Maintaining your lawn care equipment is essential for optimal performance and longevity. Understanding the intricacies of your machine can enhance its efficiency, ensuring that your outdoor spaces remain pristine. This guide aims to provide detailed insights into troubleshooting and restoring your equipment to peak condition.

Whether you’re facing minor issues or more significant challenges, having access to reliable information can make all the difference. From common mechanical problems to routine upkeep, we’ll cover a range of topics designed to empower you as an owner. By familiarizing yourself with the essential components and their functions, you can tackle repairs with confidence.

Equipped with the right knowledge, you can easily navigate through maintenance tasks and address any concerns that arise. This resource serves as a valuable companion, guiding you step-by-step through various procedures, ensuring your machine operates smoothly and efficiently for years to come.

Understanding Husqvarna YTH2348 Features

The riding mower in focus combines functionality and ease of use, making it a popular choice for homeowners. Its innovative design is tailored to enhance efficiency while providing a comfortable experience during lawn maintenance. Familiarizing oneself with the various characteristics can significantly improve user satisfaction and performance.

Engine Performance: This model is equipped with a robust engine that ensures reliable power delivery. The high-quality motor not only facilitates smooth operation but also contributes to effective cutting capabilities. Users will appreciate the consistent performance across various terrains.

Cutting Deck: One of the standout features is the cutting deck, designed for optimal grass handling. Its adjustable height settings allow for customization, ensuring that users can achieve the desired lawn appearance with ease. The deck’s design also promotes efficient grass discharge, reducing the need for additional cleanup.

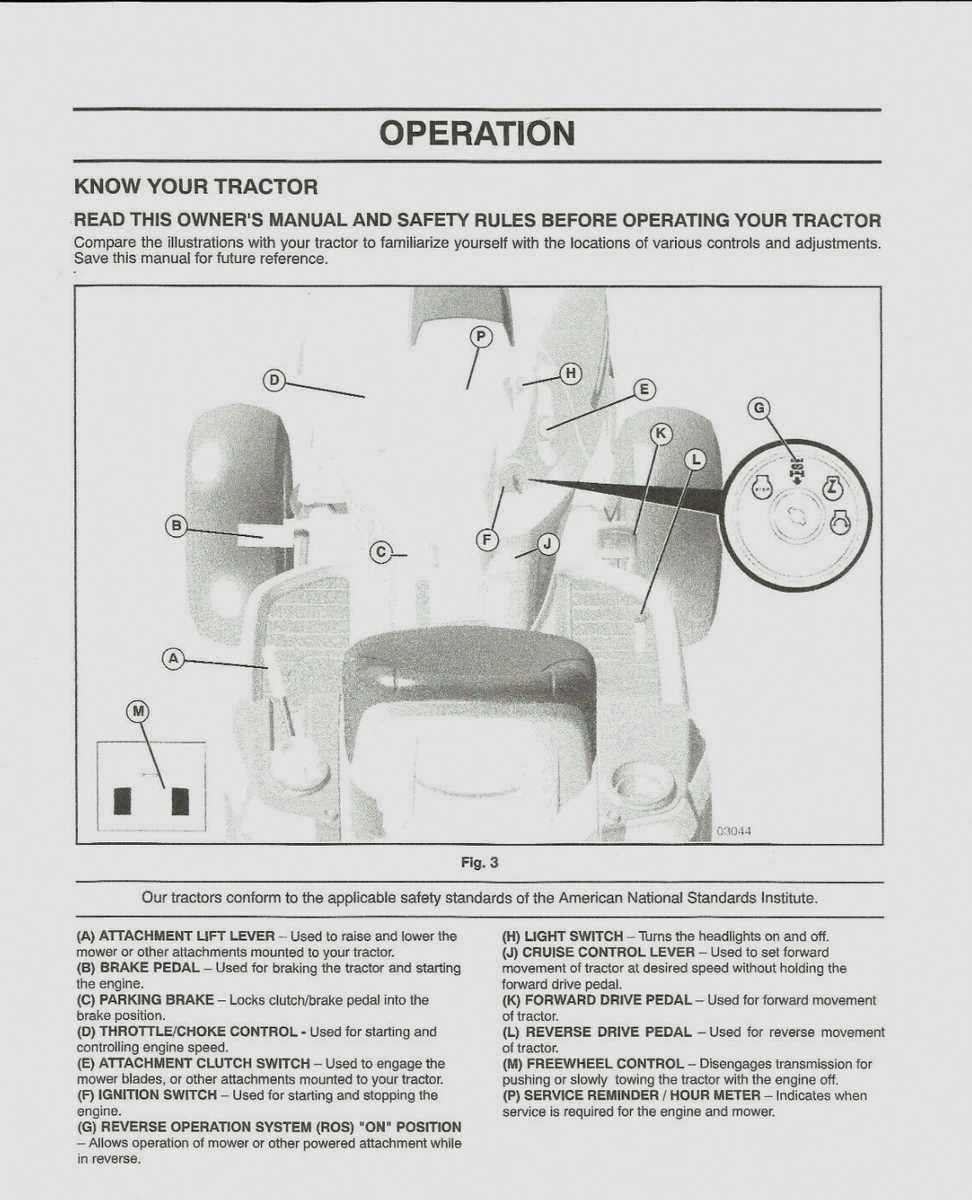

Comfort and Control: Ergonomically designed seating and controls enhance the overall user experience. The layout ensures that all necessary functions are easily accessible, minimizing distractions and allowing users to focus on their task. This attention to comfort promotes longer mowing sessions without fatigue.

Durability: Built with high-quality materials, this machine is engineered for longevity. The frame and components are resistant to wear, making it a reliable investment for those looking to maintain their lawns for years to come. Regular maintenance further enhances its lifespan.

By understanding these key attributes, users can make the most of their experience, ensuring that every mowing session is efficient and enjoyable.

Common Issues with Lawn Tractors

Lawn tractors are essential for maintaining large grassy areas, yet they can encounter several frequent problems that hinder their performance. Understanding these issues can help users identify symptoms early, allowing for timely interventions and maintenance to keep the equipment running smoothly.

Common Problems

Users often face various complications that may arise during operation. These issues can range from mechanical failures to electrical malfunctions, and recognizing them can lead to effective troubleshooting.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Engine Won’t Start | Dead battery, faulty ignition, clogged fuel filter | Check battery connections, replace ignition components, clean or replace fuel filter |

| Uneven Cutting | Uneven tire pressure, dull blades, deck height misadjusted | Check and adjust tire pressure, sharpen blades, set deck height correctly |

| Excessive Vibration | Loose components, damaged blades, unbalanced wheels | Tighten all bolts and screws, inspect and replace blades, check wheel alignment |

| Fuel Leaks | Worn fuel lines, loose fittings, damaged fuel tank | Inspect fuel lines, tighten fittings, replace damaged components |

Preventive Measures

Regular maintenance is key to avoiding many of these issues. Simple practices such as routine inspections, timely oil changes, and keeping the equipment clean can significantly extend the lifespan of lawn tractors and ensure they operate efficiently.

Essential Tools for Repairing YTH2348

When tackling maintenance tasks on your equipment, having the right instruments at hand is crucial for efficient and effective work. This section highlights the fundamental tools you’ll need to ensure smooth operation and troubleshooting of your machine.

Basic Hand Tools

- Wrenches: A set of adjustable and socket wrenches is essential for loosening and tightening various components.

- Screwdrivers: Both flathead and Phillips screwdrivers will help you access and secure parts effectively.

- Pliers: Needle-nose and regular pliers are useful for gripping and manipulating small objects.

Specialized Equipment

- Multimeter: This tool is necessary for diagnosing electrical issues by measuring voltage, current, and resistance.

- Oil Filter Wrench: Designed specifically for changing filters, ensuring that maintenance tasks are performed with ease.

- Torque Wrench: Ensures that all fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

Equipping yourself with these essential tools will not only streamline your workflow but also enhance the longevity and performance of your equipment.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This section outlines a comprehensive approach to maintenance, focusing on key areas that require attention to keep your machine running smoothly.

Essential Maintenance Tasks

Below are crucial tasks that should be performed routinely to maintain peak functionality:

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Every 10 hours | Inspect and top off engine oil as needed to ensure proper lubrication. |

| Clean Air Filter | Every 25 hours | Remove and clean the air filter to prevent debris from affecting engine performance. |

| Inspect Blades | Every 15 hours | Examine and sharpen blades to maintain cutting efficiency. |

| Check Battery | Every 30 hours | Ensure battery terminals are clean and connections are secure. |

Seasonal Upkeep Recommendations

Seasonal maintenance is important to prepare your equipment for different weather conditions. Here are some tips:

- In spring, check fuel and replace it if necessary to avoid engine issues.

- During summer, keep the cooling system clean to prevent overheating.

- In fall, clean the deck and storage area to avoid rust during winter.

Identifying Engine Problems Early

Recognizing issues with your engine at an early stage is crucial for maintaining optimal performance and extending its lifespan. Early detection can prevent minor concerns from escalating into major failures, ultimately saving time and money.

Common Symptoms to Watch For

- Unusual noises, such as knocking or grinding sounds

- Inconsistent performance or power loss during operation

- Excessive vibration while running

- Difficulty starting or frequent stalling

- Abnormal exhaust emissions or smoke

Steps for Initial Diagnosis

- Inspect the oil level and quality; dirty or low oil can indicate underlying issues.

- Check the fuel system for leaks or blockages that might affect performance.

- Examine electrical components, ensuring connections are secure and free of corrosion.

- Listen for irregular sounds while the engine is running; these can be indicative of specific problems.

- Consult a service guide for further troubleshooting based on observed symptoms.

How to Change Oil Effectively

Changing the lubricant in your machinery is essential for maintaining its performance and extending its lifespan. Regular oil changes help ensure that the engine runs smoothly, prevents wear and tear, and keeps the internal components clean. This process can be done easily at home with the right tools and a little knowledge.

Necessary Tools and Materials

Before starting, gather the following items:

| Item | Description |

|---|---|

| Oil | Check the specifications for the correct type and amount. |

| Oil filter | Replace if your machine has one to ensure optimal performance. |

| Wrench | For removing the drain plug and filter. |

| Oil pan | To catch the used lubricant during the change. |

| Funnel | To pour new oil without spilling. |

| Rags | For cleaning up spills and wiping surfaces. |

Step-by-Step Process

Follow these steps to effectively change the lubricant:

- Start by warming up the engine for a few minutes to thin the oil, making it easier to drain.

- Turn off the engine and ensure it is cool before proceeding.

- Locate the drain plug and remove it, allowing the old oil to flow into the pan.

- If applicable, replace the oil filter using the wrench.

- Once the oil has fully drained, replace the drain plug securely.

- Use the funnel to pour in the new lubricant, referring to the owner’s guide for the correct amount.

- Run the engine for a few minutes, then check the oil level and add more if necessary.

By following these guidelines, you can ensure that your equipment remains in top condition, enhancing its efficiency and longevity.

Fixing Electrical System Malfunctions

Addressing issues within an electrical system can be a challenging yet essential task for maintaining optimal performance. Common problems may arise from faulty connections, worn-out components, or intermittent failures. Understanding the fundamental aspects of the electrical setup is crucial for troubleshooting effectively and restoring functionality.

Identifying Common Issues

Begin by examining the power source and connections. Ensure that the battery is charged and all terminals are clean and securely fastened. Look for frayed wires or loose connections that might disrupt the flow of electricity. Pay close attention to any signs of corrosion, as this can impede performance and cause further complications.

Testing Components

To diagnose specific components, utilize a multimeter to measure voltage and continuity. This tool helps identify defective parts, such as switches or relays, that may need replacement. Remember to always follow safety protocols when handling electrical components to avoid hazards. If necessary, consult diagrams to understand the system’s layout and function better.

Blade Replacement and Adjustment Tips

Maintaining optimal cutting performance is essential for any lawn care enthusiast. This section provides guidance on replacing and adjusting blades, ensuring your mower operates efficiently and delivers a clean cut. Proper maintenance not only enhances the mower’s performance but also prolongs its lifespan.

How to Replace Blades

Begin by ensuring the mower is turned off and disconnected from the power source. Carefully tilt the mower to access the underside. Use a socket wrench to remove the retaining bolt and take out the old blade. When installing the new blade, ensure it is oriented correctly; the sharp edge should face the front. Secure it tightly with the bolt, and double-check that it is fastened properly before returning the mower to an upright position.

Adjusting Blade Height

To achieve an even cut, it’s important to adjust the blade height according to your lawn’s needs. Most models feature a height adjustment lever or knob. Test different settings based on grass type and desired length. Remember to adjust all blades equally to maintain a uniform cutting surface. After adjustments, conduct a trial cut to ensure optimal performance and make any necessary tweaks.

Regular checks of blade condition and adjustment can significantly improve your mowing experience and the health of your lawn. Always prioritize safety by wearing gloves and protective eyewear during the process.

Diagnosing Transmission Issues

When experiencing difficulties with a mower’s movement or performance, it is crucial to identify the root of the problem within the transmission system. Various factors can contribute to transmission failures, and understanding these can help in resolving issues effectively.

Step 1: Visual Inspection

Begin with a thorough visual examination of the transmission components. Look for any signs of wear, damage, or leaks. Check connections and ensure that all parts are securely fastened. Pay special attention to the belts and cables, as fraying or disconnection can lead to operational issues.

Step 2: Fluid Levels and Condition

Next, assess the fluid levels within the transmission. Low or contaminated fluid can severely impact performance. If the fluid appears dark or has a burnt smell, it may need to be replaced. Ensuring that the correct type of fluid is used is equally important.

Step 3: Testing Movement

Conduct a movement test by engaging the drive system and observing how the mower responds. If the unit hesitates, slips, or fails to move, these symptoms may indicate problems within the transmission mechanism itself. Note any unusual noises that occur during operation, as these can provide additional clues.

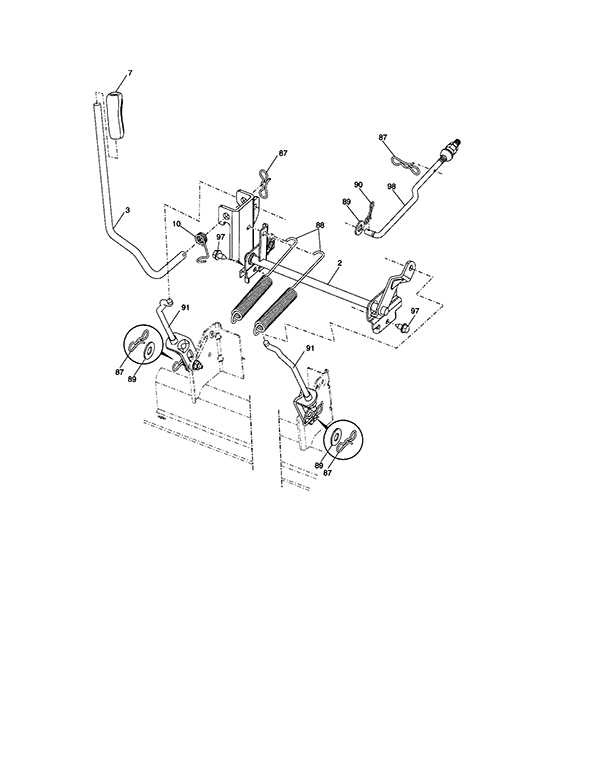

Step 4: Checking Linkages and Controls

Inspect the linkages and controls for any signs of obstruction or misalignment. Proper adjustment of these components is essential for smooth operation. If the controls feel loose or unresponsive, adjustments may be necessary to restore functionality.

Conclusion

By systematically following these steps, one can diagnose potential transmission issues effectively. Identifying the source of the problem early can prevent further complications and ensure reliable performance of the equipment.

Cleaning the Air Filter Properly

Maintaining a clean air filter is crucial for the optimal performance of your engine. A well-functioning air filter ensures that the engine receives the right amount of air, which enhances combustion efficiency and prolongs the lifespan of the equipment. Regular cleaning helps prevent dirt and debris buildup, which can lead to reduced power and increased fuel consumption.

Tools and Materials Needed

- Clean cloth or rag

- Soft brush

- Soapy water or a mild detergent

- Compressed air (optional)

- Protective gloves (optional)

Step-by-Step Cleaning Process

- Ensure the engine is turned off and cool before starting the cleaning process.

- Locate the air filter cover and remove it carefully to access the filter.

- Gently remove the air filter from its housing.

- Use a soft brush to remove loose dirt and debris from the filter surface.

- If the filter is washable, rinse it in soapy water and allow it to dry completely before reinserting.

- For filters that cannot be washed, consider replacing them if they appear excessively dirty or damaged.

- Once clean or replaced, reinsert the air filter into its housing and securely fasten the cover.

Regular maintenance of the air filter not only improves performance but also ensures the longevity of your equipment. Aim to check and clean the filter at recommended intervals or more frequently in dusty conditions.

Winterizing Your Lawn Tractor

Preparing your gardening machine for the colder months is essential to ensure its longevity and optimal performance. By taking the necessary steps to protect it from harsh weather conditions, you can avoid costly repairs and maintain its functionality for the next season.

Here are some key tasks to complete when getting your machine ready for winter:

- Clean the Exterior: Remove dirt, grass clippings, and debris to prevent rust and corrosion.

- Drain the Fuel: If you won’t be using it during winter, consider draining the fuel tank or adding a fuel stabilizer to prevent gumming.

- Change the Oil: Fresh oil will help remove impurities and protect the engine during downtime.

- Inspect the Battery: Clean terminals and ensure the battery is fully charged. Store it in a cool, dry place if necessary.

- Check Tires: Inflate tires to the recommended pressure to prevent flat spots and maintain proper support.

By following these steps, you can ensure your gardening equipment is well-prepared to withstand the winter season and ready to perform effectively when spring arrives.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on machinery is essential to prevent accidents and injuries. Adhering to certain guidelines not only protects the individual performing the tasks but also extends the lifespan of the equipment. Following proper protocols fosters a safer working environment and minimizes risks associated with mechanical failures.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and sturdy footwear to shield yourself from potential hazards. |

| Disconnect Power | Before starting any work, ensure the machine is powered off and disconnected from any electrical source. |

| Work in a Well-Lit Area | A well-illuminated workspace reduces the risk of errors and enhances visibility, allowing for safer handling of tools and parts. |

| Use Proper Tools | Employ the correct tools designed for specific tasks to avoid damaging components and to enhance safety during the process. |

| Maintain a Clean Workspace | A tidy environment minimizes the risk of slips, trips, and falls, making the area safer to work in. |

| Read Instructions | Always consult guidelines or documentation related to the equipment before beginning any work to ensure proper procedures are followed. |

Finding Replacement Parts Online

Locating spare components for your outdoor equipment can be a straightforward process if you know where to look. The internet offers a plethora of resources to help you find the right parts, ensuring your machinery operates efficiently and effectively.

Here are some steps to guide you in your search:

- Identify the Model: Before starting your search, confirm the model number and specifications of your equipment to ensure compatibility.

- Check Official Websites: Manufacturers often provide parts catalogs or links to authorized dealers on their official sites.

- Explore Online Marketplaces: Websites such as eBay, Amazon, and specialized retailers may have a wide selection of parts.

- Use Parts Lookup Tools: Many online stores feature tools that allow you to input your model number and find specific components.

Additionally, consider the following tips:

- Read Reviews: Before purchasing, check customer feedback to gauge the quality and reliability of the parts.

- Compare Prices: Don’t settle for the first option; compare prices across multiple platforms to find the best deal.

- Check Shipping Options: Ensure the retailer offers reasonable shipping costs and delivery times.

By following these guidelines, you can efficiently find and acquire the necessary components to keep your equipment in top condition.