This section provides comprehensive insights into the upkeep and troubleshooting processes essential for maintaining high-performance gaming machines. Understanding the intricacies of these devices is crucial for ensuring their longevity and optimal functionality.

Delving into the operational aspects, we explore common issues encountered during regular use. By familiarizing oneself with the internal mechanisms and standard procedures, operators can effectively address potential malfunctions before they escalate.

Furthermore, we emphasize the importance of routine checks and preventative measures. Implementing systematic maintenance practices not only enhances reliability but also improves user experience, allowing for uninterrupted enjoyment of gaming activities.

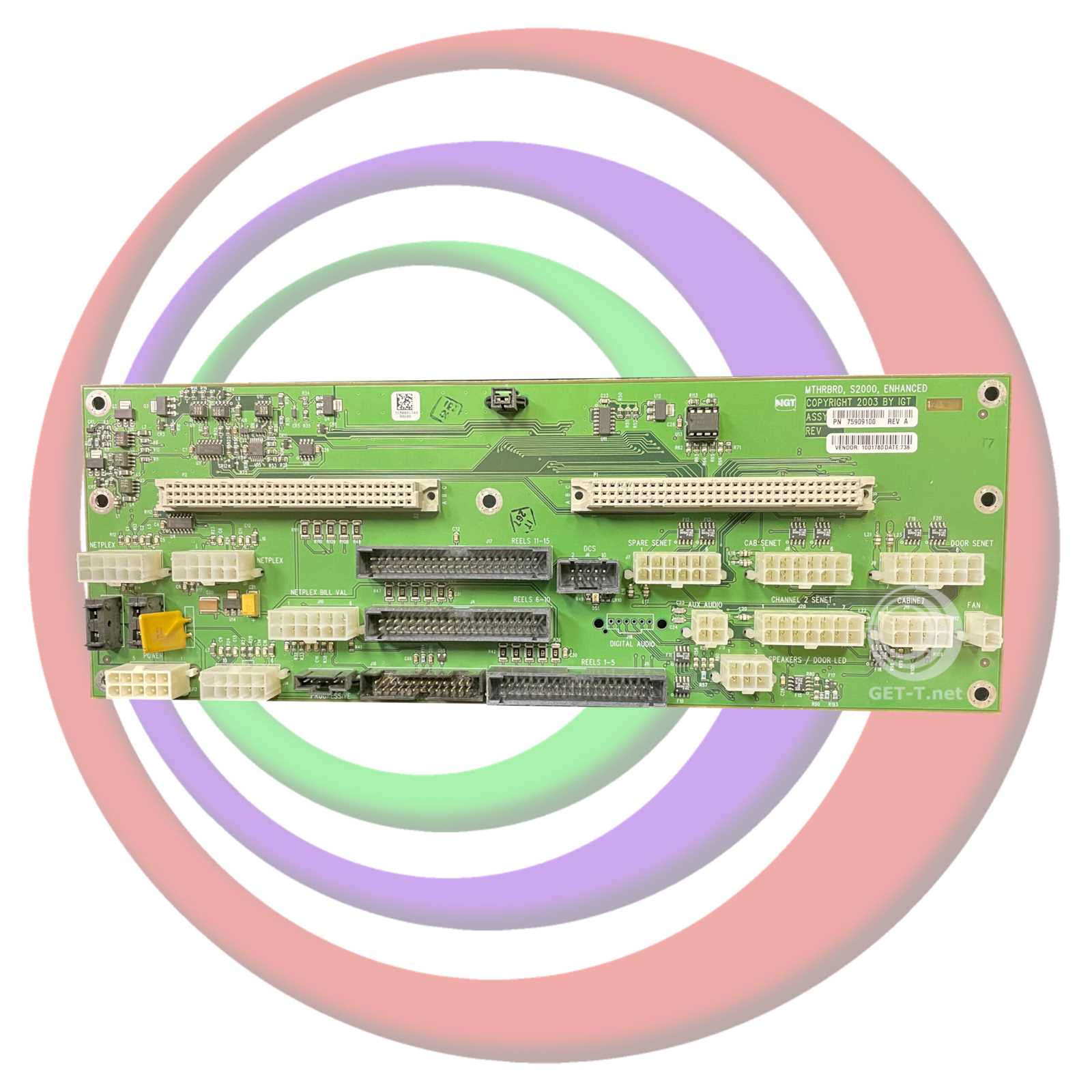

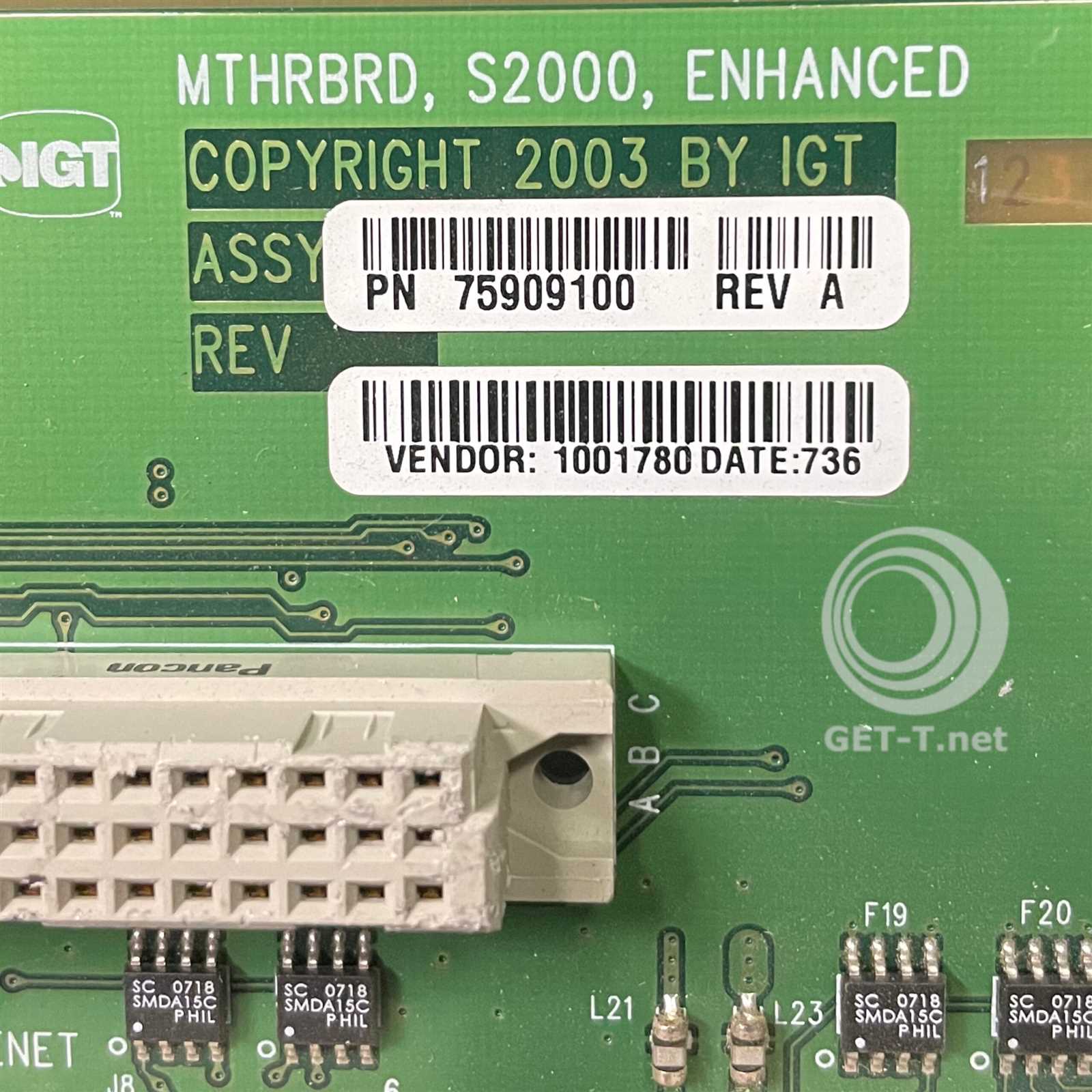

Understanding the IGT S2000 Machine

The device in question represents a sophisticated gaming system widely recognized in entertainment venues. It combines advanced technology with user-friendly features, providing an engaging experience for players. The design is both functional and aesthetically pleasing, making it a popular choice among operators.

One of the key aspects of this gaming machine is its interactive interface. Players can easily navigate through various options, enhancing their overall enjoyment. Additionally, the system is equipped with robust security features, ensuring a safe gaming environment.

Maintenance of such devices is crucial for optimal performance. Regular checks and updates can prevent common issues, allowing for uninterrupted gameplay. Understanding the inner workings of this equipment is essential for operators, as it enables them to troubleshoot minor problems effectively.

In summary, this gaming system is not only about entertainment; it embodies a blend of technology and user experience. Familiarity with its components and functions is vital for ensuring longevity and reliability in any gaming establishment.

Common Issues and Troubleshooting Tips

This section focuses on frequently encountered challenges and effective solutions when dealing with certain gaming machines. Understanding these common problems can greatly enhance the maintenance and operational efficiency of the devices.

- Power Issues:

- Check the power supply connection.

- Inspect the fuse for any signs of damage.

- Ensure the outlet is functioning properly.

- Display Problems:

- Verify cable connections between the monitor and the main unit.

- Look for any error messages on the screen.

- Adjust brightness and contrast settings.

- Coin Acceptance Issues:

- Clean the coin slot to remove any debris.

- Check for jams in the coin mechanism.

- Test with different coin types to identify compatibility.

- Button Malfunctions:

- Inspect buttons for physical damage or wear.

- Ensure proper connection of the button wiring.

- Test responsiveness and replace faulty components.

- Software Glitches:

- Restart the device to refresh the system.

- Update the software to the latest version.

- Reset to factory settings if problems persist.

By following these troubleshooting tips, operators can effectively address many common challenges and ensure smooth operation.

Essential Tools for Repairs

To effectively address issues in complex electronic devices, having the right set of instruments is crucial. This collection of essential items will ensure that technicians can troubleshoot and resolve problems efficiently. A well-organized workspace equipped with the necessary tools not only enhances productivity but also contributes to the longevity of the components being serviced.

Basic Hand Tools

Basic hand tools form the foundation of any maintenance kit. Items such as screwdrivers, pliers, and wrenches are vital for accessing internal components. Precision screwdrivers are particularly important for dealing with small screws, while needle-nose pliers can assist in manipulating delicate parts without causing damage. Additionally, a pair of tweezers can be invaluable for handling tiny components.

Diagnostic Equipment

To accurately identify faults, diagnostic equipment is essential. Multimeters allow technicians to measure voltage, current, and resistance, providing critical insights into the functionality of circuits. Oscilloscopes are also beneficial for visualizing electrical signals, enabling a deeper analysis of performance issues. By utilizing these tools, technicians can pinpoint malfunctions and implement effective solutions.

Step-by-Step Disassembly Process

Disassembling electronic devices can be a meticulous task that requires careful attention to detail. This section outlines a systematic approach to safely take apart the unit while ensuring that all components are preserved and organized for reassembly.

1. Gather Necessary Tools: Before starting, collect all required tools such as screwdrivers, pliers, and plastic prying tools. Having the right instruments will facilitate a smoother disassembly process.

2. Power Down and Disconnect: Ensure that the device is completely powered off and unplugged from any power source. This step is crucial for safety and prevents potential damage to the internal components.

3. Remove Exterior Covers: Begin by carefully removing the outer casing. Use appropriate tools to unscrew any fasteners, and gently pry open the casing to avoid breaking any clips or tabs that may hold it in place.

4. Document the Process: As you disassemble, take notes or pictures of each step. This documentation will serve as a valuable reference during reassembly, ensuring that no parts are overlooked.

5. Detach Internal Components: Once the exterior is removed, proceed to detach internal elements methodically. Identify each part, disconnect any cables, and unscrew components while keeping track of where each piece belongs.

6. Store Parts Safely: Place all removed components in labeled containers or compartments. Keeping parts organized will streamline the reassembly process and reduce the risk of losing small items.

7. Inspect Components: After disassembly, take the time to inspect all parts for wear or damage. This examination can help identify any issues that may need addressing during reassembly.

Following these steps will aid in a thorough disassembly process, setting the stage for effective maintenance or repair of the device.

Replacing Major Components Effectively

When undertaking the task of component replacement in complex systems, a systematic approach is essential to ensure optimal functionality and longevity. This section outlines key strategies and considerations for successful replacements, emphasizing the importance of preparation and precision.

Follow these steps to enhance the effectiveness of your component replacement process:

- Preparation:

- Gather all necessary tools and materials before starting the procedure.

- Review any available documentation related to the specific components to understand their functions and interconnections.

- Safety First:

- Ensure the power source is disconnected to prevent any electrical hazards.

- Wear appropriate personal protective equipment, such as gloves and safety goggles.

- Careful Disassembly:

- Take photographs or notes of the assembly before disassembly to assist in reinstallation.

- Remove components gently to avoid damaging surrounding parts.

- Replacement:

- Install the new component with attention to alignment and connections.

- Utilize manufacturer specifications to ensure compatibility and proper functioning.

- Testing:

- After replacement, reconnect the power source and conduct thorough testing.

- Observe the system for any irregularities and address them immediately.

By following these guidelines, you can enhance the reliability and efficiency of component replacements, ultimately contributing to the overall performance of the system.

Wiring Diagrams for Reference

This section provides essential wiring diagrams that serve as invaluable tools for troubleshooting and understanding electrical connections within various systems. These diagrams facilitate a clear view of the components involved and their interconnections, ensuring effective maintenance and repairs.

When working with electrical setups, having accurate diagrams is crucial for identifying wiring configurations and potential issues. Below are key aspects to consider:

- Color Coding: Different wires are often color-coded for easy identification, indicating their function and voltage level.

- Component Layout: Diagrams typically display the arrangement of components, making it easier to locate specific parts.

- Connection Points: Clear indications of where wires connect to components help prevent miswiring.

Utilizing these diagrams can significantly enhance the efficiency of troubleshooting processes and minimize errors during maintenance. Familiarity with the layout and connections is essential for successful diagnostics.

- Review the provided diagrams thoroughly.

- Take note of color codes and labels for accurate identification.

- Use the diagrams as a reference during disassembly and reassembly.

By leveraging these resources, technicians can ensure a systematic approach to resolving electrical challenges, leading to optimal performance and reliability.

Maintaining Optimal Performance

Ensuring consistent functionality and longevity of equipment requires regular attention and specific practices. By adhering to a structured maintenance routine, operators can significantly enhance the efficiency and reliability of their devices.

Key strategies for maintaining peak performance include:

- Regular Cleaning: Accumulated dust and debris can impede operation. Schedule routine cleanings to prevent buildup.

- Component Inspection: Frequently check essential parts for wear and tear. Timely replacement can avert unexpected failures.

- Software Updates: Keep the operating software up-to-date to benefit from enhancements and fixes that improve functionality.

- Calibration: Ensure that all settings are correctly adjusted to maintain optimal output and accuracy.

- Environmental Control: Maintain appropriate conditions, such as temperature and humidity, to protect sensitive components from damage.

Implementing these practices will contribute to the sustained operation and performance of the system, ensuring that it meets the demands placed upon it consistently.

Testing After Repairs

Verifying the functionality of a device following maintenance is crucial to ensure it operates as intended. This process helps identify any lingering issues that may have arisen during the servicing phase. Proper testing can prevent future malfunctions and enhance overall performance.

To effectively conduct post-maintenance evaluations, consider the following steps:

- Visual Inspection: Begin with a thorough examination of the unit to check for any obvious signs of damage or improper assembly.

- Power-On Test: Activate the device to confirm that it powers up without any unusual sounds or indicators.

- Functional Tests: Conduct specific functionality checks based on the components serviced. Ensure all features are operational.

- Stress Testing: Apply various loads or simulate typical usage scenarios to see how the device performs under different conditions.

- Final Assessment: Document any findings and address any further adjustments needed to ensure optimal operation.

By adhering to these procedures, one can confidently assess whether the unit is ready for return to service, minimizing the risk of future complications.

Understanding Error Codes

Error codes serve as essential indicators within electronic systems, allowing technicians to diagnose issues effectively. These codes communicate specific problems that may arise, guiding the user toward appropriate solutions. Recognizing and interpreting these signals can significantly enhance the troubleshooting process, ensuring efficient repairs and optimal performance.

Typically, each error code corresponds to a particular malfunction or system failure. Familiarity with these codes can streamline maintenance efforts and minimize downtime. Below is a table illustrating common error codes and their respective meanings.

| Error Code | Description |

|---|---|

| 001 | Power supply issue |

| 002 | Communication failure |

| 003 | Sensor malfunction |

| 004 | Mechanical error |

| 005 | Configuration mismatch |

Understanding these error codes allows for a more systematic approach to troubleshooting, facilitating quicker resolutions and improved functionality. Regularly consulting the relevant documentation can help maintain awareness of potential issues and their solutions.

Parts and Where to Find Them

When maintaining or restoring gaming machines, sourcing the right components is essential for ensuring optimal performance and longevity. Understanding where to locate these parts can significantly ease the repair process, providing a smoother experience for technicians and hobbyists alike.

Common Components

Below is a list of frequently needed parts, along with suggestions on where to find them:

| Part Type | Recommended Sources |

|---|---|

| Power Supply Units | Online retailers, specialty gaming supply stores |

| Motherboards | Electronic component distributors, auction sites |

| Display Panels | Local electronics shops, online marketplaces |

| Control Boards | Manufacturer websites, repair service providers |

| Cabinet Parts | Custom fabricators, dedicated restoration suppliers |

Online Marketplaces

Many parts can be sourced from online platforms that specialize in gaming equipment. Websites like eBay, Amazon, and dedicated forums often have listings for both new and used components. Always check the seller’s ratings and reviews to ensure a reliable purchase.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance tasks on electronic devices. Proper precautions can prevent accidents and protect both the technician and the equipment. By adhering to recommended guidelines, individuals can create a secure working environment conducive to effective troubleshooting and resolution of issues.

Before starting any work, it is essential to disconnect the power source to avoid electric shock. Always use insulated tools to minimize risks when handling components. Wearing appropriate personal protective equipment, such as safety glasses and gloves, can further safeguard against potential hazards.

Additionally, keeping the workspace organized and free from clutter can reduce the chance of accidents. Be aware of sharp edges and hot surfaces, as these can pose serious threats. Following a systematic approach while documenting the process helps maintain clarity and focus, ultimately enhancing safety during the task.

Upgrading Components for Better Functionality

Enhancing the performance of a device often involves upgrading its key elements. By replacing outdated components with more advanced alternatives, users can achieve improved efficiency, reliability, and overall functionality. This process not only revitalizes the equipment but also extends its lifespan, ensuring it meets the demands of modern applications.

Selecting the Right Upgrades

Choosing appropriate enhancements is crucial. Factors such as compatibility, power requirements, and intended use should guide selections. Researching available options can lead to significant improvements, such as faster processing speeds, increased memory capacity, or enhanced energy efficiency. Prioritizing quality over cost is essential to ensure lasting benefits.

After selecting new components, proper installation is vital for optimal performance. Following manufacturer guidelines during installation minimizes the risk of issues. Once installed, thorough testing should be conducted to verify functionality. Regular maintenance checks can further ensure that upgrades continue to perform at their best, ultimately leading to a more efficient and reliable device.

Frequently Asked Questions About IGT S2000

This section addresses common inquiries related to the gaming machine model, providing clarity on various operational and maintenance aspects. Whether you are experiencing technical issues or seeking to understand its functionalities better, the following FAQs aim to assist you.

General Information

- What type of game is this model designed for?

This device is primarily intended for electronic gaming, often found in casinos and gaming establishments.

- How can I identify the issues with my unit?

Common signs include unresponsive buttons, error messages on the display, or failure to power on. Troubleshooting steps can help diagnose these problems.

Maintenance and Troubleshooting

- What are the basic maintenance tasks I should perform?

Regular cleaning of components, checking connections, and updating software are crucial for optimal performance.

- How do I reset the machine if it encounters an error?

A reset can usually be performed by turning the device off and on again, or by following specific reset procedures outlined in the user guide.