In the realm of aviation maintenance, the integrity and longevity of flying machines hinge on meticulous attention to their physical composition. This section delves into essential practices and methodologies that ensure the safety and performance of these complex entities. By focusing on critical aspects of rejuvenation, professionals can safeguard the future of aerial technology.

Understanding the nuances of material rejuvenation is crucial for any technician engaged in this specialized field. The process involves not only addressing visible damage but also comprehending the underlying factors that contribute to structural integrity. This comprehensive approach empowers experts to implement effective solutions tailored to specific challenges, ensuring optimal functionality.

As technology evolves, so do the strategies for maintaining and enhancing the robustness of these sophisticated machines. Continuous education and adherence to updated protocols are vital in this ever-changing landscape. By embracing innovative techniques and best practices, practitioners can achieve remarkable outcomes in the preservation and enhancement of these vital assets.

Understanding Aircraft Repair Manuals

This section delves into the essential resources that guide the maintenance and restoration of aerial vehicles. These documents are critical for ensuring safety, compliance, and efficiency in the upkeep of aviation technology.

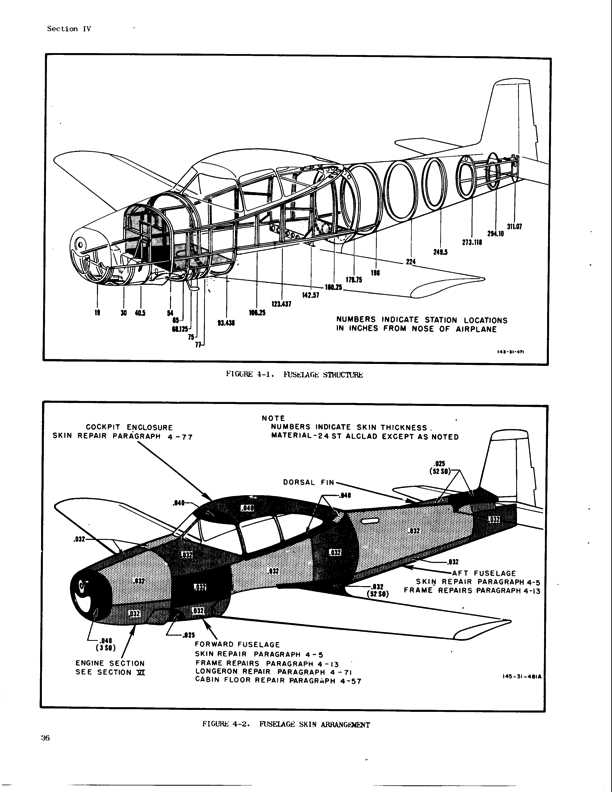

Such resources typically contain detailed information on various aspects, including:

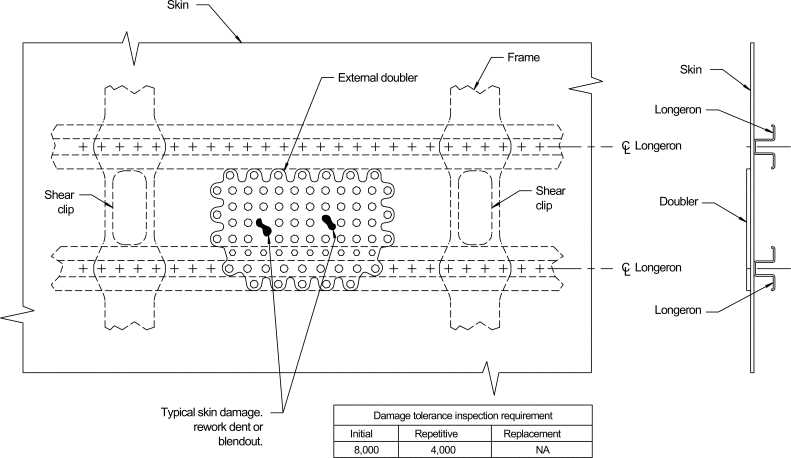

- Procedures for evaluating and addressing damage

- Specifications for materials and components

- Standards for inspections and quality control

Familiarity with these documents is crucial for professionals in the field. They provide step-by-step instructions that ensure tasks are performed correctly and safely.

- Content Organization: Information is usually divided into sections, making it easy to find relevant details.

- Illustrations and Diagrams: Visual aids enhance understanding and clarify complex procedures.

- Compliance Guidelines: Ensuring adherence to industry regulations is emphasized throughout.

Ultimately, mastery of these resources is vital for maintaining the integrity and performance of aerial vehicles, thereby contributing to the overall safety of air travel.

Importance of Structural Integrity

Maintaining the soundness of any vehicle is crucial for its overall performance and safety. The durability of key components directly impacts functionality, ensuring that operations run smoothly under various conditions. A robust framework not only supports physical loads but also contributes to the longevity and reliability of the system as a whole.

The assurance of physical strength plays a pivotal role in preventing failures that could lead to significant consequences. Regular assessments and timely interventions are essential to identify potential weaknesses before they escalate into serious issues. This proactive approach enhances safety and minimizes operational disruptions, thereby fostering trust among users and stakeholders.

Furthermore, adherence to established standards and guidelines reinforces the importance of a dependable foundation. Continuous monitoring and maintenance contribute to optimal performance, ensuring that all elements work harmoniously together. In an environment where safety is paramount, the integrity of core components cannot be overstated, making it an indispensable aspect of any operational framework.

Common Types of Aircraft Damage

Understanding the various forms of impairment that can affect flying vehicles is crucial for maintaining safety and functionality. Damage can arise from numerous factors, including environmental conditions, operational stresses, and maintenance practices. Recognizing the common types of damage helps in implementing effective mitigation strategies and ensuring longevity.

1. Surface Abrasions

Surface abrasions are often caused by foreign objects striking the exterior or by rough handling during ground operations. These imperfections can compromise the outer layers and, if not addressed, may lead to further deterioration. Regular inspections are essential for identifying and rectifying these issues promptly.

2. Impact Dents

Incidents such as impact dents can occur during loading, unloading, or when vehicles collide with other objects. These deformities can affect the aerodynamic properties and may necessitate thorough evaluation. Addressing such damage quickly is vital to maintain optimal performance and safety standards.

Overall, recognizing and addressing these common types of damage ensures that vehicles remain safe and efficient throughout their operational life.

Essential Tools for Repairs

Successful restoration tasks require a well-equipped toolkit that caters to various needs. Each instrument plays a crucial role in ensuring precision and efficiency, allowing for the effective handling of diverse challenges that may arise during the process.

Basic hand tools such as wrenches, pliers, and screwdrivers form the foundation of any toolkit. These items enable professionals to assemble, disassemble, and adjust components with ease. Additionally, specialized tools like torque wrenches and calipers are essential for achieving the necessary tightness and accuracy in connections.

Power tools enhance productivity significantly. Drills, grinders, and saws can expedite material removal or alteration, allowing for quicker progress on projects. However, it’s important to select the appropriate tool for the job to maintain safety and integrity.

Measurement instruments, including levels and tape measures, are vital for ensuring that all modifications meet stringent specifications. Accurate measurements prevent costly errors and contribute to the overall quality of the outcome.

Finally, safety equipment such as goggles, gloves, and ear protection cannot be overlooked. Protecting oneself while working with potentially hazardous materials is essential to maintain a safe working environment and promote longevity in the field.

Repair Procedures and Techniques

This section outlines essential methods and strategies for addressing issues related to air vehicle integrity and durability. Understanding these processes is vital for ensuring optimal performance and safety standards throughout the lifespan of the aircraft.

One of the primary techniques involves assessing the damage accurately to determine the most effective course of action. This may include visual inspections, non-destructive testing, and structural analysis. Once the assessment is complete, appropriate methods such as bonding, riveting, or welding can be employed to restore strength and functionality.

Additionally, adhering to established guidelines and utilizing specialized tools is crucial during the execution of these techniques. Consistency in applying these practices not only enhances the longevity of components but also minimizes the risk of future failures.

Documentation plays a significant role in this process. Maintaining detailed records of the procedures followed, materials used, and inspections conducted ensures compliance with safety regulations and provides valuable insights for future reference.

Ultimately, a combination of skillful execution and rigorous adherence to protocols will lead to successful outcomes, fostering a culture of excellence and reliability in the aviation industry.

Material Selection in Repairs

The choice of materials during the restoration process is crucial for ensuring longevity and performance. Different substances offer various properties that can significantly influence the outcome of the restoration. Understanding these characteristics helps in making informed decisions that align with safety standards and operational requirements.

One of the primary considerations is the compatibility of the selected material with existing components. It is essential to assess how well new materials will bond with or withstand environmental factors in relation to the original materials. Factors such as corrosion resistance, weight, and stress tolerance must also be evaluated to maintain the overall integrity of the structure.

Additionally, the sourcing of materials can impact the repair process. Availability, cost, and supplier reliability should be factored into the decision-making. Utilizing proven and tested materials can enhance safety and reduce the risk of future issues, thus fostering confidence in the overall restoration effort.

In conclusion, a meticulous approach to material selection is fundamental in achieving successful restoration outcomes. By prioritizing compatibility, performance, and reliability, one can ensure that the end result meets both functional and safety expectations.

Safety Protocols in Aircraft Maintenance

Ensuring the well-being of personnel and the integrity of the vehicles is paramount during maintenance operations. A comprehensive approach to safety not only protects workers but also enhances the efficiency and reliability of the maintenance process. Implementing strict guidelines and protocols is essential for mitigating risks associated with these complex tasks.

Key Safety Measures

- Personal Protective Equipment (PPE): Always wear appropriate gear, including helmets, gloves, goggles, and safety shoes.

- Hazard Communication: Ensure that all staff are aware of the materials and chemicals in use, with clear labeling and safety data sheets available.

- Workplace Organization: Maintain a clean and organized work area to reduce the chances of accidents and improve workflow.

- Emergency Procedures: Establish clear protocols for emergencies, including evacuation routes and first-aid procedures.

Training and Compliance

- Regular Training: Conduct frequent training sessions to keep staff informed about safety standards and practices.

- Certification Requirements: Ensure all personnel are certified for their specific roles and responsibilities.

- Inspection Protocols: Implement routine inspections to identify potential hazards and ensure compliance with safety regulations.

By adhering to these safety protocols, maintenance teams can create a secure working environment that prioritizes the health and safety of all individuals involved in these vital operations.

Regulatory Standards and Compliance

In the realm of aviation maintenance, adherence to established regulations and guidelines is crucial for ensuring safety and efficiency. These standards not only govern the technical aspects of modifications and enhancements but also provide a framework for operational procedures and personnel qualifications. Compliance with these regulations fosters trust and reliability within the industry, ultimately benefiting all stakeholders.

Key Regulatory Bodies

Various organizations play pivotal roles in shaping the compliance landscape. National and international authorities set forth comprehensive rules that cover everything from design to ongoing inspections. Understanding the mandates of these bodies is essential for maintaining high-quality practices and ensuring that all modifications meet the required safety benchmarks.

Importance of Documentation

Meticulous documentation is a cornerstone of compliance. Accurate records of maintenance activities, inspections, and modifications are essential for demonstrating adherence to regulatory standards. This not only supports transparency but also provides a vital resource for audits and evaluations, ensuring that all procedures align with the established norms and expectations.

Documentation and Record Keeping

Effective management of documentation and meticulous record keeping are vital for ensuring compliance, safety, and operational efficiency in any technical field. This process involves systematic organization and retention of all relevant information regarding modifications, inspections, and assessments of components. Proper documentation serves as a reference point for future work and provides a clear history of actions taken.

Importance of Documentation

Maintaining comprehensive records plays a crucial role in several key areas:

- Accountability: Well-kept records ensure that every action taken can be traced back to its origin, facilitating responsibility among personnel.

- Regulatory Compliance: Adhering to industry standards requires accurate documentation to demonstrate compliance during audits and inspections.

- Historical Reference: Access to past records aids in troubleshooting and informs future decisions based on prior experiences.

Best Practices for Record Keeping

Implementing effective practices for managing records involves several essential steps:

- Standardization: Develop a consistent format for all documents to ensure clarity and ease of use.

- Digitalization: Utilize electronic systems for storage to enhance accessibility and reduce physical space requirements.

- Regular Audits: Conduct periodic reviews of records to ensure accuracy and completeness, addressing any discrepancies promptly.

- Training: Provide personnel with training on documentation standards and the importance of meticulous record keeping.

By adhering to these principles, organizations can foster a culture of precision and accountability, ultimately contributing to enhanced safety and operational performance.

Training for Repair Personnel

Effective preparation of maintenance staff is crucial for ensuring the longevity and safety of aviation vehicles. Comprehensive education and hands-on experience equip technicians with the necessary skills to address a variety of challenges that may arise during service and upkeep. This section outlines the essential components of a training program aimed at enhancing the competencies of personnel in this field.

| Training Component | Description |

|---|---|

| Theoretical Knowledge | Understanding the principles of materials, design, and safety standards relevant to the industry. |

| Hands-on Practice | Engaging in practical exercises that simulate real-world scenarios to develop technical skills. |

| Regulatory Compliance | Familiarization with industry regulations and standards to ensure adherence during maintenance activities. |

| Problem-Solving Techniques | Training in analytical methods to diagnose and resolve issues efficiently. |

| Teamwork and Communication | Building collaborative skills to enhance coordination among diverse teams during operations. |

By focusing on these key areas, organizations can cultivate a skilled workforce capable of maintaining the highest standards of performance and reliability in their operations.

Future Trends in Aircraft Repair

The evolution of maintenance practices in the aviation sector is set to undergo significant transformations in the coming years. Innovations in technology, materials, and methodologies will shape how professionals approach the upkeep and restoration of airborne vehicles, enhancing efficiency and safety while reducing downtime.

Emerging technologies, particularly in automation and data analytics, will revolutionize traditional methods. The integration of artificial intelligence and machine learning will enable predictive maintenance, allowing technicians to anticipate issues before they arise, thereby streamlining operations and minimizing unexpected failures.

| Trend | Description |

|---|---|

| 3D Printing | This technology will facilitate the on-demand production of components, reducing inventory costs and lead times. |

| Composite Materials | Advancements in lightweight materials will enhance performance while requiring specialized techniques for servicing. |

| Digital Twins | Creating virtual replicas of physical assets will allow for real-time monitoring and analysis, improving decision-making processes. |

| Robotics | Automation of labor-intensive tasks will increase precision and efficiency, allowing human workers to focus on complex problem-solving. |

| Remote Monitoring | Continuous data collection and transmission will empower technicians to address issues remotely, minimizing the need for physical inspections. |

As these trends continue to develop, the industry will not only improve operational effectiveness but also enhance safety and sustainability, paving the way for a new era in the aviation landscape.