Every household appliance requires occasional attention to ensure optimal performance and longevity. This section provides insights into effective strategies for troubleshooting common issues encountered with your cleaning device. Understanding the intricacies of your equipment will empower you to address minor faults confidently.

Regular upkeep not only enhances the functionality of your unit but also extends its lifespan. By familiarizing yourself with essential components and their roles, you can tackle various challenges head-on. From basic cleaning to more intricate fixes, this guide aims to equip you with the knowledge necessary for effective maintenance.

In the following segments, you will find a wealth of information regarding common problems and their solutions. Each section is designed to clarify the steps needed to restore your appliance to peak condition, ensuring a cleaner and healthier environment in your home.

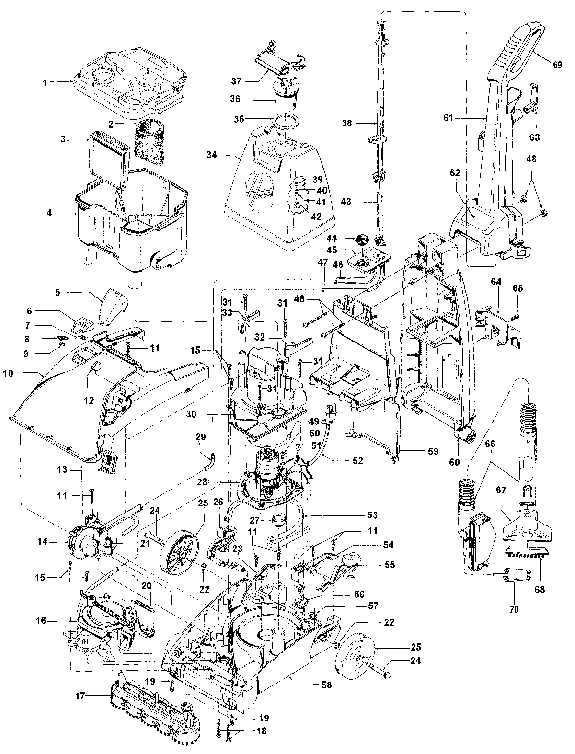

Understanding Hoover WindTunnel Models

This section aims to explore various models of a popular line of cleaning appliances known for their advanced suction technology and innovative designs. Each variant offers unique features tailored to different cleaning needs and preferences, making it essential for users to comprehend the distinctions between them.

These devices are often categorized based on their power, functionality, and specific enhancements. Below is a table that highlights key attributes and differences among several models in this series.

| Model Name | Power (Watts) | Special Features | Weight (lbs) |

|---|---|---|---|

| Model A | 1200 | Self-propelled, HEPA filtration | 15 |

| Model B | 1400 | Multi-cyclonic, pet hair attachment | 16 |

| Model C | 1300 | Lightweight, portable design | 12 |

Understanding these models can help consumers choose the right appliance based on their individual cleaning requirements and preferences, ensuring optimal performance and satisfaction.

Common Issues with Hoover Vacuums

Vacuum cleaners are essential appliances in many households, but they can experience a range of problems over time. Understanding these common issues can help users troubleshoot effectively and maintain optimal performance.

Typical Problems

- Loss of suction power

- Strange noises during operation

- Overheating

- Clogs in hoses or filters

- Difficulty in turning on or off

Maintenance Tips

- Regularly check and clean filters to prevent blockages.

- Inspect hoses for kinks or obstructions.

- Ensure the brush roll is free of debris.

- Replace bags or empty canisters as needed.

- Follow manufacturer guidelines for routine care.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is crucial for achieving effective results. The appropriate gear not only facilitates the process but also ensures safety and precision during any task. This section outlines the fundamental tools you should consider having for efficient upkeep.

Basic Hand Tools

Every maintenance toolkit should include a selection of basic hand instruments. Screwdrivers, in various sizes and types, are indispensable for accessing different components. Additionally, a good wrench set allows for secure tightening and loosening of nuts and bolts, ensuring that everything is fitted properly.

Specialized Equipment

For more intricate tasks, certain specialized tools are beneficial. A multimeter can assist in diagnosing electrical issues, providing insights into functionality. Furthermore, a vacuum cleaner attachment can help in cleaning tight spaces effectively, ensuring that no dust or debris interferes with the operation of the unit.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your cleaning device in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of the equipment, ensuring it functions efficiently over time.

Essential Cleaning Procedures

Inspecting Components

Replacing Filters and Bags

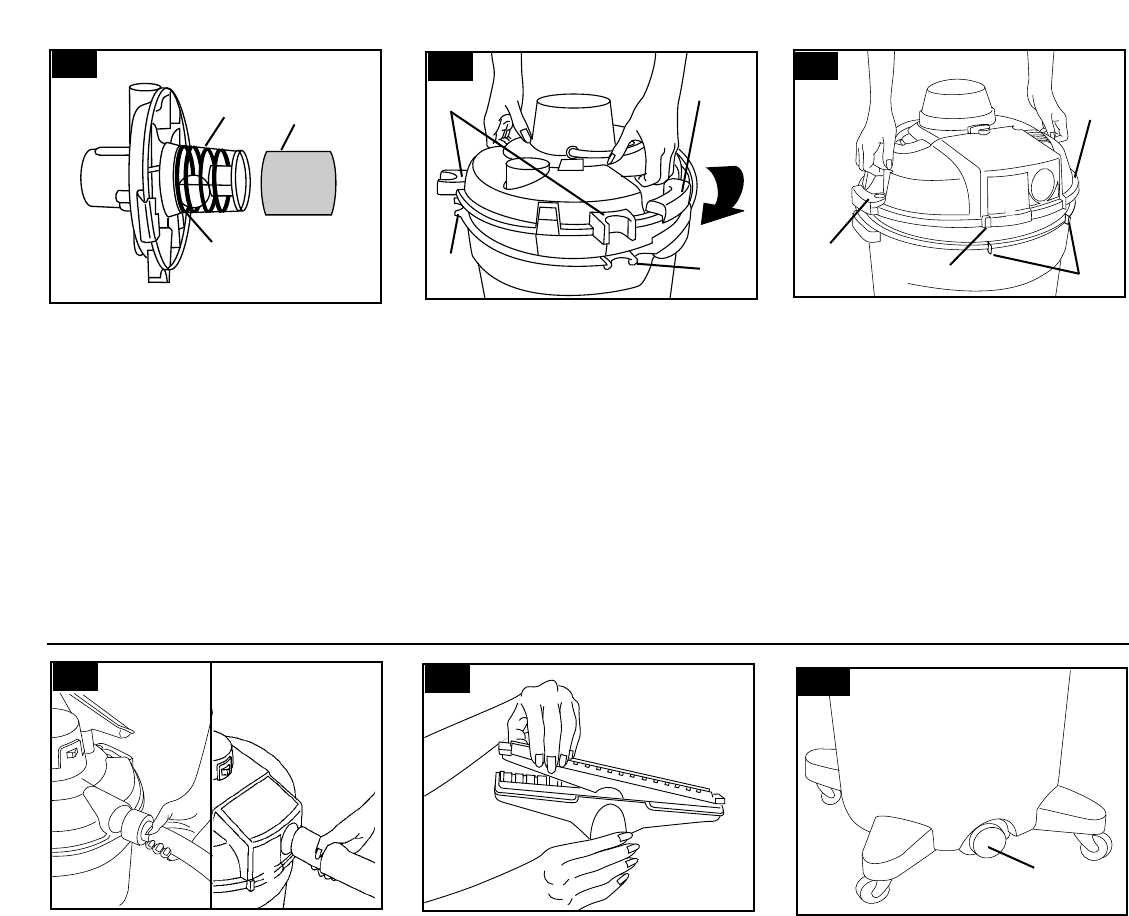

Maintaining optimal performance in your cleaning device is essential for effective operation. Regularly swapping out filtration components and collection pouches helps ensure that airflow remains unobstructed and debris is efficiently contained. This section outlines the necessary steps to effectively replace these crucial elements.

1. Identifying the Right Components: Before beginning the replacement process, verify the specifications of the required filters and bags. Refer to the documentation or packaging to confirm compatibility with your unit.

2. Disassembling the Unit: Start by turning off and unplugging the device. Carefully detach any sections that enclose the filtration components. This may involve pressing release buttons or unscrewing fasteners, depending on the design.

3. Removing Old Filters and Bags: Once exposed, gently extract the used filter and bag. Be cautious to avoid any dust or debris from escaping. Dispose of these items in accordance with local regulations to maintain a clean environment.

4. Installing New Components: Take the new filter and bag, ensuring they are oriented correctly as per the manufacturer’s guidelines. Insert them into their designated spaces, ensuring a snug fit to prevent any leakage of particles.

5. Reassembling the Unit: After the new components are securely in place, reattach any sections that were removed. Ensure all fasteners are tightened and that the assembly is intact before proceeding.

6. Testing for Proper Functionality: Plug the unit back in and power it on to confirm that it operates smoothly. Monitor for any unusual noises or decreased performance, which may indicate an issue with the installation.

Regular replacement of filtration elements not only extends the life of your appliance but also enhances its efficiency, ensuring that it continues to deliver effective cleaning results.

Fixing Motor Problems Effectively

Addressing issues related to the engine of a cleaning device is crucial for maintaining its efficiency. By understanding common symptoms and their causes, users can implement effective solutions and restore functionality. This section provides practical insights into diagnosing and fixing engine-related challenges.

Common Symptoms of Engine Issues

- Unusual noises during operation

- Overheating after a short period

- Loss of suction power

- Frequent stalling or failure to start

Steps to Troubleshoot and Resolve Problems

- Check the power supply and ensure the device is properly plugged in.

- Inspect for any blockages in the airflow path, such as clogs in hoses or filters.

- Examine the brushes and motor components for wear and tear.

- Test the switch and any electronic components for functionality.

- Consult the product specifications for guidance on replacing parts if necessary.

By systematically approaching these problems, users can enhance the lifespan and performance of their devices, ensuring reliable operation over time.

Troubleshooting Suction Issues

Addressing problems related to vacuum strength is essential for maintaining optimal performance of your cleaning device. Various factors can contribute to diminished suction, and identifying these issues can help restore functionality.

Start by examining common areas that may cause reduced airflow. Below is a table outlining potential causes and their corresponding solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Poor Suction | Clogged hose or filters | Inspect and clean or replace as needed |

| Weak Performance | Full collection bag or bin | Empty or replace the bag/bin |

| Inconsistent Airflow | Damaged or misaligned brush roll | Check for obstructions and ensure proper alignment |

| Unusual Noise | Foreign objects lodged in the system | Turn off the unit and remove any blockages |

By following these guidelines, users can effectively identify and resolve suction-related challenges, ensuring their cleaning device operates efficiently.

Cleaning and Unclogging Hoses

Maintaining the cleanliness and functionality of flexible tubing is essential for optimal performance. Over time, debris and dirt can accumulate, leading to blockages that hinder airflow and reduce efficiency. Regularly checking and cleaning these components will ensure your equipment operates smoothly.

To effectively clean and unclog the hoses, follow these steps:

- Disconnect: Safely detach the hoses from the main unit to avoid any electrical hazards.

- Visual Inspection: Examine the hoses for visible signs of blockages or damage.

- Use a Flexible Tool: Insert a long, flexible brush or a plumbing snake into the hose to dislodge any debris.

- Warm Water Rinse: Run warm water through the hoses to help dissolve stubborn clogs. Ensure the hoses are waterproof before doing this.

- Check for Residue: After rinsing, inspect for any remaining residue and repeat the process if necessary.

- Drying: Allow the hoses to air dry completely before reattaching them to the main unit.

By following these maintenance tips, you can significantly extend the lifespan of your flexible components and maintain optimal performance.

Repairing the Brush Roll Mechanism

Maintaining the rotating cleaning component is essential for optimal performance. Over time, this part may encounter issues that can hinder its efficiency. Understanding how to troubleshoot and restore its functionality can enhance the overall operation of the cleaning device.

Here are some common problems and their solutions:

- Debris Buildup:

- Inspect the brush roll for tangled hair or debris.

- Carefully remove any obstructions using scissors or a small tool.

- Wear and Tear:

- Check the bristles for signs of fraying or breakage.

- Replace the brush roll if the bristles are excessively worn.

- Motor Issues:

- Listen for unusual sounds when the unit is in operation.

- If the motor struggles, inspect the wiring connections for damage.

After addressing these concerns, always ensure to reassemble the component correctly. Regular maintenance will prolong the life of the cleaning device and enhance its performance.

Understanding Electrical Components

The operation of many devices relies on a variety of electrical elements, each serving a specific function. These components work together to ensure that power is distributed effectively, enabling the equipment to perform its intended tasks. A solid grasp of these elements is essential for troubleshooting and enhancing the functionality of any electrical system.

Power Sources are crucial as they supply the necessary energy for operation. Common types include batteries and mains electricity. Understanding how these sources interact with other components is vital for ensuring reliable performance.

Circuitry forms the backbone of any electrical device. It consists of pathways that allow current to flow between components. Knowledge of circuit layouts helps identify potential issues and aids in effective modifications or repairs.

Switches and relays play significant roles in controlling the flow of electricity. These devices can either open or close circuits, providing flexibility in how the system operates. Being familiar with their functions enables more efficient management of electrical flow.

Sensors and actuators are essential for interacting with the environment. Sensors detect changes in conditions and send signals to other components, while actuators convert electrical energy into mechanical motion. Understanding their roles can enhance both functionality and responsiveness.

Lastly, protective devices, such as fuses and circuit breakers, safeguard the system from overloads and faults. Familiarity with these components is crucial for maintaining safety and preventing damage. By comprehensively understanding these electrical components, users can effectively manage, troubleshoot, and enhance their devices.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting tasks on electrical appliances, it is essential to prioritize safety to prevent accidents and injuries. Awareness of potential hazards and adherence to safety measures can significantly enhance the overall experience and outcome of the process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes gloves to protect against sharp edges, safety goggles to shield the eyes from debris, and masks to avoid inhaling dust and particles. Ensuring that all gear fits correctly enhances comfort and safety during the task.

Work Environment

Maintain a clean and organized workspace to minimize the risk of accidents. Ensure proper lighting to see clearly and avoid working in damp or wet areas, as moisture can pose significant electrical hazards. Additionally, disconnect the appliance from its power source before starting any work to prevent electrical shocks.

Where to Find Replacement Parts

When it comes to maintaining and enhancing your cleaning device, sourcing the correct components is crucial. Various options are available for obtaining quality substitutes that ensure optimal performance and longevity of the appliance.

Online Retailers

Numerous online platforms specialize in spare components for household equipment. These websites often provide a wide selection, competitive pricing, and customer reviews to assist in making informed decisions.

- Amazon – A well-known marketplace with numerous options.

- eBay – A platform for both new and used parts, often at discounted rates.

- Specialty websites – Various sites dedicated to specific brands or types of appliances.

Local Repair Shops

Visiting local service centers or repair shops can be beneficial. Knowledgeable staff can help identify necessary parts and may even offer installation services.

- Independent repair shops – Often provide personalized service and advice.

- Authorized service centers – Ensure original parts and professional installation.