Having the right tools is crucial for ensuring efficient and successful maintenance on heavy machinery. Specialized tools allow for precise adjustments, secure fittings, and long-lasting fixes, making work smoother and reducing downtime.

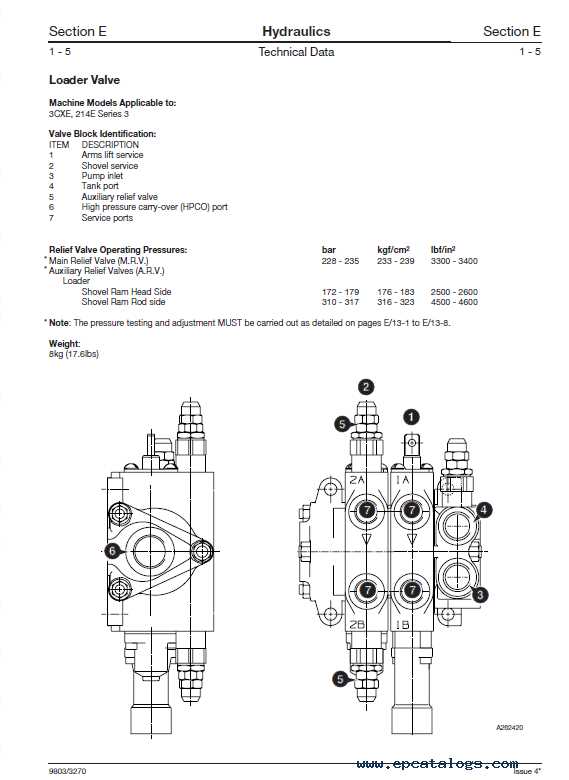

Tools designed for hydraulic systems are essential in managing fluid power systems efficiently. Pressure gauges and leak detectors ensure smooth operation by identifying and correcting issues early, protecting the overall integrity of the machinery.

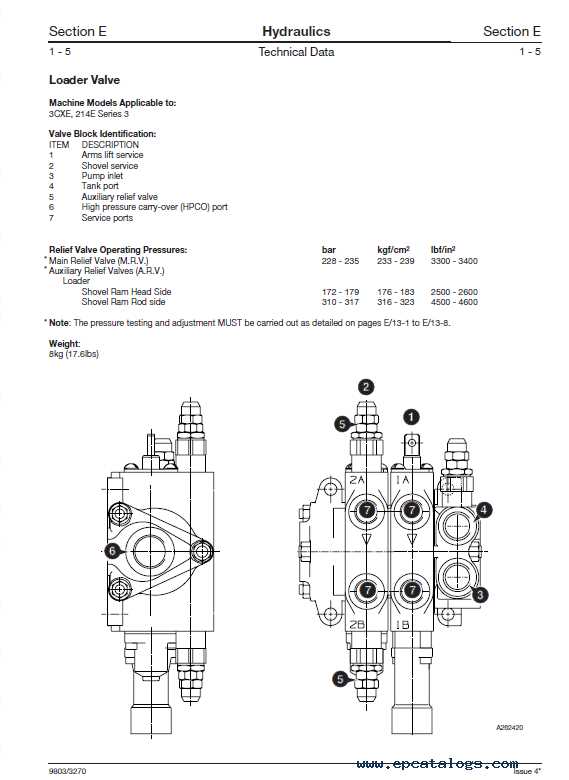

Hydraulic systems are essential for delivering the power and control needed in heavy machinery. However, issues within these systems can lead to performance declines and even system failure. This guide offers practical insights to identify and address common hydraulic problems, aiming to restore functionality and efficiency.

| Issue |

Possible Causes |

Suggested Solutions |

| Low Hydraulic Pressure |

Fluid levels too low, clogged filters, or worn pump |

Check fluid levels, replace filters, inspect pump condition |

| Overheating |

Insufficient cooling, fluid contamination, or high load |

Inspect cooling system, replace fluid if contaminated, reduce load |

Steps to Maintain Engine Health

Regular engine maintenance is essential for optimal performance and extended lifespan. Following specific steps to keep the engine in good condition helps prevent unexpected breakdowns and ensures efficient operation over time.

1. Consistent Oil Checks and Changes

Frequent oil checks are necessary to monitor the quality and level of oil. Clean and adequate oil helps reduce friction and prevents engine wear. Changing oil at recommended intervals is crucial for the engine’s longevity and efficiency.

2. Monitor Cooling System

An effective cooling system is vital to avoid overheating. Check the coolant level regularly and inspect for any leaks. Flush the cooling system periodically to remove any buildup and replace it with fresh coolant for maximum efficiency.

By following these steps, you can support the engine’s smooth functioning and reduce the likelihood of costly repairs, contributing to the overall health of the machine.

Brake System Repair Techniques

The efficiency of a vehicle’s braking system is crucial for safety and performance. Understanding the intricacies of this system allows for effective maintenance and timely interventions. Proper techniques not only enhance the functionality of the brakes but also prolong their lifespan, ensuring reliability during operation.

Common Issues and Troubleshooting

Identifying frequent problems within the braking mechanism is essential. Symptoms like unusual noises, decreased responsiveness, or fluid leaks indicate underlying issues that require attention. Conducting a thorough inspection can help pinpoint the source of these malfunctions, guiding necessary corrective actions.

Maintenance Procedures

Routine upkeep is vital for optimal brake performance. This includes regular fluid checks, pad inspections, and ensuring all components are free from debris. Adopting a systematic approach to maintenance can prevent wear and tear, significantly enhancing the overall efficiency of the braking system.

Inspection Tips for Hydraulic Hoses

Regular evaluation of hydraulic hoses is essential for maintaining optimal performance and preventing potential failures. A thorough inspection can identify issues before they lead to significant problems, ensuring the efficiency and safety of the machinery.

- Visual Checks: Look for any signs of wear, such as cracks, abrasions, or bulges on the surface of the hoses.

- Leak Detection: Monitor for any fluid leaks, which can indicate damage or deterioration in the hose.

- Connector Assessment: Examine the fittings and connectors for signs of corrosion or looseness, which could compromise the seal.

- Pressure Testing: Conduct pressure tests to ensure that the hoses can withstand operational levels without any issues.

By following these guidelines, you can enhance the longevity of hydraulic hoses and ensure safe operation.

Addressing Electrical System Problems

The electrical system of heavy machinery plays a critical role in its overall functionality and performance. Addressing issues related to this system requires a systematic approach to identify and rectify faults effectively. Common symptoms can include starting difficulties, erratic behavior of gauges, and inoperative lights, which may signal underlying electrical malfunctions.

Identifying Common Issues

Several problems can arise within the electrical system, often due to wear and tear, environmental factors, or improper maintenance. Below are some frequent electrical issues to be aware of:

| Issue |

Possible Cause |

Suggested Action |

| Poor starting |

Weak battery or corroded terminals |

Check battery charge and clean terminals |

| Dashboard lights malfunction |

Faulty wiring or blown fuse |

Inspect wiring and replace blown fuses |

| Inconsistent power supply |

Defective alternator |

Test and replace alternator if necessary |

Routine Maintenance Practices

Regular maintenance is vital for preventing electrical issues. This includes routine inspections, cleaning connections, and ensuring all components are functioning correctly. Keeping the electrical system in good condition not only enhances performance but also extends the lifespan of the equipment.

Replacing Worn-Out Backhoe Parts

Over time, certain components of heavy machinery may experience wear and tear due to regular usage and harsh conditions. This section outlines the importance of identifying and replacing these fatigued elements to ensure optimal performance and longevity of the equipment. Timely replacements not only enhance operational efficiency but also reduce the risk of unexpected breakdowns.

Identifying Worn Components

Recognizing the signs of deterioration is crucial for effective maintenance. Look for the following indicators when assessing parts:

| Part |

Signs of Wear |

Recommended Action |

| Cylinders |

Leaking fluid, reduced power |

Inspect seals, replace if necessary |

| Buckets |

Dents, cracks, excessive wear |

Repair or replace with new bucket |

| Hydraulic Hoses |

Visible cracks, leaks |

Replace damaged hoses immediately |

| Pins and Bushings |

Excessive play, noise |

Lubricate and replace if worn |

Replacement Process

Once worn parts have been identified, follow these general steps for replacement:

- Ensure the machinery is powered down and secure.

- Gather necessary tools and replacement parts.

- Carefully remove the damaged component.

- Install the new part, ensuring proper alignment.

- Test the equipment to confirm functionality.

Safety Guidelines for Repair Work

When engaging in maintenance tasks for heavy machinery, prioritizing safety is essential. This section outlines important practices that should be followed to ensure a secure working environment and minimize the risk of accidents. Adhering to these guidelines can help protect both personnel and equipment during service activities.

Personal Protective Equipment (PPE)

Utilizing appropriate personal protective equipment is crucial when conducting maintenance operations. The following items should be considered:

| Equipment |

Purpose |

| Safety glasses |

Protect eyes from debris |

| Gloves |

Shield hands from sharp objects |

| Steel-toed boots |

Prevent foot injuries |

| Hearing protection |

Reduce noise exposure |

Work Area Organization

Keeping the work area clean and organized can significantly enhance safety. Ensure tools and equipment are stored properly, and any spills are cleaned immediately to prevent slips and falls.

Cleaning and Lubricating Components

Maintaining machinery is essential for optimal performance and longevity. Regular cleaning and proper lubrication of various parts are crucial tasks that ensure smooth operation and prevent premature wear. By following systematic procedures for upkeep, operators can enhance the efficiency and reliability of their equipment.

Before beginning the cleaning process, it is important to gather the necessary materials. Ensure that you have appropriate cleaning agents, cloths, brushes, and lubricants suited for the specific components. The following table outlines the recommended practices for cleaning and lubrication:

| Component |

Cleaning Method |

Lubrication Type |

| Hydraulic System |

Flush with suitable cleaner and inspect filters |

Hydraulic oil as specified in guidelines |

| Engine |

Use engine cleaner and a soft cloth |

High-quality engine oil, check level regularly |

| Gears |

Remove debris and apply gear cleaner |

Gear lubricant according to manufacturer’s recommendations |

| Bearings |

Clean with solvent and a brush |

Grease or oil suitable for bearing applications |

By adhering to these cleaning and lubrication practices, operators can significantly extend the lifespan of their machinery while ensuring peak performance during operation. Regular inspections and timely maintenance play a pivotal role in avoiding costly repairs and downtime.

Checklist for Routine Backhoe Maintenance

Regular upkeep is essential for ensuring optimal performance and longevity of heavy machinery. This section outlines a comprehensive checklist that can help operators maintain their equipment effectively, reducing downtime and enhancing operational efficiency.

Daily Inspection

- Check fluid levels, including hydraulic fluid, oil, and coolant.

- Inspect tires for proper inflation and signs of wear.

- Examine the exterior for leaks, cracks, or damage.

- Ensure all safety devices are functional.

- Test lights and signals for proper operation.

Weekly Maintenance

- Clean air filters and check for blockages.

- Lubricate all moving parts as specified in the manufacturer’s guidelines.

- Tighten loose bolts and connections.

- Inspect the battery and clean terminals if necessary.

- Verify that all gauges and indicators are operational.

By adhering to this maintenance checklist, operators can help ensure that their equipment remains in peak condition, ready to tackle any task at hand.