In the world of all-terrain vehicles, ensuring optimal performance and longevity is paramount for enthusiasts and everyday users alike. This section offers valuable insights into essential upkeep practices, troubleshooting techniques, and guidelines for restoring functionality. By understanding the intricacies of your machine, you can enhance your riding experience and tackle potential issues effectively.

Exploring the key components and systems will empower you to perform necessary tasks with confidence. Whether you’re addressing minor adjustments or major overhauls, this guide serves as a reliable resource to navigate the challenges that come with vehicle ownership. Equip yourself with knowledge and skills that will make a significant difference in your maintenance routine.

Moreover, having access to a detailed reference can prevent costly repairs and extend the lifespan of your vehicle. By following systematic procedures and using the right tools, you’ll cultivate a deeper appreciation for the mechanics at play. Prepare to delve into a wealth of information that will transform your approach to vehicle care.

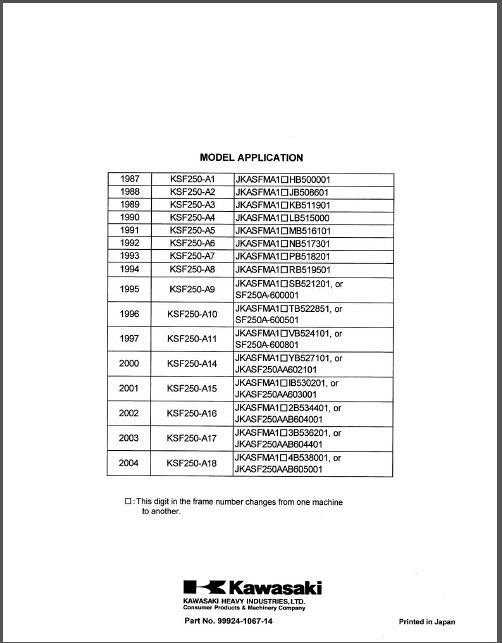

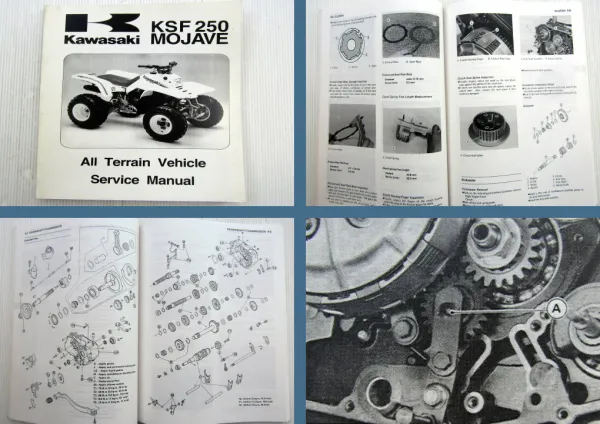

Kawasaki Mojave 250 Repair Manual Overview

This section provides an insight into the comprehensive guide designed for maintaining and troubleshooting the specific all-terrain vehicle. The document serves as an essential resource for both novice and experienced enthusiasts, detailing various aspects necessary for optimal performance and longevity of the machine.

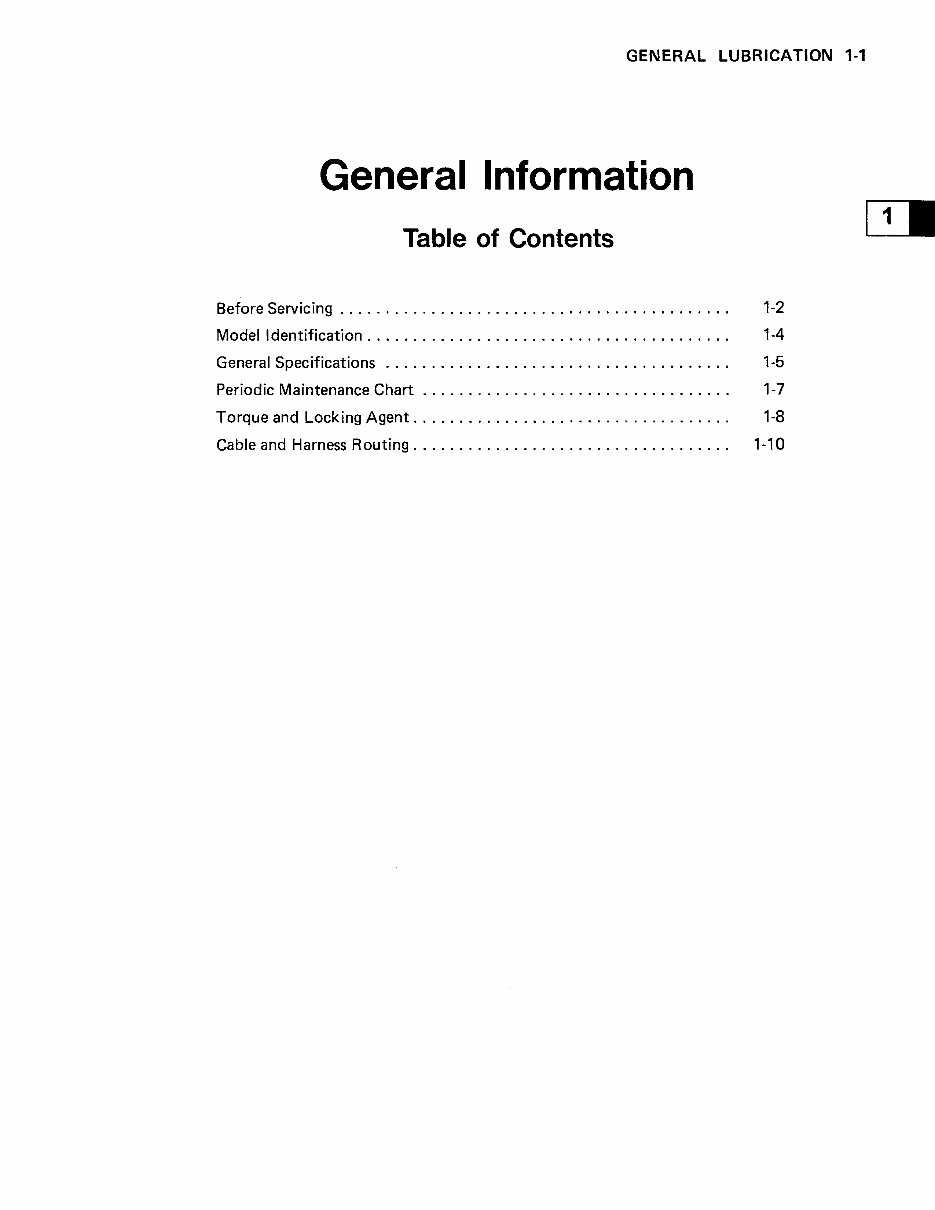

Contents and Structure

The guide is organized into several key chapters, each focusing on different components and systems. It includes instructions on regular maintenance, detailed assembly processes, and troubleshooting techniques. Users will find clear diagrams and step-by-step procedures that simplify complex tasks.

Importance of Regular Maintenance

Adhering to the recommendations within this resource ensures that the vehicle remains in peak condition. Regular check-ups and prompt repairs not only enhance the riding experience but also extend the lifespan of the machine. Neglecting maintenance can lead to serious issues, making the guidelines invaluable for any owner.

Essential Tools for Repairs

Having the right equipment is crucial for successful maintenance and troubleshooting of your vehicle. A well-equipped workspace not only makes the task easier but also ensures that the job is done efficiently and safely. Below are some key instruments that every enthusiast should consider having on hand.

Basic Hand Tools

- Wrenches: Adjustable and fixed sizes for various bolt types.

- Screwdrivers: Both flathead and Phillips types to handle different fasteners.

- Pliers: For gripping, twisting, and cutting wires or small components.

- Hex keys: Essential for tightening or loosening hexagonal screws.

Specialized Equipment

- Torque wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Multimeter: For checking electrical connections and diagnosing faults.

- Jack and stands: Necessary for lifting the vehicle safely for undercarriage work.

- Oil filter wrench: Simplifies the removal and installation of oil filters.

Equipping yourself with these fundamental and specialized tools will greatly enhance your ability to perform maintenance tasks, ensuring your vehicle remains in optimal condition for any adventure.

Common Issues with Mojave 250

This section addresses frequently encountered problems associated with a specific off-road vehicle model. Understanding these common concerns can assist owners in diagnosing and resolving issues effectively, ensuring optimal performance and longevity.

Engine Performance Problems

One of the most prevalent challenges is related to engine performance. Users often report issues such as stalling, rough idling, or difficulty starting. These symptoms may arise from factors like fuel delivery problems, clogged filters, or ignition system failures. Regular maintenance and timely inspections can help mitigate these concerns.

Suspension and Handling Difficulties

Another common issue involves the suspension system. Riders frequently experience poor handling, excessive bouncing, or unusual noises when traversing rough terrain. These problems may indicate worn-out shock absorbers or misaligned components. Proper adjustments and replacements can enhance ride quality and safety.

Step-by-Step Maintenance Procedures

Regular upkeep of your vehicle is essential to ensure its longevity and optimal performance. Following a systematic approach can help identify issues early and keep the machine running smoothly.

-

Inspection: Begin with a thorough examination of the entire unit. Look for signs of wear, leaks, and any unusual noises.

-

Fluid Checks: Regularly check oil, coolant, and other essential fluids. Replace any that appear dirty or are below the recommended levels.

-

Air Filter Replacement: Inspect and replace the air filter periodically to ensure proper airflow and engine efficiency.

-

Battery Maintenance: Check battery terminals for corrosion and ensure a secure connection. Clean as necessary and check the charge level.

-

Tire Care: Regularly inspect tire pressure and tread depth. Rotate tires as needed to promote even wear.

-

Chain Adjustment: Ensure the drive chain is properly tensioned and lubricated to enhance performance and reduce wear.

-

Brake System Check: Inspect brake pads and fluid levels. Replace worn components to maintain safe stopping power.

Following these procedures diligently will contribute to the overall health and reliability of your vehicle.

Engine Troubleshooting Tips

When facing challenges with your motor’s performance, understanding the common issues and their solutions can significantly enhance your maintenance efforts. This guide aims to provide practical advice for diagnosing and resolving engine-related problems effectively.

1. Check for Fuel Issues: Ensure that the fuel is clean and properly mixed. Contaminated or incorrect fuel can lead to poor combustion and performance. Replace the fuel if it appears cloudy or has been sitting for an extended period.

2. Inspect the Ignition System: A faulty ignition system can prevent the engine from starting or running smoothly. Examine the spark plug for wear and carbon buildup. Replacing a worn or damaged spark plug can often resolve ignition issues.

3. Evaluate Air Intake: Blockages in the air intake can restrict airflow, leading to a decrease in performance. Make sure the air filter is clean and free of debris. Regularly replacing the air filter will ensure optimal engine efficiency.

4. Examine the Exhaust: A clogged exhaust can hinder engine performance and cause overheating. Inspect the exhaust system for any obstructions and clean or replace components as necessary.

5. Monitor Engine Temperature: Overheating can lead to serious damage. Keep an eye on the temperature gauge and ensure the cooling system is functioning correctly. Check for coolant leaks and verify that the radiator is clear of debris.

6. Listen for Unusual Noises: Unexplained sounds can indicate internal issues. Pay attention to any knocking, ticking, or grinding noises, as they may suggest wear on critical components. Addressing these sounds early can prevent further damage.

By following these troubleshooting tips, you can maintain your engine’s health and enhance its longevity, ensuring a smoother and more reliable ride.

Electrical System Diagnostics

This section aims to provide a comprehensive approach to troubleshooting and assessing the functionality of the electrical components in your vehicle. Proper diagnostics are essential for identifying issues that may affect performance, reliability, and safety.

Common Issues and Symptoms

Several indicators can signify problems within the electrical framework. Recognizing these symptoms early can help prevent more significant malfunctions:

| Symptoms | Possible Causes |

|---|---|

| Dim or flickering lights | Weak battery, faulty wiring, or bad ground connection |

| Starting difficulties | Weak battery, malfunctioning starter motor, or corroded terminals |

| Unresponsive electrical components | Blown fuses, damaged switches, or broken connections |

Diagnostic Procedures

To effectively evaluate the electrical system, follow these diagnostic steps:

- Begin with a visual inspection of all connections and components.

- Utilize a multimeter to check voltage and continuity across critical areas.

- Refer to the circuit diagrams to trace and isolate faults.

- Replace any damaged parts or wiring as identified during the assessment.

Transmission Repair Techniques

Maintaining optimal functionality in mechanical systems requires a keen understanding of various methods for addressing common issues within gear systems. This section explores essential practices that ensure longevity and efficiency in power transfer components.

Diagnosis of Gear Issues

Effective troubleshooting begins with a thorough examination of the system. Identifying symptoms such as unusual noises or difficulty in shifting gears is crucial. Utilizing diagnostic tools can aid in pinpointing the source of the problem, enabling a targeted approach to fixing any anomalies.

Disassembly and Component Inspection

Once issues are diagnosed, careful disassembly of the assembly is necessary. Each component should be inspected for wear, damage, or misalignment. Cleaning parts and replacing any worn elements ensures the system operates smoothly after reassembly, promoting a seamless performance.

Suspension Adjustments and Fixes

Effective management of the suspension system is crucial for optimal performance and rider comfort. Proper adjustments can significantly enhance handling, stability, and overall ride quality. This section focuses on the various methods to fine-tune the suspension, ensuring it meets the specific needs of the rider and terrain.

Understanding Suspension Components

Before making any adjustments, it’s essential to familiarize yourself with the key elements of the suspension system, including forks, shock absorbers, and linkages. Each component plays a vital role in absorbing shocks and maintaining traction.

Adjusting Compression and Rebound Settings

Compression and rebound settings are critical for tailoring the suspension’s response. Compression adjustment affects how quickly the suspension compresses under load, while rebound adjustment influences how quickly it returns to its original position. Fine-tuning these settings based on riding conditions can greatly improve performance.

Identifying and Fixing Issues

Regular inspection for signs of wear, such as leaks or unusual noises, is essential. Addressing these issues promptly can prevent further damage and maintain the integrity of the suspension system. Common fixes may include replacing seals, adjusting preload, or servicing the shock.

Final Considerations

Maintaining an optimal suspension setup involves periodic adjustments and inspections. By understanding the mechanics behind the system and addressing issues proactively, riders can ensure a smooth and controlled experience on any terrain.

Brake System Maintenance Guidelines

Regular upkeep of the braking apparatus is crucial for ensuring safety and optimal performance. This segment outlines essential practices to maintain the braking components effectively, prolonging their lifespan and enhancing reliability during operation.

Routine Inspections

Conduct frequent assessments of the braking system, checking for wear and tear on pads and discs. Look for signs of fluid leaks or degradation in hoses. Ensure all connections are secure and free from corrosion. Address any irregularities promptly to avoid compromising the overall performance.

Fluid Replacement

The hydraulic fluid plays a vital role in the functioning of the braking mechanism. Regularly check the fluid level and quality. Replace the fluid according to the manufacturer’s recommendations, as contaminated fluid can lead to diminished braking efficiency. Use only the specified type of fluid to ensure compatibility and optimal performance.

Maintenance of the brake system is not just a precaution; it is essential for safe operation. Regular checks and timely interventions can prevent more significant issues, ensuring that every ride remains secure and enjoyable.

Fuel System Cleaning and Repair

Maintaining optimal performance of the fuel delivery system is crucial for any vehicle. Regular cleaning and troubleshooting can prevent potential issues, ensuring that the engine runs smoothly and efficiently. This section will outline essential practices for keeping the fuel system in top condition.

Cleaning the Fuel Delivery Components

The first step in maintaining the fuel system involves thoroughly cleaning the various components, including the fuel tank, lines, and injectors. Begin by removing any debris or sediment from the tank, which can affect fuel flow. Using a suitable cleaner for the fuel lines can help eliminate buildup and blockages. Ensure that injectors are also cleaned, as clogged injectors can lead to poor performance and fuel inefficiency.

Diagnosing and Fixing Common Issues

After cleaning, it’s essential to diagnose any persistent problems. Look for signs of leaks in hoses and connections, as these can lead to fuel loss and reduced efficiency. If the engine exhibits rough idling or stalling, it may indicate a deeper issue within the fuel system. Replacing faulty components such as filters or pumps is necessary to restore proper function. Regular inspections will help catch these problems early, allowing for timely resolutions.

Preventive Measures for Longevity

To ensure the extended life and optimal performance of your vehicle, it is crucial to implement a series of proactive strategies. These practices not only enhance reliability but also minimize the risk of costly repairs and breakdowns. By regularly attending to maintenance tasks, you can safeguard the integrity of your machinery and enjoy a smoother riding experience.

Regular Maintenance Checks

Routine inspections are essential for identifying potential issues before they escalate. Checking fluid levels, examining tire conditions, and assessing the overall functionality of components can prevent unexpected failures. Establishing a schedule for these checks will help maintain peak operational efficiency and prolong the lifespan of your vehicle.

Proper Storage and Care

Storing your machine in a dry, sheltered location protects it from the elements and potential corrosion. Additionally, keeping the vehicle clean and free of debris contributes to its longevity. Applying protective coatings where necessary can also shield it from wear and environmental damage, ensuring it remains in excellent condition for years to come.

Parts Replacement Recommendations

Ensuring optimal performance of your vehicle involves timely replacement of various components. Regular inspections can help identify wear and tear, preventing potential issues that could affect functionality and safety. Below are some essential recommendations for parts that may require attention during maintenance.

| Part | Frequency of Replacement | Notes |

|---|---|---|

| Air Filter | Every 12,000 miles | Replace to maintain engine efficiency and improve fuel economy. |

| Oil Filter | Every 3,000 miles | Regular changes help protect the engine from contaminants. |

| Brake Pads | Every 20,000 miles | Check for wear to ensure effective braking performance. |

| Battery | Every 3-5 years | Monitor performance, especially in extreme temperatures. |

| Tires | Every 6 years or 40,000 miles | Check tread depth and replace if uneven wear is detected. |

Safety Protocols During Repairs

Ensuring a safe working environment is crucial when undertaking any maintenance tasks on machinery. Adhering to established safety guidelines helps prevent accidents and injuries, promoting a secure atmosphere for both the technician and the equipment involved.

Before commencing any work, it is essential to wear appropriate personal protective equipment (PPE), including gloves, goggles, and a helmet, to guard against potential hazards. Additionally, familiarizing oneself with the tools and materials being utilized can significantly reduce the risk of mishaps.

Always ensure that the vehicle is securely positioned and that any moving parts are immobilized before starting the procedure. This can include using wheel chocks or stands to prevent unintended movement. Keeping the workspace organized and free of clutter further enhances safety by minimizing trip hazards.

Moreover, it is vital to follow the manufacturer’s specifications and guidelines regarding the handling and disposal of fluids and components. Properly managing waste materials not only protects the environment but also ensures compliance with legal regulations.

In case of an emergency, having a first aid kit readily available and knowing the location of emergency exits can be lifesaving. Regularly reviewing safety protocols and participating in training sessions can also reinforce awareness and preparedness among all personnel involved.