Maintaining a crafting device is essential for ensuring its longevity and optimal performance. This section provides insights into common issues that users may encounter and offers practical solutions to enhance functionality. Understanding the mechanics behind these tools can significantly improve the user experience.

Regular maintenance not only extends the lifespan of the equipment but also ensures smooth operation. Users can benefit from familiarizing themselves with troubleshooting techniques that address frequent challenges. Equipped with the right knowledge, crafters can easily navigate through potential setbacks and continue their creative projects without interruption.

Kenmore Sewing Machine 385 Repair Manual

Maintaining and troubleshooting your fabric crafting apparatus is essential for optimal performance. Understanding the common issues and solutions can enhance your experience and prolong the lifespan of your device.

Identifying Issues: Recognizing the signs of malfunction is the first step in effective maintenance. Common problems may include uneven stitching, unusual noises, or difficulty in threading. Observing these symptoms can guide you in pinpointing the underlying cause.

Basic Troubleshooting Steps: Begin by consulting the guidelines for basic adjustments. This may involve checking the threading mechanism, ensuring proper tension settings, or inspecting the needle for damage. Simple fixes can often resolve many issues without the need for professional assistance.

When to Seek Professional Help: If problems persist despite your efforts, it may be time to contact a skilled technician. Complicated mechanical failures or electronic malfunctions typically require specialized knowledge and tools for effective resolution.

Common Issues and Solutions

Understanding the frequent challenges that can arise with fabric crafting devices is essential for maintaining optimal performance. This section explores typical problems and offers practical solutions to enhance usability and longevity.

Thread Jamming: One of the most common complications involves the thread becoming stuck in the mechanism. This can often be resolved by ensuring the threading process is correct and that the tension settings are appropriately adjusted.

Uneven Stitching: If the stitches appear irregular, it may indicate an issue with the needle or thread quality. Replacing the needle with a suitable type for the fabric and using high-quality thread can significantly improve stitching consistency.

Skipping Stitches: This problem may arise due to a dull needle or incorrect threading. Regularly changing the needle and double-checking the threading path can help eliminate this issue.

Foot Pedal Malfunction: If the foot pedal does not respond as expected, inspect the connections for any damage. Cleaning the pedal and ensuring it is securely connected can often resolve the problem.

Essential Tools for Repairs

When addressing issues in fabric-related equipment, having the right instruments at your disposal is crucial. A well-equipped toolkit can facilitate effective troubleshooting and enhance the overall maintenance experience. Below are some fundamental items that every technician should consider for successful interventions.

Basic Hand Tools

The following hand tools are indispensable for any repair tasks:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws |

| Pliers | For gripping and manipulating small components |

| Wrench Set | For tightening bolts and nuts |

| Scissors | For cutting threads or fabrics |

Specialized Equipment

In addition to basic tools, some specialized equipment may be required for more intricate repairs:

| Tool | Purpose |

|---|---|

| Cleaning Brush | To remove lint and debris |

| Lubricant | For maintaining moving parts |

| Replacement Parts | Essential for addressing faulty components |

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues encountered with fabric manipulation devices. By following a systematic method, users can efficiently identify the root causes of problems and apply suitable solutions.

Identifying Common Issues

- Check for inconsistent fabric feeding.

- Inspect the stitching quality for irregularities.

- Examine any unusual noises during operation.

Troubleshooting Steps

- Ensure the device is properly plugged in and powered on.

- Verify that the fabric is correctly positioned.

- Inspect the threading process to ensure it follows the manufacturer’s guidelines.

- Clean the device to remove any lint or debris.

- Test with different fabric types to rule out material issues.

Maintaining Your Sewing Equipment

Regular upkeep is essential for ensuring smooth operation and prolonging the life of your equipment. By dedicating time to routine maintenance, you can prevent common issues and enjoy uninterrupted, precise results in your projects.

Cleaning Tips

Keeping your device free of dust and debris is key to optimal performance. Follow these steps for effective cleaning:

- Use a small brush or compressed air to remove lint buildup from hard-to-reach areas.

- Wipe down external surfaces with a soft, dry cloth to keep them clean and dust-free.

- Avoid using water or liquid cleaners directly on the device to prevent any moisture damage.

Lubrication and Inspection

Proper lubrication is vital for the efficient function of the internal mechanisms. Regularly check and oil the moving parts to reduce wear and tear:

How to Replace the Needle

Changing the needle is an essential maintenance task that ensures smooth operation and optimal performance of your textile crafting equipment. A dull or damaged needle can lead to various issues, including skipped stitches or fabric snags, making it crucial to address this task regularly.

To begin, gather the necessary tools: a new needle compatible with your device and a small screwdriver, if required. First, turn off the power to the device for safety. Next, locate the needle holder, which is typically found at the front of the needle bar.

Using the screwdriver, loosen the needle clamp screw and gently remove the old needle by sliding it downwards. Ensure that the flat side of the new needle is facing the back of the holder. Insert the new needle into the holder until it is fully seated, then tighten the clamp screw securely.

Once the new needle is in place, turn the handwheel to make sure it moves freely and does not interfere with the presser foot or other components. Finally, power on the device and test it on a scrap piece of fabric to confirm that everything is functioning smoothly.

Cleaning Tips for Longevity

Maintaining the optimal performance of your equipment involves regular cleaning practices that ensure longevity and functionality. By following simple yet effective care routines, you can significantly extend the lifespan of your device, keeping it in prime condition for all your creative projects.

Routine Maintenance Steps

- Dust the exterior regularly to prevent buildup.

- Use a soft brush to clean hard-to-reach areas.

- Wipe surfaces with a damp cloth to remove dirt and stains.

- Check for loose parts and tighten them as necessary.

Internal Cleaning Tips

Periodic internal cleaning is essential for optimal performance. Follow these suggestions to keep the internal components clean:

- Remove lint and debris from the interior using a vacuum with a soft nozzle.

- Use compressed air to blow out dust from tight spaces.

- Inspect belts and gears for wear, cleaning them gently with appropriate tools.

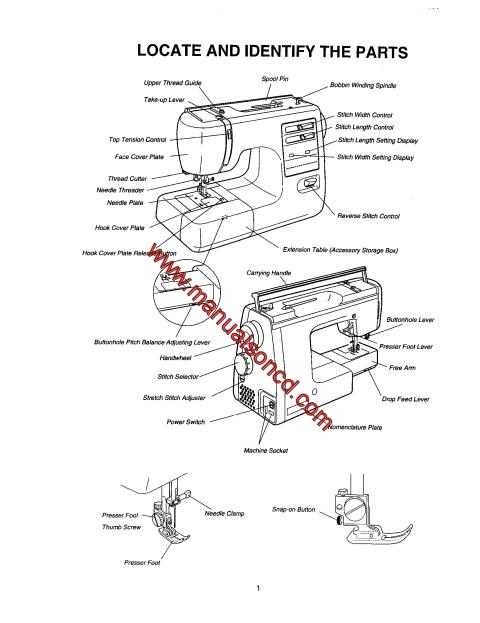

Understanding Machine Settings

Grasping the configurations of your apparatus is essential for achieving optimal performance. Adjusting various parameters can significantly enhance your crafting experience, ensuring precision and efficiency in every project. This section delves into the fundamental aspects of these adjustments, offering insights into how they can affect your outcomes.

Key Adjustments and Their Effects

Each setting plays a crucial role in determining how the device operates. Tension control, stitch length, and feed rate are among the primary elements that influence the quality of your work. Fine-tuning these variables allows for better control over the final product, whether it’s for delicate fabrics or heavier materials.

Common Configuration Challenges

Many users encounter difficulties when navigating through the various settings. Issues such as inconsistent stitching or fabric puckering often arise from improper adjustments. Understanding the purpose of each setting will empower you to troubleshoot effectively, leading to improved results and a more enjoyable crafting experience.

Fixing Thread Tension Problems

Thread tension issues can significantly impact the quality of your stitching, leading to frustration during your crafting projects. It’s essential to understand the common causes of these problems to achieve the perfect balance, ensuring even and consistent stitches. Addressing tension can often be a straightforward process, requiring minimal adjustments to restore optimal performance.

Identifying Tension Issues

Common indicators of improper tension include uneven stitches, puckering fabric, and thread breakage. Start by inspecting the upper and lower threads for any signs of fraying or knotting. Additionally, observe the stitching on your fabric; it should appear smooth and uniform. If you notice any discrepancies, it’s likely that adjustments are needed to rectify the tension settings.

Adjusting Tension Settings

Most threading devices have adjustable tension controls. Begin by turning the tension dial slightly and testing your stitch on a scrap piece of fabric. If the stitches remain uneven, continue making small adjustments until you achieve the desired results. Always ensure that both upper and lower tensions are aligned correctly for the best outcome.

Addressing Motor Malfunctions

Issues related to the motor can significantly impact the functionality of your device. Understanding the common symptoms and causes of these malfunctions is essential for effective troubleshooting and ensuring smooth operation. This section will guide you through identifying and resolving motor-related problems, enhancing the overall performance of your equipment.

Identifying Common Symptoms

Recognizing the signs of motor malfunctions is the first step towards addressing them. Look for unusual noises, such as grinding or clicking, which may indicate internal wear or misalignment. Additionally, if the motor fails to start or operates intermittently, it could signal issues with electrical connections or components.

Troubleshooting Steps

Begin troubleshooting by inspecting the power source and ensuring all connections are secure. Check for any visible damage to wires or connectors. If the device remains unresponsive, consider examining the motor brushes, as worn brushes can hinder performance. Cleaning or replacing them may resolve the issue. For persistent problems, consult a professional for further diagnosis and repairs.

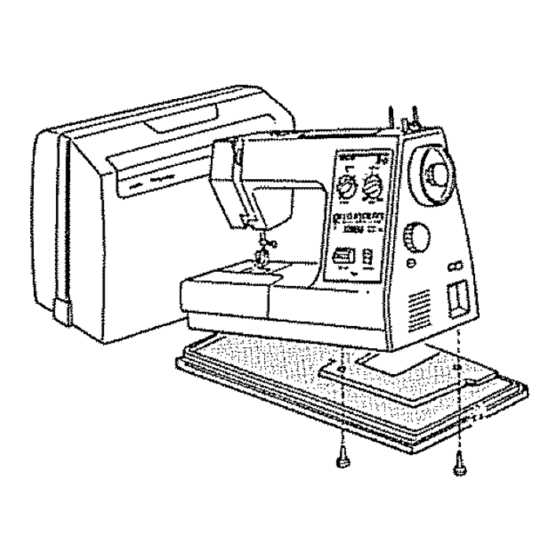

Replacing Worn Parts

Over time, components of a textile apparatus may wear out, impacting performance and functionality. It is essential to identify and replace these elements to ensure smooth operation. This section provides guidance on how to recognize signs of wear and the steps to effectively substitute these parts.

Identifying Worn Components

Common indicators of deterioration include unusual noises, inconsistent stitching, and difficulty in operation. Regular inspections can help in detecting these issues early, preventing further complications.

Steps for Replacement

Once you have identified the worn parts, follow these steps for successful replacement:

| Step | Description |

|---|---|

| 1 | Gather the necessary tools and replacement components. |

| 2 | Unplug the device and ensure it is safe to work on. |

| 3 | Carefully remove the worn part, taking note of its installation. |

| 4 | Install the new component, ensuring it is securely fitted. |

| 5 | Reconnect the device and test its functionality. |

How to Oil Your Machine

Regular lubrication is essential for ensuring the longevity and smooth operation of your equipment. Proper oiling reduces friction between moving parts, preventing wear and tear and helping to maintain optimal performance. This guide will outline the key steps to effectively oil your apparatus.

Gather Necessary Supplies

Before starting the lubrication process, collect the required tools. You will need high-quality sewing oil, a small brush or dropper for precise application, and a clean cloth to wipe away any excess oil. Ensure that the work area is well-lit and free from clutter to facilitate easy access to your tools.

Locate Oil Points

Consult the user documentation or guidelines specific to your device to identify the oiling points. Common areas that require lubrication include the needle bar, presser foot lever, and any gears or moving parts that are visible. Apply a few drops of oil to each identified spot, ensuring not to over-oil, as excess can attract dust and lint.

Helpful Resources and Support

Accessing reliable information and assistance can significantly enhance the experience of using your device. Various platforms and communities offer valuable insights, tips, and troubleshooting techniques that can prove beneficial. Whether you are seeking basic guidance or advanced solutions, these resources can empower you to optimize your usage and resolve any issues you may encounter.

Online Communities and Forums

Participating in online communities dedicated to your device can provide a wealth of knowledge. Many enthusiasts share their experiences, discuss common challenges, and offer practical solutions. Engaging with these forums allows you to ask questions, gain insights from others, and even find step-by-step guides tailored to specific situations.

Official Support Channels

Utilizing official support channels is essential for obtaining accurate and up-to-date information. Manufacturers often provide extensive documentation, FAQs, and customer service resources on their websites. Accessing these platforms ensures you receive reliable guidance tailored to your specific needs, enhancing your overall experience.