Proper functioning of water control mechanisms is essential for an efficient plumbing system. Understanding how to address common issues can significantly enhance the longevity and performance of these fixtures. Whether it’s addressing leaks, low water pressure, or malfunctioning controls, having the right information at hand can simplify the process.

In this section, we will explore the essential steps to troubleshoot and fix various complications associated with these important devices. By utilizing a systematic approach and familiarizing yourself with the components involved, you can regain optimal functionality without the need for professional intervention.

Equipping yourself with knowledge about potential challenges and solutions not only empowers you as a homeowner but also contributes to more sustainable water usage. Let’s dive into the specifics and ensure your system operates smoothly and efficiently.

Understanding Delta Shower Faucet Components

To effectively maintain and troubleshoot your water control system, it’s crucial to familiarize yourself with its various elements. Each part plays a significant role in ensuring proper functionality and a smooth experience.

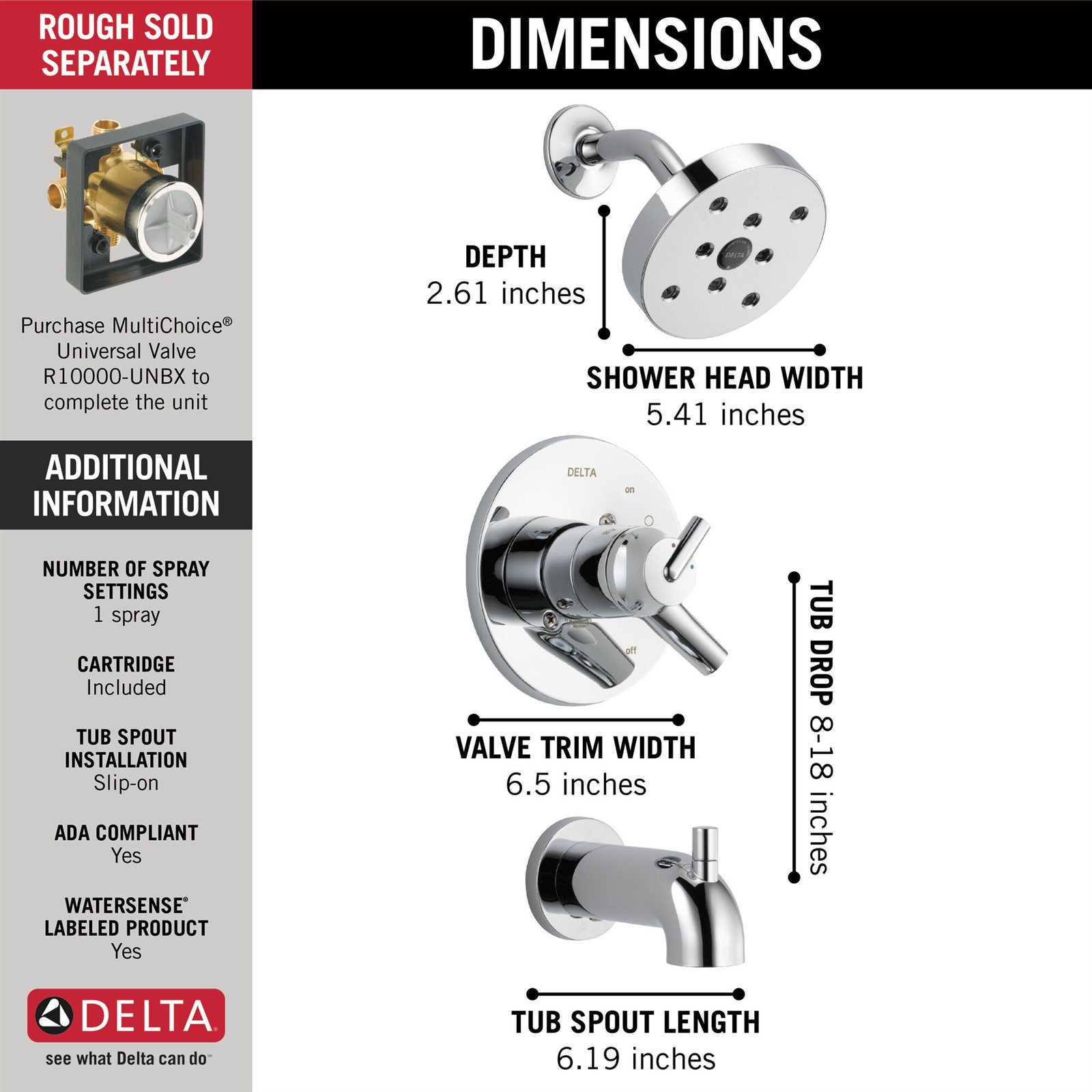

The main components typically found in such systems include:

- Handle: The part that users manipulate to adjust the flow and temperature of the liquid.

- Cartridge: A crucial element that controls the mixing of hot and cold fluids, providing the desired temperature.

- Escutcheon Plate: The decorative cover that conceals the mounting hardware and adds aesthetic value.

- Spout: The outlet through which the liquid is dispensed, designed for optimal flow.

- Valve: Responsible for regulating water flow, ensuring that the system operates smoothly.

Each component must work in harmony to provide an efficient and reliable experience. Understanding their functions can greatly assist in identifying issues and ensuring longevity.

Common Issues with Shower Faucets

Maintaining a steady flow of water from your fixtures can sometimes be challenging. Various problems can arise, impacting both functionality and comfort. Understanding these common difficulties can help homeowners address them effectively.

Leaking is one of the most frequent issues encountered. Water may drip from the handle or base, indicating a worn-out seal or cartridge. This not only wastes water but can also lead to increased utility bills.

Temperature fluctuations can cause discomfort during use. If the water temperature changes unexpectedly, it may signal a malfunctioning mixing valve, preventing proper hot and cold water regulation.

Low water pressure is another common complaint. Clogs in the aerator or issues with plumbing can restrict flow, resulting in a frustrating experience during bathing. Regular cleaning and maintenance can help alleviate this problem.

Hard-to-turn handles can indicate internal wear. If the controls are stiff or difficult to adjust, it may be time to replace components to ensure smooth operation.

Tools Needed for Repairing Faucets

When it comes to addressing issues with water fixtures, having the right equipment is crucial for a successful outcome. Various instruments can facilitate the process, ensuring that the task is completed efficiently and effectively. This section outlines essential items to consider before beginning any project related to plumbing hardware.

Essential Instruments

Basic hand tools, such as wrenches and screwdrivers, are indispensable for loosening or tightening components. A basin wrench can be particularly useful for reaching difficult areas. Additionally, pliers provide grip and leverage for handling small parts, while a utility knife may help in removing old seals or gaskets.

Specialized Equipment

In certain situations, having specialized tools can save time and effort. A pipe wrench is ideal for gripping round surfaces, while a torque wrench ensures that connections are secured to the manufacturer’s specifications. Moreover, a plumber’s tape can help prevent leaks by providing a reliable seal between threaded connections.

Step-by-Step Disassembly Process

Understanding the procedure for taking apart a water control unit is crucial for effective troubleshooting and maintenance. This section will guide you through each phase, ensuring that every component is handled carefully and efficiently.

Required Tools

Before you begin, gather the necessary tools to facilitate a smooth disassembly:

| Tool | Purpose |

|---|---|

| Screwdriver | To remove screws and fixtures |

| Adjustable Wrench | For loosening nuts and bolts |

| Pliers | To grip and pull components |

| Towel | To catch any water that may leak during the process |

Disassembly Steps

Follow these steps to effectively disassemble the unit:

- Turn off the water supply to prevent any leakage.

- Remove any decorative covers to access the screws.

- Unscrew and detach the handle using the screwdriver.

- Loosen the retaining nut with the adjustable wrench.

- Carefully pull the cartridge or valve assembly out of the housing.

- Inspect each component for wear or damage before proceeding with reassembly.

Replacing Worn-Out Seals and Washers

Over time, the components responsible for preventing leaks can wear down, leading to inefficiency and potential damage. Replacing these critical parts is essential for maintaining optimal performance and water conservation.

Before starting the replacement process, gather the necessary tools and materials:

- Adjustable wrench

- Screwdriver

- Replacement seals and washers

- Plumber’s grease

- Clean cloth

Follow these steps to successfully replace the worn components:

- Turn Off Water Supply: Ensure that the water supply to the system is completely shut off to avoid any spills.

- Disassemble the Unit: Carefully remove the handle and other outer components using a screwdriver. Keep track of all parts for easy reassembly.

- Inspect and Remove Old Parts: Check the condition of the seals and washers. Remove any worn-out components, taking note of their original positioning.

- Install New Seals and Washers: Position the new components in the same locations as the old ones. Apply a small amount of plumber’s grease to ensure a proper fit.

- Reassemble the Unit: Put the outer components back in place, ensuring everything is tightened securely.

- Turn On Water Supply: Slowly restore the water supply and check for leaks around the newly replaced parts.

Regular maintenance of these components will extend the life of the system and help prevent future issues. Always keep an eye out for signs of wear, and address them promptly to ensure continued efficiency.

How to Identify Faucet Model

Determining the specific type of plumbing fixture can be essential for maintenance or replacement tasks. Knowing the exact model helps in acquiring the right parts and understanding the features unique to that particular unit.

Step-by-Step Identification Process

- Examine the Body: Look for any markings or numbers stamped on the body of the unit. These often include the manufacturer’s name and a model number.

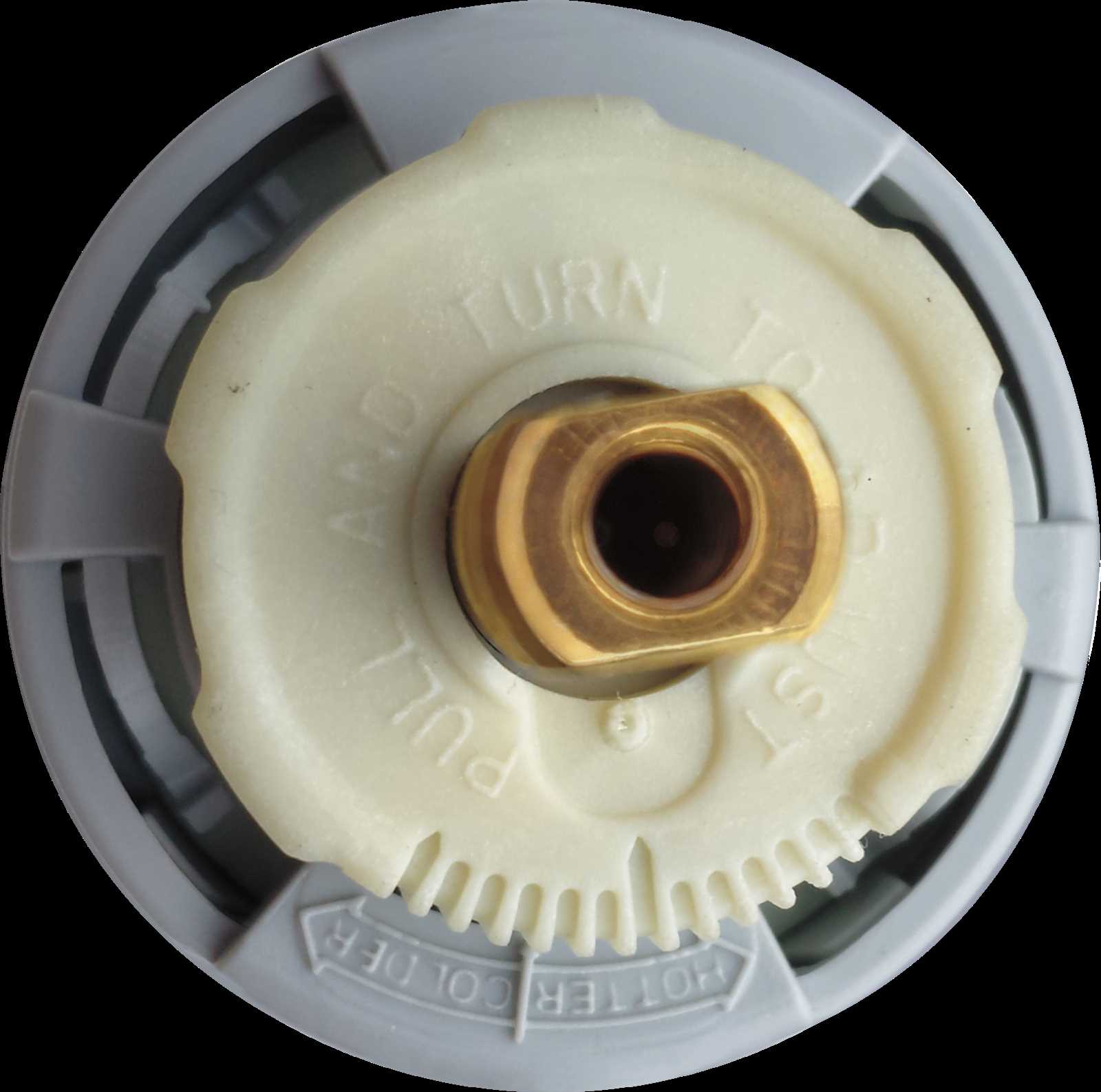

- Check the Handle: Remove the handle to see if there’s an identifier located underneath. Many models have their information discreetly placed in this area.

- Look for Installation Guides: If you have access to the original documentation, it may contain crucial details about the model and specifications.

Helpful Tips

- Take a Clear Photo: If you’re having trouble identifying the unit, a clear photograph can be helpful when consulting a professional or searching online.

- Consult Online Resources: Manufacturer websites often provide databases where you can input characteristics to help pinpoint the exact model.

- Ask for Assistance: Don’t hesitate to seek help from hardware store staff or online forums where experts can assist in identifying your fixture.

Proper Techniques for Reassembly

Reassembling components after maintenance requires careful attention to detail and systematic approaches. Following a methodical process ensures that all parts fit correctly and function as intended, preventing future issues.

Here are some essential techniques to keep in mind during the reassembly phase:

-

Organize Components:

- Lay out all parts in the order they will be reassembled.

- Use a clean workspace to avoid losing small components.

-

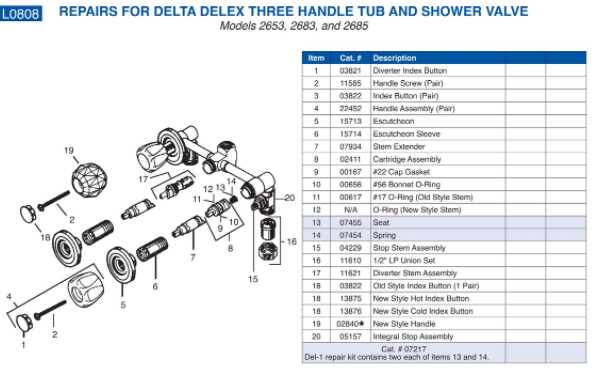

Refer to Documentation:

- Consult any available diagrams or instructions for guidance.

- Ensure you understand the function of each part before proceeding.

-

Use Appropriate Tools:

- Select tools that match the size and type of fasteners used.

- Avoid using makeshift tools that can damage parts.

-

Follow a Sequence:

- Reassemble parts in a logical order, starting from the interior to the exterior.

- Double-check the alignment of components before tightening.

-

Test Functionality:

- After reassembly, run a test to ensure everything operates smoothly.

- Look for leaks or unusual sounds that might indicate a problem.

By adhering to these techniques, you can successfully bring components back together, ensuring longevity and reliable performance.

Testing for Leaks After Repair

Ensuring that your plumbing installation is functioning properly after any adjustments is crucial. A thorough assessment helps to confirm that all connections are secure and that there are no unwanted water escapes, which can lead to damage and increased utility bills.

Initial Inspection

Start with a visual check of the entire area where the modifications were made. Look for any signs of moisture or water pooling around joints or connections. Pay special attention to the seals, as these are common points for potential issues.

Pressure Test

To further ascertain that everything is sealed correctly, conduct a pressure test. This involves turning on the water supply and allowing it to reach its maximum pressure. Observe for any leaks during this period. If water begins to escape from any joints, it may indicate that the seals are compromised and require additional tightening or replacement.

Implementing these steps will help ensure that your installation remains leak-free and functions as intended.

Regular Maintenance Tips for Longevity

Ensuring the durability of your plumbing fixtures requires consistent care and attention. By following a few simple guidelines, you can prevent common issues and extend the lifespan of your installations.

- Inspect Regularly: Check for any signs of leaks or wear. Early detection can save you from costly repairs.

- Clean Components: Regularly clean the surfaces and internal parts to remove mineral buildup. Use gentle cleaners to avoid damaging finishes.

- Check Water Pressure: High pressure can lead to wear and tear. Use a gauge to monitor levels and adjust if necessary.

- Replace Washers and O-Rings: These parts can degrade over time. Replacing them periodically can prevent leaks and ensure proper function.

- Maintain Temperature Control: Regularly test and adjust temperature settings to avoid stress on the mechanisms.

By implementing these maintenance practices, you can enhance the performance and longevity of your plumbing fixtures, ensuring they operate smoothly for years to come.

When to Call a Professional

Determining when to seek assistance from an expert can be crucial in avoiding further complications. While many issues can be resolved independently, some situations require specialized knowledge and tools.

Signs You Need Expert Help

- Persistent leaks that do not improve with basic maintenance.

- Unusual noises or vibrations that indicate underlying issues.

- Water pressure fluctuations that are inconsistent and troubling.

- Visible damage to components that may lead to bigger problems.

- Difficulty understanding or following troubleshooting steps.

Benefits of Hiring a Specialist

- Access to advanced tools and techniques for effective solutions.

- Professional experience ensures a thorough examination of the problem.

- Warranty protection and assurance of quality workmanship.

- Time-saving, allowing you to focus on other important tasks.

Resources for Further Assistance

For those seeking additional support with their plumbing fixtures, numerous avenues are available to enhance your understanding and resolve any issues. Accessing the right information can significantly simplify the troubleshooting process and ensure effective solutions.

Online Forums: Engaging in community discussions can provide valuable insights. Websites dedicated to home improvement often feature threads where individuals share experiences, tips, and solutions to common challenges.

Instructional Videos: Visual learners may benefit from video tutorials available on various platforms. These resources often demonstrate step-by-step procedures, making it easier to grasp complex tasks and techniques.

Manufacturer’s Website: The official website of the manufacturer can be an excellent source of comprehensive guidance. It frequently includes FAQs, troubleshooting tips, and downloadable documents to assist users with their specific models.

Local Hardware Stores: Don’t underestimate the expertise of local retailers. Staff members are usually well-versed in common issues and can provide advice or direct you to useful products for your needs.

Professional Services: When in doubt, seeking help from qualified professionals can be a wise choice. Licensed plumbers can offer expert assessments and resolve complex problems that may arise.