Understanding the intricacies of a beloved crafting tool can be both rewarding and essential for maintaining its longevity. This section delves into various methods and strategies aimed at revitalizing these cherished instruments, ensuring they continue to perform at their best for years to come. With a focus on practical solutions, the information provided here is tailored for enthusiasts and novices alike.

From identifying common issues to implementing effective fixes, this guide will equip you with the knowledge needed to tackle challenges head-on. Each step is designed to demystify the process, enabling you to approach repairs with confidence and clarity. Whether you’re looking to enhance performance or simply extend the lifespan of your equipment, this resource offers valuable insights.

Additionally, understanding the construction and components of your device will empower you to make informed decisions. With careful attention to detail and a commitment to quality, you can restore functionality and enjoy the satisfaction of a job well done. Let this guide serve as your companion on the journey to maintaining your treasured tools.

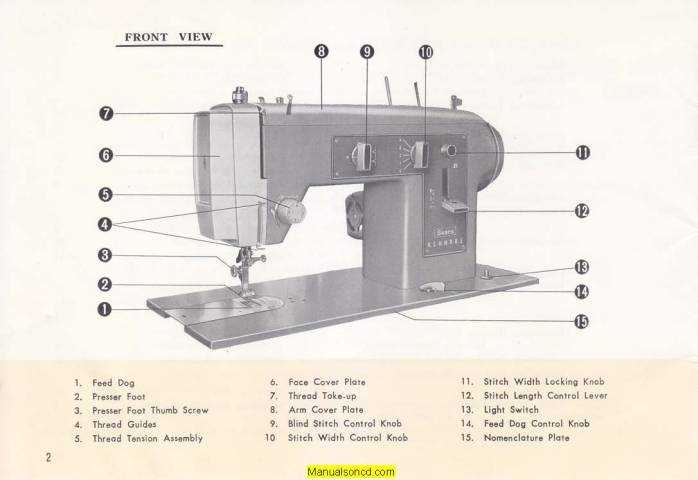

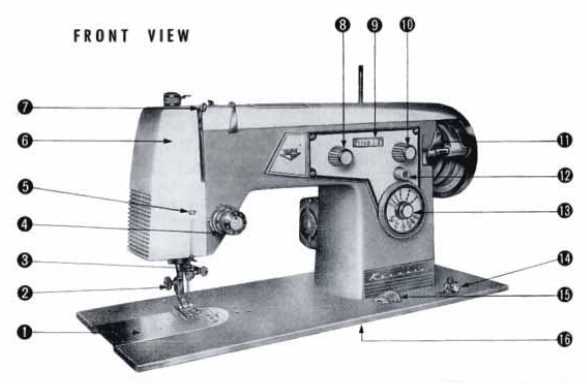

Overview of Kenmore 158 Sewing Machines

This section provides insight into a popular model known for its reliability and versatility in textile crafting. Many enthusiasts appreciate its user-friendly design and robust construction, which cater to both beginners and seasoned users alike.

Characterized by a variety of features, this particular unit excels in delivering consistent performance. Its comprehensive set of functions allows for a wide range of creative projects, from basic alterations to intricate designs.

| Feature | Description |

|---|---|

| Stitch Options | A diverse selection of stitching patterns, including straight, zigzag, and decorative stitches. |

| Built Quality | Designed with durable materials to withstand frequent use and provide longevity. |

| User Interface | An intuitive interface that simplifies the selection of functions and adjustments. |

| Accessory Compatibility | Compatible with a wide range of attachments and feet for enhanced functionality. |

This model has stood the test of time, earning a loyal following due to its performance and ease of use. Whether for everyday tasks or specialized projects, it remains a favored choice in the crafting community.

Common Issues with Kenmore 158 Models

Many users encounter frequent challenges when operating their vintage crafting devices. Understanding these common problems can help enhance performance and extend the life of the unit.

Frequent Problems

- Thread jamming in the feed system

- Inconsistent stitching quality

- Difficulty with tension adjustments

- Need for regular lubrication

Maintenance Tips

- Regularly clean and oil moving parts.

- Check and replace worn components as needed.

- Ensure correct threading before use.

- Consult a specialist for persistent issues.

Essential Tools for Repairing Sewing Machines

When it comes to maintaining and fixing fabric crafting equipment, having the right tools is crucial for achieving effective results. A well-equipped workspace can significantly streamline the process, ensuring that you can address issues efficiently and safely.

Basic Hand Tools are fundamental for any repair endeavor. A good set of screwdrivers, including both flathead and Phillips types, is essential for accessing various components. Additionally, pliers and tweezers are invaluable for handling small parts that may be difficult to grasp.

Cleaning Supplies play a vital role in upkeep. A soft brush and lint-free cloth will help remove dust and debris from intricate areas, while specialized oils designed for machinery can keep moving parts lubricated, reducing wear and tear.

Measuring Instruments are also important. A quality ruler or measuring tape ensures that adjustments are precise, while a seam gauge can assist with ensuring uniformity in fabric handling.

Replacement Parts should be readily available as well. Keeping a stock of common components, such as belts, needles, and bobbins, can save time when troubleshooting unexpected malfunctions.

In conclusion, equipping yourself with these essential tools will not only enhance your ability to perform maintenance tasks but also prolong the lifespan of your equipment, ensuring it continues to function effectively for years to come.

Step-by-Step Troubleshooting Guide

When encountering issues with your crafting device, a systematic approach can often lead to a swift resolution. This guide provides clear steps to identify and address common problems, ensuring optimal performance.

Start by inspecting the power source. Ensure that the device is plugged in securely and that the outlet is functioning. If the power light does not illuminate, try a different outlet or check the power cord for damage.

Next, examine the threading. Incorrect threading can lead to various complications, including skipping stitches or tangling. Refer to the threading diagram specific to your model and rethread the needle and bobbin if necessary.

If you notice inconsistent stitch quality, check the needle. A bent or dull needle can significantly affect performance. Replace the needle with a new one suited for your fabric type and see if this resolves the issue.

Clogged feed dogs may also cause problems with fabric movement. Remove any lint or debris that may have accumulated in this area. Regular cleaning is essential to maintain smooth operation.

Lastly, consult the user guide for specific error codes or troubleshooting tips related to your device. Often, manufacturers provide helpful insights that can pinpoint the exact problem. Following these steps methodically can help restore functionality efficiently.

How to Clean Your Sewing Machine

Regular maintenance is essential for ensuring the longevity and optimal performance of your crafting device. By keeping it clean, you can prevent issues that may arise from dust and debris accumulation, which can affect functionality and stitching quality.

Tools You’ll Need

- Soft brush

- Lint-free cloth

- Screwdriver (if needed)

- Vacuum with a small nozzle attachment

- Oiling solution (if recommended)

Step-by-Step Cleaning Process

- Unplug the Device: Always ensure that your device is disconnected from the power source before starting any cleaning.

- Remove Accessories: Take off any presser feet, needles, and bobbins to access all areas.

- Brush Away Lint: Use a soft brush to remove lint and dust from the feed dogs and surrounding areas.

- Vacuum Debris: Carefully use a vacuum with a small nozzle to suck up any stubborn particles.

- Wipe Down Surfaces: Use a lint-free cloth to clean the exterior and any accessible parts, ensuring no residue is left behind.

- Oil Moving Parts: If your device requires it, apply a few drops of oil to the designated areas to keep everything running smoothly.

- Reassemble: Once everything is clean and dry, reattach all removed components and plug the device back in.

Following these steps regularly will help maintain your equipment in peak condition, allowing for enjoyable and hassle-free crafting experiences.

Replacing the Needle and Threading Tips

Ensuring optimal performance in your crafting project begins with proper maintenance of your tools. One essential aspect is the timely replacement of the needle and correct threading. This section outlines straightforward steps to achieve effective results.

How to Replace the Needle

Follow these simple steps to replace the needle safely:

- Turn off the device to prevent accidental starts.

- Loosen the needle clamp screw using a screwdriver.

- Remove the old needle by sliding it downwards.

- Insert the new needle, ensuring it is positioned correctly.

- Tighten the clamp screw securely.

Threading Tips

Proper threading is crucial for smooth operation. Here are some tips to keep in mind:

- Always use the recommended thread type for your projects.

- Ensure the thread spool is placed correctly to prevent tangling.

- Thread the needle from front to back for optimal results.

- Check the tension settings; adjust if necessary for different materials.

- Regularly clean the threading path to remove lint and debris.

Fixing Tension Problems Effectively

Tension issues can significantly impact the quality of your projects, leading to frustration and unsatisfactory results. Understanding the fundamentals of how to adjust and troubleshoot these challenges is crucial for achieving consistent outcomes. This section will guide you through identifying common tension problems and provide practical solutions to restore optimal performance.

Identifying Common Issues

One of the first steps in addressing tension difficulties is recognizing the signs. If you notice uneven stitches, thread breaking, or puckering fabric, it may indicate an imbalance in the tension settings. Examine the upper and lower threads to ensure they are properly threaded and free from tangles or knots. Often, these minor oversights can lead to major complications.

Adjusting the Settings

Once you’ve identified the issues, make adjustments to the tension settings. Begin with small increments, testing the results after each adjustment. For most projects, the upper tension should be tighter than the lower. Remember to always refer to the user guidelines for specific recommendations on appropriate tension levels for various fabrics. If problems persist, consider cleaning and oiling the relevant components to ensure smooth operation.

Maintaining Your Kenmore 158 for Longevity

Ensuring the durability of your fabric crafting equipment requires consistent attention and care. Regular maintenance not only enhances performance but also extends the lifespan of the device. By implementing a few simple practices, you can keep your tool running smoothly for years to come.

Regular Cleaning: Dust and lint can accumulate quickly, impacting functionality. After each use, take a moment to clear debris from the feed dogs and around the needle area. A soft brush or a lint roller can effectively remove unwanted particles.

Lubrication: Proper lubrication is essential for optimal operation. Use a high-quality oil recommended for textile equipment to keep moving parts functioning seamlessly. Refer to your guidelines for specific points that require lubrication.

Needle Maintenance: A sharp needle is crucial for achieving clean stitches. Replace the needle regularly, especially if you notice skipped stitches or uneven fabric feeding. This simple step can significantly improve your results.

Tension Adjustment: Ensure that the tension settings are correctly adjusted for the type of fabric being used. Regularly check and calibrate the tension to prevent issues such as puckering or loose threads.

Storage Practices: When not in use, cover your equipment to protect it from dust and environmental factors. Store it in a cool, dry place to prevent damage from humidity or extreme temperatures.

By incorporating these maintenance tips into your routine, you can enhance the reliability and efficiency of your fabric crafting equipment, ensuring it remains a trusted companion for all your projects.

Common Parts to Replace on Kenmore 158

When maintaining a vintage model, certain components may require attention over time to ensure optimal performance. Identifying these parts is essential for preserving functionality and extending the lifespan of your equipment. Regular replacements can help mitigate issues related to wear and tear.

1. Belts

One of the most frequently replaced components is the belt. Over time, belts can stretch, crack, or wear out, leading to decreased efficiency. Replacing the belt with a new, high-quality option can restore the proper tension and improve overall performance.

2. Needles and Bobbins

Another critical area involves the needles and bobbins. As these parts undergo constant use, they can become dull or damaged, affecting the quality of your output. Investing in a supply of fresh needles and bobbins is a simple yet effective way to enhance results and prevent frustration during projects.

By paying attention to these key components, you can ensure your device remains in peak condition, allowing you to enjoy your crafting experience without interruptions.

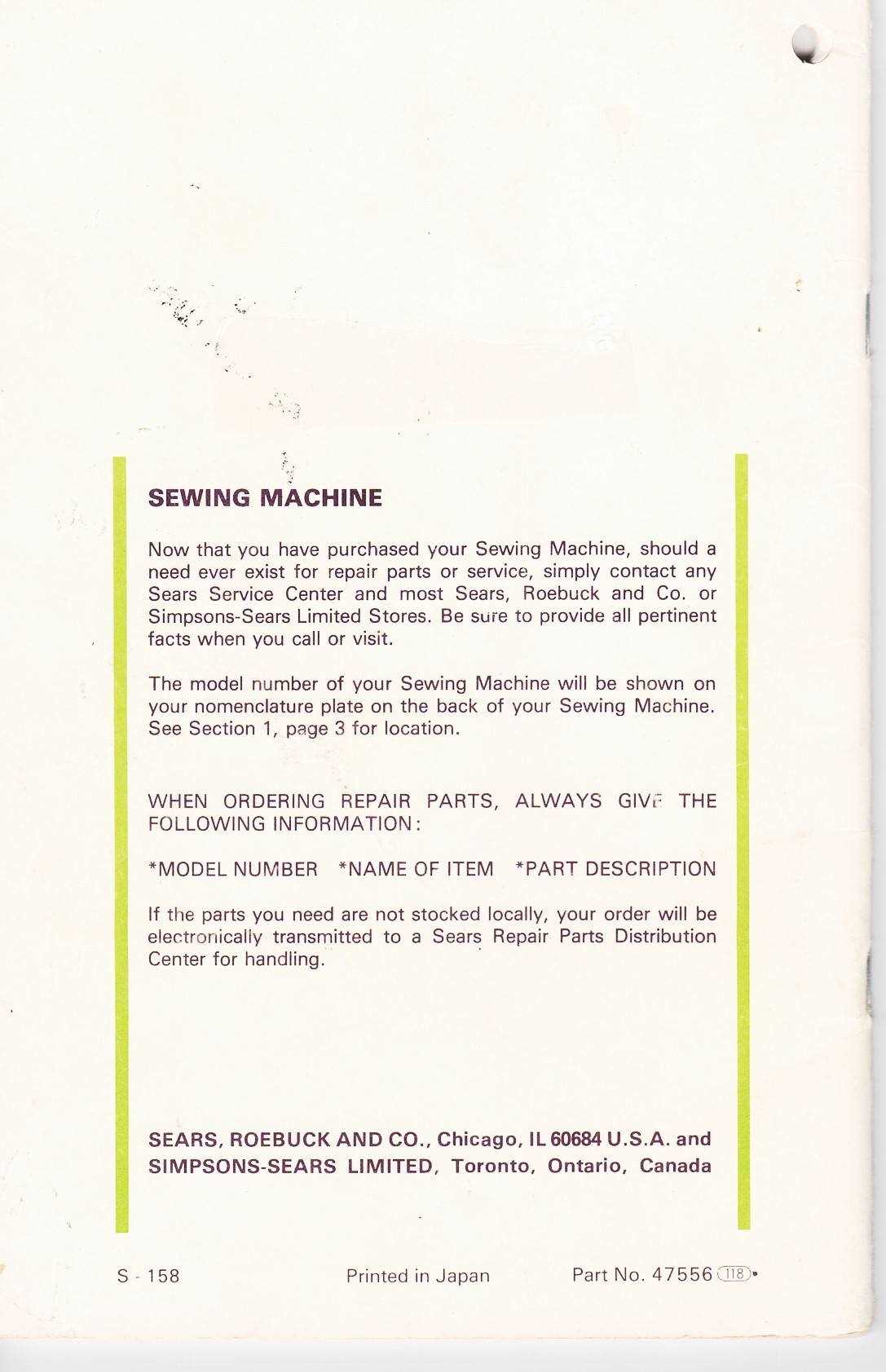

Resources for Kenmore Sewing Machine Manuals

Accessing detailed guides and helpful resources can greatly enhance your experience with your crafting equipment. A wealth of information is available for those seeking to understand their devices better, troubleshoot issues, or simply explore their features. These resources range from online databases to community forums, providing a comprehensive support system for users.

Numerous websites host digital copies of various guides, offering free downloads or purchase options. Additionally, many enthusiasts and collectors share their knowledge through blogs and video tutorials, making complex processes more approachable. Joining online communities can also be invaluable, as members often exchange tips, tricks, and documentation that can assist in resolving specific queries.

For those who prefer physical copies, local libraries or specialty shops may carry printed guides or have the ability to order them. Manufacturer archives and second-hand stores can be treasure troves for finding older literature, ensuring that users can maintain and enhance their equipment effectively.

When to Seek Professional Help

Understanding when to consult an expert can be crucial for maintaining the longevity and functionality of your equipment. While some issues may seem manageable, certain signs indicate that professional assistance is warranted. Recognizing these indicators can save time, effort, and resources in the long run.

Consider the following situations where it may be best to reach out to a specialist:

- Persistent Issues: If problems persist despite attempts at troubleshooting or adjustment.

- Unusual Noises: Any strange sounds that are not typical for your device should be investigated.

- Damaged Parts: Visible damage to components that could affect performance or safety.

- Frequent Breakdowns: Repeated failures that disrupt your workflow indicate a deeper issue.

- Lack of Knowledge: If you’re unsure about the source of a problem or how to resolve it safely.

Seeking the help of a qualified technician can ensure that issues are diagnosed correctly and resolved efficiently, ultimately prolonging the lifespan of your equipment.

Tips for Sewing Machine Safety

Ensuring a safe environment while working with textile equipment is essential for preventing accidents and promoting a productive atmosphere. By following some straightforward guidelines, you can protect yourself and maintain your tools in optimal condition.

General Safety Precautions

- Always keep your work area tidy to avoid tripping hazards.

- Ensure proper lighting in your workspace to enhance visibility.

- Use the correct attachments and accessories as recommended by the manufacturer.

- Regularly inspect your equipment for any signs of wear or damage.

Operational Guidelines

- Never operate the device while distracted or under the influence of substances.

- Keep hands and loose clothing away from moving parts.

- Disconnect the power supply when changing needles or making adjustments.

- Use a protective cover when the device is not in use to prevent dust accumulation.