Maintaining marine engines is crucial for ensuring optimal performance and longevity. This section provides essential insights into the various aspects of engine upkeep, aimed at enhancing reliability on the water.

Understanding the intricacies of mechanical systems can significantly reduce operational issues. By following systematic procedures, users can troubleshoot common problems effectively, ensuring smooth functionality during outings.

Equipping oneself with the right knowledge empowers boat enthusiasts to tackle maintenance tasks with confidence. Comprehensive guidance not only streamlines the process but also fosters a deeper connection with the equipment, promoting a more enjoyable experience on the water.

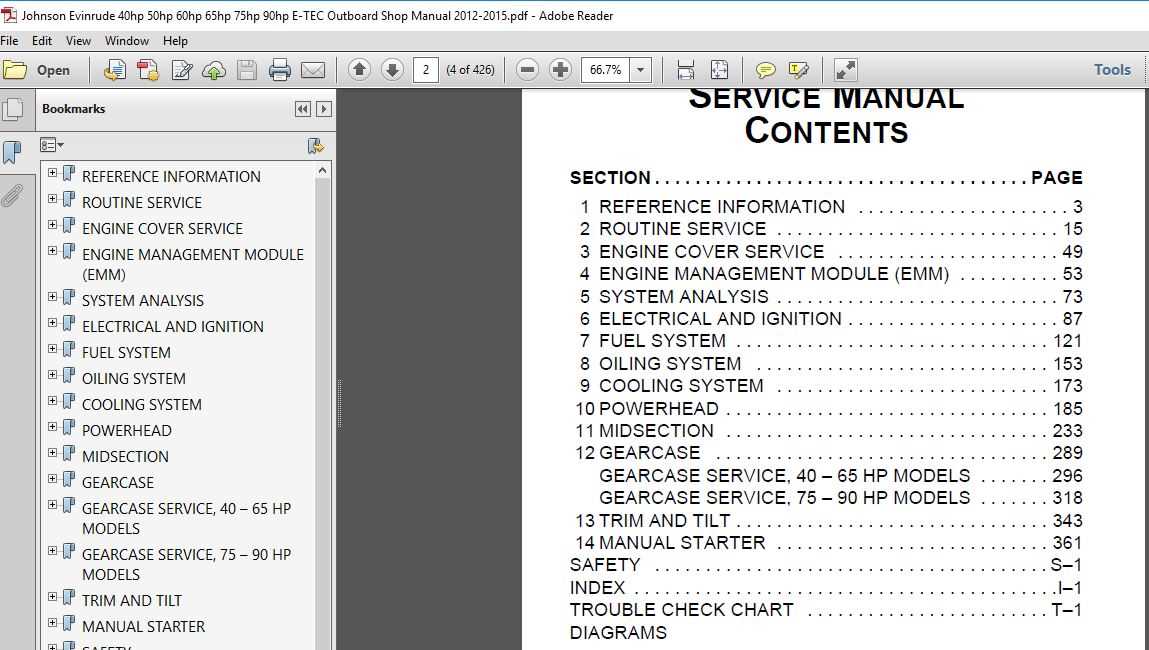

Gaining a comprehensive understanding of your marine propulsion unit is essential for optimal performance and longevity. This section aims to provide insights into the various components and functionalities that make these engines efficient and reliable. Knowing how each part works together will help you maintain and troubleshoot effectively.

| Component | Description |

|---|---|

| Powerhead | The heart of the engine, responsible for generating power through combustion. |

| Gearcase | Houses the transmission and propeller shaft, transferring power to the propeller. |

| Fuel System | Ensures the proper delivery of fuel and air to the combustion chamber. |

| Cooling System | Prevents overheating by circulating water through the engine. |

| Electrical System | Includes the battery, ignition, and wiring that power the engine’s components. |

Familiarity with these essential parts will enhance your ability to diagnose issues and ensure the smooth operation of your vessel. Regular maintenance and attention to these components will contribute to a more enjoyable experience on the water.

Common Issues with Omc Outboards

Many marine engines can encounter a variety of challenges that affect performance and reliability. Understanding these common problems can help users identify and address issues before they escalate.

Frequent Problems

- Fuel system blockages leading to inadequate flow.

- Electrical failures caused by corroded connections.

- Overheating due to coolant circulation issues.

- Unusual noises indicating potential mechanical failure.

Prevention and Maintenance

Regular upkeep is essential to prolong the lifespan of your marine engine. Consider the following:

- Inspect fuel lines for leaks and clogs.

- Check electrical components for corrosion and wear.

- Monitor temperature gauges to prevent overheating.

- Perform routine inspections and service as recommended.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to effectively addressing common issues encountered with marine engines. By following a systematic approach, you can ensure optimal performance and longevity of your equipment.

Assessing the Problem

Begin by identifying the symptoms exhibited by the engine. Gather information regarding the context in which the issues arise. Observing patterns can be invaluable in diagnosing the root cause.

Executing the Solution

Once the problem is clear, proceed with the necessary actions to resolve it. Ensure you have the appropriate tools and components on hand. Follow each step carefully to avoid complications, and regularly check your progress.

Always prioritize safety while working. Utilizing protective gear and maintaining a clean workspace will enhance both efficiency and security during the process.

By adhering to these guidelines, you can tackle maintenance tasks with confidence, enhancing your marine experience.

Preventive Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of your marine engine. By implementing proactive measures, you can ensure optimal performance and minimize the risk of unexpected failures. Here are some effective strategies to maintain your vessel’s engine in top condition.

Routine Inspections

Conducting frequent checks is vital. Look for signs of wear and tear, such as leaks or corrosion, and address them immediately. Regular inspections help identify potential issues before they escalate, ensuring smooth operations.

Proper Storage Practices

When not in use, store your engine in a dry, protected environment. This prevents damage from environmental factors. Additionally, consider using protective covers to shield against dust and moisture. Maintaining a clean storage area further enhances longevity.

Diagnosing Electrical Problems

Identifying issues within a vessel’s electrical system is crucial for maintaining optimal performance. Various symptoms may indicate underlying faults, and understanding these can help streamline troubleshooting efforts.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Dead battery or faulty connections | Check battery voltage and inspect terminals for corrosion. |

| Flickering lights | Loose wiring or bad ground | Examine wiring connections and ensure proper grounding. |

| Blown fuses | Overload or short circuit | Replace the fuse and investigate for potential short circuits. |

| Instruments not working | Faulty gauge or wiring | Test gauges individually and trace wiring for breaks. |

Fuel System Troubleshooting Techniques

Effectively diagnosing issues within the fuel system is crucial for maintaining optimal engine performance. This section outlines various approaches and techniques to identify and resolve common problems that may arise.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Fuel Starvation | Engine stalling, difficulty starting | Check fuel lines for clogs; inspect the fuel filter; ensure fuel pump operation. |

| Leaking Fuel | Strong fuel odor, visible leaks | Examine fuel lines and connections; replace damaged components; tighten fittings. |

| Contaminated Fuel | Engine misfiring, poor acceleration | Inspect fuel quality; drain contaminated fuel; replace with fresh, clean fuel. |

| Faulty Fuel Pump | Low pressure, inconsistent engine performance | Test pump functionality; check electrical connections; replace if necessary. |

Following these techniques can help ensure a well-functioning fuel system, ultimately enhancing overall engine reliability and efficiency.

Replacing Worn Parts Effectively

Maintaining optimal performance in marine engines often requires the timely replacement of components that have become fatigued or damaged. Addressing these issues promptly ensures the longevity of the machinery and enhances overall efficiency.

First, it is crucial to identify parts that exhibit signs of wear. Frequent inspections can reveal deterioration, allowing for early intervention. Look for discoloration, cracks, or unusual noises that may indicate a malfunction. Once identified, the next step is to source high-quality replacements that match the original specifications.

When installing new components, ensure that you follow proper procedures to avoid further complications. This includes cleaning the area thoroughly, applying appropriate lubricants, and securing parts according to the manufacturer’s guidelines. Taking these steps will facilitate a smooth integration and maintain the integrity of the overall system.

Regular maintenance checks following part replacement will help catch any potential issues early, ensuring the machinery continues to operate at peak performance. By adopting a proactive approach, you can significantly reduce the risk of breakdowns and extend the lifespan of your equipment.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking any maintenance tasks. Proper measures help prevent accidents and injuries, allowing for a smoother process. Familiarizing oneself with the necessary precautions can significantly enhance safety and efficiency.

Personal Protective Equipment

Always wear appropriate personal protective gear, such as gloves, goggles, and masks. This equipment protects against harmful substances and potential hazards encountered during maintenance tasks. Additionally, ensure that your work area is well-lit and organized to minimize the risk of accidents.

Workspace Considerations

Maintain a clutter-free workspace to avoid tripping or falling. Keep tools and materials within reach and store hazardous substances in secure containers. Proper ventilation is essential when working with chemicals or fuels, as this reduces the risk of inhalation and exposure to harmful fumes.

Finding Replacement Parts Easily

Locating suitable components for marine engines can be straightforward when you know where to look. Understanding the right sources and methods can streamline the process, ensuring that you find the necessary items without hassle.

One effective approach is to utilize online marketplaces that specialize in marine equipment. These platforms often have extensive catalogs, making it easier to search by model or part number. Additionally, forums and community groups dedicated to boating enthusiasts can provide valuable insights and recommendations on reliable suppliers.

Another beneficial tactic is to consult local marine shops. Establishing a relationship with these retailers can lead to personalized assistance and access to hard-to-find components. They can also help you identify alternatives that may serve the same purpose.

Researching part compatibility is crucial to ensure you purchase the correct items. Utilize manuals or technical specifications to verify that replacements match your engine’s requirements. Furthermore, always consider checking for reviews or feedback on specific parts to gauge their quality and reliability.

By leveraging these resources and strategies, you can simplify the process of finding the right components, ultimately enhancing the performance and longevity of your marine equipment.

Resources for Further Learning

Expanding your knowledge in the field of marine engine maintenance can significantly enhance your skills and confidence. Numerous resources are available to help you deepen your understanding and tackle various challenges effectively.

Online Courses: Numerous platforms offer specialized courses focusing on engine upkeep and troubleshooting techniques. These courses often include video tutorials and interactive content to facilitate learning.

Books and Guides: Consider exploring comprehensive literature that covers theoretical and practical aspects of engine functionality. Well-reviewed books often provide step-by-step instructions and valuable insights.

Forums and Communities: Engaging with online communities can be a great way to exchange experiences and seek advice from fellow enthusiasts. These platforms often host discussions that cover a wide range of topics, from basic maintenance to complex repairs.

Manufacturer Resources: Many manufacturers provide detailed documentation, including specifications and troubleshooting tips. Accessing these resources can offer valuable insights into specific models and their maintenance requirements.

Utilizing these resources will empower you to enhance your skills and tackle various challenges with confidence.