Maintaining the functionality of industrial engines is crucial for ensuring their longevity and efficiency. Knowledge of the intricate systems and components allows operators to tackle issues proactively, enhancing performance and reducing downtime. This section delves into essential guidelines that equip users with the skills to address common challenges encountered with these powerful machines.

Every engine type has its unique characteristics, and familiarizing oneself with specific components can make a significant difference in upkeep. Proper techniques and troubleshooting methods are indispensable for anyone looking to optimize their engine’s operations. With the right approach, potential problems can be identified early, paving the way for effective solutions.

This comprehensive overview serves as a resource for those seeking to deepen their understanding of engine upkeep. By leveraging practical knowledge and strategies, operators can navigate the complexities of maintenance with confidence, ensuring their equipment remains in peak condition for all operational demands.

Overview of Hatz 1D81S Engine

This section provides an in-depth look at a compact, efficient power unit known for its durability and performance in various applications. The design and engineering of this engine emphasize reliability, making it a preferred choice in industries requiring consistent operation under challenging conditions.

Technical Specifications

The following table summarizes the key technical specifications of this engine, highlighting its capabilities and features:

| Specification | Value |

|---|---|

| Cylinder Configuration | Single-cylinder |

| Displacement | 0.81 L |

| Power Output | 8.5 kW |

| Fuel Type | Diesel |

| Cooling System | Air-cooled |

Applications and Uses

This power unit finds applications in various fields, including agriculture, construction, and industrial machinery. Its compact size allows for easy integration into different equipment, while its robust performance ensures effective operation even in demanding environments.

Common Issues with Hatz 1D81S

This section addresses frequent challenges encountered with this compact diesel engine, commonly used in various applications. Understanding these issues can aid in timely maintenance and enhance performance longevity.

One prevalent problem is overheating, which can stem from inadequate cooling system functionality. Blocked radiators or malfunctioning water pumps often contribute to this situation, leading to potential engine damage if not resolved promptly.

Fuel system difficulties are another common concern. Clogged fuel filters or faulty injectors can result in poor combustion, causing loss of power and increased emissions. Regular checks and replacements can help maintain optimal performance.

Additionally, electrical issues may arise, particularly with the starter or battery connections. Corroded terminals or weak batteries can hinder engine start-up, creating frustration and downtime.

Finally, abnormal noises during operation might indicate mechanical wear or misalignment. Identifying these sounds early can prevent more serious damage and ensure smooth operation.

Essential Tools for Repairing Hatz

When maintaining and fixing small engines, having the right equipment is crucial for efficiency and effectiveness. This section outlines the fundamental tools necessary for troubleshooting and restoring functionality to these machines.

- Wrenches: A set of both metric and imperial wrenches is vital for loosening and tightening various components.

- Screwdrivers: Flathead and Phillips screwdrivers in various sizes will assist in accessing different parts.

- Socket Set: A comprehensive socket set allows for easy removal and installation of nuts and bolts.

- Pliers: Needle-nose and standard pliers are essential for gripping and bending components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for diagnosing electrical issues and checking the functionality of components.

- Diagnostic Tools: Specialized equipment can help identify issues more effectively than visual inspections alone.

- Oil Filter Wrench: Specifically designed for changing oil filters, making maintenance easier.

Equipping oneself with these tools not only enhances the repair process but also contributes to the longevity and performance of the equipment.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your engine. Following a systematic procedure will not only enhance efficiency but also prevent potential issues that could arise from neglecting routine care.

Begin by gathering all necessary tools and supplies to facilitate the process. Regular inspection of essential components such as the air filter, fuel system, and electrical connections is crucial. Replace any worn or damaged parts promptly to maintain smooth operation.

Next, focus on the lubrication system. Regularly check oil levels and quality, replacing oil as needed to ensure proper functioning of the internal mechanisms. This will help minimize friction and wear on vital components.

Cooling systems also require attention. Inspect coolant levels and hoses for any signs of leaks or deterioration. Keeping these systems in optimal condition prevents overheating and promotes reliability during operation.

Finally, always adhere to the recommended service intervals for various components. Keeping a detailed log of maintenance activities will aid in tracking performance and identifying trends over time, allowing for proactive measures before minor issues escalate.

Understanding the Engine Components

The internal workings of an engine are a symphony of various parts, each playing a crucial role in its operation. Grasping the function and interrelation of these components is essential for anyone looking to maintain or enhance performance. This section aims to demystify the key elements that contribute to the effective functioning of an engine.

Key Components Overview

Engines are composed of numerous elements, including the cylinder block, which houses the cylinders where combustion occurs, and the piston, which moves up and down within these cylinders. Other vital parts include the crankshaft, responsible for converting linear motion into rotational energy, and the camshaft, which controls the timing of valve openings and closings.

Importance of Maintenance

Regular upkeep of these components is vital for ensuring longevity and efficiency. Neglecting any single part can lead to a cascade of failures that may compromise the entire system. Understanding how each piece interacts helps in diagnosing issues and performing preventive measures to keep the engine running smoothly.

Diagnosing Performance Problems

Identifying issues that affect engine efficiency is crucial for ensuring optimal operation. Various factors can lead to decreased power output or irregular performance, necessitating a systematic approach to pinpoint the root causes. Understanding these potential problems allows for timely interventions and restores functionality.

Common Symptoms and Indicators

Users may observe specific signs that suggest underlying performance issues. These can include unusual noises, reduced acceleration, or difficulty starting. Monitoring fuel consumption is also essential; significant increases can indicate inefficient combustion or leaks. Recognizing these indicators early can prevent more severe damage and costly repairs.

Step-by-Step Diagnostic Approach

To effectively diagnose performance problems, follow a structured method. Begin with a visual inspection of key components, checking for wear or damage. Next, assess fuel delivery systems, ensuring that filters and injectors are functioning correctly. Analyzing exhaust emissions can provide insights into combustion efficiency. Utilize diagnostic tools to read error codes, as these can reveal specific malfunctions. Lastly, comparing operational parameters with manufacturer specifications can highlight discrepancies, guiding necessary adjustments or repairs.

Replacing Engine Parts Safely

Ensuring the safety and effectiveness of component replacement is crucial when working with machinery. Proper techniques not only enhance the performance of the unit but also minimize the risk of accidents. Following systematic procedures and adhering to safety guidelines will facilitate a smoother workflow and protect the technician’s wellbeing.

Before initiating the process, it’s essential to prepare adequately. Gather the necessary tools and components, and ensure the work area is clean and well-organized. Familiarizing oneself with the engine’s specifications and understanding the replacement procedure is vital. Here is a summary of key safety tips:

| Step | Safety Tip |

|---|---|

| 1 | Disconnect the power source to prevent accidental starts. |

| 2 | Use personal protective equipment (PPE), such as gloves and goggles. |

| 3 | Follow the manufacturer’s instructions for part removal and installation. |

| 4 | Handle tools and components with care to avoid injury. |

| 5 | Keep the work area free from distractions and clutter. |

Following these guidelines will help ensure a safe and efficient process during the replacement of engine components. Proper planning and adherence to safety measures will lead to a successful outcome and longevity of the machinery.

Tips for Regular Servicing

Maintaining optimal performance of your equipment requires consistent attention and care. Regular servicing not only extends the lifespan but also ensures efficiency and reliability. By incorporating a few key practices into your routine, you can prevent potential issues before they arise.

Establish a Routine

Setting a regular schedule for checks and maintenance can be immensely beneficial. Daily inspections of fluid levels, filters, and overall functionality can help catch problems early. Create a checklist to streamline this process and ensure nothing is overlooked.

Use Quality Parts

When replacements are necessary, always opt for genuine or high-quality components. This decision can significantly impact performance and longevity. Cheap alternatives may save money initially, but they often lead to more frequent issues and greater costs in the long run.

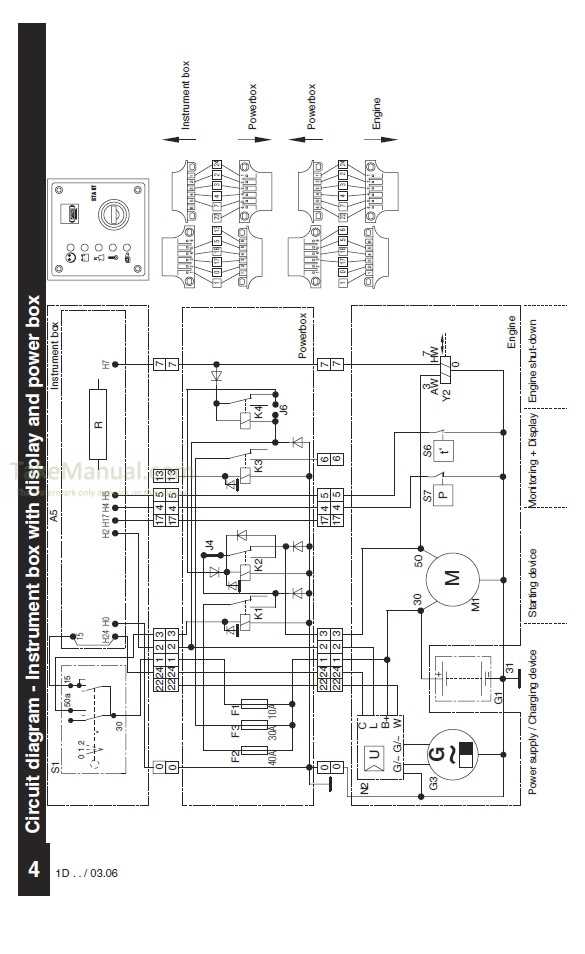

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of machinery requires a systematic approach to identify faults effectively. Understanding the components and their functions is crucial in isolating problems that may lead to operational failures. This section outlines essential steps and methods to assist in the identification and resolution of electrical anomalies.

Begin by assessing the power supply, as interruptions or inconsistencies in voltage can lead to malfunction. Next, inspect wiring and connectors for signs of wear, corrosion, or loose connections. Utilizing diagnostic tools can greatly enhance the troubleshooting process, enabling you to pinpoint faults with precision.

| Component | Common Issues | Troubleshooting Steps |

|---|---|---|

| Battery | Weak charge, leaks | Test voltage, check terminals |

| Fuses | Blown or damaged | Inspect visually, replace if necessary |

| Wiring | Frayed insulation, loose connections | Examine thoroughly, tighten or replace |

| Switches | Failure to engage/disengage | Test functionality, clean contacts |

By following these guidelines and utilizing the provided table, one can systematically address electrical system issues, ensuring reliable operation and longevity of the equipment.

Fuel System Care and Maintenance

The longevity and efficiency of any engine heavily depend on the upkeep of its fuel delivery components. Regular attention to the fuel system is essential for optimal performance and to prevent potential issues that may arise from neglect. This section outlines key practices to ensure your fuel system remains in excellent condition.

Proper maintenance involves routine inspections, cleaning, and timely replacements of critical elements. By adhering to these guidelines, you can enhance fuel efficiency, reduce emissions, and extend the lifespan of the engine.

| Component | Maintenance Task | Frequency |

|---|---|---|

| Fuel Filter | Inspect and replace as needed | Every 500 hours |

| Fuel Pump | Check for leaks and proper operation | Every 1000 hours |

| Injectors | Clean and test for proper spray pattern | Every 1000 hours |

| Fuel Lines | Inspect for cracks or wear | Every 500 hours |

| Fuel Tank | Clean and check for contaminants | Annually |

Implementing these maintenance practices will not only safeguard the integrity of the fuel system but also contribute to the overall efficiency and reliability of your engine. Regular monitoring and prompt action can prevent small issues from escalating into significant problems, ensuring seamless operation for years to come.

Expert Advice on Engine Upgrades

Enhancing engine performance can significantly improve efficiency and reliability. This section provides valuable insights into modifications and improvements that can elevate your power unit to the next level. Careful consideration of upgrades can lead to optimal performance while maintaining durability.

When contemplating enhancements, it’s essential to focus on several key areas:

- Air Intake Systems: Upgrading the air intake can increase airflow, improving combustion efficiency.

- Exhaust Systems: A more efficient exhaust setup reduces back pressure, allowing for better engine breathing.

- Fuel Delivery: Consider high-performance fuel injectors or carburetors to ensure optimal fuel mixture for power enhancement.

- ECU Remapping: Tuning the engine control unit can optimize fuel and ignition timing for better performance.

Each modification should be carefully assessed for compatibility with existing components. Additionally, it’s advisable to consult with a specialist to avoid potential issues that might arise from improper upgrades.

- Research: Gather information about available modifications and their benefits.

- Evaluate Needs: Determine the specific goals you want to achieve with your enhancements.

- Consult Experts: Seek advice from professionals who specialize in performance upgrades.

- Test and Monitor: After implementing upgrades, conduct thorough testing and monitor performance metrics.

Investing time and resources into engine enhancements can yield impressive results, leading to a more responsive and powerful system. Stay informed about the latest advancements in technology to ensure your upgrades are effective and sustainable.

Resources for Further Learning

Expanding your knowledge in the field of engine maintenance and troubleshooting is essential for anyone looking to enhance their skills. A variety of resources are available that can help deepen your understanding and provide practical insights into effective techniques and strategies.

Online Courses and Webinars

Many platforms offer comprehensive courses focusing on engine mechanics, diagnostics, and maintenance practices. These courses often include video lectures, interactive quizzes, and real-world scenarios that can enhance your learning experience. Additionally, webinars hosted by industry professionals can provide valuable insights and updates on the latest technologies and methods.

Books and Technical Publications

A wealth of literature exists that covers a broad spectrum of topics related to engine systems. Technical manuals, repair guides, and reference books can serve as excellent resources for both beginners and seasoned professionals. Look for publications that include detailed diagrams, troubleshooting tips, and step-by-step instructions to aid in your learning journey.