When it comes to enjoying the thrills of outdoor adventures, ensuring that your off-road machine operates at its best is crucial. A well-maintained vehicle not only enhances performance but also extends its lifespan, allowing you to tackle rough terrains with confidence. This section aims to provide essential insights into the upkeep and troubleshooting of your all-terrain companion.

Understanding the intricacies of your vehicle’s components is vital. Whether it’s the engine, suspension, or transmission, knowing how each part functions and how to address common issues can save you time and money. This guide will walk you through the necessary steps to diagnose problems and perform routine maintenance, ensuring a smooth ride every time.

Moreover, having a reliable reference for repairs empowers you to take control of your machine’s health. From simple adjustments to more complex fixes, mastering the art of vehicle maintenance will enhance your overall experience. Dive in to discover practical tips and detailed instructions that will keep your all-terrain vehicle in peak condition.

Understanding the Hammerhead Twister 250

This section delves into the essential features and functionalities of a popular off-road vehicle designed for thrill-seekers. Combining agility with robust construction, it offers an exhilarating experience for users of all ages. Its design reflects a perfect balance between performance and safety, making it a favored choice among enthusiasts.

Key Features

Equipped with a powerful engine, this vehicle is tailored for both speed and durability. The advanced suspension system ensures a smooth ride over rugged terrains, while the spacious seating provides comfort during extended adventures. Safety features, including a sturdy frame and reliable braking system, contribute to a worry-free driving experience.

Performance Insights

Performance is at the heart of this off-road machine. It is designed to tackle challenging landscapes, from steep hills to muddy trails. With responsive handling and impressive acceleration, it captivates riders looking for excitement. The blend of power and control makes it suitable for both casual outings and competitive rides.

Common Issues with the Hammerhead Twister

When operating a recreational vehicle designed for off-road adventures, users may encounter a variety of challenges. Understanding these common problems can enhance the overall experience and ensure the longevity of the machine.

Electrical Failures: One of the most frequently reported concerns involves the electrical system. This can manifest as difficulty starting the engine or intermittent power loss during operation. Regularly checking connections and fuses can help mitigate these issues.

Fuel System Problems: Another prevalent issue relates to fuel delivery. Clogs in the fuel lines or a malfunctioning carburetor can lead to poor performance or stalling. Maintaining clean fuel filters and ensuring proper fuel quality are essential for optimal function.

Suspension Troubles: Riders often report challenges with the suspension system. This can include excessive bouncing or uneven handling, often due to worn-out components. Regular inspections and timely replacements can greatly improve ride quality.

Tire Wear: Uneven tire wear can significantly impact traction and stability. It’s important to regularly inspect tire pressure and alignment to prevent premature wear and ensure safety on various terrains.

Addressing these common issues promptly can lead to a more enjoyable and trouble-free riding experience. Regular maintenance and attention to detail are key in preventing minor problems from escalating into major repairs.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for achieving effective results. A well-equipped workspace not only simplifies the process but also ensures safety and precision. Whether you’re addressing minor adjustments or significant overhauls, the proper tools can make all the difference in efficiency and outcome.

Basic Toolkit

A foundational set of tools is vital for any undertaking. Essential items such as screwdrivers, wrenches, and pliers are necessary for various tasks. Each tool serves a specific purpose, enabling you to disassemble, adjust, or tighten components with ease. Additionally, ratchet sets and socket wrenches provide versatility for different sizes of fasteners.

Specialized Equipment

For more complex issues, certain specialized instruments come into play. Torque wrenches are invaluable for ensuring that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening. Multimeters and diagnostic tools can help in troubleshooting electrical components, making them essential for any detailed examination. Having these specialized items on hand can significantly enhance your ability to address more intricate problems effectively.

Step-by-Step Repair Process

This section outlines a systematic approach to restoring the functionality of your off-road vehicle. By following these detailed instructions, you will be able to diagnose issues, replace parts, and ensure your machine operates efficiently. Each step is crucial to maintaining performance and prolonging the lifespan of the equipment.

Diagnosis and Preparation

The first phase involves a thorough assessment of the vehicle’s condition. Begin by inspecting all components for visible damage or wear. Check the fluid levels and look for any leaks. Document your findings to create a clear action plan. Gather the necessary tools and replacement parts before proceeding to the next steps.

Execution of Repairs

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a vehicle can be crucial for ensuring optimal performance and safety. This section aims to guide users through common problems, their symptoms, and effective solutions. Understanding the basic components and their functions will aid in identifying faults quickly.

Below is a table summarizing potential electrical issues, their signs, and recommended actions:

| Issue | Symptoms | Recommended Action |

|---|---|---|

| Battery Failure | Engine won’t start, dim lights | Test battery voltage; replace if low |

| Faulty Wiring | Intermittent power loss, fuses blowing | Inspect wires for damage; repair or replace |

| Defective Alternator | Warning light on, battery not charging | Test alternator output; replace if faulty |

| Starter Problems | Clicking noise, engine not turning over | Check connections; replace starter if necessary |

| Electrical Shorts | Burning smell, blown fuses | Locate short circuit; repair damaged components |

By following these guidelines, users can effectively address and resolve electrical issues, ensuring reliable operation of their vehicle.

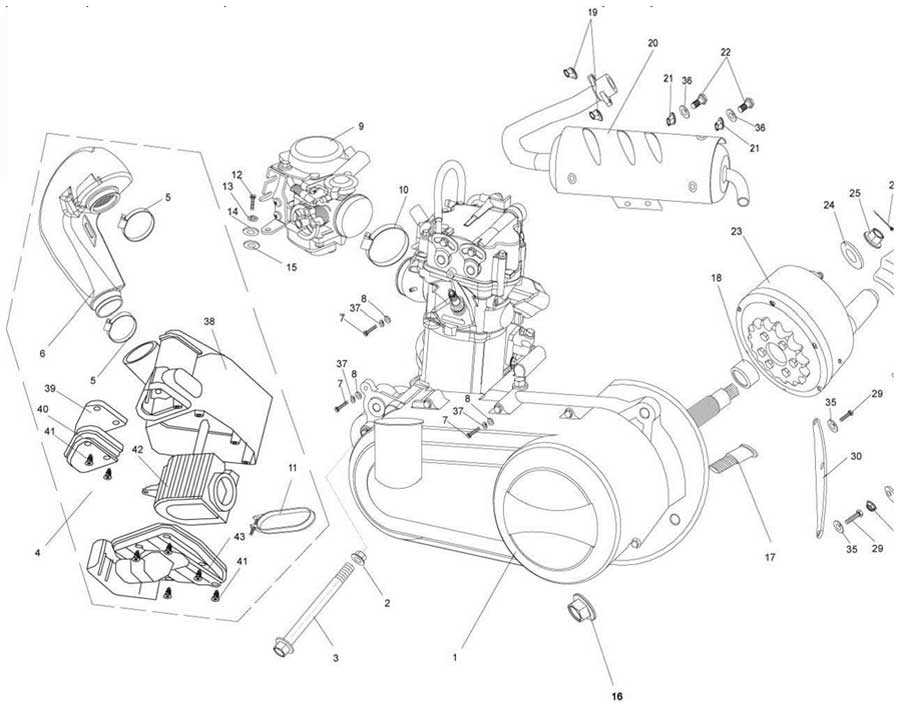

Engine Maintenance and Repair Tips

Proper upkeep of your vehicle’s powertrain is essential for optimal performance and longevity. Regular checks and timely interventions can prevent minor issues from escalating into major problems, ensuring smooth operation and enhancing overall efficiency. This section provides valuable insights into maintaining and troubleshooting the engine, allowing for a better understanding of its components and functions.

Start with routine inspections of fluid levels, including oil, coolant, and fuel. Regularly changing the oil and replacing the oil filter are critical steps to keep the engine running smoothly. Ensure that the air filter is clean, as a clogged filter can restrict airflow and decrease efficiency. Keep an eye on belts and hoses for signs of wear and tear, replacing them as necessary to avoid unexpected breakdowns.

Pay attention to any unusual noises or vibrations while the engine is running. These can be early indicators of underlying issues. Additionally, monitor the performance of the vehicle during operation. If you notice a drop in power or changes in responsiveness, it may be time to conduct a deeper examination.

For more complex repairs, consulting with a qualified technician is advisable. They can provide expert diagnostics and ensure that any necessary repairs are performed correctly. Always refer to the manufacturer’s specifications for parts and procedures to maintain integrity and compatibility.

Finally, keeping a maintenance log can help track service history and upcoming needs. This practice promotes accountability and aids in forecasting future maintenance tasks, contributing to the overall health of your engine.

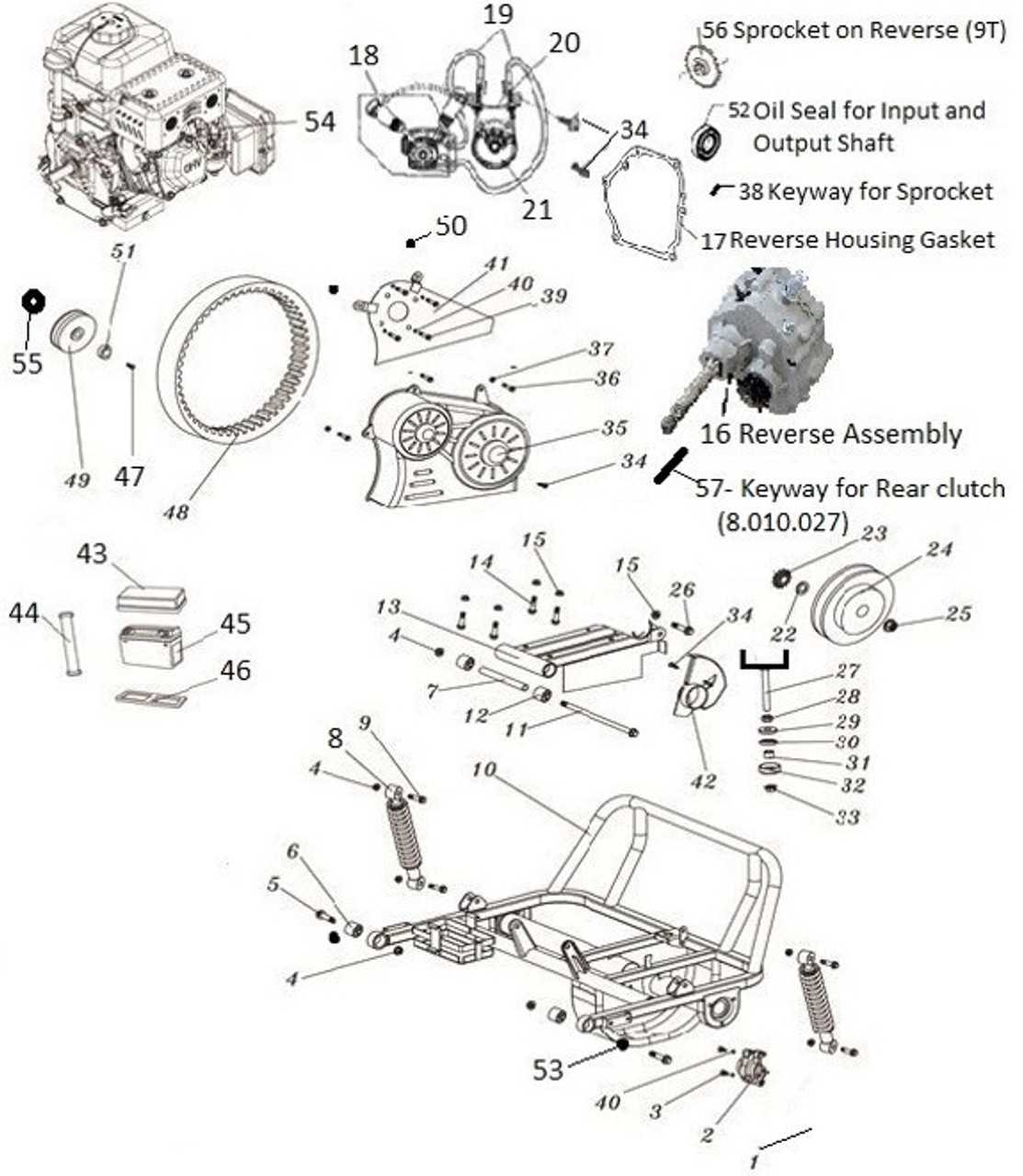

Transmission and Drive System Fixes

This section addresses the common issues associated with the transmission and drive components, focusing on identification, troubleshooting, and solutions to enhance performance and reliability. Proper maintenance of these systems is essential to ensure smooth operation and prevent further complications.

Common Issues

- Difficulty in shifting gears

- Unusual noises during operation

- Slipping of the drive belt

- Excessive vibrations while driving

Troubleshooting Steps

- Inspect the transmission fluid level and condition. Low or dirty fluid can lead to shifting problems.

- Check for any visible damage or wear in the belts and gears. Look for fraying or cracking.

- Listen for any abnormal sounds during operation. This may indicate issues with the internal components.

- Test the engagement of the gears. Ensure they shift smoothly without hesitation.

Regular inspections and prompt attention to any identified issues will significantly improve the longevity and functionality of the drive system.

Brake System Inspection and Repair

The braking mechanism is crucial for safe operation and performance. Regular examination and maintenance ensure that the system functions effectively, providing reliable stopping power when needed. This section outlines the steps to evaluate and address common issues related to the braking system.

Begin the inspection process by performing a visual check of the brake components:

- Examine brake pads for wear; replace them if they are worn down to the minimum thickness.

- Inspect the brake rotors for signs of damage, such as warping or scoring.

- Check brake lines for leaks or cracks that could compromise fluid integrity.

- Ensure that the brake fluid is at the appropriate level and has not absorbed excessive moisture.

If any abnormalities are detected during the inspection, follow these steps to rectify the issues:

- Replace worn brake pads to maintain optimal stopping performance.

- Resurface or replace damaged rotors to prevent uneven wear.

- Repair or replace any damaged brake lines to avoid fluid leaks.

- Flush and refill the brake fluid system to ensure it remains effective and free of contaminants.

After completing the necessary repairs, it is essential to test the braking system. Conduct a series of slow-speed tests to ensure responsiveness and check for any unusual noises or behaviors. Regular maintenance not only enhances safety but also prolongs the life of the braking system.

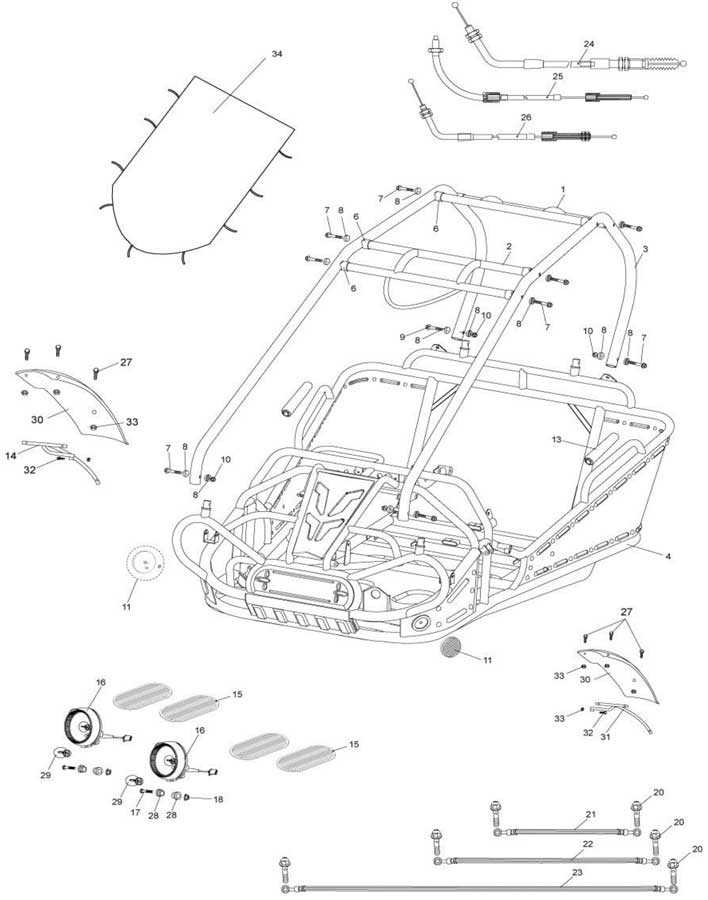

Suspension and Steering Adjustments

Proper alignment and tuning of the suspension and steering systems are crucial for optimal performance and safety. Adjustments in these areas can enhance handling, comfort, and overall stability, ensuring a smoother ride and better maneuverability. This section focuses on the key aspects of fine-tuning these components to achieve the desired ride quality and responsiveness.

Suspension Tuning

To optimize the suspension, start by checking the preload settings of the springs. Adjusting the preload can significantly impact ride height and stiffness, allowing for a more customized setup based on the terrain and load. Regularly inspecting the shock absorbers for any signs of wear or leaks is essential, as well-maintained shocks contribute to effective damping and overall vehicle control.

Steering System Calibration

Accurate steering adjustments are vital for precise handling. Begin by assessing the toe-in and toe-out settings, as these will affect how the vehicle responds during turns. Additionally, ensure that the steering wheel is centered when the wheels are aligned. Regularly check for any play in the steering components, as excessive movement can lead to poor handling and safety issues.

Bodywork Repairs and Modifications

Maintaining and enhancing the exterior of your vehicle is essential for both aesthetics and functionality. This section delves into the techniques and considerations involved in addressing damage and customizing the outer shell, ensuring your machine not only performs well but also stands out on the road.

Assessing Damage: The first step in any restoration process is to thoroughly examine the body for dents, scratches, or structural issues. Identifying these imperfections allows for informed decisions on whether to repair or replace specific components. Using a systematic approach will ensure that no underlying problems are overlooked.

Materials and Tools: Selecting the appropriate materials is crucial for successful modifications. Depending on the extent of the work, you may need body filler, paint, or replacement panels. Additionally, having the right tools, such as sanders, sprayers, and protective gear, will facilitate a smoother workflow and better results.

Techniques for Repair: Common methods for addressing surface damage include sanding, filling, and repainting. For more severe issues, it might be necessary to weld or replace sections of the body. Learning these techniques can significantly improve the quality and durability of your repairs.

Customization Options: Beyond repairs, many enthusiasts enjoy personalizing their vehicles. This can include adding decals, modifying fenders, or altering the overall shape for a unique look. Careful planning and execution are vital to ensure that modifications align with safety standards while enhancing visual appeal.

Finishing Touches: Once the repairs and modifications are complete, a final polish and protective coating can enhance the vehicle’s appearance and longevity. Regular maintenance of the bodywork will help preserve its condition and prevent future issues, ensuring that your vehicle remains a standout performer.

Safety Precautions During Repairs

When undertaking maintenance or restoration tasks on your vehicle, ensuring safety is paramount. Proper precautions not only protect you but also extend the lifespan of your machine. Adhering to guidelines can prevent accidents and promote a secure working environment.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Ensure that the vehicle is on a stable surface and secured properly to prevent any movement during servicing.

- Disconnect the battery before starting any electrical work to avoid shocks.

Additionally, it is essential to familiarize yourself with the tools you will be using. Misuse of equipment can lead to injuries.

- Read the instructions for each tool carefully before use.

- Keep your workspace organized to minimize hazards.

- Never rush through tasks; take your time to ensure precision and safety.

Following these safety measures will not only protect you but also contribute to the successful completion of your project.