Proper maintenance of outdoor power equipment is crucial for optimal performance and longevity. Understanding the intricacies of your engine can enhance its functionality and prevent unexpected breakdowns. This section aims to provide a comprehensive overview of troubleshooting and upkeep strategies tailored for specific engine models.

By familiarizing yourself with common issues and their solutions, you can effectively address problems before they escalate. Whether you are a seasoned mechanic or a novice enthusiast, the following insights will equip you with the knowledge needed to ensure your equipment runs smoothly.

In this guide, you will discover step-by-step instructions that will delve into essential practices, empowering you to take control of your machinery’s health. Embracing these techniques will ultimately lead to a more reliable and efficient outdoor experience.

Understanding Briggs Stratton 10T502 Basics

This section delves into the fundamental aspects of a widely used small engine model, exploring its features, functionality, and common applications. Gaining insight into these core components is essential for effective maintenance and troubleshooting.

Key Features

The engine is known for its reliability and efficiency. It is designed to provide optimal performance in various outdoor equipment, including lawn mowers and generators. With a robust build, it offers durability and ease of use, making it a preferred choice among users.

Common Applications

This engine type is primarily utilized in residential and commercial gardening tools. Its versatility allows it to power not only mowers but also pressure washers and snow throwers. Understanding the specific applications can help users maximize its potential and ensure longevity.

In summary, familiarizing oneself with the basics of this engine model equips users with the knowledge needed for effective operation and upkeep.

Common Issues with Briggs Stratton Engines

Engines from this well-known manufacturer often encounter a variety of challenges that can affect their performance and reliability. Understanding these common problems can help users diagnose and address issues effectively, ensuring smooth operation and longevity.

| Issue | Description | Possible Solutions |

|---|---|---|

| Hard Starting | Difficulty in starting the engine can be caused by fuel issues, spark plug problems, or carburetor blockages. | Check fuel quality, replace spark plugs, and clean or rebuild the carburetor. |

| Excessive Vibration | Unusual vibrations may arise from loose components or imbalanced parts. | Tighten all bolts and screws, and inspect blades or other rotating elements for balance. |

| Overheating | Engines can overheat due to inadequate lubrication, clogged air filters, or cooling system failures. | Ensure proper oil levels, clean or replace air filters, and check cooling fins for obstructions. |

| Fuel Leaks | Leaks can occur from deteriorated fuel lines, gaskets, or connections. | Inspect and replace damaged fuel lines and seals to prevent leaks. |

| Loss of Power | Reduced power output may result from air intake issues, fuel delivery problems, or worn internal components. | Examine air filters, fuel systems, and conduct compression tests on internal parts. |

By recognizing these prevalent issues and implementing appropriate solutions, users can maintain optimal engine function and extend the lifespan of their equipment.

Essential Tools for Engine Repair

When it comes to maintaining and fixing engines, having the right instruments at your disposal can significantly impact the efficiency and effectiveness of your work. A well-equipped toolkit not only streamlines the repair process but also enhances safety and precision. Below are the fundamental tools every technician should consider essential for engine work.

Basic Hand Tools

Hand tools form the backbone of any engine servicing operation. These include a variety of wrenches, pliers, and screwdrivers designed to facilitate disassembly and reassembly of engine components. A well-structured selection ensures that you can tackle most tasks with ease.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts |

| Torque Wrench | To apply specific torque to fasteners |

| Pliers | For gripping and bending components |

| Screwdrivers | For assembling and disassembling parts |

Specialized Equipment

In addition to standard tools, certain specialized equipment can greatly enhance your ability to diagnose and repair issues effectively. These instruments provide precision and accuracy that are crucial for successful engine maintenance.

| Tool | Purpose |

|---|---|

| Multimeter | To measure electrical properties |

| Compression Tester | For assessing engine compression |

| Oil Pressure Gauge | To check oil pressure levels |

| Timing Light | For setting ignition timing accurately |

Step-by-Step Repair Process Explained

This section outlines a comprehensive approach to addressing common issues in small engine systems. Following a structured procedure ensures that each aspect is thoroughly evaluated and resolved, leading to optimal performance and longevity of the equipment.

The process can be broken down into distinct phases, allowing for systematic troubleshooting and correction of faults. Below is a detailed table summarizing each stage, its purpose, and key actions to be taken:

| Step | Purpose | Key Actions |

|---|---|---|

| 1 | Initial Assessment | Inspect the unit for visible damage or leaks. |

| 2 | Diagnostic Testing | Use appropriate tools to identify performance issues. |

| 3 | Disassembly | Carefully take apart the engine components for inspection. |

| 4 | Cleaning | Remove dirt and debris from all parts to ensure smooth operation. |

| 5 | Replacement of Parts | Swap out any worn or damaged components with new ones. |

| 6 | Reassembly | Put the engine back together, ensuring all parts are secure. |

| 7 | Final Testing | Run the engine to confirm that it operates correctly. |

Following this methodical framework will facilitate effective troubleshooting and maintenance of small engine devices, ensuring they operate at peak efficiency.

Maintaining Your Engine for Longevity

Proper upkeep is essential for ensuring the extended lifespan and reliable performance of your machinery. By implementing a consistent maintenance routine, you can prevent potential issues and enhance overall efficiency. This section outlines key practices that will help keep your engine in top condition.

- Regular Oil Changes: Changing the oil at recommended intervals prevents buildup of contaminants and ensures smooth operation.

- Air Filter Maintenance: Check and replace air filters as needed to ensure optimal airflow, which is crucial for combustion efficiency.

- Spark Plug Inspection: Regularly inspect and replace spark plugs to maintain ignition efficiency and prevent misfires.

- Fuel Quality: Use high-quality fuel and consider adding stabilizers to prevent degradation, especially during storage.

- Cooling System Care: Ensure that the cooling system is free of debris and has sufficient coolant to prevent overheating.

In addition to these practices, always refer to the manufacturer’s guidelines for specific maintenance schedules and procedures. Consistent attention to these details can significantly extend the life of your engine, saving you time and money in the long run.

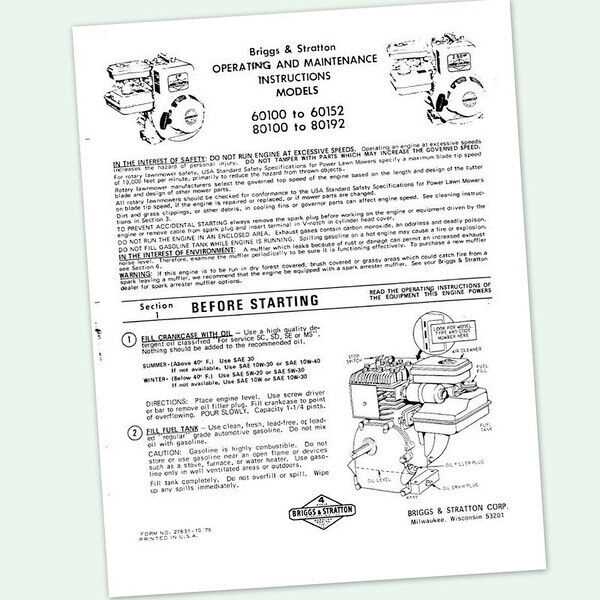

Safety Precautions During Repairs

When undertaking maintenance tasks on mechanical equipment, ensuring personal safety and minimizing risks should be a top priority. Adopting proper precautions not only protects the individual performing the work but also contributes to the longevity and functionality of the machinery. Awareness of potential hazards and implementing safety measures can significantly reduce the likelihood of accidents.

Essential Safety Gear

Before starting any maintenance work, it is crucial to equip oneself with the right protective gear. Wearing safety glasses shields the eyes from debris and potential splashes. Additionally, gloves can prevent cuts and abrasions, while sturdy footwear provides support and protection against heavy objects. In some cases, ear protection may also be necessary to guard against excessive noise levels.

Work Area Organization

Maintaining an orderly workspace is vital for safe operations. Clear away unnecessary tools and materials to minimize trip hazards. Ensure that all equipment is properly positioned and secured before commencing work. A well-lit environment further enhances visibility, allowing for greater attention to detail and reducing the risk of mistakes.

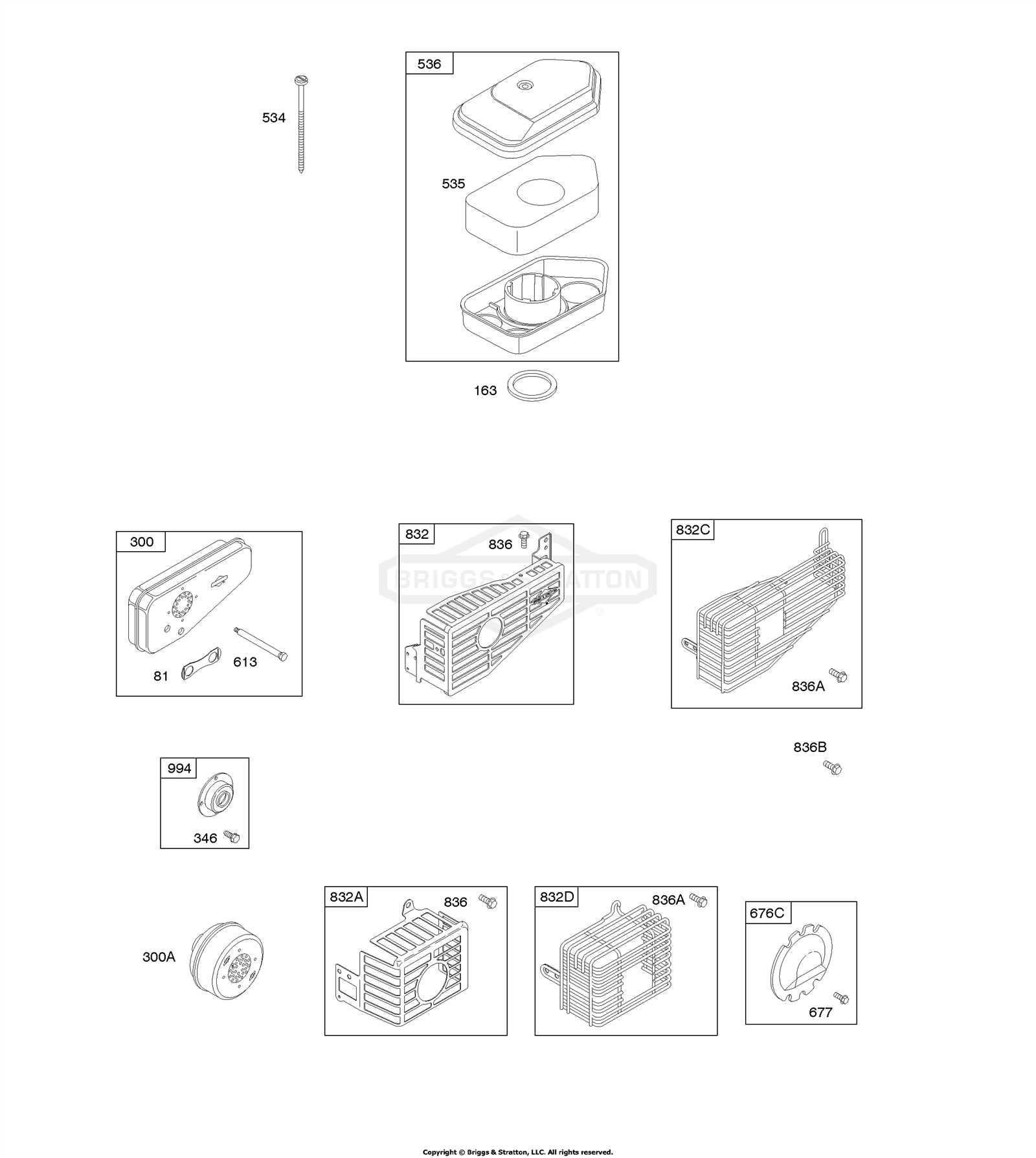

Parts Replacement: What You Need

When it comes to maintaining outdoor power equipment, understanding which components may require substitution is essential for optimal performance. Regular checks and timely exchanges can prolong the life of your machinery, ensuring it runs smoothly and efficiently. Below, we outline the necessary parts and considerations for effective replacements.

| Component | Signs of Wear | Recommended Replacement Frequency |

|---|---|---|

| Air Filter | Reduced airflow, visible dirt accumulation | Every 25 hours of use or annually |

| Fuel Filter | Difficulty starting, sputtering engine | Every 50 hours of use or annually |

| Oil Filter | Dirty oil, reduced lubrication | Every 100 hours of use or annually |

| Spark Plug | Hard starting, poor engine performance | Every 100 hours of use or annually |

| Blade | Dull edges, visible damage | Every 25 hours of use or as needed |

Staying ahead of these potential issues will not only enhance the functionality of your equipment but also provide peace of mind during operation. Always refer to the manufacturer’s guidelines for specific recommendations regarding your unit.

Troubleshooting Common Engine Problems

Addressing typical issues that arise in small engines is crucial for maintaining performance and longevity. Identifying symptoms and understanding their potential causes can lead to effective solutions. Common problems often include difficulty starting, irregular operation, and unusual noises. By systematically diagnosing these issues, users can restore functionality and prevent further damage.

One frequent concern is the engine failing to start. This may stem from fuel-related issues, such as stale or contaminated gasoline. Ensuring the fuel system is clean and using fresh fuel can resolve this. Additionally, checking the spark plug for wear or damage is vital, as a faulty plug can prevent ignition.

Irregular running is another common issue, often indicated by sputtering or stalling. This can be attributed to air or fuel blockages. Inspecting the air filter and fuel lines for clogs or dirt is essential. Proper maintenance of these components can enhance airflow and fuel delivery, promoting smoother operation.

Unusual noises, such as knocking or rattling, can signal mechanical problems within the engine. Low oil levels or using the wrong type of lubricant may cause excessive wear. Regularly checking and maintaining appropriate oil levels can mitigate this risk. If noises persist, further examination of internal components may be necessary to identify and rectify the issue.

By understanding these common challenges and their solutions, users can effectively troubleshoot and maintain engine performance, ensuring reliable operation for years to come.

Finding Reliable Replacement Parts Online

Locating trustworthy components for machinery can be a daunting task, especially with the abundance of options available on the internet. To ensure optimal performance and longevity, it is crucial to source parts that meet quality standards. This section provides guidance on how to effectively navigate online platforms for reliable replacements.

When searching for components online, consider the following steps:

- Research Reputable Retailers: Start by identifying well-known suppliers. Look for those with positive customer reviews and a solid track record in the industry.

- Check Product Specifications: Ensure that the items match the required specifications. Compare dimensions, material quality, and compatibility with your equipment.

- Look for Warranty Offers: Reliable vendors often provide warranties on their parts. A warranty indicates confidence in the product’s quality.

- Read Customer Feedback: Reviews from previous buyers can offer insights into the reliability and performance of the parts. Pay attention to both positive and negative comments.

- Compare Prices: While cost shouldn’t be the only factor, comparing prices across different platforms can help you find fair deals. Avoid extremely low-priced items, as they may indicate poor quality.

By following these steps, you can enhance your chances of finding dependable replacement components, ensuring your equipment runs smoothly and efficiently.

Tips for Efficient Engine Maintenance

Proper upkeep of your engine is essential for ensuring longevity and optimal performance. Regular maintenance can prevent costly repairs and improve efficiency, making it crucial for any engine owner to adopt effective strategies. Below are some valuable insights to help you maintain your engine effectively.

Regular Inspections

Consistent checks can identify potential issues before they escalate. Look for signs of wear and tear, leaks, or unusual noises that may indicate underlying problems. A proactive approach will save time and resources in the long run.

Fluid Management

Maintaining the right fluid levels is vital for engine health. Regularly check oil, coolant, and fuel levels to ensure optimal operation. Clean or replace fluids as needed to prevent damage and maintain efficiency.

| Fluid Type | Recommended Maintenance Interval |

|---|---|

| Engine Oil | Every 50 hours or annually |

| Coolant | Every 2 years |

| Fuel | Every season |

By following these tips, you can ensure that your engine remains in peak condition, ultimately enhancing its performance and lifespan.