Maintaining optimal performance in a compact diesel engine requires a comprehensive understanding of its components and systems. This section provides vital insights into ensuring longevity and reliability through regular servicing and troubleshooting techniques.

By familiarizing yourself with the operational characteristics and potential issues, you can enhance the efficiency of your machinery. Understanding the intricacies of maintenance will empower you to address common concerns swiftly, thus preventing costly downtimes and ensuring smooth operation.

The following details outline the essential practices for upkeep, including inspection protocols, common repair techniques, and recommended intervals for servicing. Adopting these guidelines will not only sustain the functionality of your engine but also contribute to its overall performance and durability.

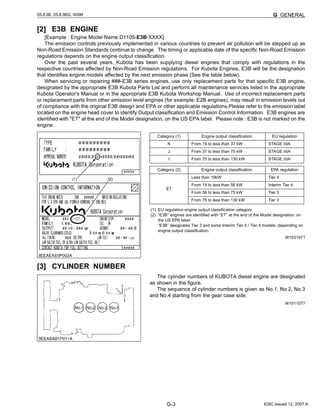

This section aims to provide a comprehensive understanding of a specific engine model, highlighting its key characteristics and functionalities. By exploring its components, performance metrics, and maintenance requirements, readers will gain valuable insights into this powerful machinery.

Key Features of the Engine

- Compact and efficient design

- High torque output for various applications

- Durability and reliability under diverse conditions

- Advanced cooling system for optimal performance

Technical Specifications

- Cylinder configuration and number

- Displacement volume

- Power output ratings

- Fuel type and consumption efficiency

Understanding these aspects is crucial for effective utilization and longevity of the engine.

Common Issues with Kubota V1505

In the realm of small engines, certain problems tend to arise frequently, affecting overall performance and reliability. Recognizing these issues early can help in maintaining efficiency and extending the lifespan of the equipment.

Engine Overheating

One prevalent concern is overheating, which can lead to severe damage if not addressed promptly. Common causes include inadequate coolant levels, blocked cooling passages, or a malfunctioning thermostat. Regular maintenance checks are essential to prevent this problem.

Fuel System Complications

Another issue involves complications within the fuel system, which can disrupt engine operation. Problems may stem from clogged filters, contaminated fuel, or air leaks. Ensuring a clean and stable fuel supply is crucial for optimal functionality.

| Issue | Symptoms | Solutions |

|---|---|---|

| Overheating | High temperature readings, steam | Check coolant levels, clean radiator |

| Fuel System Problems | Stalling, poor acceleration | Replace filters, inspect fuel lines |

Tools Needed for Repairs

When undertaking maintenance on machinery, having the right equipment is essential for achieving optimal results. This section outlines the various instruments and materials that will facilitate effective servicing and troubleshooting tasks.

Essential Hand Tools

Basic hand tools are fundamental for any maintenance work. A set of wrenches, screwdrivers, and pliers will allow you to tackle most fasteners and components with ease. Ensure to include a torque wrench for precision when applying force, as this is critical for maintaining the integrity of connections.

Diagnostic Equipment

In addition to standard tools, having diagnostic devices can significantly enhance your ability to identify issues. A multimeter for electrical testing, along with a compression tester, will provide insights into the operational state of various systems. Using these tools effectively can save time and prevent further complications during the servicing process.

Step-by-Step Engine Disassembly

This section provides a detailed guide on the process of disassembling a compact engine. Understanding the correct sequence and techniques is crucial for successful maintenance and repairs. Following these steps ensures that components are removed safely and efficiently, minimizing the risk of damage.

Preparation and Safety Measures

Before starting the disassembly, ensure you have the necessary tools and a clean workspace. Safety gear such as gloves and goggles should be worn to protect against sharp edges and debris. It’s important to disconnect the battery and drain any fluids to prevent spills.

Disassembly Process

Begin by removing external accessories, including the air intake and exhaust systems. Carefully document each step to aid in reassembly. Once the outer components are detached, proceed to take off the cylinder head, followed by the engine block. Make sure to keep track of all fasteners and components in a labeled container to avoid confusion later.

Replacing Engine Components

When it comes to maintaining an engine’s efficiency and longevity, replacing worn or damaged parts is essential. This process involves careful assessment and systematic steps to ensure that each component functions optimally.

Before starting the replacement, gather the necessary tools and materials. It is also advisable to refer to specific guidelines related to the components being changed. The following steps outline the general procedure:

- Prepare the workspace by ensuring it is clean and well-lit.

- Disconnect the power source and remove any protective covers.

- Carefully detach the old component, noting its connections and positions.

- Inspect adjacent parts for any signs of wear or damage.

- Install the new component, ensuring all connections are secure and properly aligned.

- Replace any protective covers and reconnect the power source.

Regular checks and timely replacements can significantly enhance the performance and reliability of the engine. Always prioritize safety and consult relevant resources when necessary.

Reassembly Procedures Explained

This section provides a comprehensive overview of the steps involved in putting together the components of a specific engine model. Proper reassembly is crucial to ensure optimal performance and longevity of the machinery. Understanding the correct sequence and techniques will facilitate a smoother process and reduce the likelihood of errors.

Begin by gathering all necessary tools and parts before starting the reassembly. Ensure that all components are clean and free from debris, as this can prevent proper fitting and function. Following the manufacturer’s guidelines, carefully align each part, ensuring that all fasteners are torqued to the specified values. This is vital for maintaining structural integrity and operational efficiency.

Attention to detail is essential during this phase. Double-check the placement of gaskets and seals to avoid leaks. After assembling, perform a thorough inspection to confirm that everything is securely fitted and aligned correctly. Finally, conduct a test run to verify that the engine operates as intended, making adjustments as necessary.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent and proactive care. Implementing effective maintenance strategies can significantly enhance performance and extend the lifespan of your equipment.

- Regular Inspections: Conduct routine checks to identify wear and tear. Early detection can prevent larger issues.

- Fluid Checks: Monitor oil and coolant levels frequently. Maintaining appropriate fluid levels is crucial for optimal operation.

- Filter Replacement: Replace air and fuel filters at recommended intervals to ensure clean operation and prevent damage.

- Cleaning: Keep the exterior and components free from dirt and debris to avoid overheating and maintain efficiency.

- Scheduled Servicing: Follow a regular servicing schedule as outlined by the manufacturer to keep the machine in top condition.

- Proper Storage: Store machinery in a dry, protected area to avoid corrosion and deterioration from environmental factors.

By following these guidelines, you can ensure your equipment remains reliable and performs at its best over time.

Troubleshooting Electrical Problems

Addressing electrical issues requires a systematic approach to identify and resolve faults effectively. Understanding the components involved and their functions is crucial in diagnosing malfunctions within the system.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical problems can aid in early detection. Typical symptoms include:

| Symptom | Possible Cause |

|---|---|

| Unresponsive ignition | Faulty starter or battery |

| Intermittent power loss | Loose connections or corroded terminals |

| Warning lights on dashboard | Electrical system fault |

Steps for Diagnosing Electrical Issues

To effectively diagnose electrical problems, follow these steps:

- Inspect the battery and connections for corrosion or damage.

- Check fuses and relays for continuity.

- Test the wiring harness for signs of wear or shorts.

- Utilize a multimeter to measure voltage and resistance at various points.

Recommended Lubricants and Fluids

Maintaining optimal performance in your machinery requires the use of appropriate lubricants and fluids. Selecting the right products is essential for ensuring longevity and efficiency.

Engine Oil: High-quality engine oil is crucial for smooth operation. It minimizes friction and wear, while also enhancing cooling. Choose a viscosity grade recommended for your specific engine requirements.

Transmission Fluid: The proper transmission fluid ensures seamless gear shifting and protects components from excessive wear. Refer to the specifications to find the right type and viscosity.

Coolant: Using the correct coolant is vital for maintaining ideal operating temperatures. A mixture of antifreeze and water can prevent overheating and corrosion within the cooling system.

Grease: Regular application of suitable grease on moving parts is important for reducing friction and preventing rust. Look for products designed for heavy-duty machinery to achieve the best results.

By following these guidelines and using the recommended products, you can enhance the performance and lifespan of your equipment.

Safety Precautions During Repairs

Ensuring safety is paramount when conducting maintenance on machinery. Proper precautions help prevent accidents and injuries, creating a safer work environment. It is essential to adhere to guidelines and utilize protective equipment effectively to mitigate potential risks.

Personal Protective Equipment

Wearing the right gear is crucial for safeguarding against hazards. Essential items include:

| Equipment | Purpose |

|---|---|

| Safety goggles | Protects eyes from debris and fluids |

| Gloves | Prevents cuts and chemical exposure |

| Steel-toed boots | Protects feet from heavy objects |

| Ear protection | Reduces noise exposure |

Work Environment Considerations

Creating a safe workspace is equally important. Ensure the area is well-lit and free from clutter. Keeping tools organized and accessible minimizes the risk of accidents. Additionally, proper ventilation should be maintained to avoid inhaling harmful fumes.

Resources for Further Assistance

This section provides a compilation of valuable resources that can enhance your understanding and support your efforts in maintaining and servicing your engine. Access to reliable information is essential for effective troubleshooting and ensuring optimal performance.

Online Forums and Communities

Participating in online forums can offer insights from experienced users and experts. These platforms allow you to share experiences, ask questions, and gain advice tailored to specific challenges you may face.

Manufacturer Websites

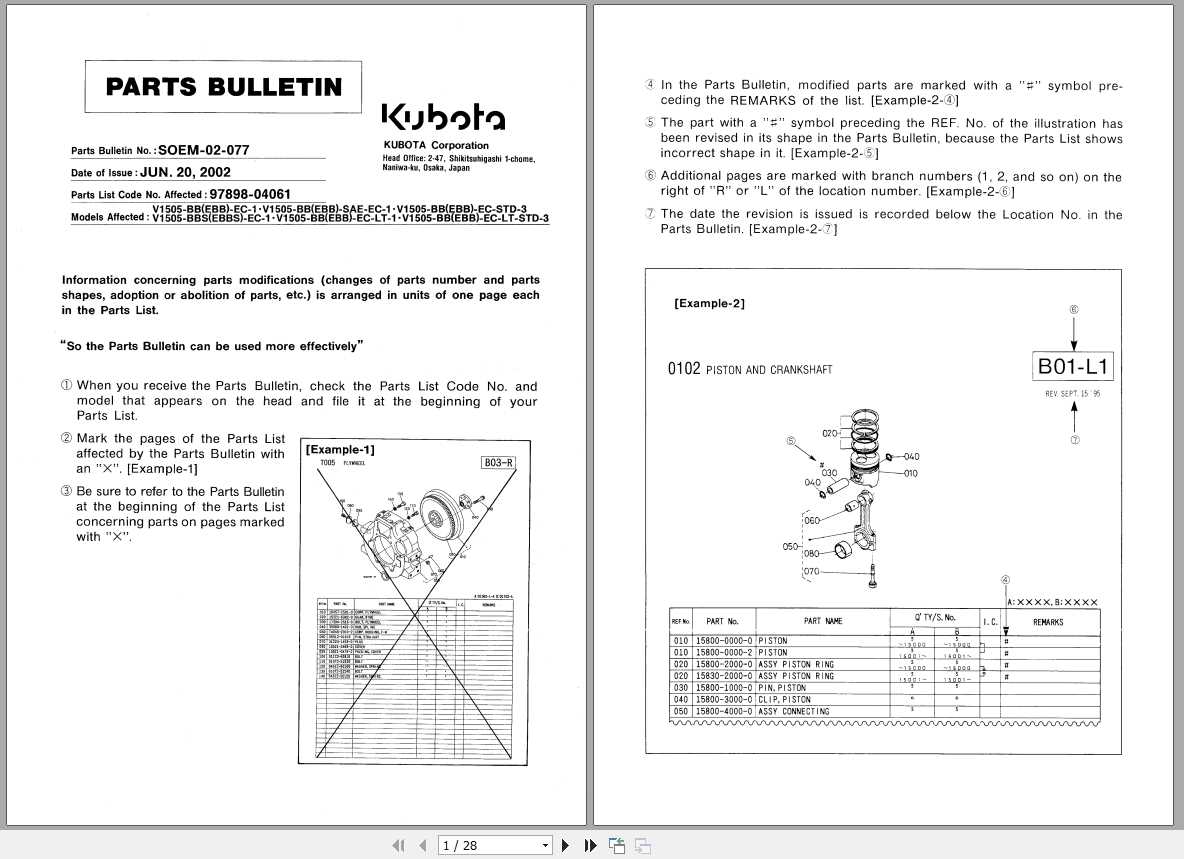

Official websites often provide technical documents, user guides, and product information. These resources can be crucial for obtaining accurate specifications and best practices for your engine.

| Resource Type | Examples |

|---|---|

| Online Forums | Discussion boards, community websites |

| Manufacturer Sites | Official product pages, technical support sections |

| Video Tutorials | YouTube channels, instructional videos |