Ensuring the longevity and optimal performance of your outdoor equipment is essential for any enthusiast. This section provides comprehensive insights into the necessary steps and best practices to maintain your machinery effectively. By understanding the fundamental aspects of upkeep, users can prevent common issues and enhance the overall functionality of their devices.

Regular inspections play a crucial role in identifying potential problems before they escalate. It is vital to familiarize oneself with the various components and their respective functions, allowing for timely intervention and necessary adjustments. This proactive approach not only improves efficiency but also extends the lifespan of the equipment.

In addition to inspections, proper cleaning and storage techniques are equally important. Keeping the machinery free from debris and contaminants helps maintain its performance and reliability. Implementing a routine care schedule will ensure that every aspect is addressed, paving the way for a seamless experience every time the equipment is utilized.

This section provides a comprehensive overview of the essential characteristics that make this snow-clearing machine effective and user-friendly. By exploring its design and operational capabilities, readers will gain insights into how to maximize its performance during winter conditions.

- Powerful Engine: The machine is equipped with a robust motor that delivers ample horsepower, ensuring efficient snow removal even in heavy snowfall.

- Wide Clearing Width: The substantial width of the clearing blade allows for quick and thorough snow clearance, reducing the time spent on the task.

- Adjustable Speed Settings: Users can select from various speed options, providing flexibility to tackle different snow depths and conditions.

- Ergonomic Controls: The design features user-friendly controls that enhance comfort and reduce fatigue during extended use.

- Durable Construction: Made from high-quality materials, this equipment is built to withstand harsh winter elements and provide long-lasting service.

Understanding these features will assist users in making informed decisions and optimizing their snow-clearing experience.

Common Issues and Troubleshooting Steps

This section addresses frequent problems encountered with outdoor power equipment and offers effective solutions. Understanding these common challenges can help users maintain optimal performance and extend the lifespan of their machinery.

Typical Problems

Users may experience various issues, such as difficulty starting, unusual noises, or inconsistent operation. Identifying the root cause of these problems is essential for effective troubleshooting.

Troubleshooting Solutions

| Issue | Possible Cause | Suggested Action |

|---|---|---|

| Difficulty starting | Empty fuel tank or stale fuel | Refill with fresh fuel |

| Unusual noises | Loose components | Tighten all bolts and screws |

| Inconsistent operation | Clogged air filter | Clean or replace air filter |

| Excessive vibration | Worn blades | Inspect and replace blades if necessary |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring peak efficiency and longevity of your equipment. By adhering to a consistent maintenance schedule, you can prevent potential issues and enhance overall functionality. This section outlines crucial practices that can help you maintain your machine effectively.

Routine Inspections

Conducting frequent assessments is vital for identifying any wear or damage. Check components such as belts, blades, and filters for signs of deterioration. Early detection of problems can save time and resources in the long run.

Proper Cleaning

Keeping your device clean is key to maintaining optimal performance. After each use, remove debris and dirt from the exterior and undercarriage. Regular cleaning not only improves efficiency but also prolongs the lifespan of the machinery.

Safety Precautions During Repairs

When engaging in maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and ensure efficient operation. Proper precautions not only protect the individual performing the service but also help maintain the integrity of the equipment.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear. This gear provides essential protection against potential hazards, including sharp objects and chemical exposure. A safety helmet may be necessary when working in environments where overhead risks are present.

Work Environment Safety

Ensure that the workspace is clean and well-lit to minimize the risk of accidents. Keep all tools organized and within reach, reducing the chance of misplacing items. Additionally, be mindful of your surroundings; ensure that any potential hazards, such as spills or loose wires, are promptly addressed.

Tools Required for Efficient Repairs

Having the right equipment is essential for performing effective maintenance on outdoor machinery. Using suitable instruments not only streamlines the process but also ensures safety and precision. Whether addressing minor issues or conducting comprehensive overhauls, the proper toolkit can make a significant difference in the outcome.

Essential Hand Tools

Basic hand tools are the foundation of any maintenance endeavor. A sturdy screwdriver set, wrenches, and pliers are crucial for tackling various fasteners and components. Additionally, a reliable torque wrench is vital for applying the correct tension to bolts, which prevents damage and ensures optimal performance.

Specialized Equipment

In certain scenarios, specialized gear may be necessary for more intricate tasks. Diagnostic tools can assist in identifying issues, while a mechanic’s creeper provides comfort and mobility during work underneath machinery. Having a quality toolbox to organize these items will enhance efficiency and keep everything accessible.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues and performing maintenance tasks on your outdoor equipment. Following a structured method not only enhances efficiency but also ensures safety and effectiveness in restoring functionality.

Assessing the Problem

Begin by thoroughly examining the device to identify any visible signs of wear or damage. Take note of unusual noises or performance issues that may indicate specific faults. Documenting these observations will guide the troubleshooting process and help in determining the necessary actions.

Executing Repairs

Once the problem has been identified, gather the required tools and replacement parts. Follow the recommended procedures to disassemble the affected components, taking care to keep track of screws and small parts. Replace any faulty elements and reassemble the unit carefully, ensuring all connections are secure before testing the equipment to confirm successful resolution.

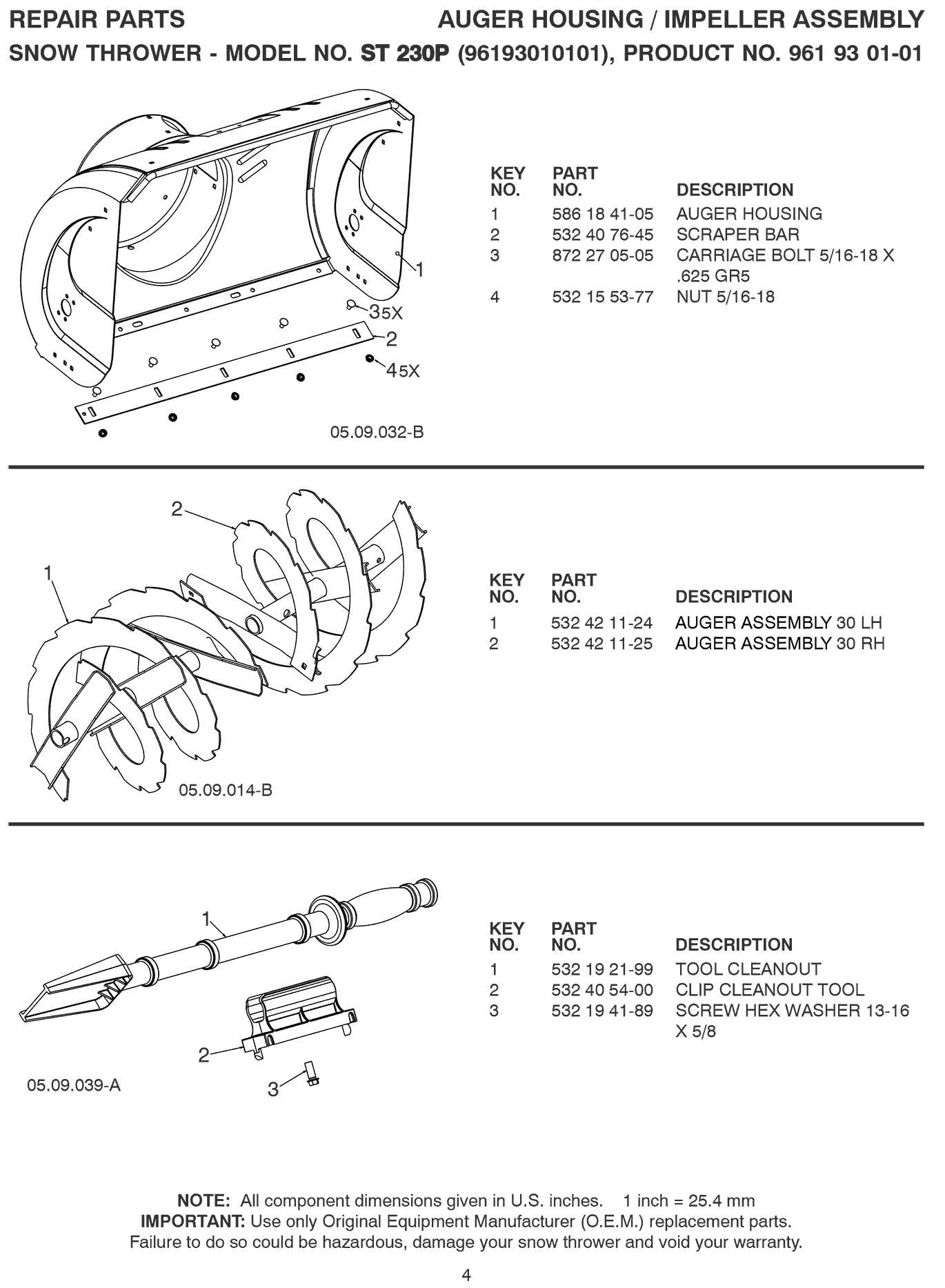

Parts Replacement Guide for ST230P

This section provides essential information for efficiently replacing components of your snow-clearing machine. Regular maintenance and timely part replacements are crucial for ensuring optimal performance and longevity.

When considering component swaps, follow these steps:

- Identify the part: Recognize the specific component that requires attention. Common issues may involve the auger, belt, or engine parts.

- Gather necessary tools: Ensure you have all required tools, including wrenches, screwdrivers, and any specialty items for your particular model.

- Refer to the specifications: Consult the technical details for your machine to select compatible replacement parts. Always opt for high-quality components to maintain reliability.

Commonly replaced components include:

- Auger blades: Essential for effective snow removal, these should be inspected regularly for wear and replaced as needed.

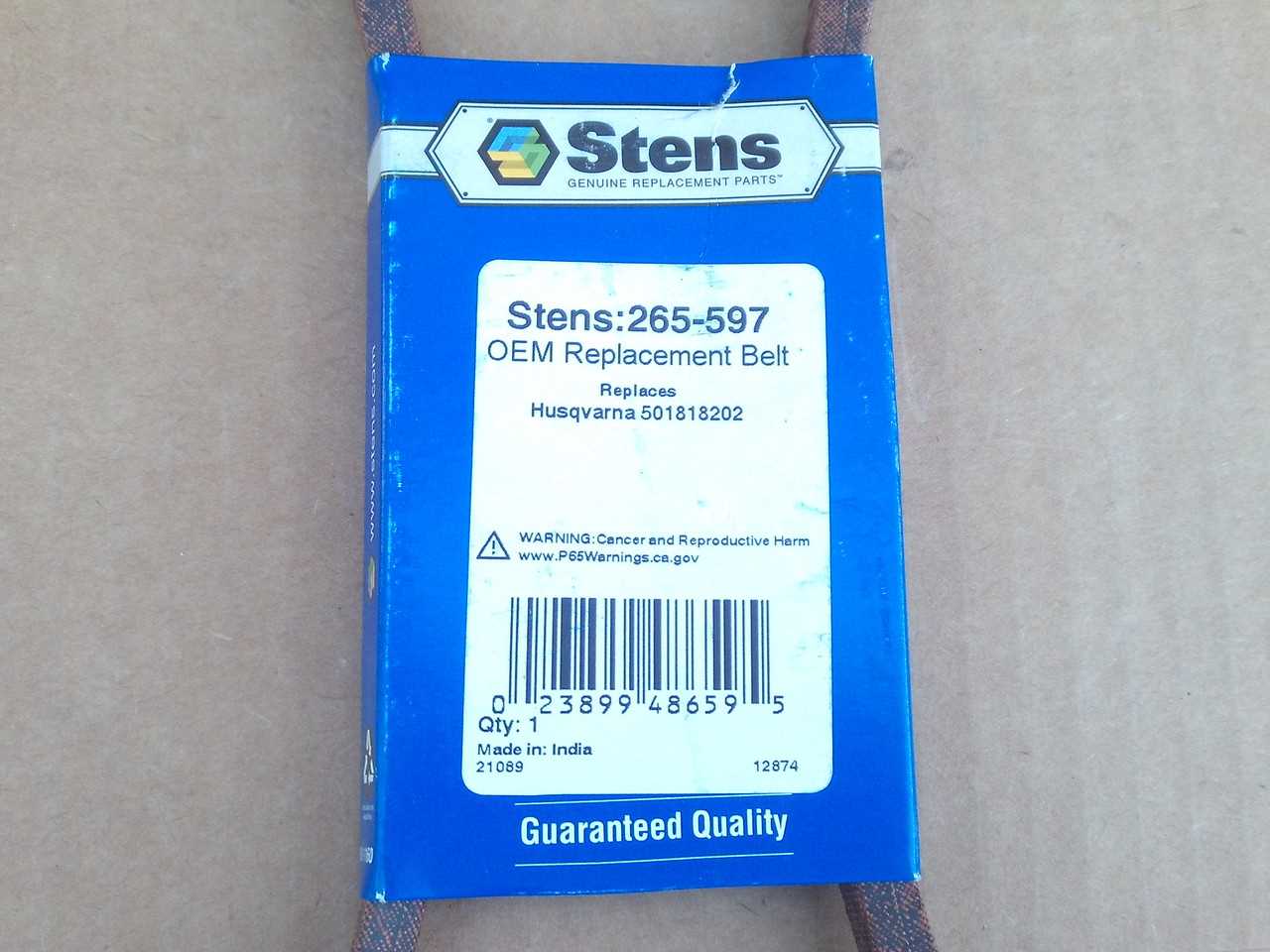

- Belt: This vital part transfers power; check for fraying or damage during routine maintenance.

- Fuel filter: Regular replacement ensures clean fuel flow, promoting efficient engine operation.

Following these guidelines will help you maintain your equipment in excellent working condition, allowing for efficient operation during the winter months.

Seasonal Maintenance Recommendations

Regular upkeep is essential for ensuring the longevity and efficiency of your outdoor equipment. Adopting a seasonal maintenance routine can help prevent issues and enhance performance throughout the year. Below are key suggestions for maintaining your machine during different seasons.

Spring Maintenance

- Inspect and clean air filters to ensure optimal airflow.

- Sharpen or replace blades for efficient cutting.

- Check fuel lines and replace any worn components.

- Test battery performance and clean terminals to prevent corrosion.

Summer Maintenance

- Monitor fluid levels and top off as necessary.

- Examine tires for wear and proper inflation.

- Keep the exterior clean to prevent rust and buildup.

- Inspect and adjust belts for proper tension.

Autumn Maintenance

- Change the oil and replace the oil filter.

- Drain fuel or add a stabilizer to prevent deterioration.

- Inspect spark plugs and replace if necessary.

- Store equipment in a dry, sheltered location to protect against harsh weather.

Winter Maintenance

- Check all safety features to ensure they are functioning correctly.

- Cover equipment to protect it from snow and ice.

- Perform any needed repairs during downtime to prepare for the next season.

- Review the entire maintenance log to plan for upcoming service needs.

Following these seasonal tips will help maintain peak performance and prolong the life of your outdoor machinery, ensuring you are ready for every task ahead.

User Experiences and Tips

This section gathers valuable insights and suggestions from users who have encountered various challenges and successes while using their outdoor equipment. Sharing these experiences can help others navigate common issues and enhance the overall functionality of their machines.

Common Issues and Solutions

Many users have reported specific difficulties that often arise during operation. Addressing these problems with practical solutions can significantly improve performance and longevity.

| Issue | Suggested Solution |

|---|---|

| Difficulty starting the engine | Check the fuel level and ensure the choke is in the correct position. |

| Unusual vibrations during use | Inspect for loose bolts or damaged components that may need tightening or replacement. |

| Reduced cutting efficiency | Sharpen the blades regularly and ensure they are properly aligned. |

Maintenance Tips

Routine maintenance plays a crucial role in ensuring optimal performance. Users have found that adhering to a maintenance schedule can prevent many common issues.

Regularly check and replace filters, lubricate moving parts, and clean the exterior to prevent debris buildup. Staying proactive can lead to a smoother experience and fewer disruptions in operation.

Finding Authorized Service Centers

Locating certified service providers is essential for maintaining equipment performance and ensuring reliable support. These centers are equipped with trained technicians who possess in-depth knowledge and expertise to handle various models efficiently.

To find a nearby authorized service center, start by visiting the manufacturer’s official website. Many brands offer a dedicated section where you can input your location to receive a list of nearby facilities. Additionally, consider reaching out to customer service representatives who can guide you through the process and provide valuable insights.

Another effective method is to check local directories or forums where fellow users share their experiences. Recommendations from others can lead you to trustworthy service centers that deliver quality care. Be sure to verify their credentials and read reviews to ensure a positive service experience.