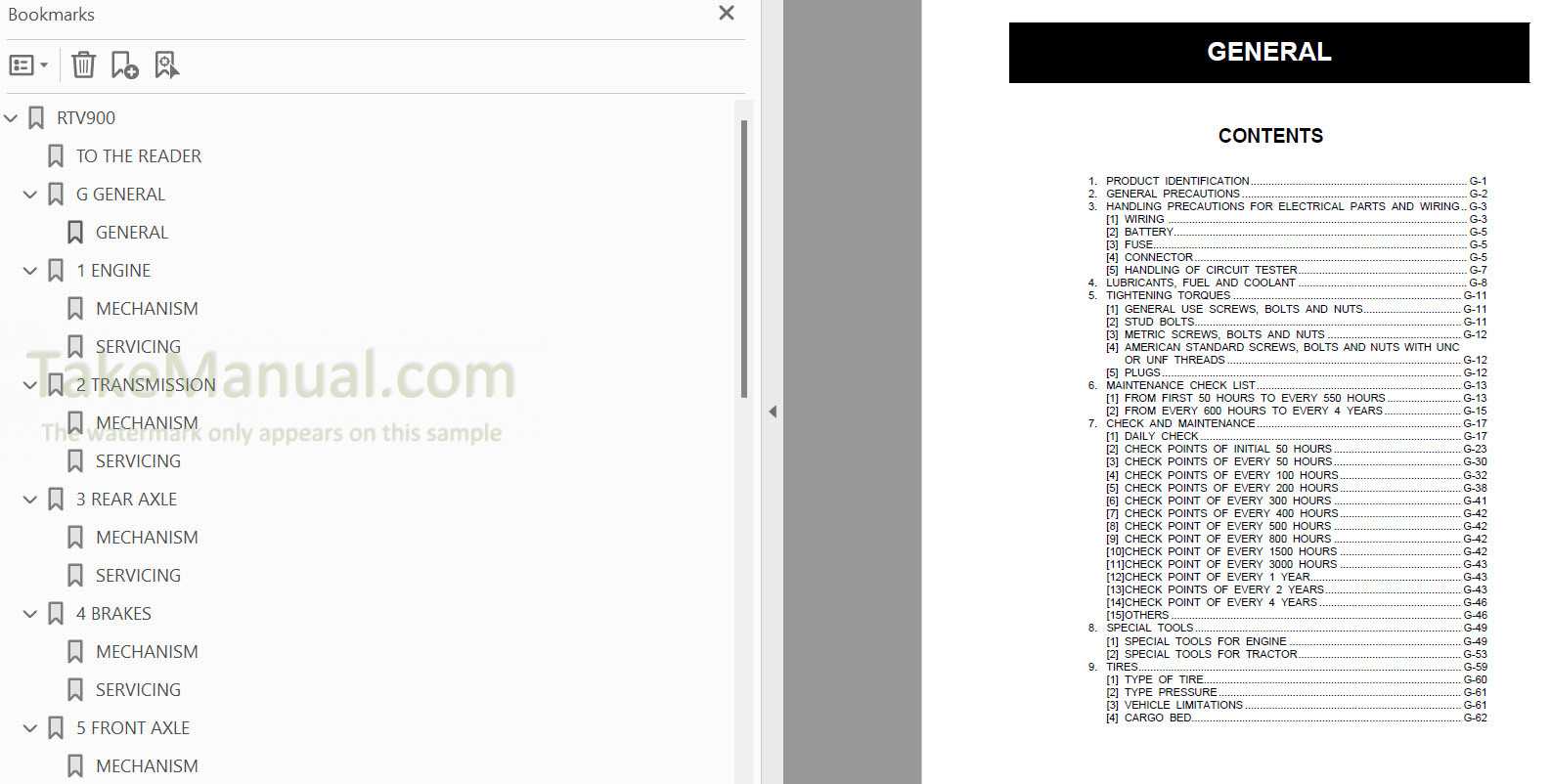

The upkeep of versatile utility vehicles is essential for ensuring their longevity and optimal performance. This section provides insights into the essential practices and considerations that every owner should be aware of to maintain their vehicle effectively.

Understanding the components and systems of your vehicle is crucial. Regular inspections and preventive measures can help identify potential issues before they escalate. Knowledge of basic troubleshooting techniques can empower owners to address minor problems independently, thus minimizing downtime.

Moreover, having access to comprehensive guidance on service procedures can facilitate informed decisions when performing maintenance tasks. This resource aims to enhance your understanding and enable you to keep your vehicle in peak condition, ensuring it meets the demands of various tasks efficiently.

To ensure the extended life of your utility vehicle, regular upkeep and attention to detail are essential. By following a systematic maintenance routine, you can prevent potential issues and enhance performance over time.

Begin with routine inspections, focusing on key components such as the engine, transmission, and brakes. Checking fluid levels and replacing filters at recommended intervals can significantly impact functionality. Additionally, regular tire pressure checks and rotation will promote even wear and improve handling.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Check | Every 100 hours | Ensure all fluids are at optimal levels. |

| Filter Replacement | Every 200 hours | Use manufacturer-approved filters. |

| Tire Inspection | Monthly | Check for wear and proper inflation. |

| Brake Check | Every 300 hours | Inspect for wear and functionality. |

By adhering to these guidelines, you can maximize the operational lifespan of your vehicle and maintain its reliability for various tasks. Consistent attention to maintenance will ensure that your machine continues to perform effectively in all conditions.

Essential Tools for Repairs

Having the right equipment is crucial when addressing maintenance tasks for any vehicle. Proper tools not only streamline the process but also enhance efficiency and safety. A well-equipped toolkit allows for effective troubleshooting and ensures that each task is completed to a high standard.

Wrenches are fundamental for loosening and tightening various components. A set that includes both standard and metric sizes is essential to accommodate different fittings. Additionally, screwdrivers of various types and sizes will be necessary for accessing tight spaces and securing or removing covers and panels.

Another critical tool is a socket set, which offers versatility for handling nuts and bolts of different dimensions. Pairing this with a ratchet wrench can significantly reduce the time spent on fastening tasks. For tasks that require a firm grip, pliers come in handy, especially for manipulating wires or other small components.

Furthermore, having a reliable jack and jack stands is vital for safely elevating the vehicle, allowing for easier access to the undercarriage. Finally, consider investing in a multimeter to diagnose electrical issues, which can be a common source of problems.

By equipping yourself with these essential tools, you will be well-prepared to tackle various maintenance and service challenges effectively.

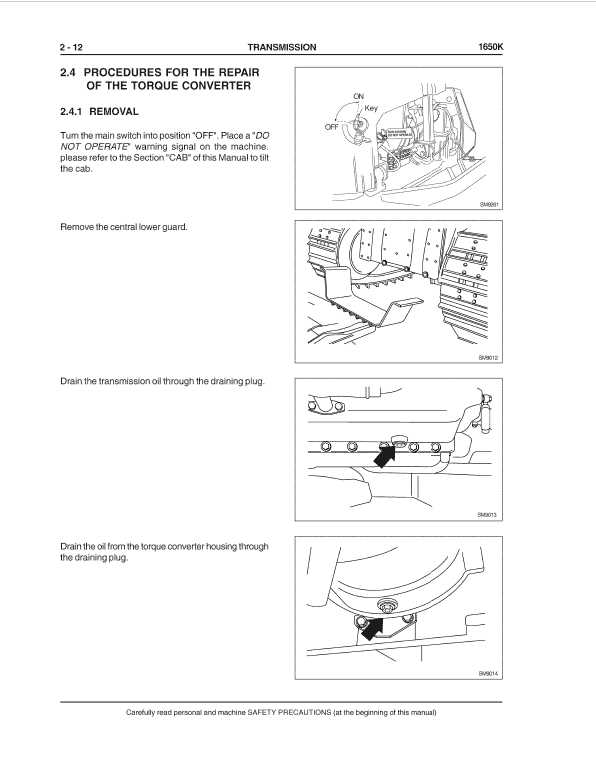

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing mechanical issues in off-road vehicles. By following detailed instructions, users can effectively troubleshoot and resolve common problems that may arise during operation. This methodical process ensures that every aspect of the repair is covered, promoting a thorough understanding of the vehicle’s systems.

Below are the essential steps to successfully complete the repair tasks:

| Step | Description |

|---|---|

| 1 | Begin by assessing the vehicle to identify any visible signs of damage or wear. |

| 2 | Gather all necessary tools and replacement parts required for the procedure. |

| 3 | Follow safety protocols to ensure a safe working environment before starting any repairs. |

| 4 | Refer to technical specifications to understand the components that need attention. |

| 5 | Carefully disassemble the parts that require maintenance, taking care to label and organize components. |

| 6 | Replace or repair damaged components as necessary, ensuring all replacements match the original specifications. |

| 7 | Reassemble the vehicle, double-checking that all parts are securely fastened. |

| 8 | Conduct a thorough inspection post-repair to confirm that the vehicle operates correctly. |

By adhering to these steps, individuals can enhance their ability to maintain and restore off-road vehicles, ensuring optimal performance and longevity.

Parts Replacement Guide

This section provides essential information for replacing components in utility vehicles. Proper maintenance and timely part replacements enhance performance and longevity, ensuring reliable operation in various conditions.

Identifying Necessary Components

Before commencing any replacement work, it is crucial to accurately identify the components that require attention. Consult the specifications for compatibility and performance standards. Regular inspections can help detect wear and tear, allowing for proactive maintenance.

Replacement Procedure

Follow these general steps to ensure effective replacement:

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and replacement parts. |

| 2 | Ensure the vehicle is on a stable surface and powered off. |

| 3 | Remove the old component carefully to avoid damage. |

| 4 | Install the new part, ensuring proper alignment and fit. |

| 5 | Test the installation by checking functionality. |

Safety Precautions During Repairs

Ensuring safety while conducting maintenance and service tasks is paramount. Proper precautions help prevent accidents and injuries, promoting a secure working environment. This section outlines essential guidelines to follow, emphasizing the importance of preparation and awareness during mechanical interventions.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is critical. This includes safety goggles, gloves, and sturdy footwear to protect against potential hazards. Proper attire minimizes the risk of injury from sharp tools or hazardous materials encountered during the service process.

Work Area Safety

Maintaining a clean and organized workspace significantly reduces the likelihood of accidents. Ensure that tools and materials are stored properly and that the area is free from obstructions. Adequate ventilation is also essential, particularly when working with chemicals or materials that produce harmful fumes.

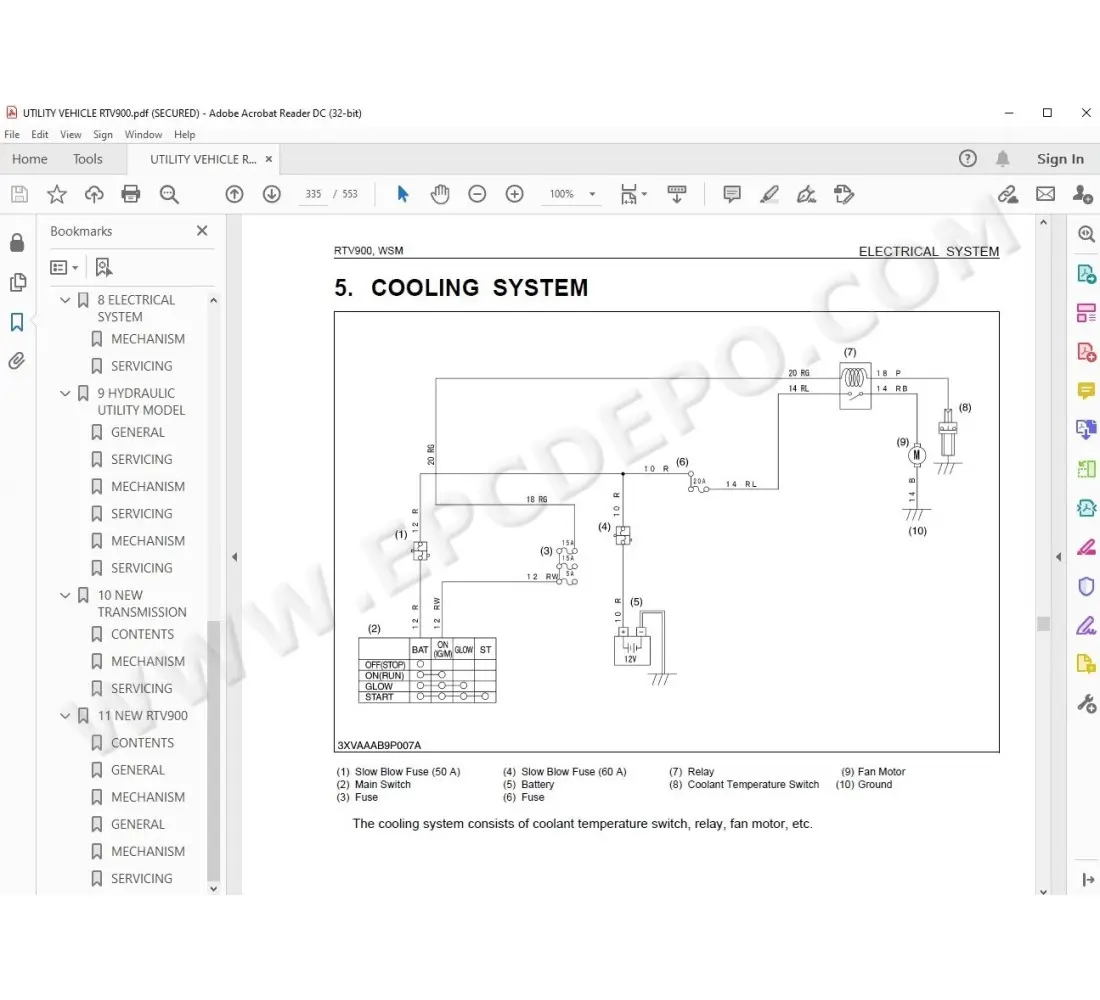

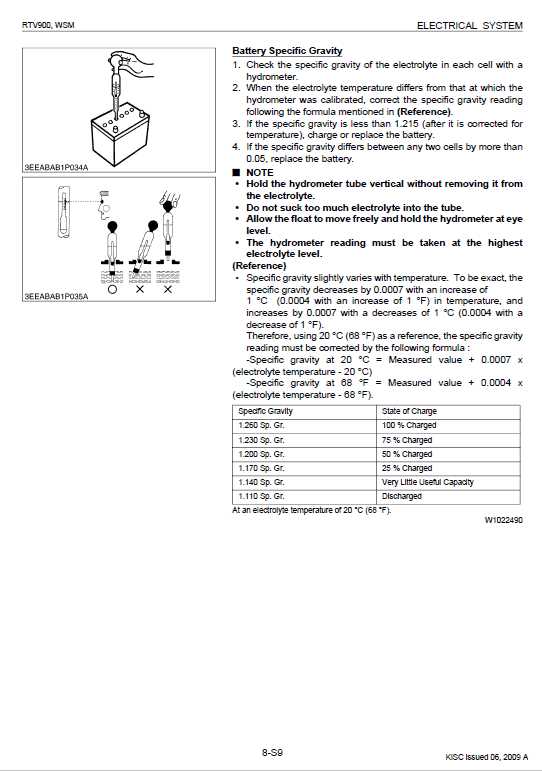

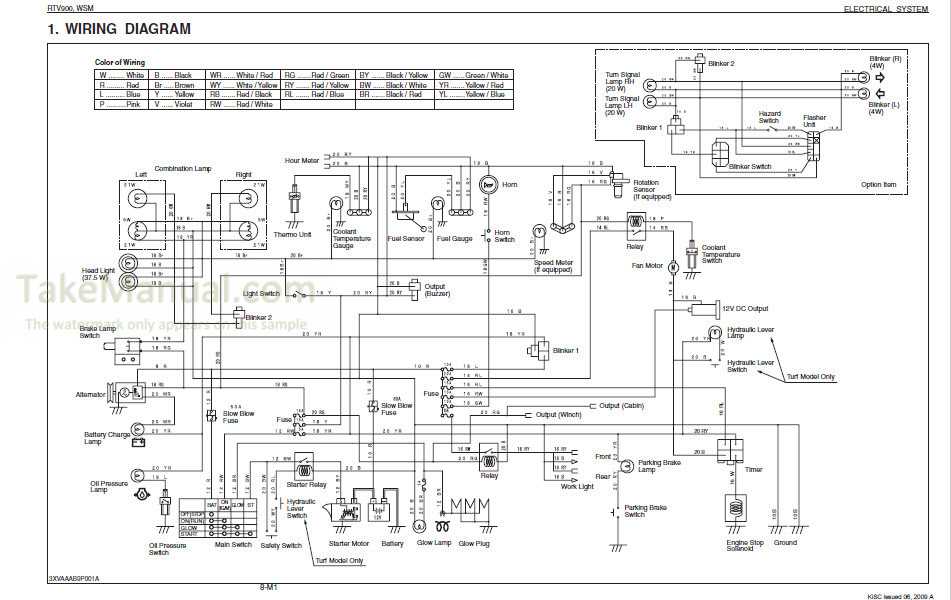

Wiring Diagram and Electrical Components

This section provides an overview of the electrical layout and key components found in utility vehicles, emphasizing their interconnections and functionality. Understanding the wiring diagram is essential for troubleshooting issues and ensuring efficient operation.

Key Electrical Parts

Important electrical components include the battery, starter motor, and various sensors. These elements work together to power the vehicle and enable essential features, such as lighting and instrumentation.

Importance of Wiring Diagrams

A clear wiring diagram serves as a crucial tool for maintenance and repair tasks. It illustrates the relationships between components, aiding in the identification of faults and facilitating effective troubleshooting.

Engine Specifications and Adjustments

This section outlines the critical parameters and necessary modifications for optimizing engine performance in utility vehicles. Understanding these specifications is essential for ensuring smooth operation and longevity of the machinery.

Technical Parameters

The engine’s capacity, power output, and torque ratings are vital components that influence overall performance. It is important to consider the following specifications:

- Displacement: The volume displaced by the pistons in a single cycle, measured in liters or cubic centimeters.

- Horsepower: A measure of engine power output, indicative of the vehicle’s performance capabilities.

- Torque: The rotational force produced by the engine, crucial for handling heavy loads.

Adjustments for Optimal Performance

Regular adjustments are necessary to maintain engine efficiency. Key areas to focus on include:

- Valvetrain Adjustments: Proper clearance settings ensure efficient valve operation, impacting power and fuel efficiency.

- Fuel System Calibration: Ensuring the fuel mixture is optimal for combustion leads to improved performance and reduced emissions.

- Ignition Timing: Adjusting ignition timing can enhance engine responsiveness and fuel economy.

By adhering to these specifications and making necessary adjustments, operators can significantly enhance the operational efficiency of their vehicles.

After Repair: Testing and Validation

Once the maintenance tasks are completed, it is essential to ensure that the vehicle operates efficiently and reliably. The process of evaluation involves a series of systematic checks to confirm that all components function as intended.

The following steps should be taken during the validation phase:

- Visual Inspection: Check all areas for signs of leaks, loose fittings, or any other visible issues.

- Functional Testing: Operate the vehicle to verify that all systems perform properly. This includes testing the steering, braking, and power delivery.

- Performance Assessment: Monitor the vehicle under various conditions to ensure it meets expected performance standards.

- Noise Evaluation: Listen for any unusual sounds that may indicate underlying problems.

- Safety Checks: Confirm that all safety features are operational, including lights and signals.

After completing these evaluations, document the results and make any necessary adjustments to optimize the vehicle’s performance and safety.