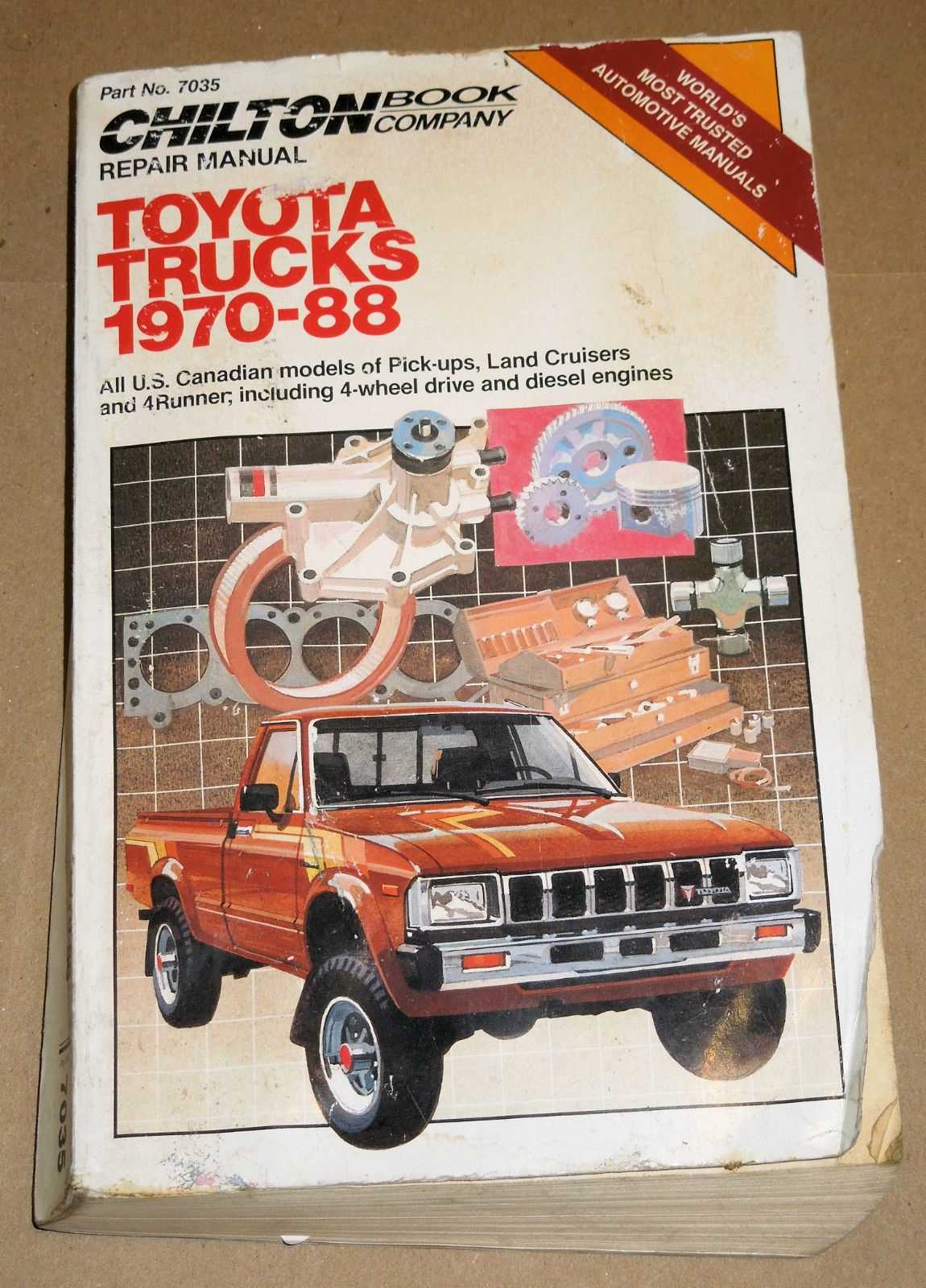

When it comes to keeping vintage automobiles in top shape, having access to detailed documentation is essential. This resource serves as an invaluable tool for enthusiasts and owners, providing essential insights into the upkeep and restoration of beloved vehicles. A thorough understanding of the components and systems within these machines can make a significant difference in performance and longevity.

In this section, we delve into various aspects of maintaining older models, exploring troubleshooting techniques, and offering practical advice. From routine checks to more complex repairs, knowledge is power, and being well-informed can transform the ownership experience. The following information is designed to guide you through the intricate processes involved in caring for your classic vehicle.

Equipped with diagrams, specifications, and step-by-step instructions, this guide aims to empower owners to take on their own maintenance tasks confidently. Whether you’re a seasoned mechanic or a passionate beginner, understanding your vehicle’s intricacies can lead to a more rewarding and satisfying journey on the road.

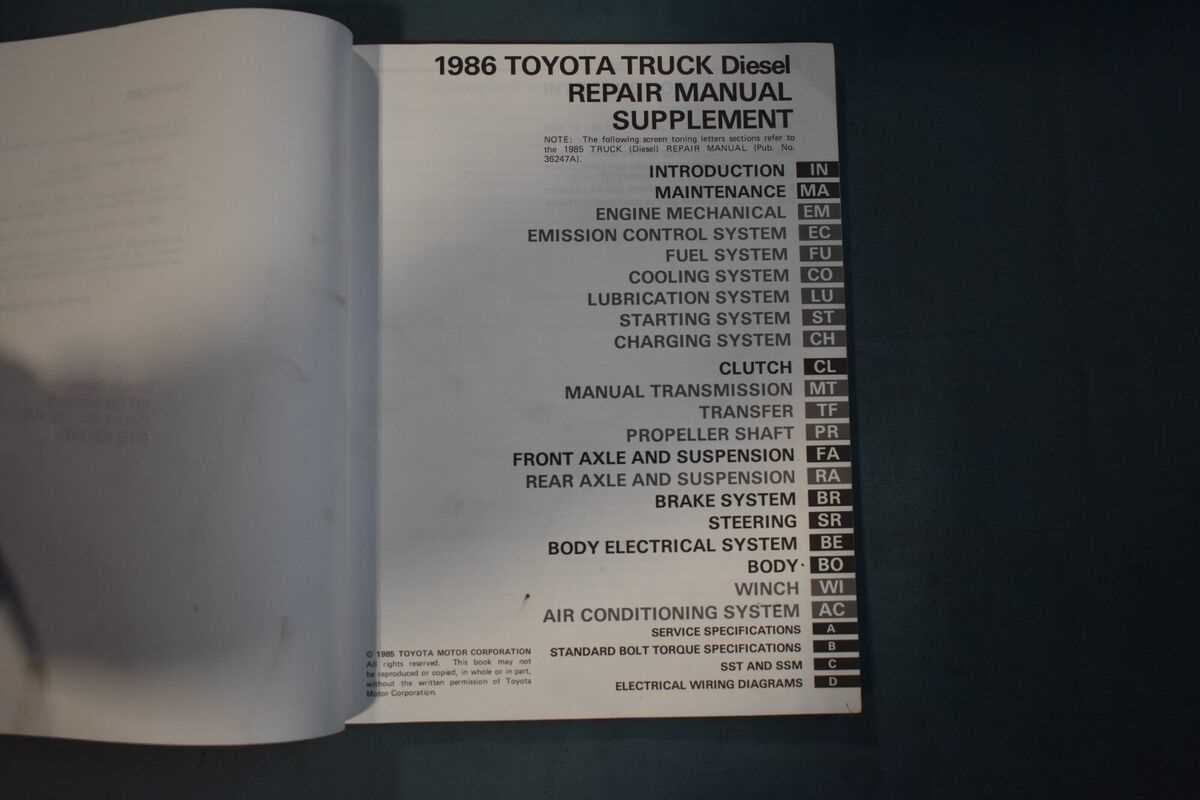

Overview of the 1986 Toyota Truck

This section provides a comprehensive look at a classic vehicle model known for its reliability and rugged performance. Designed to meet the demands of both urban and off-road environments, this model has secured a reputation for its durability and ease of maintenance.

Key Features

Featuring a robust chassis and a variety of engine options, this vehicle caters to diverse driving needs. Its design prioritizes functionality, making it a favorite among enthusiasts and casual users alike. Engine performance is complemented by an efficient transmission system, ensuring a smooth driving experience.

Maintenance Considerations

Regular upkeep is essential for maintaining optimal performance. Key areas to monitor include the suspension system, brake components, and electrical systems. Understanding the basic mechanics will empower owners to handle minor issues independently, prolonging the vehicle’s lifespan.

Common Issues with 1986 Models

Vehicles from this particular year often exhibit a range of prevalent problems that can affect performance and reliability. Owners may encounter difficulties that arise from both mechanical and electrical components, which can lead to unexpected malfunctions over time.

One frequent concern is related to the fuel system, where clogged filters and failing pumps can hinder engine performance. Additionally, issues with the ignition system, such as worn spark plugs or faulty coils, can result in poor starting or misfiring during operation.

Another area that often requires attention is the suspension. Components such as bushings and shock absorbers may degrade, leading to a rough ride and reduced handling capabilities. Furthermore, the braking system can also present challenges; worn pads and corroded rotors can compromise safety and necessitate timely replacement.

Electrical glitches, including malfunctioning gauges and intermittent lights, are not uncommon. These can stem from corroded connections or aging wiring, which may need thorough inspection and repair to ensure proper functionality. Overall, understanding these common issues can aid owners in maintaining their vehicles and ensuring longevity.

Essential Tools for Repairs

When tackling mechanical challenges, having the right instruments at your disposal is crucial for effective problem-solving. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are completed safely and accurately. Understanding which tools are indispensable can make all the difference in achieving successful outcomes.

Basic Hand Tools

At the foundation of any toolkit lies a selection of fundamental hand instruments. Wrenches, screwdrivers, and pliers are essential for various tasks, allowing you to tighten, loosen, and manipulate components with ease. Investing in high-quality versions of these tools will ensure longevity and reliability during your projects.

Specialized Equipment

In addition to basic tools, certain specialized equipment can significantly aid in more complex undertakings. A torque wrench is vital for applying the correct amount of force, while a multimeter is indispensable for diagnosing electrical issues. Having these specialized instruments on hand can simplify troubleshooting and enhance your overall effectiveness.

Understanding the Engine Specifications

Engine specifications are crucial for anyone looking to maintain or restore their vehicle. They provide essential information about the powertrain’s capabilities, efficiency, and performance characteristics. Understanding these details not only aids in troubleshooting but also enhances the overall driving experience.

Key components such as displacement, horsepower, and torque ratings offer insights into how the engine performs under various conditions. Displacement indicates the total volume of the engine cylinders, directly impacting power output. Horsepower measures the engine’s ability to perform work, while torque refers to the rotational force that drives the vehicle forward.

Additionally, fuel type and compression ratios are significant factors influencing engine efficiency and emissions. A higher compression ratio can lead to improved performance but may require premium fuel to avoid knocking. It’s essential to align the specifications with the intended use of the vehicle, whether for daily commuting or off-road adventures.

Regular maintenance, guided by these specifications, ensures longevity and optimal function. Understanding the nuances of engine performance can lead to more informed decisions when it comes to repairs and upgrades, ultimately enhancing both reliability and enjoyment behind the wheel.

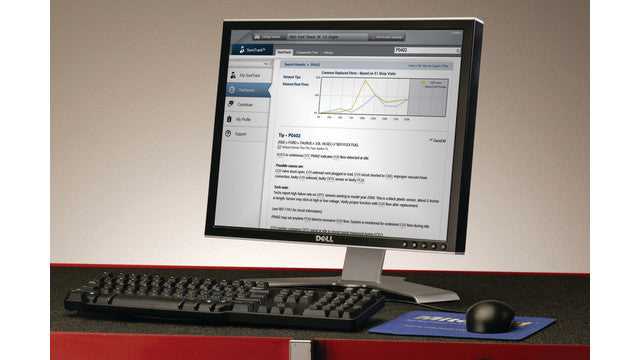

Electrical System Troubleshooting Guide

This section provides essential strategies for diagnosing and resolving issues within the electrical components of your vehicle. A well-functioning electrical system is critical for performance, and identifying problems early can prevent more significant complications down the line.

Begin by assessing the following areas:

- Battery:

- Check for corrosion on terminals.

- Ensure the battery is fully charged.

- Inspect the battery cables for wear or damage.

- Fuses:

- Locate the fuse box and examine each fuse.

- Replace any blown fuses with the correct amperage.

- Identify the cause of any recurring fuse failures.

- Wiring:

- Inspect all visible wiring for signs of fraying or breaks.

- Check for loose connections that may cause intermittent issues.

- Utilize a multimeter to test for continuity in wires.

- Electrical Components:

- Test switches and relays for proper operation.

- Verify that lights, indicators, and accessories function as expected.

- Consider any unusual noises or smells that may indicate a problem.

By following these steps, you can effectively troubleshoot and address electrical issues, ensuring a reliable and efficient operation of your vehicle.

Transmission Maintenance and Repair Tips

Ensuring the longevity and optimal performance of your vehicle’s transmission system is crucial for smooth operation. Regular attention to maintenance can prevent costly issues down the line. Here are some essential tips to help keep your transmission in top shape.

| Tip | Description |

|---|---|

| Fluid Inspection | Regularly check the transmission fluid level and condition. Clean fluid is typically red or pink, while dark or brown fluid indicates contamination. |

| Change Fluid | Follow the manufacturer’s recommendations for fluid changes to ensure proper lubrication and prevent overheating. |

| Check for Leaks | Look for signs of fluid leakage underneath the vehicle. Early detection can save significant repair costs. |

| Monitor Shifting | Pay attention to how the vehicle shifts gears. Slipping, hesitation, or unusual noises can signal problems that need addressing. |

| Cooling System Maintenance | Ensure the transmission cooler is functioning properly. Overheating can lead to severe damage. |

By following these straightforward practices, you can maintain a reliable and efficient transmission, extending its lifespan and enhancing overall vehicle performance.

Suspension and Steering Adjustments

Maintaining the proper alignment and functionality of the suspension and steering systems is essential for ensuring a smooth and safe driving experience. Regular adjustments help in enhancing vehicle handling, promoting tire longevity, and improving overall stability. This section delves into the key aspects of suspension and steering calibration that are crucial for optimal performance.

Understanding Alignment

Alignment refers to the angles of the wheels in relation to the vehicle’s body. Correct alignment minimizes tire wear and enhances control. Key components that require attention include camber, caster, and toe settings. Camber is the tilt of the wheels; caster relates to the steering axis; and toe determines how the wheels point in relation to each other. Regular checks are recommended to maintain the appropriate angles and prevent uneven wear.

Suspension Component Adjustments

Adjusting suspension components can significantly influence ride quality. Important elements include shock absorbers, springs, and bushings. Shock absorbers control the damping of movement, while springs support the vehicle’s weight and absorb bumps. Regular inspection and adjustment of these components can prevent excessive bouncing and ensure a stable ride. Additionally, bushing wear can lead to increased noise and vibrations, making timely replacement vital for maintaining comfort and safety.

Brake System Inspection Procedures

Regular evaluation of the braking mechanism is crucial for ensuring optimal vehicle performance and safety. A thorough assessment helps identify potential issues before they escalate, allowing for timely maintenance and repairs. This section outlines the necessary steps to effectively inspect the braking system components.

Inspection Steps

To conduct a comprehensive inspection, follow these essential procedures:

| Step | Description |

|---|---|

| 1 | Visual Examination: Inspect the brake components for any visible signs of wear, corrosion, or damage. |

| 2 | Fluid Level Check: Ensure that the brake fluid level is within the recommended range and check for leaks. |

| 3 | Pad Thickness Measurement: Measure the thickness of the brake pads to determine if they need replacement. |

| 4 | Rotor Inspection: Check the brake rotors for warping or scoring, which may affect braking performance. |

| 5 | Line Assessment: Examine brake lines for any signs of wear or leakage that could compromise functionality. |

Conclusion

By adhering to these inspection protocols, vehicle owners can maintain the integrity of their braking systems, promoting safety and enhancing overall performance. Regular checks are vital for identifying issues early and ensuring reliable operation on the road.

Body and Frame Restoration Techniques

Restoring the outer shell and structural elements of a vehicle requires a blend of skill, patience, and the right methods. Proper techniques not only enhance the aesthetic appeal but also ensure the longevity and safety of the vehicle. This section explores various strategies to effectively rejuvenate these vital components, addressing common challenges faced during the restoration process.

Preparation and Assessment

Before diving into the restoration work, a thorough evaluation of the body and frame is essential. Inspecting for rust, dents, and structural integrity helps in formulating a precise plan of action. Effective preparation involves the following steps:

| Step | Description |

|---|---|

| 1 | Visual Inspection |

| 2 | Rust Assessment |

| 3 | Structural Evaluation |

| 4 | Documentation |

Techniques for Restoration

Once the assessment is complete, several techniques can be employed to restore the body and frame. These methods include metal repair, painting, and reinforcement. Each technique serves a distinct purpose and requires specialized tools:

| Technique | Purpose |

|---|---|

| Welding | To repair or replace damaged sections of the frame |

| Body Filler Application | To smooth out dents and imperfections |

| Painting | To protect surfaces and enhance visual appeal |

| Coating | To prevent future rust and corrosion |

Recommended Fluids and Lubricants

Ensuring optimal performance of your vehicle requires the use of appropriate fluids and lubricants. These substances play a crucial role in maintaining engine efficiency, protecting components from wear, and ensuring smooth operation across various systems. Selecting the right products is essential for longevity and reliability.

Engine Oil: The heart of any vehicle, engine oil must meet specific viscosity and performance standards. Look for high-quality oils that offer excellent protection against oxidation and wear. Synthetic blends can provide superior performance in extreme temperatures.

Transmission Fluid: Proper lubrication of the transmission is vital for shifting smoothly. Ensure to use fluids that meet the manufacturer’s specifications, as this can greatly affect performance and durability.

Coolant: Maintaining the right temperature is critical for engine health. Use a coolant that provides excellent heat transfer and corrosion protection. Antifreeze solutions should be mixed appropriately to prevent freezing in cold conditions.

Brake Fluid: For effective braking performance, choose fluids that have a high boiling point and are compatible with the brake system. Regular checks are essential to prevent moisture absorption, which can compromise braking efficiency.

Grease: Lubrication of moving parts is essential to minimize friction. Use high-quality greases designed for specific applications, ensuring they can withstand varying pressures and temperatures.

Selecting the right fluids and lubricants is not just a matter of maintenance; it’s an investment in the overall performance and lifespan of your vehicle. Regularly check and replace these substances as recommended to keep everything running smoothly.

Accessing Wiring Diagrams

Understanding the electrical layout of a vehicle is essential for troubleshooting and modifications. Wiring diagrams serve as invaluable resources, providing a visual representation of the connections and circuits that power various components. Accessing these diagrams can significantly enhance your ability to diagnose issues and implement repairs effectively.

Where to Find Wiring Diagrams

- Online Resources: Numerous websites offer downloadable diagrams for specific models and years. These platforms can often be a quick and efficient way to obtain the information you need.

- Service Publications: Many manufacturers release detailed service publications that include wiring diagrams. These can often be purchased or accessed through automotive libraries.

- Community Forums: Enthusiast forums and communities often share valuable resources, including wiring diagrams. Engaging with other users can lead to discovering diagrams that may not be readily available elsewhere.

Using Wiring Diagrams Effectively

- Identify Key Components: Familiarize yourself with the symbols and notations used in the diagrams to understand which parts correspond to specific functions.

- Trace Circuits: Follow the lines on the diagram to identify how power flows through the system, which can help isolate problems.

- Refer to Color Codes: Many diagrams include color coding for wires, aiding in identifying connections quickly.

By effectively accessing and utilizing wiring diagrams, you can enhance your diagnostic skills and streamline your repair process, ultimately leading to more efficient vehicle maintenance.

DIY Maintenance Checklist for Owners

Regular upkeep is essential for ensuring the longevity and reliability of your vehicle. By performing simple tasks yourself, you can save money while gaining a better understanding of your machine. This checklist provides a structured approach to maintaining your vehicle effectively, helping you catch potential issues before they become major problems.

Essential Tasks to Perform

Fluid Levels: Regularly check and top off engine oil, coolant, brake fluid, and transmission fluid. Maintaining proper levels is crucial for optimal performance and safety.

Tire Care: Inspect tire pressure and tread depth monthly. Properly inflated tires enhance fuel efficiency and ensure better handling.

Visual Inspections

Belts and Hoses: Examine for signs of wear, such as cracks or fraying. Replace any damaged components to prevent breakdowns.

Lights and Wipers: Ensure all lights are functioning and replace burnt-out bulbs. Check wiper blades for wear and replace them if they are not clearing the windshield effectively.

Following this checklist regularly will help keep your vehicle in top condition, ultimately enhancing your driving experience and safety on the road.