Proper upkeep of air-powered devices is essential for ensuring longevity and optimal performance. This section focuses on essential practices that every owner should consider to maintain their equipment effectively. Understanding common issues and their solutions can significantly enhance the user experience and prolong the life of the device.

Whether you are encountering performance issues or simply wish to enhance the functionality of your apparatus, familiarizing yourself with basic maintenance techniques is crucial. Identifying potential problems early can save time and resources, allowing enthusiasts to enjoy their hobby without unnecessary interruptions. Regular checks and simple adjustments can lead to a more satisfying experience.

In this guide, you will find practical tips and strategies for diagnosing common faults and performing necessary adjustments. By following these recommendations, users can ensure their equipment remains in top condition, ready for use whenever the need arises. Engaging in routine maintenance will not only improve performance but also enhance safety, providing peace of mind while using the device.

This section outlines a structured approach for an informative piece focused on the maintenance and troubleshooting of a specific air-powered device. The aim is to provide enthusiasts with essential insights and practical guidance to ensure optimal performance and longevity.

Understanding Your Device

Gaining a clear understanding of the components and functionality is crucial. Familiarity with how each part contributes to the overall operation will aid in recognizing potential issues.

Common Issues Encountered

Identifying frequent problems can streamline the troubleshooting process. Users often face similar challenges, making it beneficial to compile these observations.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Loss of Pressure | Poor performance, inconsistent firing | Leaking seals, damaged valve |

| Misfeeding | Inconsistent shots, jamming | Obstructions in the chamber, defective magazine |

| Inaccurate Shooting | Wider groupings, stray shots | Worn barrel, misaligned sights |

By addressing these common concerns, users can better prepare themselves for effective interventions. This understanding leads to more efficient maintenance strategies, ensuring the device remains in top condition.

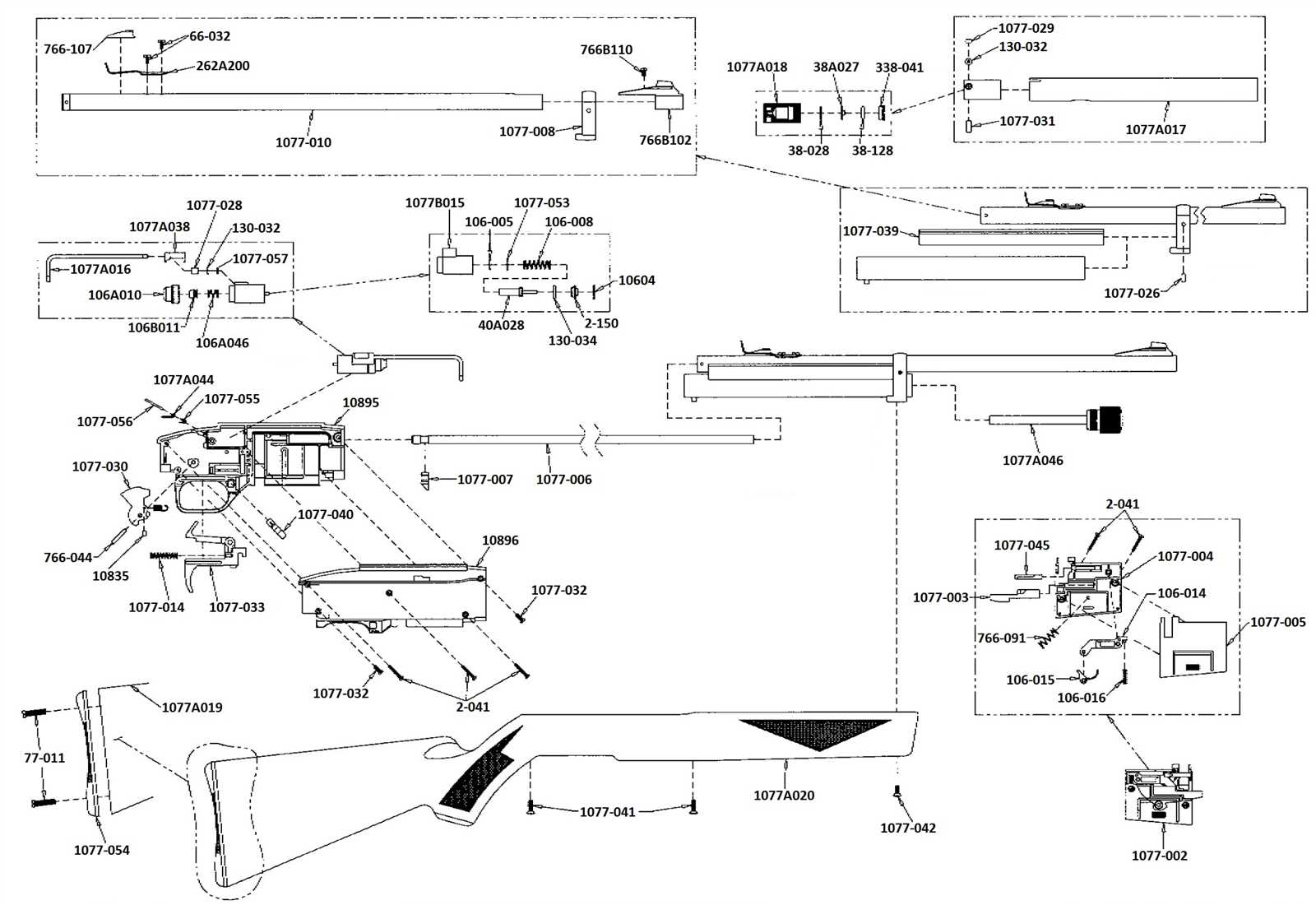

Understanding Crosman 1077 Components

In this section, we will delve into the various parts that make up this air rifle, providing insights into their functions and significance. A comprehensive understanding of these elements is essential for optimal performance and maintenance of the firearm.

Key Parts Overview

Each component of the device plays a vital role in its overall operation. From the barrel that directs the projectile to the trigger mechanism that initiates firing, every part must work harmoniously to ensure reliability and accuracy. Familiarizing oneself with these parts is crucial for effective handling.

Maintenance and Care

Regular inspection and care of the components can prevent malfunctions and prolong the life of the firearm. Understanding the specific functions of each element will aid in identifying potential issues and addressing them promptly. Proper upkeep is not only beneficial for performance but also enhances safety during use.

Common Issues with Crosman 1077

This section addresses frequent problems encountered with a popular air rifle model, providing insights into typical malfunctions and their potential causes. Understanding these issues can assist users in identifying and troubleshooting difficulties, enhancing the overall shooting experience.

| Issue | Description | Potential Solutions |

|---|---|---|

| Inconsistent Velocity | Variations in projectile speed may occur, impacting accuracy. | Check for CO2 leaks, ensure proper cartridge installation, and verify the integrity of seals. |

| Feeding Problems | The mechanism may fail to load projectiles correctly, causing jams. | Inspect the loading system for obstructions, clean the magazine, and ensure proper alignment. |

| Accuracy Issues | Groupings may be wider than expected, leading to unsatisfactory performance. | Examine the sight alignment, adjust the scope if applicable, and test with different ammunition. |

| Air Leaks | Loss of gas pressure can lead to diminished power and efficiency. | Inspect all seals and O-rings for wear, replacing any damaged components as needed. |

Tools Needed for Repairs

When undertaking maintenance or fixing issues with a pneumatic device, having the right equipment is essential for achieving optimal results. The appropriate tools not only streamline the process but also help prevent damage to components, ensuring a smooth workflow.

First and foremost, a screwdriver set is crucial, as various screws hold parts together securely. Having both flathead and Phillips screwdrivers allows for flexibility in handling different types of fasteners. Additionally, a wrench set will assist in loosening and tightening nuts and bolts, making adjustments easier.

For more intricate work, a precision tool kit with smaller tools like tweezers and pliers can be invaluable. These tools facilitate access to tight spaces and help manipulate delicate components without causing damage. It is also beneficial to have a cleaning kit on hand to maintain the device in good condition, ensuring longevity and functionality.

Lastly, a reliable work surface or bench provides a stable area for conducting repairs, minimizing the risk of losing small parts and enhancing overall safety during the process. With these essential items, tackling maintenance tasks becomes a more manageable and efficient endeavor.

Step-by-Step Disassembly Guide

This section provides a comprehensive overview of the disassembly process for your air rifle. Following a systematic approach will ensure that each component is carefully removed, allowing for efficient maintenance and troubleshooting. By understanding the layout and function of various parts, you will enhance your ability to manage repairs and upgrades effectively.

Preparation and Safety

Before beginning the disassembly, make sure to prepare your workspace. Gather the necessary tools, such as screwdrivers, pliers, and a clean cloth. Ensure that the air rifle is unloaded and safe to handle to prevent any accidents during the process.

Disassembly Steps

Follow the steps below to carefully disassemble the air rifle:

| Step | Description |

|---|---|

| 1 | Remove any external accessories, such as scopes or sights, to avoid damage. |

| 2 | Locate and unscrew the main body screws using a compatible screwdriver. |

| 3 | Carefully separate the body halves, ensuring not to force any components. |

| 4 | Remove the internal mechanism gently, taking note of its orientation for reassembly. |

| 5 | Inspect each part for wear or damage, replacing any faulty components as needed. |

| 6 | Reassemble by reversing the steps, ensuring all screws are tightened properly. |

Fixing the Air Chamber Problems

The air chamber is a crucial component in pneumatic devices, as it ensures proper pressure regulation for optimal performance. Issues with this part can lead to inefficient operation or complete failure. Understanding how to identify and resolve these problems can greatly enhance the functionality and lifespan of your equipment.

Common Issues with the Air Chamber

- Air Leaks: One of the most frequent problems is the presence of leaks, which can significantly reduce pressure.

- Blockages: Dust and debris can accumulate, obstructing airflow and hindering performance.

- Poor Seals: Worn or damaged seals can allow air to escape, leading to pressure loss.

Steps to Address Air Chamber Problems

- Inspect for Leaks: Use soapy water to detect air leaks around joints and fittings.

- Clean the Chamber: Remove any debris and ensure all pathways are clear.

- Replace Seals: Check seals for wear and replace them if necessary to maintain airtight conditions.

- Test Functionality: After making repairs, test the system to ensure proper operation and pressure levels.

Replacing the Trigger Mechanism

Over time, the trigger assembly of a shooting device may exhibit signs of wear or malfunction, impacting its overall performance. This section provides a detailed guide on how to effectively replace the trigger mechanism, ensuring optimal functionality and safety.

Tools Needed

To successfully carry out the replacement, gather the following tools:

| Tool | Purpose |

|---|---|

| Screwdriver | For removing screws and securing components |

| Pliers | For gripping and manipulating small parts |

| Replacement Trigger Assembly | New mechanism to be installed |

Step-by-Step Instructions

Follow these steps to replace the trigger mechanism:

- Ensure the device is unloaded and safe to handle.

- Remove the screws securing the trigger housing using the screwdriver.

- Carefully detach the old trigger mechanism from the housing.

- Install the new trigger assembly in the same orientation as the original.

- Reattach the trigger housing and secure it with screws.

Maintenance of the Barrel Assembly

Ensuring the optimal performance of a shooting device relies heavily on the proper upkeep of its barrel assembly. Regular maintenance not only enhances accuracy but also prolongs the lifespan of the equipment. This section outlines essential practices to maintain the barrel and ensure smooth operation.

Cleaning the Barrel

Regular cleaning is crucial for maintaining the integrity of the barrel. Follow these steps to effectively clean the assembly:

- Gather necessary materials: cleaning rod, patches, cleaning solution, and a brush.

- Remove the barrel from the device according to the manufacturer’s guidelines.

- Apply a suitable cleaning solution to a patch and insert it into the barrel using the cleaning rod.

- Scrub the interior gently with a brush to dislodge any residue.

- Run dry patches through the barrel until they come out clean.

Inspecting for Damage

Regular inspections are vital to detect any potential issues early. Check for the following:

- Look for cracks or dents along the barrel surface.

- Examine the alignment of the barrel with the main body of the device.

- Ensure that all mounting screws and fittings are secure and not loose.

By following these maintenance practices, the functionality and accuracy of the barrel assembly can be significantly enhanced, ensuring reliable performance during use.

Reassembling the Crosman 1077

Reassembling your air rifle is a crucial step in ensuring its optimal functionality and longevity. Proper assembly allows the various components to work harmoniously, contributing to enhanced performance. This section provides a comprehensive overview of the assembly process, detailing the necessary steps to restore your device effectively.

Gathering the Components

Before you begin the assembly, it is essential to have all the necessary parts at hand. This includes the main body, trigger assembly, barrel, and any additional components that may have been disassembled. Ensuring that you have a clean workspace will help prevent losing any small pieces during the process.

Step-by-Step Assembly Process

Start by attaching the barrel to the main body, ensuring that it fits securely. Next, install the trigger assembly, making sure all screws are tightened appropriately. Pay close attention to any springs or small parts, as they can easily become misplaced. Once all components are in place, perform a thorough check to ensure everything is functioning as intended.

In summary, following these guidelines will assist you in effectively reassembling your air rifle, promoting reliable operation and enhancing your shooting experience.

Testing After Repairs

Once modifications have been made to the device, it is crucial to ensure its functionality and safety. Proper evaluation can help identify any lingering issues and confirm that everything is operating as intended. This section will outline essential steps to effectively assess performance following any adjustments.

Initial Functionality Check

Begin with a thorough examination of all components. Inspect for any loose parts or misalignments that may have occurred during the process. Ensure that the device powers on correctly and that all controls respond appropriately. A systematic approach to this initial check can help in spotting potential concerns early.

Performance Testing

After confirming that the device is intact, it is essential to conduct performance tests. Engage the primary features to verify that they work seamlessly. Pay attention to any unusual noises or behaviors, which may indicate underlying issues. Keeping a log of these observations can provide valuable insights for future reference.

Preventative Measures for Longevity

Ensuring the durability and optimal performance of your equipment requires a proactive approach. By implementing certain strategies, you can significantly extend the lifespan and functionality of your device. This section outlines key practices to maintain and enhance the reliability of your apparatus over time.

Regular Maintenance

Consistent upkeep is essential for preventing wear and tear. Routine checks can help identify potential issues before they escalate. Simple tasks like cleaning and lubrication can make a substantial difference. Below is a summary of recommended maintenance tasks:

| Task | Frequency | Benefits |

|---|---|---|

| Inspect seals and joints | Monthly | Prevents leaks and ensures airtightness |

| Clean exterior | Every few weeks | Reduces dirt buildup and potential corrosion |

| Lubricate moving parts | Every 3 months | Minimizes friction and wear |

| Check battery levels | Monthly | Ensures consistent power supply |

Proper Storage

Storing your equipment correctly is vital for its longevity. It’s crucial to keep it in a dry, temperature-controlled environment to avoid damage from moisture or extreme temperatures. Protective cases can also help shield it from dust and impact.

Where to Find Replacement Parts

Locating suitable components for your airgun can significantly enhance its performance and longevity. Various resources are available for enthusiasts seeking to replace or upgrade essential parts, ensuring your equipment remains in optimal condition.

Online Retailers

Numerous online stores specialize in firearm accessories and components. These platforms often provide a wide range of parts tailored for different models. Be sure to compare prices and read customer reviews to ensure you’re purchasing high-quality items.

Local Gun Shops

Your nearby firearms retailer may carry parts or can assist in ordering specific components. Building a relationship with local shop owners can lead to valuable advice and recommendations for sourcing rare or specialized items.