Ensuring a comfortable indoor environment often relies on a well-functioning device that regulates temperature and airflow. Understanding the complexities of this technology can empower homeowners to maintain optimal performance and extend the lifespan of their systems. This section aims to provide essential insights into common issues and solutions related to these innovative devices.

Identifying Problems: Various symptoms may indicate that your unit is not operating at peak efficiency. From unusual noises to fluctuating temperatures, recognizing these signs early can save time and resources. In this guide, we will explore the typical challenges users face and how to diagnose them effectively.

Practical Solutions: Equipped with the right knowledge, individuals can often address minor issues independently. We will outline straightforward steps for troubleshooting, ensuring that users feel confident in their ability to manage basic maintenance tasks and enhance the reliability of their systems.

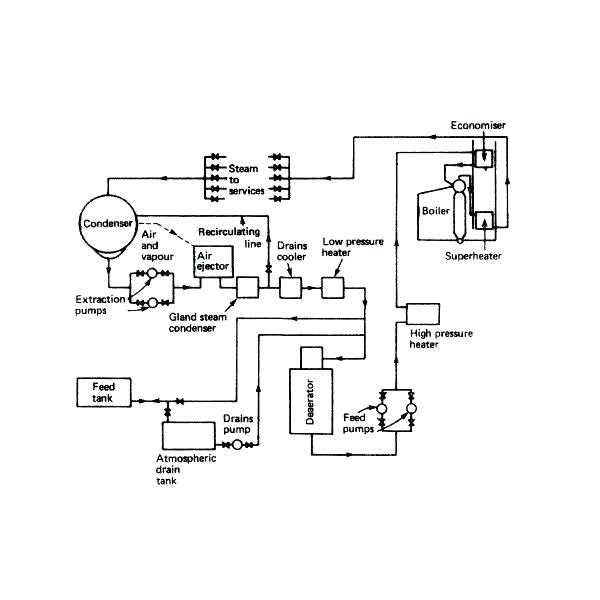

Understanding Heat Pump Basics

In the realm of climate control systems, certain devices stand out for their versatility and efficiency. These systems can provide both warmth and coolness, adapting seamlessly to seasonal changes. A fundamental understanding of their operation is essential for anyone looking to optimize their energy usage and maintain a comfortable environment.

Principles of Operation

The primary function of these devices revolves around the transfer of thermal energy. By utilizing refrigerants, they absorb warmth from one area and release it in another. This process not only enhances indoor comfort but also promotes energy savings by recycling existing thermal energy, rather than generating new heat or cold.

Key Components

Several essential parts work together to ensure efficient functionality. Compressors, evaporators, and condensers are crucial in facilitating the movement of thermal energy. Each component plays a specific role in maintaining the balance between heating and cooling, ensuring optimal performance throughout the year.

Common Heat Pump Issues

When it comes to climate control systems, various challenges can arise that hinder their optimal performance. Understanding these prevalent problems can help users recognize early signs of trouble, ensuring timely action and maintenance. Below, we explore some frequent complications that may affect these systems, allowing for better awareness and management.

1. Insufficient Heating or Cooling

One of the most common complaints is inadequate temperature regulation. Users may notice that the environment remains uncomfortable despite the system’s operation. This can stem from several factors, including refrigerant leaks, faulty thermostats, or blocked filters, all of which require careful examination to restore functionality.

2. Unusual Noises

Unexpected sounds can indicate underlying issues within the system. Rattling, buzzing, or grinding noises may suggest loose components or mechanical failure. Identifying and addressing these sounds promptly is essential to prevent further damage and ensure the longevity of the unit.

Essential Tools for Repairs

To effectively maintain and troubleshoot complex systems, a specific set of instruments is crucial. These tools not only facilitate the identification of issues but also streamline the process of restoring functionality. Understanding which items to keep on hand can make all the difference in efficiency and accuracy.

Basic Instrumentation

Starting with the fundamental tools, a few key pieces are indispensable for any technician. These include both hand tools and diagnostic equipment, ensuring that all aspects of the job can be tackled confidently.

| Tool | Purpose |

|---|---|

| Screwdrivers | For securing and loosening components. |

| Multimeter | To measure voltage, current, and resistance. |

| Wrenches | For tightening and loosening bolts and nuts. |

| Manifold Gauge Set | To assess system pressure and performance. |

Advanced Equipment

In addition to basic tools, having access to advanced equipment can enhance troubleshooting capabilities. These items allow for more in-depth analysis and ensure that problems can be diagnosed accurately.

| Tool | Purpose |

|---|---|

| Thermometer | To measure temperature variations in the system. |

| Leak Detector | For identifying refrigerant leaks quickly. |

| Vacuum Pump | To remove moisture and contaminants from the system. |

| Flare Tool | For creating secure connections in refrigerant lines. |

Step-by-Step Troubleshooting Guide

This section aims to provide a comprehensive approach to identifying and resolving common issues that may arise in your system. By following a structured procedure, you can effectively diagnose problems and implement solutions, ensuring optimal performance.

| Step | Description |

|---|---|

| 1 | Check the power supply and ensure that the unit is receiving electricity. |

| 2 | Inspect the thermostat settings to confirm they are correctly configured. |

| 3 | Examine the filters for dirt or blockages, and clean or replace them as needed. |

| 4 | Look for any visible signs of leaks in the system components. |

| 5 | Evaluate the airflow around the unit and ensure there are no obstructions. |

| 6 | Listen for unusual noises that could indicate mechanical issues. |

| 7 | Check the drainage system for clogs or blockages that might cause water accumulation. |

| 8 | If problems persist, consult a professional technician for further evaluation. |

By systematically addressing each of these areas, you can identify the root cause of the issues and take appropriate action to restore functionality.

Electrical Components and Their Functions

This section delves into the crucial electronic elements that play a significant role in the operation of thermal management systems. Understanding these components is essential for troubleshooting and ensuring optimal functionality. Each element serves a specific purpose, contributing to the overall efficiency and reliability of the system.

Key Electronic Parts

Among the most vital electronic components are relays, which act as switches that control the flow of electricity to various parts of the system. They help regulate operations by opening and closing circuits in response to specific signals. Another important part is the thermostat, which monitors and adjusts temperatures according to user settings, ensuring a comfortable environment.

Control Systems

Control boards serve as the brain of the operation, processing inputs from various sensors and making decisions based on programmed algorithms. These boards are essential for maintaining system stability and efficiency. Additionally, fuses and circuit breakers protect against electrical overloads, safeguarding the components from potential damage.

Maintaining Refrigerant Levels

Ensuring optimal fluid quantities in your system is crucial for its efficient operation. Proper management of these substances not only enhances performance but also prolongs the lifespan of the entire setup. Regular checks and maintenance can prevent potential issues that may arise from imbalances, ensuring a stable and effective environment.

Importance of Regular Checks

Frequent monitoring of fluid levels is essential. Low quantities can lead to inadequate cooling or heating, causing strain on the system. Conversely, excessive amounts can result in increased pressure, potentially damaging components. Establishing a routine for inspections can help catch any discrepancies early, saving time and resources.

Best Practices for Maintenance

To maintain proper levels, consider the following tips:

- Conduct visual inspections for any signs of leaks or wear.

- Use appropriate gauges to check fluid pressures accurately.

- Follow manufacturer guidelines for refilling and adjustments.

- Keep records of maintenance activities to track performance trends.

By adhering to these practices, you can ensure that your system operates efficiently and effectively, minimizing risks and enhancing overall functionality.

Cleaning and Maintaining Coils

Proper care and upkeep of the coils are essential for ensuring optimal performance and longevity of your system. Regular maintenance not only enhances efficiency but also prevents costly breakdowns. A clean surface allows for better heat exchange, which is vital for maintaining the desired indoor climate.

To effectively clean and maintain the coils, follow these steps:

| Step | Description |

|---|---|

| 1. Safety First | Disconnect power to the unit before beginning any maintenance to avoid electrical hazards. |

| 2. Visual Inspection | Check the coils for dirt, debris, or any visible damage. This will help identify the level of cleaning needed. |

| 3. Dust Removal | Use a soft brush or vacuum to gently remove dust and dirt from the surface of the coils. |

| 4. Cleaning Solution | Apply a suitable coil cleaner according to the manufacturer’s instructions. Ensure it is safe for the materials used in your system. |

| 5. Rinse Thoroughly | After allowing the cleaner to work, rinse the coils with water to remove any residue, ensuring not to damage sensitive components. |

| 6. Final Check | Inspect the coils once more for any remaining debris or damage before reassembling the unit. |

Regular maintenance should be conducted at least twice a year to ensure the coils operate efficiently and to prolong the lifespan of the system. Keeping the coils clean is a simple yet effective way to enhance performance and reliability.

Identifying Compressor Problems

Recognizing issues with the central unit of a refrigeration system is crucial for maintaining optimal performance. When these components fail to operate correctly, it can lead to inefficiencies and increased energy costs. This section provides guidance on diagnosing common malfunctions that may arise in these essential elements of climate control systems.

Unusual Noises: One of the first signs of trouble is often unusual sounds emanating from the unit. These could include loud clanking, buzzing, or hissing noises, which may indicate mechanical failure or refrigerant leaks. It’s important to pay attention to these sounds, as they can help pinpoint the specific problem.

Temperature Fluctuations: If the system struggles to maintain consistent temperatures, this could signal an underlying issue. Irregular cooling or heating cycles often point to a malfunctioning component that requires immediate attention to prevent further complications.

Increased Energy Consumption: A sudden spike in energy bills can indicate that the unit is working harder than it should. This inefficiency may stem from a failing unit that is unable to compress refrigerant effectively, leading to excessive energy usage.

Overheating: If the central unit feels unusually hot to the touch, this could signify an internal problem. Overheating may result from various factors, including blocked airflow or electrical malfunctions, and should be investigated promptly.

Frequent Cycling: An increase in the frequency of the unit’s on and off cycles can indicate an issue. This short cycling may result from a variety of problems, such as thermostat malfunctions or low refrigerant levels, and can lead to further system damage if not addressed.

Monitoring these signs and understanding their implications can aid in early detection of issues, ultimately ensuring the longevity and efficiency of the overall system.

Thermostat Calibration Techniques

Ensuring accurate temperature control is vital for optimal performance in any climate regulation system. Properly calibrating the controlling device can significantly enhance energy efficiency and comfort levels within a space. This section outlines effective strategies for achieving precise measurements and adjustments.

1. Visual Inspection: Begin by examining the control device for any visible issues. Look for loose connections, debris, or signs of wear that might affect functionality. A clean and well-maintained device is essential for accurate readings.

2. Utilize a Reference Thermometer: For precise calibration, use a reliable thermometer as a standard. Place it near the control device and compare the readings. This helps identify any discrepancies that need to be addressed.

3. Adjusting the Settings: Many controlling devices have calibration screws or settings that allow for fine-tuning. Follow the manufacturer’s guidelines to make necessary adjustments based on the differences noted during comparison with the reference thermometer.

4. Test and Verify: After making adjustments, it’s important to test the system. Monitor the temperature over time to ensure it aligns with both the desired setting and the reference thermometer. Recalibrate if necessary.

5. Regular Maintenance: Establish a routine for checking and calibrating the controlling device. Regular maintenance helps prevent inaccuracies and prolongs the lifespan of the system.

By implementing these techniques, you can ensure that the regulating device operates effectively, leading to enhanced efficiency and a more comfortable environment.

Repairing Ductwork Leaks

Ensuring the efficiency of your climate control system often hinges on the integrity of the duct network. When gaps or fissures form in the pathways, air can escape, leading to decreased performance and increased energy consumption. Addressing these leaks is essential for maintaining a comfortable indoor environment and optimizing energy usage.

Identifying Leaks

To effectively tackle the problem, start by pinpointing the locations of the leaks. Common areas include joints, seams, and places where ducts connect to vents. You can utilize visual inspections and tools such as a smoke pencil or an infrared thermometer to detect areas where air is escaping. A thorough examination during periods of high airflow will enhance your chances of finding the issues.

Sealing Techniques

Once leaks are identified, various methods can be employed to seal them. Foil tape is a popular choice for its durability and strong adhesion. Alternatively, mastic sealant can be applied to larger gaps for a more robust solution. Ensure that all surfaces are clean and dry before application for optimal adhesion. Regular maintenance checks can prevent future leaks, prolonging the lifespan of the entire system.

When to Call a Professional

Understanding the right moment to seek assistance from a specialist can save you time, money, and potential hazards. Certain signs indicate that issues may be beyond basic troubleshooting, requiring expert evaluation and intervention.

Signs That Indicate Professional Help is Needed

- Persistent Malfunctions: If your system continues to show problems despite your attempts to fix them, it may be time to consult a technician.

- Unusual Noises: Sounds like grinding, hissing, or rattling can signal underlying issues that need professional diagnosis.

- Unexplained Energy Bills: A sudden spike in energy costs could suggest inefficiencies that require expert analysis.

- Leaking Fluids: Any signs of fluid leakage should be addressed immediately by a qualified individual.

- Age of the System: Older models may require specialized knowledge for maintenance or replacement.

Why Professional Expertise Matters

Engaging a qualified technician ensures that any complications are addressed safely and effectively. Professionals possess the tools, knowledge, and experience to diagnose issues accurately and implement solutions that may not be apparent to the average homeowner.

- Comprehensive Diagnostics

- Access to Specialized Tools

- Guarantee of Work Quality

- Knowledge of Current Regulations and Standards

Preventive Maintenance Tips for Longevity

Ensuring the durability and efficiency of your climate control system requires consistent attention and care. By adopting preventive measures, you can significantly extend the lifespan of your equipment while maintaining optimal performance. This section provides essential tips to help you keep your system running smoothly for years to come.

Regular Inspection

Routine checks are vital for identifying potential issues before they escalate. Inspect components for wear and tear, ensuring all parts function correctly. Look for signs of corrosion or damage and address them promptly to avoid costly replacements.

Cleaning and Maintenance

Maintaining cleanliness is crucial for efficiency. Dust and debris can obstruct airflow and reduce performance. Regularly clean filters, coils, and vents to promote proper circulation and enhance energy efficiency.

| Task | Frequency | Notes |

|---|---|---|

| Inspect components | Monthly | Check for signs of damage or wear. |

| Clean filters | Every 1-3 months | Replace if damaged or excessively dirty. |

| Examine ducts | Annually | Ensure there are no blockages or leaks. |

| Schedule professional service | Annually | Professional checks can catch issues early. |