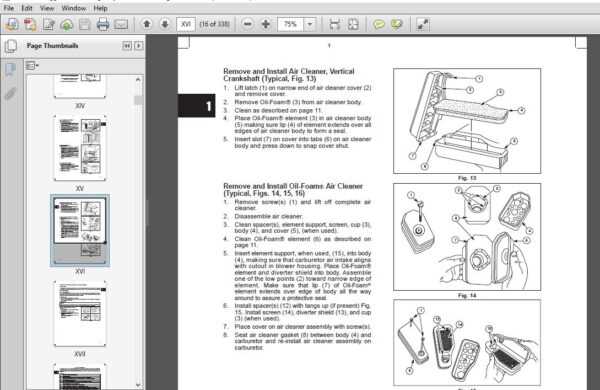

Step-by-Step Maintenance Procedures

Regular upkeep of small engines is essential to ensure optimal performance and longevity. Following a structured approach to maintenance helps identify potential issues before they escalate. This section outlines a series of essential tasks that can be performed systematically to maintain engine efficiency and reliability.

Essential Maintenance Tasks

- Check the oil level and condition

- Inspect the air filter for cleanliness

- Examine fuel lines for wear or leaks

- Replace the spark plug as needed

- Clean or replace the fuel filter

Detailed Procedure

- Begin by ensuring the engine is off and cool.

- Remove the oil dipstick and check the level, adding oil if necessary.

- Take out the air filter, clean it with compressed air, and reinstall.

- Inspect the fuel lines for cracks or damage; replace if necessary.

- Remove the spark plug using a wrench, check for carbon buildup, and replace it if necessary.

- Change the fuel filter to ensure clean fuel flow to the engine.

By adhering to these straightforward maintenance procedures, users can significantly enhance the reliability and performance of their engines, prolonging their operational life and ensuring smooth functionality.

Identifying Engine Components

Understanding the various elements of an engine is essential for effective maintenance and troubleshooting. Each part plays a crucial role in the overall performance and efficiency of the machinery. Recognizing these components helps in diagnosing issues and implementing appropriate solutions.

Main Components

The following are key components typically found in engines:

- Crankshaft: Converts linear motion into rotational energy.

- Piston: Moves up and down within the cylinder, creating compression.

- Connecting Rod: Links the piston to the crankshaft.

- Valves: Regulate the intake of air and fuel and the exhaust of combustion gases.

- Flywheel: Stabilizes engine speed and smoothens operation.

Additional Elements

Besides the main components, several other parts contribute to engine functionality:

- Ignition System: Initiates the combustion process.

- Fuel System: Delivers the necessary fuel for operation.

- Cooling System: Maintains optimal temperature to prevent overheating.

- Lubrication System: Reduces friction between moving parts.

- Air Filter: Cleans incoming air before it enters the combustion chamber.

Repair Techniques for Performance Boost

Enhancing the efficiency and output of small engine machines can significantly impact their overall functionality. Various methods can be employed to elevate performance, ensuring the engine operates at its peak capabilities. This section outlines several effective strategies that can be utilized for improvement.

Consider implementing the following techniques to optimize performance:

- Regular Maintenance: Consistent checks and upkeep of essential components can prevent potential issues.

- Airflow Improvement: Upgrading the air intake system can enhance combustion efficiency.

- Fuel Quality: Using high-quality fuel can improve engine response and longevity.

- Ignition System Tuning: Adjusting ignition settings can lead to better fuel combustion and power output.

- Exhaust System Optimization: Upgrading the exhaust can reduce back pressure, allowing the engine to breathe more freely.

By applying these methods, users can ensure that their equipment functions effectively, delivering the desired performance levels. Each technique contributes uniquely to enhancing overall efficiency.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for preventing accidents and injuries. Proper precautions should be taken to create a secure working environment. This involves understanding the equipment and following guidelines to mitigate risks.

Always wear appropriate protective gear, including gloves and safety goggles, to shield against potential hazards. Before beginning any work, ensure that the machinery is turned off and disconnected from its power source. This prevents unintentional activation during the process.

It is essential to maintain a tidy workspace, keeping tools organized and removing any obstacles that may cause tripping. Familiarize yourself with the specific components of the equipment you are handling to avoid mistakes. Additionally, ensure good ventilation in the area to prevent the accumulation of harmful fumes or gases.

In case of any uncertainty about the procedures, consult relevant guidelines or seek professional advice. Understanding the risks associated with each task will help in making informed decisions, ultimately contributing to a safer repair experience.

Replacing Engine Parts Effectively

Ensuring optimal performance in machinery often involves replacing worn or damaged components. This process not only enhances functionality but also prolongs the lifespan of the entire system. Understanding the steps and considerations for effective replacement is crucial for achieving satisfactory results.

Identifying Worn Components

Before initiating the replacement, it is essential to accurately identify which parts need attention. Look for signs of wear such as unusual noises, vibrations, or performance issues. Regular inspections can aid in early detection, preventing further damage and costly repairs down the line.

Proper Installation Techniques

Once the defective parts are identified, proper installation techniques must be followed. Ensure that all replacement components are compatible with your system to avoid misalignment or functional failures. Utilize the correct tools and adhere to manufacturer guidelines during installation for optimal results. Taking the time to perform this task accurately can significantly impact the overall efficiency of the engine.

Tuning for Optimal Performance

Achieving peak efficiency in engine operation requires careful adjustment of various components. By focusing on specific areas, one can enhance performance, improve fuel efficiency, and extend the lifespan of the machinery. This section outlines essential tuning techniques that contribute to optimal functionality.

Adjusting the Carburetor

Fine-tuning the fuel delivery system is crucial for maintaining the right air-fuel mixture. Ensuring the carburetor is properly calibrated allows for smooth operation and responsive throttle performance. Regular inspection for wear and blockages can prevent performance issues.

Ignition System Optimization

Maintaining an effective ignition system is vital for reliable starts and overall engine health. Replacing spark plugs and ensuring proper timing can lead to significant improvements in efficiency and power output. Regular maintenance of this system is essential to avoid unnecessary setbacks.

Regular Maintenance Schedules

Consistent upkeep is crucial for ensuring the longevity and efficient performance of outdoor power equipment. Establishing a routine maintenance plan helps to identify potential issues early and keeps the machinery in optimal condition. By adhering to suggested timelines for various tasks, users can enhance reliability and reduce the likelihood of unexpected breakdowns.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours of operation or annually |

| Air Filter Inspection | Every 25 hours of operation |

| Spark Plug Replacement | Every 100 hours of operation or annually |

| Fuel System Cleaning | Every season or as needed |

| Blade Sharpening | Every 25 hours of operation or as needed |

Following these outlined intervals will ensure smooth operation and extend the lifespan of the equipment. Regular attention to these tasks is a small investment compared to the potential costs associated with major repairs due to neglect.

Understanding Engine Specifications

When delving into the intricacies of motor mechanics, it is essential to grasp the various technical details that define a power unit’s performance and functionality. These specifications serve as the foundation for understanding how to maintain and optimize the engine’s operation effectively. Knowledge of these parameters not only enhances performance but also aids in diagnosing potential issues.

Key Parameters

Among the critical attributes to consider are displacement, horsepower, torque, and fuel type. Displacement indicates the engine’s size and capacity, influencing both power output and efficiency. Horsepower reflects the engine’s ability to perform work, while torque represents the rotational force available for driving tasks. Additionally, selecting the appropriate fuel type can significantly impact overall performance and longevity.

Importance of Specifications

Understanding these specifications is vital for ensuring that any modifications or repairs align with the manufacturer’s guidelines. Adhering to the specified parameters helps to maintain optimal efficiency and prolong the lifespan of the engine. Regularly reviewing and adhering to these details fosters a deeper appreciation of engine functionality and performance.

Expert Tips for Troubleshooting

When faced with engine issues, effective diagnostics are crucial for identifying problems and implementing solutions. This section provides valuable insights to help you navigate common challenges, ensuring smooth operation and longevity of your equipment. By employing systematic approaches, you can pinpoint malfunctions and enhance overall performance.

Begin by conducting a thorough inspection of the components. Check for loose connections, signs of wear, or any visible damage. Ensure that fuel lines are intact and free of obstructions. Regularly examining these elements can prevent minor issues from escalating into significant failures.

Next, assess the starting mechanism. If the engine fails to start, evaluate the battery charge and ignition system. A weak battery or faulty spark plug can lead to operational failures. Replacing these parts can often restore functionality without extensive repairs.

Pay attention to unusual noises or vibrations during operation. These can indicate underlying issues such as misalignment or component fatigue. Addressing these signs early can prevent further damage and ensure safe usage.

Finally, maintain a detailed log of any symptoms and repairs conducted. This documentation can assist in recognizing patterns over time and streamline future troubleshooting efforts. Keeping track of maintenance activities will contribute to better decision-making and enhance the reliability of your equipment.