Ensuring the longevity and optimal performance of outdoor machinery is crucial for both enthusiasts and professionals. This segment aims to provide invaluable insights into the processes involved in maintaining and troubleshooting small engines. By delving into systematic approaches and practical tips, users can enhance their understanding and tackle common challenges effectively.

From routine checks to more intricate adjustments, the importance of proper upkeep cannot be overstated. A well-structured approach to addressing issues not only saves time but also contributes to the overall efficiency of the equipment. This guide will serve as a vital resource, equipping you with the knowledge needed to handle various mechanical tasks with confidence.

Furthermore, familiarizing yourself with the intricacies of your engine will empower you to identify potential problems before they escalate. Whether you’re a novice or an experienced technician, this information will pave the way for a smoother maintenance journey, ultimately ensuring that your machinery operates at its best.

Kawasaki FH500V Overview

This section provides an insightful look into a high-performance engine designed for durability and efficiency. It embodies the ultimate blend of power and reliability, making it a preferred choice for various applications in the outdoor power equipment sector.

Engine Specifications

Featuring a robust configuration, this engine delivers impressive horsepower while maintaining low fuel consumption. The engineering design focuses on optimal performance, ensuring longevity and ease of maintenance, crucial for operators seeking dependable machinery.

Applications and Use Cases

Commonly found in lawn care and commercial landscaping equipment, this power unit excels in heavy-duty tasks. Its adaptability allows it to meet the demands of both residential and professional environments, ensuring seamless operation under diverse conditions.

Common Issues and Troubleshooting

When dealing with small engines, it’s essential to recognize typical problems that may arise during operation. Understanding these issues can help diagnose malfunctions quickly and ensure optimal performance. This section outlines common challenges and provides straightforward solutions to help maintain efficiency and reliability.

Engine Not Starting

If the engine fails to start, there are several potential causes to consider. First, check the fuel supply to ensure that it is fresh and free from contaminants. Inspect the ignition system, including the spark plug, for wear or damage. Additionally, verify that the air filter is clean and unobstructed, as restricted airflow can hinder combustion.

Overheating Issues

Overheating is a common concern that can lead to serious damage if not addressed promptly. Ensure that the cooling system is functioning properly by checking the coolant level and inspecting for leaks. Clean any debris that may block airflow to the engine. Also, examine the oil level and quality, as insufficient lubrication can contribute to excessive heat buildup.

Essential Tools for Repairs

When it comes to maintaining and restoring machinery, having the right equipment is crucial for achieving effective results. A well-equipped toolkit not only enhances efficiency but also ensures safety during the servicing process. Below are some key instruments that every technician should have on hand for successful maintenance tasks.

Basic Hand Tools

Hand tools form the foundation of any maintenance operation. These instruments are essential for tasks ranging from assembly to disassembly, making them indispensable for any technician.

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening or loosening bolts and nuts. |

| Screwdrivers | Essential for driving screws into various materials. |

| Pliers | Useful for gripping, bending, and cutting wire. |

| Socket Set | Facilitates easier fastening of bolts in tight spaces. |

Specialized Equipment

In addition to standard hand tools, certain specialized devices can significantly enhance repair capabilities. These tools are designed to tackle specific challenges and improve precision during the servicing process.

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Multimeter | Measures voltage, current, and resistance for electrical diagnostics. |

| Compression Tester | Assesses the health of the engine’s internal components. |

| Diagnostic Scanner | Identifies issues through onboard computer systems. |

Step-by-Step Maintenance Procedures

Regular upkeep of your engine is essential for optimal performance and longevity. By following systematic procedures, you can ensure that your equipment operates smoothly and efficiently. Below are detailed steps to help you maintain your machine effectively.

1. Preliminary Checks

- Inspect the air filter for dirt and blockages.

- Check the oil level and look for any signs of contamination.

- Examine fuel lines for leaks or damage.

2. Routine Maintenance Tasks

- Changing the Oil:

- Drain the old oil using a suitable container.

- Replace the oil filter if applicable.

- Refill with fresh, recommended oil.

- Cleaning the Air Filter:

- Remove the air filter from its housing.

- Use compressed air or a mild detergent to clean it.

- Allow it to dry completely before reinstalling.

- Inspecting the Spark Plug:

- Remove the spark plug and check for wear.

- Clean or replace it as necessary.

- Ensure proper gap settings before reinstallation.

By adhering to these steps, you can maintain your engine’s performance and avoid unexpected breakdowns. Regular attention to these details will pay off in the long run, ensuring reliable operation when you need it most.

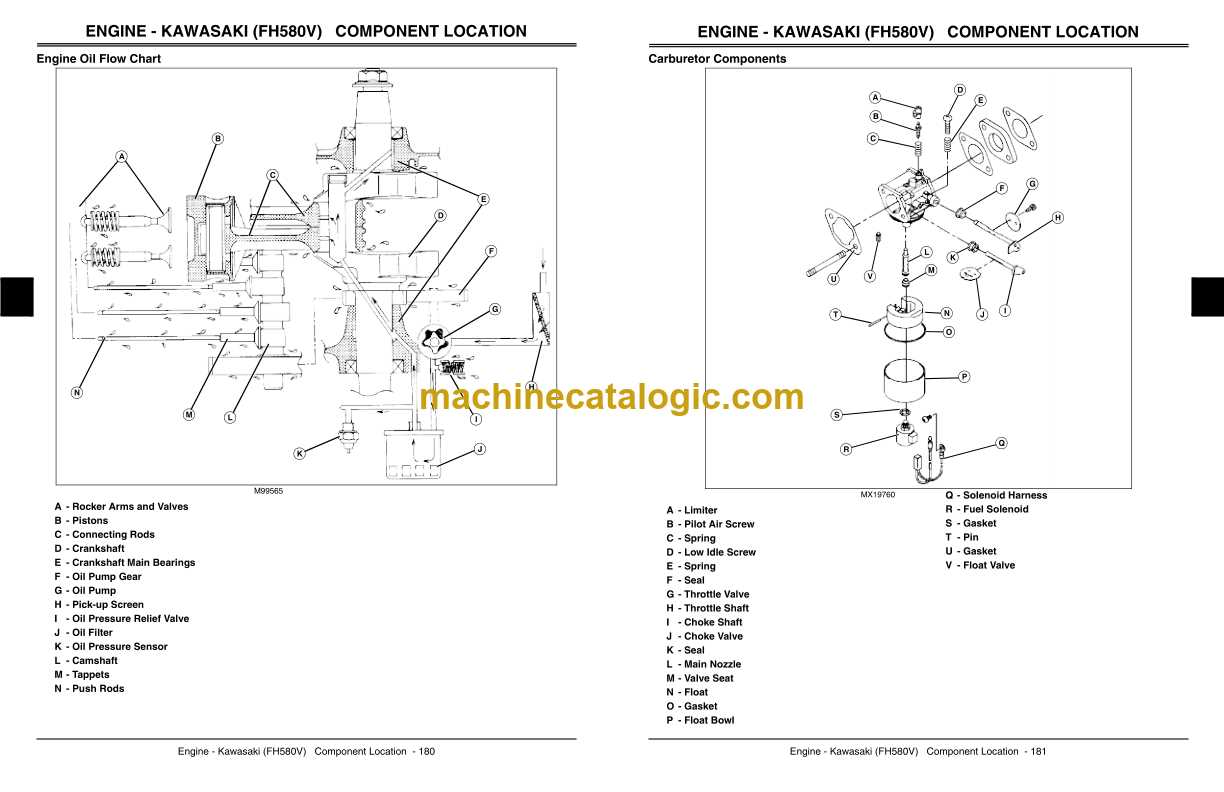

Engine Specifications and Features

This section provides an overview of the fundamental characteristics and capabilities of a specific type of air-cooled four-stroke engine, emphasizing its design, performance, and operational efficiency.

- Type: Air-cooled, four-stroke

- Cylinder Arrangement: V-twin configuration

- Displacement: 493 cc

- Bore x Stroke: 88 mm x 64 mm

Understanding the specifications helps in assessing the engine’s potential for various applications, including residential and commercial use. Key features include:

- Power Output: Approximately 15.5 HP at 3600 RPM

- Torque: 27.1 Nm at 2600 RPM

- Fuel System: Carburetor with a float-type design

- Ignition: Transistorized magneto ignition system

- Lubrication: Pressure lubrication with a full-flow filter

The combination of these specifications results in a robust engine capable of delivering reliable performance across a range of tasks, ensuring efficiency and durability under various conditions.

Replacing Spark Plugs Effectively

Maintaining optimal engine performance involves regular attention to various components, one of which is the spark plug. Replacing these crucial elements not only enhances efficiency but also promotes longevity in engine life. Understanding the process ensures that the task is completed accurately and efficiently.

Preparation is key before starting the replacement. Gather the necessary tools, including a spark plug socket, a torque wrench, and a gap gauge. It’s also advisable to consult the specifications for the required spark plug type and gap setting to ensure compatibility with the engine.

Begin by removing the old spark plugs. Disconnect the ignition wire carefully to prevent damage, then use the spark plug socket to loosen and extract the plugs. Inspect them for wear and signs of carbon buildup, which can indicate larger issues within the engine.

Once the old plugs are out, install the new spark plugs with precision. Adjust the gap using the gap gauge as needed, then gently thread the new plugs into their sockets. It’s crucial to tighten them to the specified torque to avoid any risk of damage or leakage.

After securing the new plugs, reconnect the ignition wires carefully, ensuring they are seated properly. Finally, start the engine to verify that it runs smoothly, indicating that the replacement was successful. Regular checks and timely replacements will keep the engine operating at its best.

Fuel System Maintenance Tips

Proper upkeep of the fuel delivery system is essential for optimal engine performance and longevity. Regular attention to this component can prevent issues related to fuel efficiency and engine responsiveness. This section outlines key practices to ensure that the fuel system operates smoothly and effectively.

Routine Inspection

Conducting regular inspections can help identify potential problems before they escalate. Check for signs of wear and tear, leaks, or blockages in the fuel lines. Additionally, ensuring that the fuel filter is clean and functioning properly can significantly enhance system performance.

Fuel Quality Management

Using high-quality fuel is crucial for maintaining the integrity of the fuel system. Contaminated or low-grade fuel can lead to deposits that hinder performance. It’s advisable to avoid letting the fuel level drop too low, as this can allow sediment to enter the system.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect fuel lines | Monthly | Look for cracks or leaks |

| Change fuel filter | Every 100 hours | Replace with high-quality filters |

| Check fuel quality | Before each use | Use fresh, clean fuel |

| Clean fuel tank | Annually | Remove any debris or sediment |

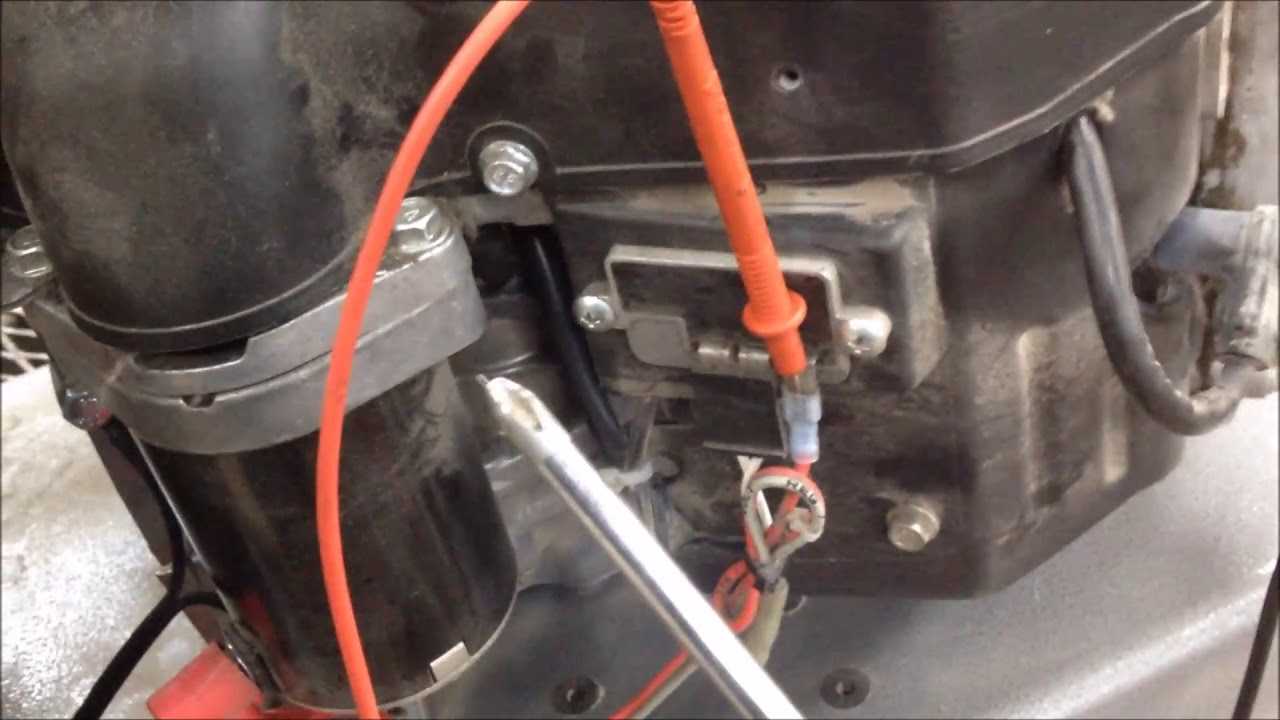

Understanding Electrical System Problems

Electrical issues can often manifest as erratic behavior or complete failure of equipment. Recognizing the signs of these malfunctions is crucial for effective troubleshooting and maintenance. By understanding common symptoms and underlying causes, users can address problems more efficiently and ensure optimal performance of their machinery.

Several key components are integral to the electrical systems, and problems in these areas can lead to significant operational disruptions. Below is a table outlining typical symptoms, potential causes, and suggested solutions.

| Symptoms | Potential Causes | Suggested Solutions |

|---|---|---|

| Equipment fails to start | Dead battery, faulty ignition switch | Check battery charge, inspect ignition connections |

| Dim or flickering lights | Loose wiring, voltage fluctuations | Examine wiring connections, test voltage levels |

| Unusual noises from electrical components | Worn-out alternator, failing relays | Inspect components for wear, replace faulty parts |

| Blown fuses | Overloaded circuit, short circuits | Identify source of overload, replace fuses |

By systematically evaluating these symptoms and applying the appropriate solutions, users can maintain the integrity of their electrical systems and minimize downtime. Regular inspections and proactive maintenance can prevent many of these issues from occurring in the first place.

Cooling System and Fluid Changes

The cooling system plays a vital role in maintaining optimal operating temperatures for small engines. Regular maintenance and fluid changes are essential to ensure efficient performance and longevity of the equipment. This section outlines the importance of the cooling system and provides guidelines for fluid maintenance.

Importance of the Cooling System

A well-functioning cooling system prevents overheating, which can lead to serious engine damage. Key components include:

- Radiator

- Thermostat

- Cooling fan

- Hoses and connections

Each of these parts contributes to effective heat dissipation and must be monitored regularly.

Fluid Change Procedures

Changing the cooling fluid is crucial for optimal engine function. Follow these steps for a successful fluid change:

- Gather necessary tools and replacement fluid.

- Ensure the engine is cool before starting.

- Locate the drain plug and remove it to allow old fluid to flow out.

- Inspect the fluid for contaminants and replace any damaged components if needed.

- Refill with the recommended cooling fluid, ensuring no air bubbles are trapped in the system.

- Check for leaks and run the engine briefly to circulate the new fluid.

Regular inspection and timely fluid changes can significantly enhance the efficiency and lifespan of the engine.

Transmission and Gearbox Repairs

Maintaining optimal functionality of the transmission and gearbox is crucial for ensuring the smooth operation of any machinery. Regular inspection and timely interventions can prevent extensive damage and costly overhauls. This section outlines essential procedures and considerations for addressing issues related to the transmission system.

Common Issues and Symptoms

- Unusual noises during operation

- Difficulty in shifting gears

- Slipping gears

- Fluid leaks around the transmission

- Overheating of the system

Repair Steps

- Diagnosis: Begin with a thorough inspection to identify the root cause of the problem. Check for any visible signs of wear and tear.

- Fluid Check: Assess the condition and level of transmission fluid. Replace if contaminated or low.

- Component Inspection: Examine gears, bearings, and seals for damage. Replace any worn or broken parts.

- Adjustment: Make necessary adjustments to align the components properly and ensure smooth shifting.

- Reassembly: Carefully reassemble the transmission system, ensuring all parts are correctly positioned and secured.

- Testing: After repairs, conduct a series of tests to confirm proper functionality and address any remaining issues.

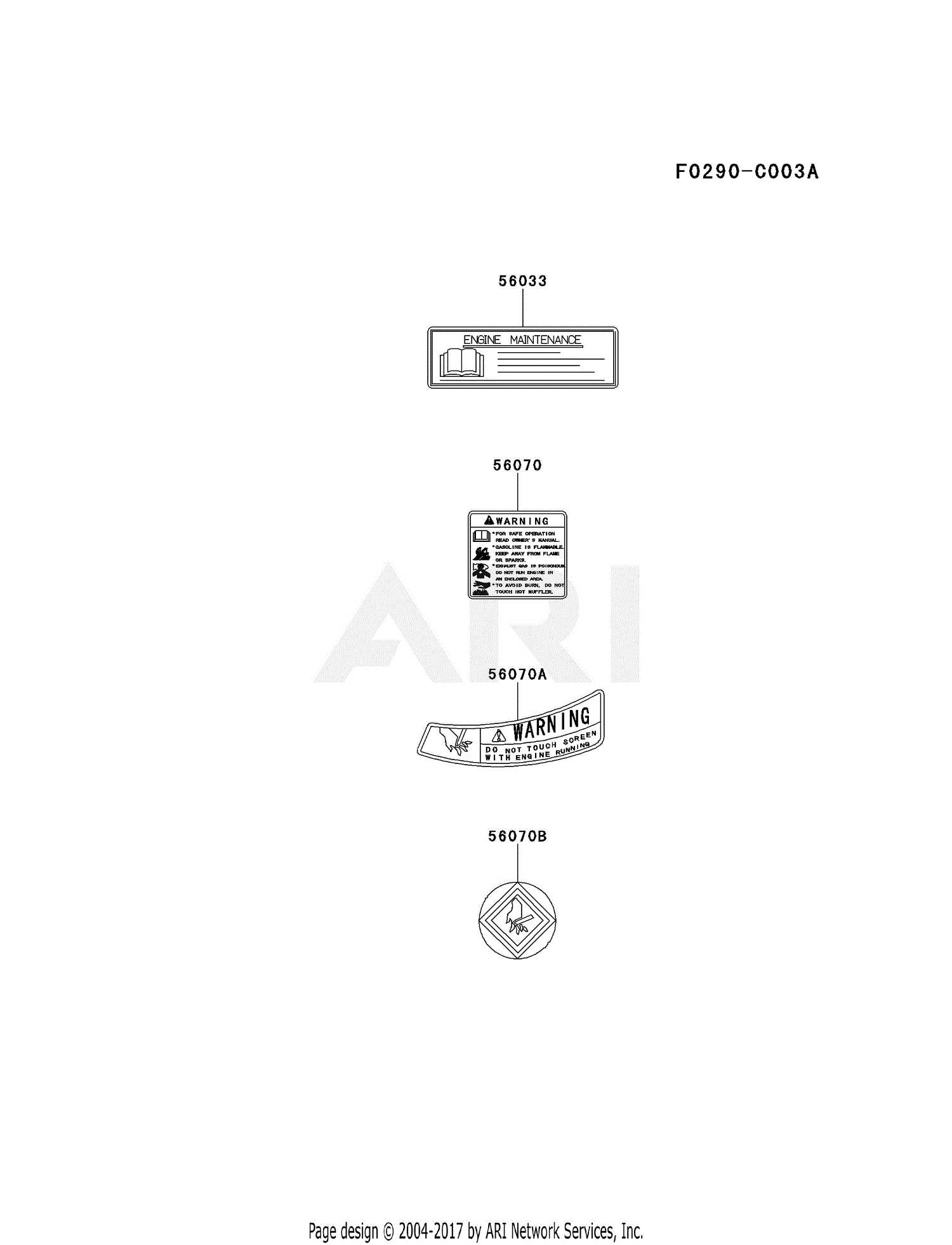

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is essential to prioritize safety to prevent accidents and injuries. Adhering to proper protocols not only protects the individual performing the work but also ensures the longevity of the equipment. Understanding potential hazards and taking preventive measures can significantly reduce risks associated with mechanical upkeep.

Personal Protective Equipment (PPE)

Utilizing personal protective equipment is a fundamental aspect of ensuring safety. This includes wearing gloves, goggles, and sturdy footwear to shield against potential hazards such as sharp edges or flying debris. Additionally, utilizing ear protection can mitigate the effects of loud machinery, safeguarding hearing in the long term.

Workspace Organization

Maintaining a well-organized workspace is critical for minimizing risks. Ensure that tools and materials are stored properly and that the area is free from clutter. A clean environment reduces the chances of accidents, such as trips or falls, and allows for more efficient work processes. Always be mindful of your surroundings and the location of heavy or moving parts.

When to Seek Professional Help

Understanding when to consult an expert can significantly impact the longevity and performance of your equipment. While many maintenance tasks can be managed independently, certain situations demand the skills and knowledge of a trained technician. Recognizing these scenarios is essential for preventing further damage and ensuring optimal operation.

If you encounter persistent issues that do not resolve with basic troubleshooting, it may be time to seek assistance. Symptoms like unusual noises, irregular performance, or failure to start often indicate underlying problems that require specialized attention. Additionally, if you notice any leaks or unusual odors, these could signal serious concerns that should not be overlooked.

Complex repairs, such as those involving intricate mechanical or electrical systems, often exceed the capabilities of a casual user. In these cases, professional evaluation is advisable to avoid costly mistakes. Furthermore, if you lack the necessary tools or experience for a particular task, relying on an expert can save time and ensure the job is done correctly.

Finally, if your equipment is still under warranty, seeking professional help may be a requirement to maintain that coverage. Ignoring this aspect can lead to voiding the warranty and potentially incurring additional expenses down the line. Prioritizing professional support in these instances can protect your investment and guarantee peace of mind.