Ensuring the longevity and performance of your commercial vehicle requires a thorough understanding of its components and systems. This section offers valuable insights into the upkeep and troubleshooting of a specific model designed for transport tasks. Whether you’re a seasoned mechanic or a diligent owner, having access to detailed information is crucial for optimal functionality.

In-depth knowledge about the intricacies of your vehicle can significantly reduce downtime and enhance productivity. From routine checks to more complex issues, being equipped with the right guidance allows you to address concerns effectively and efficiently. This guide emphasizes practical solutions and step-by-step approaches tailored to the needs of your model.

As you navigate through this resource, you’ll discover essential techniques for maintenance and care, ensuring that your vehicle remains reliable and performs at its best under various conditions. With the right tools and information at your disposal, you’ll be empowered to tackle any challenge that arises, keeping your fleet running smoothly for years to come.

Mitsubishi Canter Overview

This section provides a comprehensive look at a popular light commercial vehicle, known for its versatility and efficiency in various applications. Ideal for businesses requiring reliable transport solutions, this vehicle stands out due to its robust construction and adaptability to different environments.

The following characteristics highlight its appeal:

- Durability: Built to withstand challenging conditions, ensuring long-term reliability.

- Efficiency: Engineered for optimal fuel consumption, making it cost-effective for daily operations.

- Load Capacity: Designed to handle substantial loads, accommodating diverse transport needs.

- Versatility: Available in multiple configurations, suitable for various industries.

Additionally, the vehicle boasts a range of modern features aimed at enhancing the driving experience:

- Advanced safety systems to protect both the driver and cargo.

- Comfortable interiors designed for long hours on the road.

- User-friendly controls for ease of operation.

This light-duty truck continues to be a favored choice among operators seeking a reliable and efficient solution for their transportation requirements.

Common Issues with Mitsubishi Canter

This section addresses frequent challenges encountered with a popular light commercial vehicle. Understanding these typical problems can assist owners in maintaining optimal performance and ensuring longevity. Knowledge of common faults can lead to timely interventions and repairs, ultimately reducing downtime and costs.

Electrical Problems

One of the most prevalent issues relates to the vehicle’s electrical system. Owners often report failures in the battery, starter, or alternator, leading to starting difficulties and electrical malfunctions. Regular inspections of the electrical components can help mitigate these problems.

| Component | Common Issues | Solutions |

|---|---|---|

| Battery | Corrosion, low charge | Regular cleaning, replacement as needed |

| Starter | Failure to engage | Check connections, replace if faulty |

| Alternator | Charging issues | Inspect belts and connections, replace as necessary |

Engine Performance Issues

Another area of concern involves the engine, where symptoms such as reduced power, unusual noises, or overheating may arise. Regular maintenance, including oil changes and filter replacements, plays a critical role in preventing these complications.

| Issue | Symptoms | Preventive Measures |

|---|---|---|

| Oil leaks | Oil spots, low oil levels | Routine checks and timely replacements |

| Overheating | High temperature gauge | Check coolant levels, inspect radiator |

| Poor acceleration | Delayed response | Regular tune-ups, clean air filters |

Essential Tools for Repairs

Having the right equipment is crucial for performing effective maintenance and fixes on vehicles. Proper tools not only enhance efficiency but also ensure that tasks are completed safely and accurately. This section will highlight some of the most important items that should be included in any maintenance toolkit.

Basic Hand Tools

Every technician should have a solid collection of hand tools. This includes wrenches, screwdrivers, and pliers. These items are fundamental for loosening, tightening, and manipulating various components. A set of socket wrenches can be particularly useful for accessing hard-to-reach areas.

Diagnostic Equipment

In addition to traditional tools, modern troubleshooting often requires specialized diagnostic equipment. A reliable OBD-II scanner is essential for reading error codes and diagnosing issues effectively. Furthermore, a multimeter can assist in assessing electrical systems, making it indispensable for comprehensive vehicle maintenance.

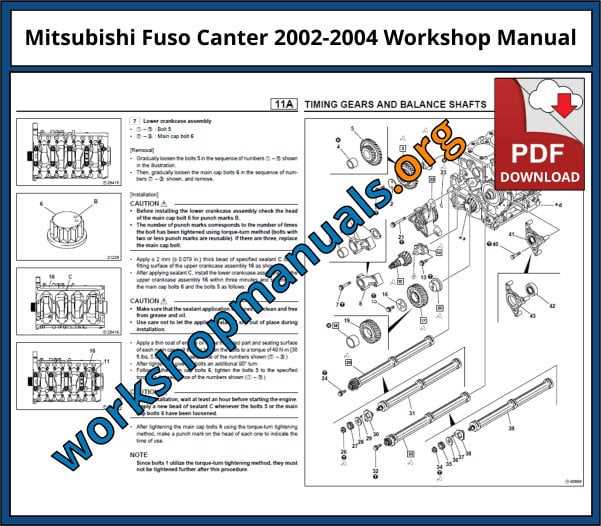

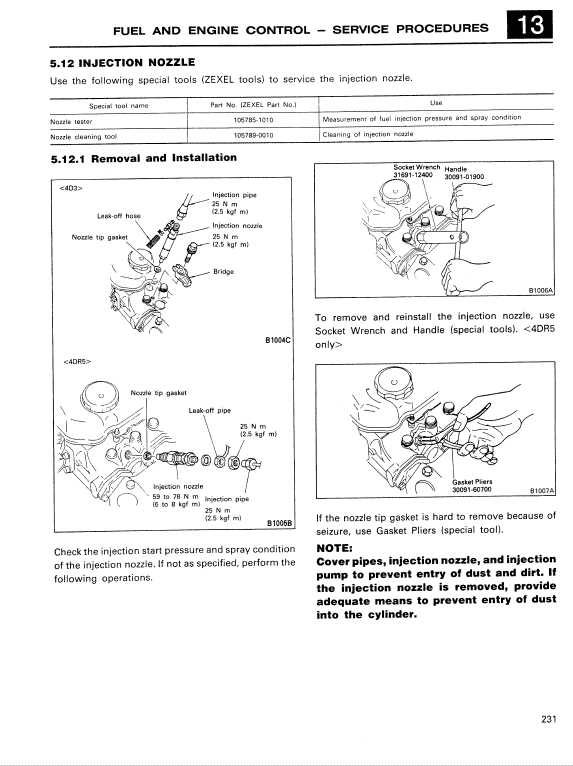

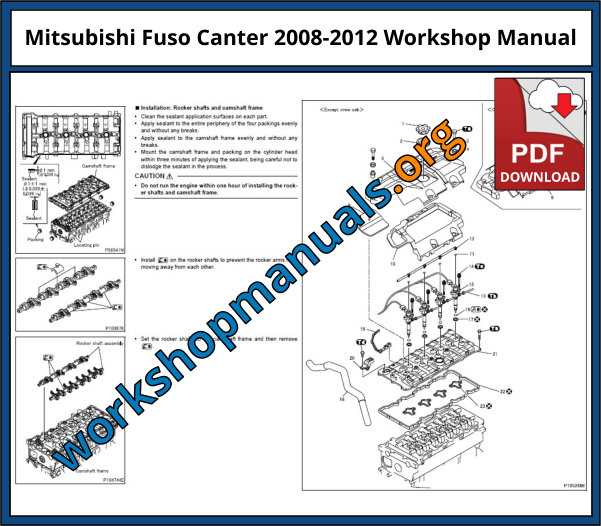

Step-by-Step Maintenance Procedures

Regular upkeep of your vehicle is essential to ensure its longevity and optimal performance. This section outlines systematic procedures to maintain key components, helping you to avoid costly repairs and enhance safety on the road. By following these steps, you can keep your vehicle in peak condition, contributing to a smoother driving experience.

Begin with the engine oil. Check the oil level regularly and replace it according to the manufacturer’s recommendations. Ensure you use the correct type of oil for optimal lubrication. Next, inspect the air filter; a clean filter improves airflow and engine efficiency. Replace it if it appears dirty or clogged.

Brake system maintenance is crucial for safety. Regularly check the brake pads for wear and ensure the fluid level is adequate. If you notice any unusual noises or decreased responsiveness, have the system examined immediately. Tire care is also vital; maintain proper inflation and tread depth to ensure traction and fuel efficiency. Rotate tires as recommended to promote even wear.

Don’t overlook the battery. Clean the terminals and check for corrosion. Test the battery’s charge regularly and replace it if it shows signs of weakness. Finally, inspect the cooling system. Check the coolant level and condition, and look for any leaks in hoses or connections. Maintaining this system prevents overheating and engine damage.

Engine Troubleshooting Techniques

Diagnosing issues within an engine can be a complex task, yet employing systematic approaches can greatly simplify the process. Identifying the root cause of malfunctions requires a combination of observation, analytical thinking, and methodical testing. By following established techniques, one can efficiently pinpoint problems and facilitate effective solutions.

1. Visual Inspection: Begin with a thorough visual assessment of the engine components. Look for signs of wear, leaks, or loose connections. Pay attention to hoses, belts, and wiring, as these are often the first indicators of potential issues.

2. Listening for Anomalies: Start the engine and listen carefully for any unusual sounds. Knocking, ticking, or hissing noises can reveal underlying problems, such as internal wear or exhaust leaks. Documenting these sounds can aid in further diagnostics.

3. Checking Fluid Levels: Regularly monitor engine fluids, including oil, coolant, and transmission fluid. Low levels can lead to overheating or inadequate lubrication, resulting in significant damage. Always ensure that fluids are at optimal levels before proceeding with further tests.

4. Utilizing Diagnostic Tools: Invest in electronic diagnostic equipment to retrieve error codes from the engine control unit. These codes provide valuable insights into which systems may be malfunctioning, allowing for a more focused investigation.

5. Performing Compression Tests: Conduct compression tests to evaluate the health of the engine’s cylinders. Low compression can indicate issues such as worn piston rings or valve problems, guiding you toward necessary repairs.

6. Analyzing Exhaust Emissions: Examine the exhaust gases to identify potential fuel mixture problems. Excessive smoke or unusual colors can signify improper combustion or other engine troubles that require attention.

By following these troubleshooting techniques, one can enhance the likelihood of accurately diagnosing engine issues, leading to timely and effective resolutions.

Electrical System Diagnostics

Effective troubleshooting of the electrical framework is crucial for ensuring optimal performance and longevity of vehicles. This process involves systematically evaluating various components to identify and resolve issues that may impede functionality.

Key Components to Inspect

- Batteries: Check for charge levels, corrosion, and connections.

- Alternators: Ensure proper voltage output and belt tension.

- Fuses: Inspect for any blown fuses that could disrupt circuits.

- Wiring: Look for frayed wires, shorts, and secure connections.

- Switches: Test functionality and resistance levels.

Diagnostic Steps

- Begin with a visual inspection of all electrical components.

- Utilize a multimeter to measure voltage and continuity.

- Conduct load tests on batteries and alternators.

- Examine ground connections for integrity.

- Consult the vehicle’s schematics for circuit paths and potential problem areas.

By following these guidelines, one can systematically diagnose and address electrical issues, enhancing reliability and performance.

Transmission Repair Insights

Understanding the intricacies of gearbox maintenance is crucial for ensuring optimal performance and longevity of any vehicle. This segment delves into the common issues that arise within transmission systems, offering valuable knowledge for enthusiasts and professionals alike.

One prevalent challenge is the degradation of fluid quality over time, which can lead to overheating and inadequate lubrication. Regularly checking and replacing transmission fluid can significantly enhance the functionality and prevent costly failures.

Additionally, identifying symptoms such as slipping gears or unusual noises early on can aid in mitigating further damage. Conducting routine inspections and being attentive to the vehicle’s behavior allows for timely interventions and repairs.

In some cases, electronic components play a critical role in transmission operation. Issues with sensors or control modules can disrupt shifting patterns and performance. Utilizing diagnostic tools to pinpoint electrical faults can save time and resources.

Lastly, it’s essential to follow manufacturer guidelines regarding maintenance schedules and part replacements. Staying informed about recommended practices ensures that the system operates smoothly, enhancing overall driving experience.

Brake System Maintenance Tips

Ensuring the optimal performance of the braking mechanism is essential for safety and longevity. Regular upkeep can prevent costly repairs and enhance the overall driving experience.

Here are some key maintenance practices to keep in mind:

- Regular Inspections: Check the brake pads and discs frequently for wear and tear. Look for any signs of damage or excessive wear.

- Fluid Checks: Monitor the brake fluid level and quality. Replace it according to the manufacturer’s recommendations to maintain efficiency.

- Listen for Unusual Sounds: Pay attention to any grinding or squeaking noises when braking. These sounds may indicate worn components that need attention.

- Keep Components Clean: Regularly clean the brake calipers and other parts to prevent dirt buildup that can affect performance.

- Inspect Brake Lines: Examine the brake lines for leaks, cracks, or corrosion. Address any issues immediately to avoid brake failure.

By adhering to these guidelines, drivers can ensure their stopping system remains reliable and effective, contributing to a safer driving environment.

Bodywork and Exterior Fixes

Maintaining the exterior and body components of a vehicle is crucial for both aesthetics and functionality. This section focuses on essential repairs and improvements that can enhance the overall appearance and durability of the vehicle’s outer structure. Whether addressing minor dents, rust spots, or paint imperfections, a well-executed approach can significantly extend the lifespan of the vehicle.

Assessing Damage

Before beginning any restoration efforts, it is important to thoroughly assess the extent of the damage. Look for signs of corrosion, scratches, or misalignments in body panels. Identifying these issues early on can prevent further deterioration and save time and resources in the long run.

Repair Techniques

There are various methods to address bodywork issues. For small dents, paintless dent repair is a popular option that retains the original finish while restoring the panel’s shape. For rust damage, it’s essential to remove any affected areas and apply protective coatings to prevent future corrosion.

Painting and Finishing

Once repairs are completed, reapplying paint is often necessary to achieve a seamless look. It is recommended to use high-quality paint matched to the vehicle’s original color. Applying a clear coat can further protect the finish from environmental factors and enhance its shine.

Final Touches

After completing the exterior repairs, inspect the vehicle for any remaining imperfections. Regular maintenance, including washing and waxing, can help preserve the newly restored exterior, ensuring it remains in excellent condition for years to come.

Finding Replacement Parts Easily

Locating suitable components for your vehicle can be a straightforward process if you know where to look. Understanding the various sources available and the options for acquiring necessary items will ensure you can maintain your vehicle effectively without excessive downtime.

Online Resources

The internet offers a wealth of platforms dedicated to automotive parts. Websites specializing in aftermarket components, as well as manufacturer-authorized suppliers, provide extensive catalogs. Utilizing search engines with specific queries can yield numerous results, making it easier to compare prices and availability. Additionally, forums and online communities can offer insights and recommendations from fellow vehicle owners.

Local Dealers and Junkyards

Visiting local dealerships and salvage yards is another effective way to find the parts you need. Authorized dealers often have the latest components available, while junkyards can be treasure troves for hard-to-find items at reduced prices. Building relationships with local suppliers can also lead to better service and potential discounts on future purchases.