For enthusiasts and owners of classic marine propulsion devices, understanding the intricacies of these machines is vital for optimal performance. This section aims to provide comprehensive insights into the upkeep and troubleshooting of engines manufactured in a bygone era, focusing on the unique characteristics that define them.

The journey of maintaining these historic engines involves a thorough examination of their components and functions. Knowing how to address common issues and perform necessary adjustments can significantly enhance the longevity and efficiency of these beloved watercraft. Whether you are a seasoned expert or a curious novice, mastering the art of maintenance will ensure smooth sailing on your aquatic adventures.

Equipped with the right knowledge, users can tackle a variety of challenges that may arise over time. From minor tweaks to more involved interventions, this guide serves as a valuable resource for anyone looking to preserve the spirit and functionality of these classic devices. Join us as we explore essential techniques and best practices to keep your engine running like new.

Overview of Johnson Evinrude Motors

This section provides an insightful look into the range of marine propulsion systems produced by a well-known manufacturer, emphasizing their historical significance and evolution over the decades. These engines have been a staple in the boating community, known for their reliability and performance across various watercraft types.

Historical Context

Throughout the years, these power units have undergone significant changes in design and technology. Understanding their development helps enthusiasts appreciate their impact on recreational and commercial boating.

- Initial designs focused on simplicity and ease of use.

- Advancements in engineering led to improved fuel efficiency and reduced emissions.

- The introduction of innovative features enhanced user experience and safety.

Key Features

These engines are characterized by several standout features that contribute to their popularity:

- Durability: Built to withstand harsh marine conditions.

- Power Options: A variety of horsepower ratings to suit different needs.

- Maintenance: User-friendly design facilitating easier upkeep.

Overall, the legacy of these marine engines reflects a commitment to quality and innovation, making them a preferred choice among boating enthusiasts. Their influence continues to be felt in today’s marine technology advancements.

History of Outboard Engine Development

The evolution of marine propulsion systems has significantly influenced the accessibility and enjoyment of water activities. Innovations in design and technology have transformed how vessels are powered, allowing for greater efficiency, maneuverability, and user experience.

In the early 20th century, the need for reliable propulsion became apparent as recreational boating gained popularity. Initial designs were rudimentary, relying on simple mechanisms that provided limited power and speed. However, advancements in engineering during the 1920s and 1930s led to more powerful and compact solutions, enabling boaters to traverse larger bodies of water with ease.

Post-World War II, the introduction of lightweight materials and the development of two-stroke and four-stroke engines revolutionized the industry. These innovations not only improved fuel efficiency but also enhanced overall performance, making recreational boating accessible to a broader audience. Manufacturers focused on creating engines that were both powerful and user-friendly, catering to the needs of hobbyists and professionals alike.

By the 1980s, significant strides had been made in emission control and environmental sustainability. Manufacturers began prioritizing cleaner technologies, which paved the way for more eco-friendly alternatives. The incorporation of advanced electronics further improved the reliability and ease of use, transforming the boating experience.

Today, the legacy of these developments is evident in the diverse range of propulsion options available, catering to various types of vessels and activities. As technology continues to advance, the future promises even more innovative solutions, ensuring that marine adventures remain enjoyable for generations to come.

Common Issues in Vintage Models

Vintage aquatic propulsion devices often exhibit a range of challenges that can hinder their performance and reliability. Understanding these common problems can help enthusiasts maintain and restore their cherished equipment effectively. This section outlines prevalent issues that users may encounter with older models and offers insights into potential remedies.

| Issue | Description | Possible Solutions |

|---|---|---|

| Fuel System Problems | Clogs and leaks in the fuel lines can lead to inadequate power delivery. | Regularly inspect and clean fuel lines, replace old filters. |

| Electrical Failures | Wiring deterioration may result in starting issues or complete failure. | Check connections, replace corroded components, and test the battery. |

| Cooling System Issues | Blockages in the cooling channels can lead to overheating. | Flush the cooling system and inspect for any debris or obstructions. |

| Wear and Tear | Seals and gaskets may degrade over time, causing leaks. | Replace worn components and regularly check for signs of wear. |

| Propulsion Problems | Deteriorated propellers can affect speed and handling. | Examine and repair or replace damaged blades as needed. |

By addressing these common issues proactively, users can enhance the longevity and performance of their vintage aquatic devices, ensuring they remain reliable companions on the water for years to come.

Essential Tools for Repairing Motors

When it comes to maintaining and fixing engines, having the right equipment is crucial for achieving optimal performance and longevity. Various instruments and devices are needed to tackle different aspects of engine functionality, from diagnostics to assembly. Understanding these essentials can significantly enhance your ability to troubleshoot and resolve issues effectively.

Basic Hand Tools

Every technician should have a well-stocked set of hand tools. Common items include wrenches, screwdrivers, and pliers. These tools are vital for loosening and tightening bolts, as well as for general adjustments. A socket set is particularly useful for reaching fasteners in tight spaces, allowing for more efficient work.

Specialized Diagnostic Equipment

In addition to basic tools, specialized diagnostic equipment plays a key role in identifying issues. A compression gauge can assess the health of cylinders, while a multimeter is essential for electrical troubleshooting. Having these devices on hand allows for precise measurements and quicker problem resolution, ensuring that your engine operates at peak efficiency.

Step-by-Step Maintenance Procedures

Regular upkeep of aquatic propulsion systems is essential for ensuring optimal performance and longevity. Following a structured approach to maintenance helps prevent issues and enhances reliability. This section outlines key procedures that every owner should consider to maintain their equipment in top condition.

Routine Inspection

Start by conducting a thorough visual assessment of the unit. Check for any signs of wear or damage, including corrosion on external components and leaks around seals. Ensure that all connections are secure and that there are no loose wires. A regular inspection can help identify potential problems before they escalate.

Fluid Changes

Changing essential fluids is critical for smooth operation. Begin with the gear oil; drain the old fluid and refill with the recommended type. Next, check the fuel system for cleanliness and replace any filters if necessary. Regularly changing these fluids not only promotes efficiency but also extends the lifespan of the equipment.

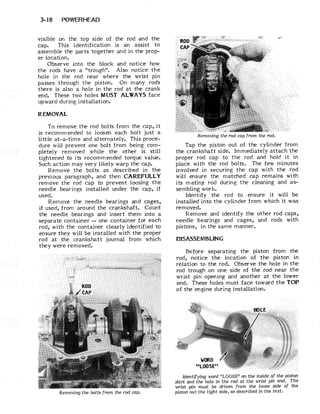

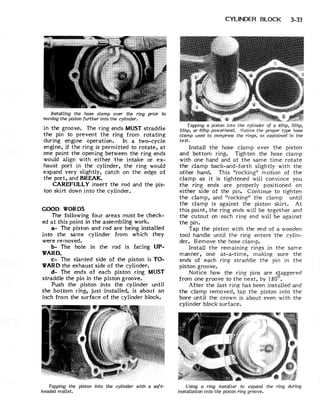

Understanding Engine Components and Functions

Gaining insight into the various elements of an internal combustion engine is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall performance and efficiency of the engine, and understanding how they interact can lead to improved operation and longevity.

Key Components Overview

Engine assembly consists of several vital parts, each serving a distinct purpose. Familiarizing oneself with these components can facilitate better diagnostics and enhancements. Below is a brief overview of some primary elements:

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides a foundation for the engine assembly. |

| Piston | Moves up and down within the cylinder, converting fuel energy into mechanical energy. |

| Crankshaft | Transforms linear motion of the pistons into rotational motion, enabling power transfer. |

| Camshaft | Controls the opening and closing of the valves, regulating airflow into and out of the cylinders. |

| Ignition System | Initiates the combustion process, igniting the air-fuel mixture in the cylinders. |

Interactions Between Components

The interplay between these elements is critical for achieving optimal functionality. For instance, the synchronized movement of the crankshaft and camshaft ensures precise timing for valve operation, which directly affects performance. Understanding these relationships helps in diagnosing issues and implementing effective solutions.

Diagnostic Techniques for Troubleshooting

Effective troubleshooting requires a systematic approach to identify and resolve issues in marine propulsion systems. Understanding the principles of diagnostics is crucial for ensuring optimal performance and longevity of the equipment.

When facing a malfunction, follow these key techniques to accurately diagnose the problem:

- Visual Inspection:

- Check for any visible damage or wear on components.

- Inspect connections and wiring for corrosion or loose fittings.

- Look for fluid leaks or abnormal signs of operation.

- Listening for Unusual Sounds:

- Identify any irregular noises during operation, such as grinding or knocking.

- Pay attention to the pitch and frequency of sounds, which may indicate specific issues.

- Testing Electrical Systems:

- Utilize a multimeter to check voltage and continuity.

- Examine switches and relays for proper function.

- Fuel System Evaluation:

- Inspect fuel lines for clogs or leaks.

- Check filters for cleanliness and replace if necessary.

- Performance Metrics:

- Measure RPM and compare with manufacturer specifications.

- Assess acceleration and top speed for inconsistencies.

By employing these techniques, you can systematically pinpoint issues and implement effective solutions, ensuring reliable operation of your equipment.

Parts Sourcing for Vintage Motors

Finding the right components for classic engines can be a rewarding yet challenging endeavor. Collectors and enthusiasts often face the difficulty of sourcing specific parts that may no longer be in production. Understanding where to look and how to evaluate options is crucial for maintaining the integrity and performance of these timeless machines.

Online marketplaces and specialty retailers serve as valuable resources for locating hard-to-find pieces. Websites dedicated to vintage equipment often feature listings from various sellers, making it easier to compare prices and conditions. Additionally, forums and communities focused on classic machinery can provide insights and recommendations for trusted suppliers.

Salvage yards and local shops specializing in older equipment also present opportunities for sourcing parts. These locations may carry remnants of vintage models, and their knowledgeable staff can assist in identifying compatible components. Networking within the enthusiast community can lead to private sales or trades, further expanding your search possibilities.

When evaluating potential sources, consider the reputation of the seller and the authenticity of the parts. Look for reviews or testimonials from previous buyers to ensure reliability. Quality is paramount, especially when working with older technology, as original or high-quality reproductions can significantly impact performance and longevity.

Ultimately, persistence and resourcefulness are key. The journey of restoring a vintage engine is often as fulfilling as the end result, and every successful part acquisition brings you one step closer to reviving a piece of history.

Safety Precautions During Repairs

When working on any mechanical device, ensuring personal safety is of paramount importance. Adhering to specific guidelines can help prevent accidents and injuries, allowing for a smooth and efficient maintenance process. Understanding potential hazards and implementing preventive measures is essential for anyone involved in servicing equipment.

- Wear Appropriate Personal Protective Equipment (PPE):

- Safety glasses to protect your eyes from debris.

- Gloves to shield your hands from sharp edges and chemicals.

- Steel-toed boots to guard against heavy objects.

- A dust mask if working with potentially harmful dust or fumes.

- Work in a Well-Ventilated Area:

Ensure adequate airflow to avoid inhaling toxic fumes or vapors. If working indoors, consider using fans or opening windows to promote circulation.

- Keep Your Workspace Organized:

A tidy area reduces the risk of accidents. Remove unnecessary tools and materials to minimize tripping hazards.

- Disconnect Power Sources:

Before starting any work, always disconnect power supplies to avoid accidental starts. This is crucial for equipment with electrical components.

- Be Mindful of Heavy Parts:

Use lifting techniques and equipment, such as hoists or dollies, to manage heavy components. Never attempt to lift items beyond your capacity.

Following these guidelines can significantly reduce the risk of injury and ensure a safer working environment. Always prioritize safety to maintain not only your well-being but also the integrity of the equipment you are servicing.

Restoration Tips for Classic Models

Restoring vintage equipment can be a rewarding endeavor, allowing enthusiasts to breathe new life into cherished machines. This process not only enhances performance but also preserves the historical value of these iconic pieces. With the right approach, tools, and knowledge, you can successfully revitalize these classics for future enjoyment.

Assessment and Planning

Before diving into the restoration, conduct a thorough assessment. Inspect all components for wear, damage, and corrosion. Create a detailed plan outlining the necessary steps and parts required for the project. Prioritize tasks based on the condition of each element, ensuring a systematic approach to the restoration.

Essential Techniques

Utilizing proper techniques is crucial for a successful overhaul. Start by cleaning all parts meticulously; removing grime and residue is vital for both functionality and appearance. Repainting can significantly enhance aesthetics; use appropriate coatings designed for durability. Additionally, replacing worn seals and gaskets can improve performance and prevent future leaks. Remember to document your progress, as this can provide valuable insights for future projects or fellow enthusiasts.

Resources for Enthusiasts and Technicians

For those passionate about maintaining and enhancing their marine equipment, a variety of valuable resources are available. These tools not only provide essential guidance but also foster a community of like-minded individuals eager to share knowledge and expertise. Whether you are a seasoned technician or a novice hobbyist, access to the right information can significantly improve your skills and confidence.

Online Forums and Communities

Participating in online forums is a great way to connect with fellow enthusiasts and professionals. These platforms offer a space for exchanging tips, troubleshooting advice, and sharing personal experiences. Websites dedicated to marine technology often have sections specifically for discussing common issues and solutions, allowing users to benefit from collective wisdom.

Instructional Videos and Tutorials

Video content has become a popular medium for learning practical skills. Numerous channels focus on step-by-step guides for various tasks related to marine equipment. These tutorials can help you visualize complex processes, making it easier to follow along and replicate techniques at home. Look for channels that feature expert advice and user-friendly explanations to enhance your understanding.