The maintenance and troubleshooting of specialized equipment are crucial for ensuring optimal performance and longevity. This section aims to provide a comprehensive guide that equips users with the knowledge necessary to navigate potential issues that may arise during operation. By familiarizing oneself with the intricacies of these devices, users can enhance their efficiency and reliability.

Proper handling and periodic upkeep are essential in mitigating common problems that could lead to significant downtime. Each unit, with its unique features and functionalities, requires a tailored approach to diagnostics and solutions. Whether you are a seasoned technician or a newcomer to the field, understanding the fundamentals will empower you to tackle challenges with confidence.

This guide emphasizes the importance of recognizing the signs of malfunction, performing routine checks, and implementing corrective measures. By utilizing the right techniques and adhering to recommended practices, you can ensure that your equipment operates smoothly and effectively, minimizing disruptions and maximizing productivity.

Overview of Robinair 34134Z

This section provides a comprehensive understanding of a widely used piece of equipment in the automotive service industry. It highlights its features, functionality, and significance in maintaining vehicle cooling systems. The device is engineered to streamline the recovery, recycling, and recharging processes, ensuring efficiency and effectiveness in service operations.

Key Features

The unit boasts an array of advanced features designed to enhance performance and user experience. It typically includes an intuitive interface for easy operation, robust diagnostics for troubleshooting, and compatibility with various refrigerants. Its durable construction ensures longevity, making it a reliable choice for professionals.

Importance in Automotive Service

Common Issues with the Unit

This section addresses frequent problems encountered with this particular refrigerant recovery device. Understanding these common issues can help users troubleshoot effectively and maintain optimal performance.

Typical Problems

- Poor suction capability

- Inaccurate pressure readings

- Inconsistent refrigerant flow

- Unusual noises during operation

- Electrical malfunctions

Troubleshooting Tips

- Check hoses and connections for leaks or blockages.

- Inspect the pressure gauges for proper calibration.

- Ensure the unit is adequately charged with refrigerant.

- Listen for abnormal sounds and assess potential mechanical failures.

- Examine electrical components for signs of wear or damage.

By recognizing these issues and applying the suggested solutions, users can enhance the longevity and reliability of the equipment.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance tasks. A well-equipped toolkit not only streamlines the process but also enhances efficiency and safety. Understanding the essential instruments can make all the difference in achieving optimal results.

Basic hand tools such as wrenches, screwdrivers, and pliers form the foundation of any toolkit. These items are indispensable for disassembling and assembling various components. Power tools, including drills and impact drivers, significantly reduce manual effort and save time when working on larger projects.

In addition to hand and power tools, specialized instruments such as gauges and testers are essential for diagnostics. These tools help in identifying issues quickly, allowing for informed decision-making and precise actions. Safety gear, including gloves and goggles, should never be overlooked, ensuring protection during any task.

Finally, having organizational solutions like toolboxes and trays can aid in keeping everything accessible and orderly, further enhancing productivity. Investing in quality tools is a step towards achieving reliable and lasting outcomes in any maintenance endeavor.

Step-by-Step Repair Instructions

This section provides a detailed guide to addressing common issues in your device. By following these comprehensive steps, you can troubleshoot effectively and restore functionality without professional assistance.

Begin by gathering the necessary tools and materials, ensuring you have a clean workspace. Familiarize yourself with the components involved, as understanding their layout is crucial for efficient handling.

Start with the initial inspection. Look for visible signs of wear or damage, such as frayed wires or loose connections. Document any findings to keep track of potential issues.

Next, disassemble the unit carefully, noting the order of parts removed. This will aid in reassembly later. Take your time with this step to avoid damaging any components.

Once disassembled, clean all accessible areas using appropriate cleaning agents. This can help prevent future malfunctions caused by dust and debris.

Address specific issues as identified in your initial inspection. Replace any faulty components and secure all connections tightly to ensure proper operation.

Reassemble the unit in the reverse order of disassembly. Double-check that all parts are properly aligned and secured, as this will affect overall performance.

Finally, conduct a thorough test to confirm that the device is functioning correctly. Monitor it closely for any signs of recurring problems, and don’t hesitate to revisit any step if necessary.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention. By following essential maintenance practices, you can significantly extend the lifespan of your tools while enhancing their efficiency. Here are some vital tips to consider for effective care.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check for Leaks | Monthly | Inspect connections and hoses for any signs of leakage to prevent fluid loss and ensure proper function. |

| Clean Filters | Every 3 Months | Regularly clean or replace filters to maintain airflow and efficiency, reducing strain on the system. |

| Inspect Cables | Monthly | Examine power and service cables for wear or damage to avoid electrical issues and ensure safe operation. |

| Lubricate Moving Parts | Quarterly | Apply appropriate lubricants to moving components to minimize friction and wear. |

| Calibration Check | Annually | Verify accuracy by checking calibration settings to ensure reliable performance over time. |

By implementing these practices, you can help ensure that your equipment remains in peak condition, thereby reducing the likelihood of unexpected failures and costly repairs.

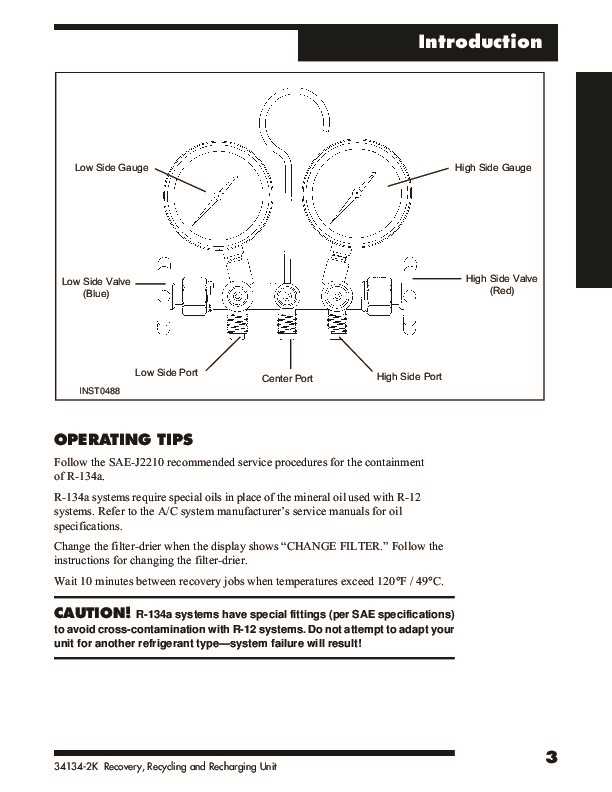

Understanding the Parts Diagram

The parts diagram serves as a vital tool for comprehending the assembly and function of various components within a system. By visualizing the relationship between different parts, users can better understand how each piece contributes to the overall operation. This understanding is crucial for effective troubleshooting, maintenance, and repair procedures.

Key Components of the Diagram

Each section of the diagram typically identifies specific elements and their respective functions. Labels and numbering systems are commonly employed to correlate parts with their descriptions, making it easier to locate and reference them. Familiarizing oneself with these components allows for more efficient problem-solving when issues arise.

Interpreting the Information

To effectively utilize the diagram, one must be able to interpret the various symbols and notations presented. Understanding these representations enables users to grasp how different parts interact with one another. Moreover, this knowledge can aid in identifying potential wear or damage, ensuring timely interventions and prolonging the lifespan of the equipment.

Troubleshooting Electrical Problems

Electrical issues can often disrupt the functionality of various devices, leading to frustration and downtime. Identifying the source of these problems is essential for effective resolution. This section provides guidance on systematically diagnosing common electrical faults.

1. Check Power Supply

Before delving into more complex diagnostics, ensure that the power source is operational. Verify that the device is plugged in securely and that any switches are turned on. Additionally, inspect the outlet with another device to confirm it is providing power.

2. Inspect Cables and Connectors

Cables and connectors are often the culprits behind electrical malfunctions. Look for visible signs of wear, damage, or corrosion. A frayed wire or loose connection can disrupt the flow of electricity, causing the device to fail.

3. Test Fuses and Circuit Breakers

Fuses and circuit breakers serve as protective components for electrical systems. If a device is unresponsive, check these elements to determine if they have tripped or blown. Replacing a fuse or resetting a breaker may restore functionality.

4. Use a Multimeter

For a more thorough investigation, utilize a multimeter to measure voltage, current, and resistance. This tool can help pinpoint issues within the circuitry, allowing for targeted repairs. Familiarize yourself with how to interpret the readings to aid in the troubleshooting process.

5. Consult Documentation

If problems persist, reviewing the device’s documentation can provide valuable insights. Technical specifications often include troubleshooting steps and common issues that can guide your efforts. This resource can enhance your understanding and facilitate effective problem-solving.

By following these steps, you can systematically address electrical issues, ensuring a more reliable operation of your equipment.

Replacing Key Components Safely

Ensuring the proper exchange of essential parts in any equipment is crucial for maintaining optimal functionality and safety. This process requires a thorough understanding of the components involved and adherence to best practices to avoid accidents and ensure longevity. Implementing the right techniques not only protects the equipment but also safeguards the technician performing the work.

Preparation and Safety Precautions

Before initiating the replacement of components, it is vital to prepare adequately. Begin by disconnecting the power source to eliminate any risk of electrical shock. Utilize appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from potential hazards. Additionally, reviewing the equipment specifications and guidelines will provide insights into the specific parts that require attention and the tools necessary for the task.

Step-by-Step Component Replacement

When replacing components, follow a systematic approach to ensure each step is executed correctly. Document the process to maintain a clear reference for reassembly. Carefully remove the old part, taking care not to damage surrounding components. When installing the new piece, align it properly and secure it firmly to prevent future issues. Finally, conduct a thorough inspection to confirm that everything is correctly positioned before reconnecting the power supply.

Calibrating the Equipment Properly

Ensuring that your tools are accurately calibrated is essential for achieving optimal performance and reliable results. Proper calibration helps maintain consistency in measurements and can significantly enhance the effectiveness of the equipment in various applications.

Step-by-step calibration involves several key procedures. First, it is important to establish a baseline by using reference standards that are known for their precision. This will allow you to compare the readings from your device and determine any discrepancies.

Next, adjustments should be made according to the manufacturer’s specifications. These guidelines often provide specific instructions on how to fine-tune the settings for maximum accuracy. Regular checks and recalibrations are recommended to ensure continued reliability over time.

Lastly, maintaining a calibration log can be beneficial. Documenting each calibration session, including dates and results, helps track the performance history and ensures that necessary adjustments are made promptly. This practice not only aids in compliance with industry standards but also enhances the longevity of the equipment.

Testing Performance After Repairs

Once maintenance tasks have been completed on a unit, it’s essential to evaluate its functionality to ensure everything operates smoothly. This process not only verifies that the issues have been addressed but also confirms that the device meets the necessary performance standards. A systematic approach to testing can help identify any lingering problems that may require further attention.

Initial Checks

Begin by performing basic functionality tests. These include assessing the overall operation of the equipment, checking for any unusual noises, and monitoring for leaks or irregularities during use. It’s crucial to observe the unit under various conditions to mimic real-world usage scenarios. Documenting these observations will provide valuable insights into the success of the maintenance performed.

Performance Metrics

After conducting initial checks, focus on specific performance metrics relevant to the equipment’s intended use. This may involve measuring efficiency, output levels, and responsiveness. Compare these figures to the manufacturer’s specifications or industry standards to gauge the effectiveness of the service carried out. If discrepancies arise, further investigation may be necessary to pinpoint underlying issues.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting of specific equipment. It provides essential insights to assist users in understanding various aspects and resolving issues effectively.

What should I do if my device is not powering on?

First, check the power source and ensure the unit is plugged in properly. If the connection is secure, try a different outlet or check for any blown fuses.

How can I identify leaks in the system?

Look for visible signs of fluid or use a specialized detection tool. Listening for hissing sounds can also indicate a leak. Regular inspections are recommended to maintain performance.

What maintenance is necessary to prolong the lifespan of my equipment?

Routine cleaning and servicing are crucial. Ensure filters are replaced regularly, and all components are checked for wear. Following the manufacturer’s recommendations can significantly enhance durability.

How can I troubleshoot unusual noises coming from the unit?

Unusual sounds may indicate loose parts or internal issues. Inspect the unit for any visible damage and consult the troubleshooting guide for specific noises.

Is it necessary to use specific types of fluids for operation?

Yes, always refer to the specifications for the correct fluid types. Using incorrect substances can lead to performance issues or damage the system.

When should I seek professional assistance?

If you encounter persistent problems or if the troubleshooting steps do not resolve the issue, it is advisable to consult a qualified technician for further evaluation.