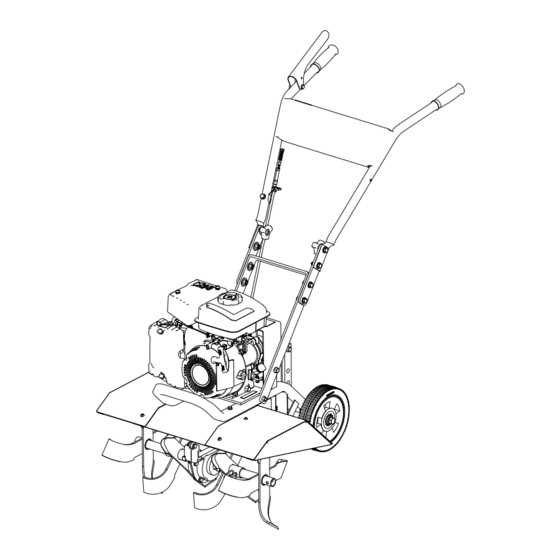

Maintaining outdoor machinery is crucial for ensuring optimal performance and longevity. Proper understanding of various components and their functions enables owners to address issues efficiently, reducing downtime and enhancing the overall user experience.

In this section, we delve into essential practices and techniques that facilitate the upkeep of garden tools. By equipping yourself with the right knowledge, you can tackle common challenges, streamline processes, and ultimately achieve better results in your landscaping endeavors.

Whether you are a seasoned user or a newcomer, familiarizing yourself with operational nuances will empower you to take control of maintenance tasks confidently. This approach not only saves time but also fosters a deeper appreciation for the equipment at hand.

Essential Tools for Lawn Mower Repair

Maintaining and fixing outdoor equipment requires a specific set of instruments that enhance efficiency and effectiveness. Having the right tools not only simplifies the process but also ensures safety while working. Below are key implements that every technician should consider having on hand.

- Wrench Set: Essential for loosening and tightening various components.

- Screwdriver Set: Useful for securing and adjusting parts with screws.

- Socket Set: Ideal for more complex fasteners that require a specific fit.

- Pliers: Handy for gripping and bending metal components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

- Oil Can: Necessary for lubrication to keep moving parts functioning smoothly.

With these tools at your disposal, tackling maintenance tasks becomes a more manageable and rewarding experience.

Common Issues with Huskee Mowers

When it comes to outdoor machinery, several recurring challenges can arise, affecting performance and efficiency. Understanding these frequent problems can help users maintain their equipment better and ensure smooth operation.

1. Engine Troubles: One of the most prevalent concerns involves engine performance. This can manifest as difficulty starting, stalling during operation, or reduced power output. Regular checks of the fuel system and air filters can mitigate these issues.

2. Cutting Quality: Inconsistent cutting can frustrate users, leading to uneven grass length. This often results from dull blades or misalignment. Keeping blades sharp and correctly positioned is essential for optimal results.

3. Electrical Failures: Electrical components may also present issues, including faulty wiring or dead batteries. Regular inspections can help identify problems early, ensuring that the machinery operates efficiently.

4. Transmission Problems: Transmission-related difficulties, such as slipping gears or loss of drive, can impede functionality. Maintaining the transmission system and checking fluid levels are critical for preventing these concerns.

5. Overheating: Overheating is another issue that can occur, especially during prolonged use. Ensuring proper ventilation and regular cleaning can help prevent overheating and extend the lifespan of the machine.

By addressing these common challenges proactively, users can enhance the reliability and longevity of their outdoor equipment.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor equipment. By following systematic procedures, you can prevent potential issues and enhance the overall efficiency of your machinery. This section provides a comprehensive guide to routine tasks that should be performed to maintain your equipment in peak condition.

Start by cleaning the exterior surfaces to remove dirt and debris that can lead to corrosion or other damage. Next, inspect the cutting components for wear and tear, replacing any parts that show signs of deterioration. It’s also important to check fluid levels, including oil and fuel, to ensure that everything is operating smoothly.

Sharpening blades is a crucial step, as dull edges can reduce effectiveness and cause strain on the engine. After this, examine the air filters and replace them if necessary to maintain airflow. Lastly, conduct a thorough check of the belts and cables, tightening or replacing them as needed to avoid unexpected failures during operation.

Understanding Engine Components and Functions

Engines are intricate machines composed of various elements that work together to convert fuel into mechanical energy. Each component plays a vital role in ensuring efficient operation, contributing to the overall performance and longevity of the system.

Key elements include the cylinder, where combustion occurs, and the piston, which translates the force generated into motion. The crankshaft is essential for converting this linear motion into rotational force, driving the attached machinery. Additionally, the intake and exhaust valves regulate the flow of air and fuel, optimizing the combustion process.

Understanding these parts and their functions is crucial for anyone looking to maintain or troubleshoot performance issues. A comprehensive knowledge of how each component interacts can lead to more effective diagnostics and enhanced operational efficiency.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when performing maintenance tasks on outdoor equipment. Adhering to specific guidelines not only protects the individual but also enhances the effectiveness of the service being conducted. Proper measures should always be taken to minimize risks and ensure safe practices throughout the process.

Essential Safety Measures

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Disconnect the power source before starting any work to prevent accidental activation.

- Keep the workspace clean and organized to avoid trips and falls.

Tool and Equipment Safety

- Inspect all tools for damage before use, and replace any that are worn or broken.

- Use tools for their intended purposes only to prevent misuse-related accidents.

- Store tools properly after use to keep the work area safe and tidy.

How to Diagnose Mechanical Problems

Identifying issues within a mechanical system is essential for effective troubleshooting. A systematic approach helps in pinpointing faults and ensuring efficient restoration. This process involves observing symptoms, conducting tests, and understanding the underlying mechanics involved.

Initial Observations

Begin by inspecting the equipment visually. Look for signs of wear, loose components, or any unusual behavior during operation. Listen for strange noises or vibrations that could indicate a deeper issue. Keeping detailed notes during this phase can be beneficial for tracking changes over time.

Testing Components

Once initial observations are made, perform targeted tests on specific parts of the system. Use tools such as multimeters or pressure gauges to measure performance levels. This quantitative data can reveal discrepancies that might not be apparent through visual inspection alone. Comparing these readings against standard values will help in determining whether components are functioning properly or require attention.

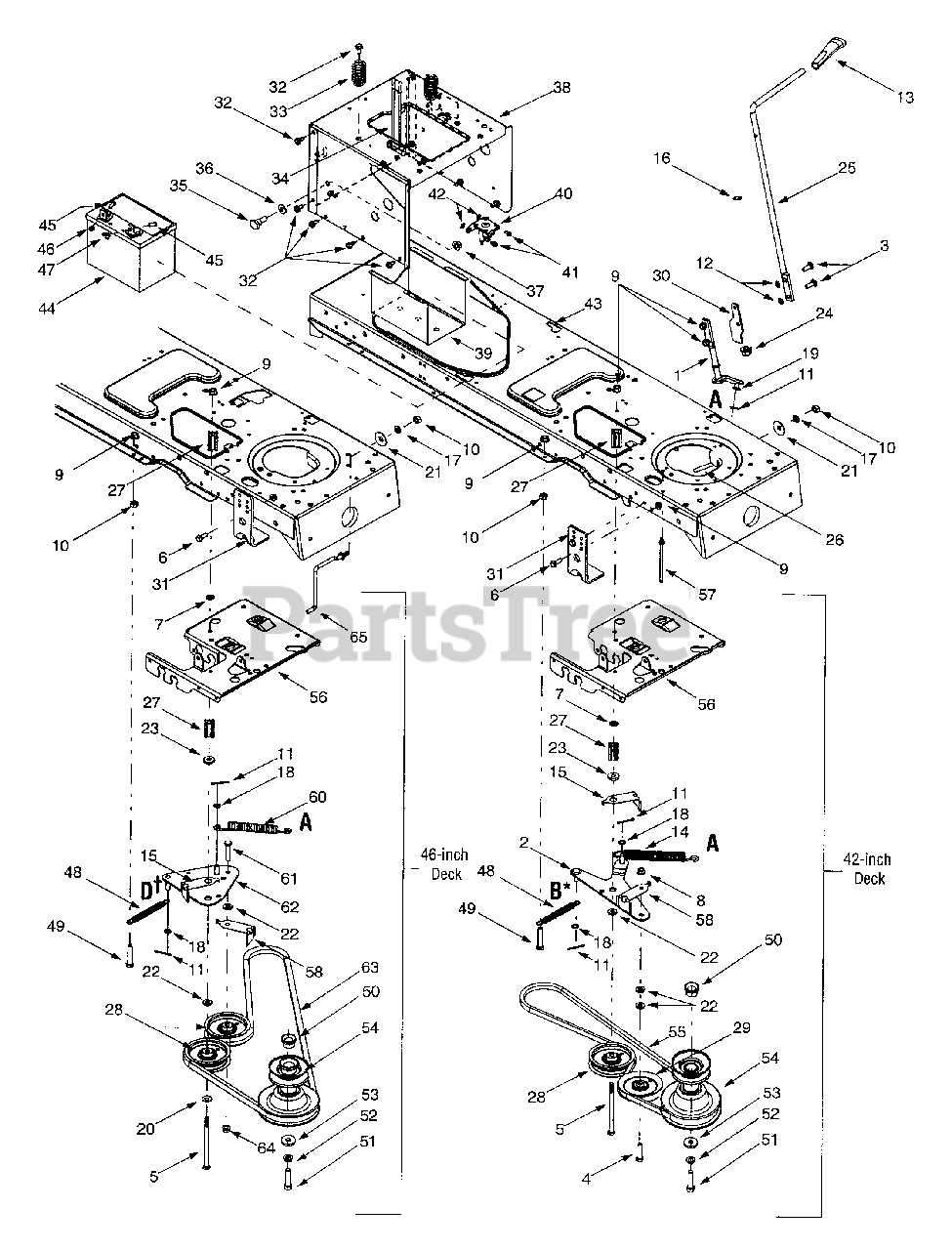

Replacing Blades and Belts

Maintaining optimal performance in your equipment involves periodically changing certain components that experience wear and tear. This section focuses on the steps needed to efficiently replace cutting edges and drive components to ensure a smooth operation.

Tools and Materials Needed

- Wrench set

- Socket set

- Safety gloves

- Replacement blades

- Replacement belts

- Lubricant

Step-by-Step Guide

- Begin by disconnecting the power source to prevent accidental activation.

- Use the appropriate tools to remove the existing blades. Ensure you retain the mounting hardware.

- Install the new blades, ensuring they are securely fastened and properly aligned.

- Next, check the condition of the belts. If worn or damaged, remove the old belts and replace them with new ones.

- After installation, lubricate moving parts as necessary to enhance performance.

- Reconnect the power source and conduct a test to verify proper functionality.

Electrical System Troubleshooting Tips

Diagnosing issues within electrical systems can be challenging yet essential for maintaining optimal performance. Understanding common problems and applying systematic approaches can simplify the troubleshooting process, ensuring effective solutions.

Check for Power Supply: Begin by verifying that the unit receives power. Inspect connections and ensure that fuses and breakers are functioning correctly. A simple continuity test can help identify any disruptions in the circuit.

Inspect Wiring and Connections: Examine all wires for signs of wear, corrosion, or damage. Loose or frayed connections can lead to malfunctions. Secure any loose terminals and replace damaged wires to restore functionality.

Test Components: Utilize a multimeter to test individual components, such as switches and relays. Measure resistance and voltage to determine if parts are operating within their specifications. Replace any faulty components to resolve issues.

Observe for Symptoms: Pay attention to any unusual behaviors, such as flickering lights or intermittent operation. Document these occurrences, as they can provide valuable insights into the underlying problems.

By following these guidelines, one can effectively troubleshoot electrical systems, enhancing reliability and performance.

Winterization Techniques for Storage

Preparing outdoor equipment for the cold season is essential to ensure longevity and optimal performance. Proper procedures can prevent damage from freezing temperatures and moisture accumulation, allowing your machinery to function efficiently when the time comes to use it again. Implementing effective winterization strategies will protect vital components and preserve overall functionality.

Cleaning and Maintenance

Before storing, thoroughly clean the device to remove any debris, dirt, or grass clippings. This step is crucial as leftover residues can promote rust and corrosion. Additionally, inspect all parts for wear and tear, addressing any necessary maintenance, such as changing fluids and tightening loose bolts.

Protective Measures

To shield the equipment from harsh conditions, consider applying a protective coating to metal surfaces. This can help prevent oxidation. Moreover, disconnecting the battery and storing it in a dry place will prolong its life. If applicable, cover the machinery with a breathable tarp to prevent moisture build-up while allowing air circulation.

Finding Genuine Replacement Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. Using original parts not only ensures compatibility but also contributes to the overall reliability of the machine. With so many options available, knowing where to look can save both time and frustration.

Identifying Authorized Dealers

One of the most effective ways to find original components is by purchasing from authorized dealers. These retailers are recognized by the manufacturer and typically carry a range of certified parts. They often provide warranties and customer support, ensuring you receive the right component for your needs.

Utilizing Online Resources

In today’s digital age, the internet serves as a valuable tool for finding authentic parts. Various online platforms specialize in genuine components, offering detailed catalogs and user reviews. When using these resources, be sure to verify the seller’s credibility and read through customer feedback to avoid counterfeit items.

DIY Troubleshooting vs. Professional Help

When facing issues with your equipment, deciding between handling the problem yourself or seeking expert assistance can be challenging. Both approaches have their merits and can lead to effective solutions, but understanding the nuances of each can help you make an informed choice.

Here are some factors to consider when weighing your options:

- Skill Level: Assess your knowledge and experience. If you have a strong background in mechanics, DIY troubleshooting may be viable. However, if you’re unfamiliar with the machinery, professional help might be safer.

- Complexity of the Issue: For simple problems like routine maintenance or minor adjustments, tackling it yourself can save time and money. In contrast, complicated malfunctions may require specialized tools and expertise.

- Time Commitment: Evaluate how much time you can dedicate to diagnosing and fixing the issue. Professionals can often complete repairs more quickly due to their experience.

- Cost Considerations: DIY repairs can be cost-effective if you have the necessary tools. However, improper fixes might lead to higher expenses down the line, making professional services a worthwhile investment.

- Warranty Implications: Consider whether your equipment is still under warranty. Some warranties require professional service for coverage, which may influence your decision.

Ultimately, the choice between self-repair and enlisting a professional hinges on your specific situation, skill set, and the nature of the issue at hand. Weighing these factors will guide you toward the most suitable approach for resolving the problem effectively.

Maintaining Optimal Performance Year-Round

To ensure your outdoor equipment operates at its best throughout the seasons, regular upkeep and attention to detail are essential. Implementing a consistent maintenance routine can enhance longevity, efficiency, and reliability.

Here are some key practices to keep in mind:

- Regular Cleaning: Remove debris, grass, and dirt after each use to prevent buildup and corrosion.

- Sharp Blades: Check and sharpen cutting implements periodically to maintain clean and efficient cuts.

- Fluid Checks: Monitor and replace oil and fuel regularly to ensure optimal engine performance.

- Inspecting Belts: Examine drive and control belts for wear and tension, replacing them as necessary.

In addition to these practices, consider seasonal preparations:

- Spring: Tune up the engine and replace any worn parts after winter storage.

- Summer: Keep an eye on overheating; clean cooling fins and check airflow.

- Fall: Prepare for colder months by winterizing your equipment and storing it properly.

By adhering to these guidelines, you can ensure that your outdoor apparatus remains in peak condition, providing dependable service for years to come.