Maintaining a high-performance engine is crucial for ensuring longevity and optimal functionality. This section provides an in-depth exploration of the processes involved in diagnosing issues, conducting repairs, and implementing regular upkeep. Understanding these elements can significantly enhance the overall performance of your marine vessel.

Knowledge of engine components is essential for any enthusiast or professional. By familiarizing yourself with the intricacies of your propulsion system, you can effectively identify potential problems before they escalate. This guide emphasizes the importance of routine inspections and the role they play in preventing costly repairs.

Furthermore, the information presented here is designed to empower you with the skills needed for effective troubleshooting. Utilizing detailed procedures and expert insights, you will learn how to tackle various challenges, ensuring that your equipment remains in top condition throughout its operational life.

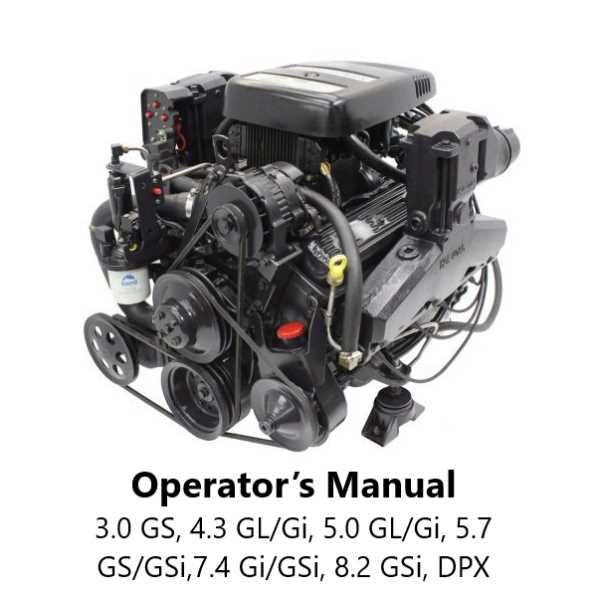

Understanding Mercruiser 350 MAG MPI

This section provides an overview of a specific marine engine known for its efficiency and performance in various watercraft. The engine is designed to deliver reliable power and is a popular choice among boaters for both recreational and commercial use.

Key Features

- Robust construction for durability and longevity

- Optimized fuel efficiency to reduce operating costs

- Advanced ignition system for improved starting and performance

- Comprehensive cooling system to maintain optimal operating temperatures

Common Applications

- Sport fishing boats

- Ski and wakeboarding vessels

- Yachts and cruising boats

- Commercial workboats

Understanding the intricacies of this engine helps boat owners maintain optimal performance and longevity, ensuring enjoyable experiences on the water.

Common Issues with the Engine

Engines, regardless of their design, can encounter various problems that may affect performance and reliability. Understanding these issues is essential for proper maintenance and troubleshooting. Below are some of the most frequently observed challenges that can arise in marine engines.

Common Problems

- Overheating: Excessive temperatures can lead to severe damage. This may be caused by:

- Blocked cooling passages

- Malfunctioning thermostats

- Insufficient coolant levels

- Rough Idling: Unstable engine performance can stem from:

- Fuel delivery issues

- Clogged air filters

- Improper ignition timing

- Excessive Oil Consumption: High oil usage may indicate:

- Worn piston rings

- Faulty valve seals

- Oil leaks in the system

lessCopy code

Diagnosing Issues

Identifying the root cause of these problems often requires a systematic approach. Regular inspections and performance tests can help pinpoint potential faults before they escalate. Attention to detail in maintenance can enhance the longevity and efficiency of the engine.

Essential Tools for Repairs

When tackling any mechanical project, having the right set of instruments is crucial for achieving optimal results. The effectiveness of your work often hinges on the quality and variety of tools at your disposal. This section outlines the indispensable equipment you will need to efficiently address issues and maintain performance.

Basic Hand Tools

Every technician should possess a well-rounded collection of hand tools. These are the foundation for any job and are often all you need for routine maintenance or troubleshooting.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips.

- Wrenches: Both open-end and socket types, in various sizes to fit different fasteners.

- Pliers: Needle-nose, slip-joint, and cutting pliers for gripping and manipulating components.

- Hammers: A ball-peen hammer is versatile for various tasks.

Specialized Equipment

In addition to basic hand tools, specific tasks may require specialized equipment to ensure precision and safety.

- Torque Wrench: Essential for applying the correct amount of force when tightening bolts.

- Multimeter: Useful for diagnosing electrical issues and testing circuits.

- Oil Filter Wrench: A must-have for changing filters efficiently.

- Compression Tester: Important for evaluating engine health.

Equipping yourself with these essential tools will significantly enhance your capability to perform necessary adjustments and ensure long-lasting functionality. Proper preparation is the first step toward successful maintenance and repair tasks.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your marine engine in optimal condition. Regular upkeep not only enhances performance but also prolongs the lifespan of the machinery. Following these outlined steps will help ensure that your equipment runs smoothly and efficiently.

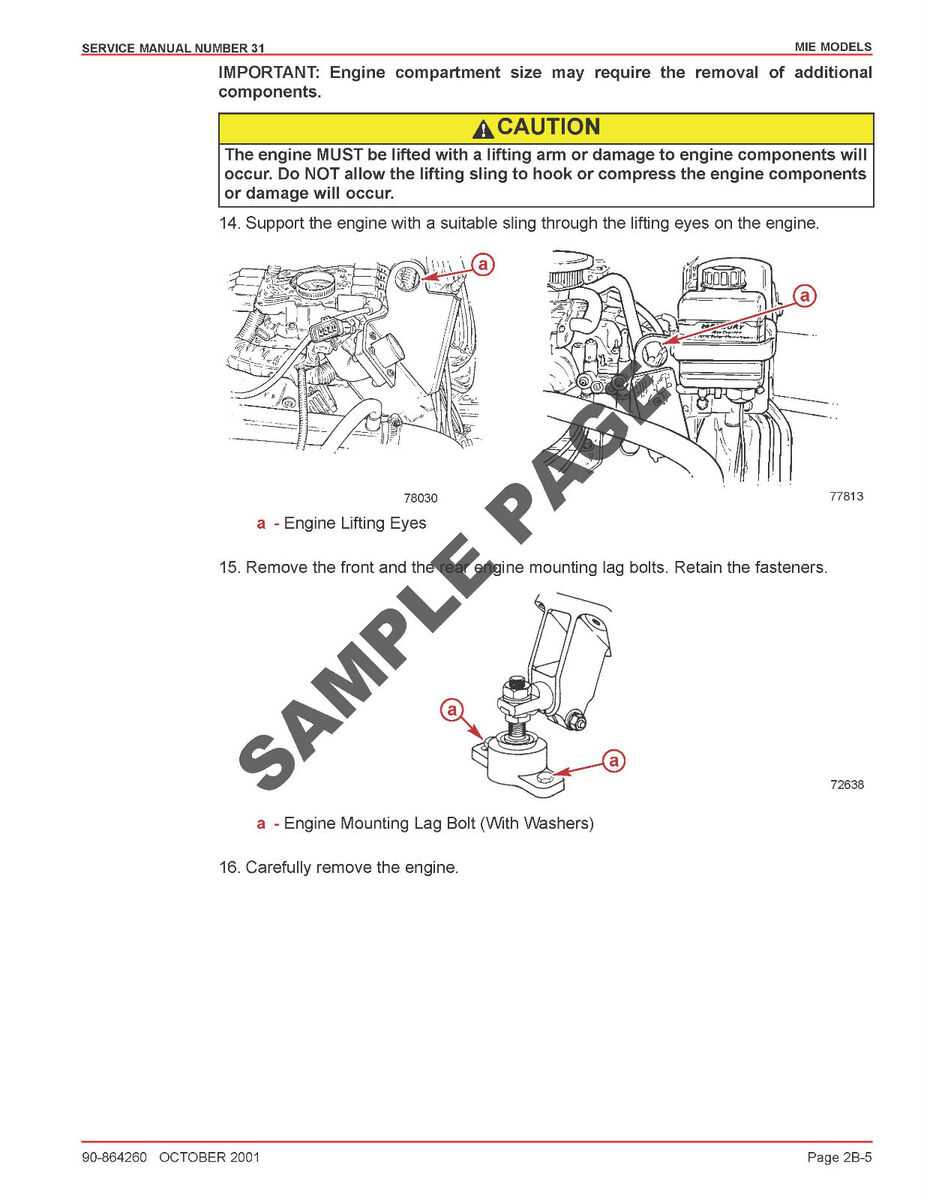

1. Inspection and Cleaning: Begin with a thorough inspection of the engine compartment. Look for signs of wear, leaks, or corrosion. Cleaning any debris and ensuring proper airflow can significantly improve performance.

2. Oil Change: Regularly changing the lubricant is crucial. Use the recommended oil type and follow the specified intervals for replacement. This will help in reducing friction and preventing damage.

3. Fuel System Maintenance: Check the fuel filters and lines for clogs or leaks. Replace filters as needed and ensure that fuel is fresh to avoid issues with combustion.

4. Cooling System Check: Inspect the cooling system for blockages or leaks. Flush the system periodically to prevent overheating and maintain optimal operating temperatures.

5. Battery Care: Regularly inspect the battery for corrosion and ensure that connections are secure. Keep the terminals clean and check the charge levels to prevent starting issues.

6. Drive System Maintenance: Examine the drive components for signs of wear. Regularly lubricate necessary parts and ensure that all seals are intact to prevent water ingress.

7. Propeller Inspection: Check the propeller for any damage or debris. Regular cleaning and maintenance will ensure efficient propulsion and reduce strain on the engine.

Following these steps will help maintain the functionality and reliability of your marine engine. Always refer to specific guidelines provided by the manufacturer for detailed instructions and safety precautions.

Identifying Engine Symptoms

Understanding the signs of engine trouble is crucial for timely intervention and effective maintenance. By recognizing these symptoms early, you can prevent minor issues from escalating into significant problems, ensuring optimal performance and longevity of your vessel’s power unit.

Here are some common indicators to watch for:

- Unusual Noises: Listen for knocking, tapping, or grinding sounds, which may signal internal damage.

- Excessive Vibration: Noticeable shaking during operation can indicate an imbalance or misalignment.

- Overheating: Frequent temperature spikes may suggest coolant issues or blocked passages.

- Oil Leaks: Visible oil on the engine surface or under the vessel can point to seal or gasket failures.

- Starting Difficulties: Problems with ignition may arise from battery, starter, or fuel delivery issues.

- Loss of Power: A noticeable decrease in acceleration or top speed often signifies underlying mechanical issues.

To effectively diagnose the situation, consider maintaining a log of these symptoms over time. This record can provide valuable insights to technicians and assist in identifying patterns that might indicate more serious concerns.

Regular inspection and attention to these warning signs can greatly enhance the reliability and safety of your engine.

Replacement Parts Overview

When maintaining a high-performance marine engine, understanding the various components available for replacement is crucial. This section provides an insight into the essential parts that may require attention over time, ensuring optimal functionality and longevity of your vessel’s power system.

Critical Components include items such as pistons, gaskets, and ignition systems, which play pivotal roles in the engine’s operation. Regular inspection of these elements can prevent potential failures and enhance performance. Each part should be selected based on compatibility and quality to ensure seamless integration.

Aftermarket Options are also worth considering. Many manufacturers offer alternatives that can provide similar or improved performance compared to original equipment. It is important to research and choose reputable suppliers to guarantee reliability and durability.

Maintenance Kits are often available, bundling several essential items needed for routine upkeep. These kits simplify the repair process by providing all necessary components in one package, allowing for a more efficient service experience.

Ultimately, a thorough understanding of available replacement parts is vital for any vessel owner aiming to maintain peak engine performance and reliability. Prioritizing quality and compatibility will lead to a more enjoyable and trouble-free maritime experience.

Cooling System Maintenance Tips

Proper upkeep of the cooling system is essential for ensuring optimal performance and longevity of your marine engine. Regular maintenance helps prevent overheating and minimizes the risk of costly repairs. Here are some effective strategies to maintain your engine’s cooling system.

Regular Inspection

Consistently check the cooling system for any signs of wear or damage. Look for leaks, corrosion, and loose connections. Pay special attention to hoses and clamps, as these components can degrade over time. Replace any worn parts promptly to avoid further issues.

Flush the System

Flushing the cooling system is vital for removing debris and preventing buildup. Use a suitable flushing agent to clean the system periodically. This process will enhance circulation and improve overall efficiency. After flushing, ensure the system is refilled with the appropriate coolant mixture to maintain optimal temperature regulation.

Fuel System Troubleshooting Techniques

Troubleshooting issues within a fuel delivery system is essential for maintaining optimal engine performance. Understanding the fundamental components and their interactions can help identify problems effectively. This section outlines various techniques to diagnose fuel system issues, ensuring a thorough approach to repairs and maintenance.

Common Symptoms of Fuel System Issues

Several signs may indicate a malfunction in the fuel system. These include difficulty starting the engine, poor acceleration, decreased power, or stalling. Additionally, unusual sounds from the fuel pump or a noticeable decrease in fuel efficiency can also signal a problem. Recognizing these symptoms early can prevent further complications and ensure timely interventions.

Diagnostic Steps to Identify Fuel System Problems

Begin the diagnostic process by inspecting the fuel lines for leaks or blockages. A visual check can often reveal obvious issues. Next, test the fuel pump pressure using a gauge to ensure it meets manufacturer specifications. If the pressure is insufficient, it may indicate a failing pump or a clogged filter. Additionally, examining the fuel injectors for proper operation is crucial; a malfunctioning injector can lead to uneven fuel distribution and performance issues. Finally, check the electrical connections to ensure that all components are receiving adequate power.

By following these techniques, one can systematically identify and address issues within the fuel delivery system, leading to improved engine reliability and performance.

Electrical System Checks and Repairs

Ensuring the functionality of the electrical components is crucial for optimal performance and safety. This section will outline essential evaluations and maintenance tasks necessary to keep the electrical system in excellent condition.

Common Issues to Identify

- Battery performance and charge status

- Corrosion on terminals and connections

- Fuses and circuit integrity

- Wiring condition and insulation integrity

- Switch functionality and responsiveness

Maintenance Steps

- Check the battery voltage using a multimeter to ensure it is within the acceptable range.

- Inspect all battery terminals for signs of corrosion; clean with a wire brush if necessary.

- Examine fuses for continuity; replace any that are blown.

- Inspect wiring for fraying or damage; replace any compromised wires.

- Test switches by toggling them on and off to confirm proper operation.

By regularly performing these assessments and repairs, the reliability of the electrical system will be maintained, preventing unexpected failures and ensuring smooth operation.

Best Practices for Winterization

Preparing your vessel for the colder months is essential to ensure its longevity and optimal performance. Proper winterization helps protect various systems from the damaging effects of freezing temperatures, moisture, and corrosion. Following a systematic approach will minimize potential issues when spring arrives and your craft is ready for the water.

1. Thorough Cleaning and Inspection

Before winter sets in, conduct a comprehensive cleaning of your vessel. Remove any debris, dirt, and salt from surfaces to prevent buildup and deterioration. Inspect all components, including hoses, fittings, and electrical connections, looking for signs of wear or damage. Address any identified issues promptly to avoid complications during the boating season.

2. Fluid Management

Draining and replacing fluids is critical during the winterization process. Ensure that the engine oil and filter are changed to eliminate contaminants. Additionally, replace the coolant with an antifreeze solution suitable for your engine type. Don’t forget to empty and flush the fuel system to prevent condensation and fuel degradation. This practice will safeguard the integrity of your engine and associated systems.

Following these best practices will enhance the reliability and durability of your vessel, ensuring that it remains in excellent condition when it’s time to hit the water again.

Finding Professional Repair Services

When it comes to maintaining and fixing your marine engine, selecting the right expert can make all the difference. Whether you’re facing minor issues or major challenges, the right technicians can ensure your vessel operates smoothly and efficiently. This section will guide you on how to locate skilled professionals who can address your engine’s needs effectively.

Where to Look

- Local Marine Dealerships

- Authorized Service Centers

- Online Forums and Communities

- Word of Mouth Recommendations

Evaluating Technicians

- Check for Certifications and Training

- Read Customer Reviews and Testimonials

- Ask About Warranty and Service Guarantees

- Inquire About Experience with Specific Engine Types

By taking the time to research and evaluate potential service providers, you can ensure that your engine receives the care it deserves, prolonging its lifespan and enhancing your boating experience.