Ensuring the optimal performance of vital equipment is crucial for any operation. This section delves into the intricacies of maintaining and addressing common issues associated with essential fluid transport systems. Understanding the mechanics behind these systems can significantly enhance longevity and efficiency.

In the following paragraphs, you will discover detailed instructions and tips for identifying and resolving various complications. From minor adjustments to more complex interventions, mastering these techniques will empower users to keep their systems functioning smoothly.

Moreover, the guide emphasizes the importance of regular check-ups and proactive measures to prevent potential failures. By fostering a thorough understanding of the inner workings, users can ensure that their equipment remains in peak condition, ready to meet demanding tasks.

Understanding Grundfos Pump Types

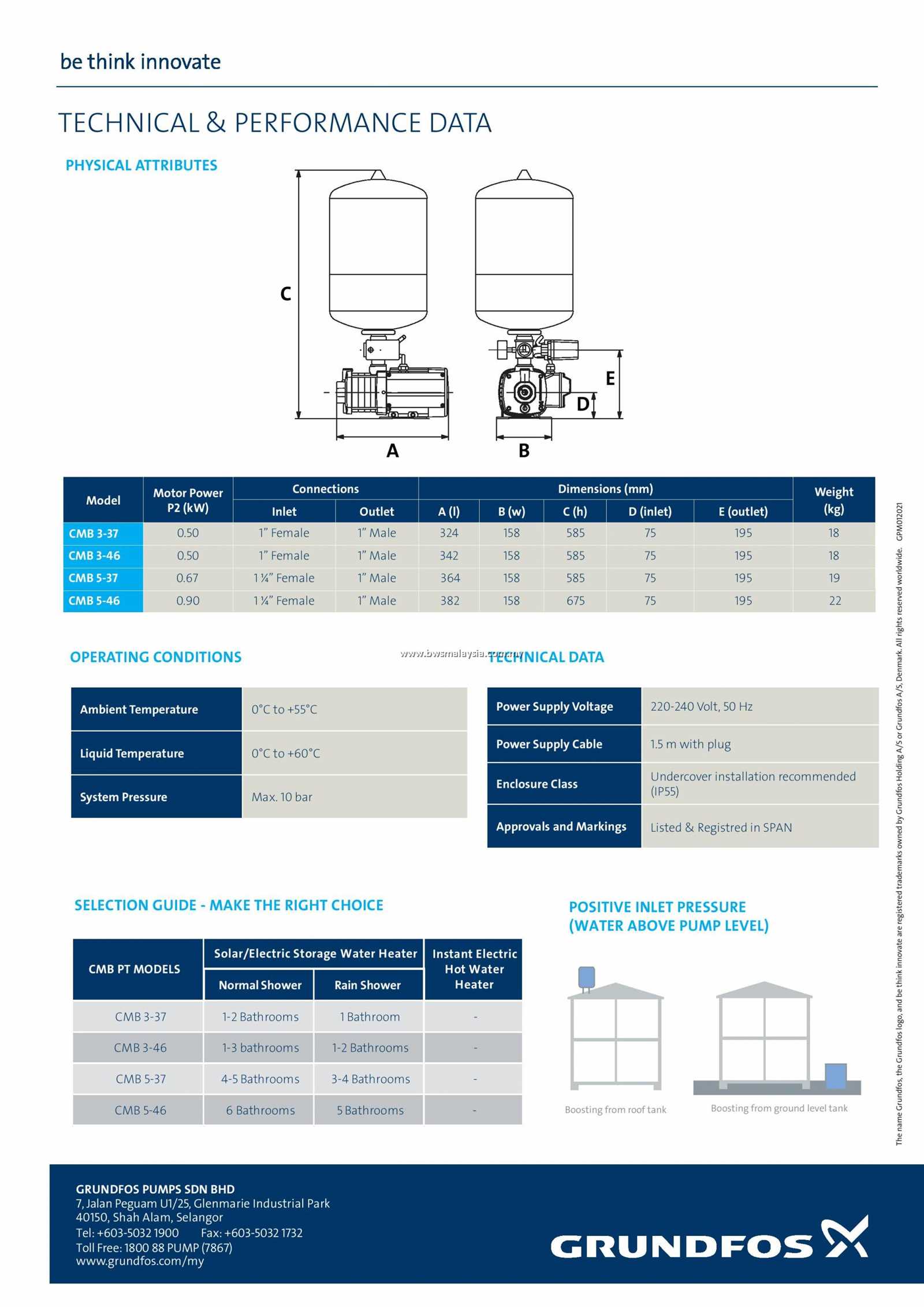

Exploring various categories of fluid-moving devices reveals the diverse applications and mechanisms that define their functionality. Each type serves specific purposes, ensuring efficiency and reliability in different environments. By examining these classifications, one can gain insight into their operational characteristics and appropriate usage scenarios.

Categories of Fluid-Moving Devices

- Centrifugal Devices: These rely on rotational energy to transfer liquids, commonly used in high-flow applications.

- Positive Displacement Units: This category operates by trapping a fixed volume and forcing it through the discharge, ideal for high-viscosity fluids.

Key Considerations for Selection

- Application Requirements: Assess the specific needs such as flow rate and pressure.

- Fluid Characteristics: Consider the viscosity, temperature, and chemical compatibility of the fluid.

- Energy Efficiency: Evaluate the energy consumption relative to the performance output.

Common Issues in Pump Operation

When dealing with fluid transfer systems, various challenges may arise that can hinder optimal performance. Understanding these common problems is essential for maintaining efficiency and ensuring longevity. This section highlights typical concerns encountered during operation, along with their potential causes and solutions.

- Insufficient Flow Rate:

- Clogged inlet or outlet lines

- Incorrect sizing of components

- Air leaks in suction lines

- Excessive Noise:

- Improper mounting or installation

- Vibrations from misaligned parts

- Inadequate lubrication of moving elements

- Overheating:

- Blocked cooling pathways

- Inappropriate fluid viscosity

- Insufficient flow causing stagnant zones

- Frequent Stalling:

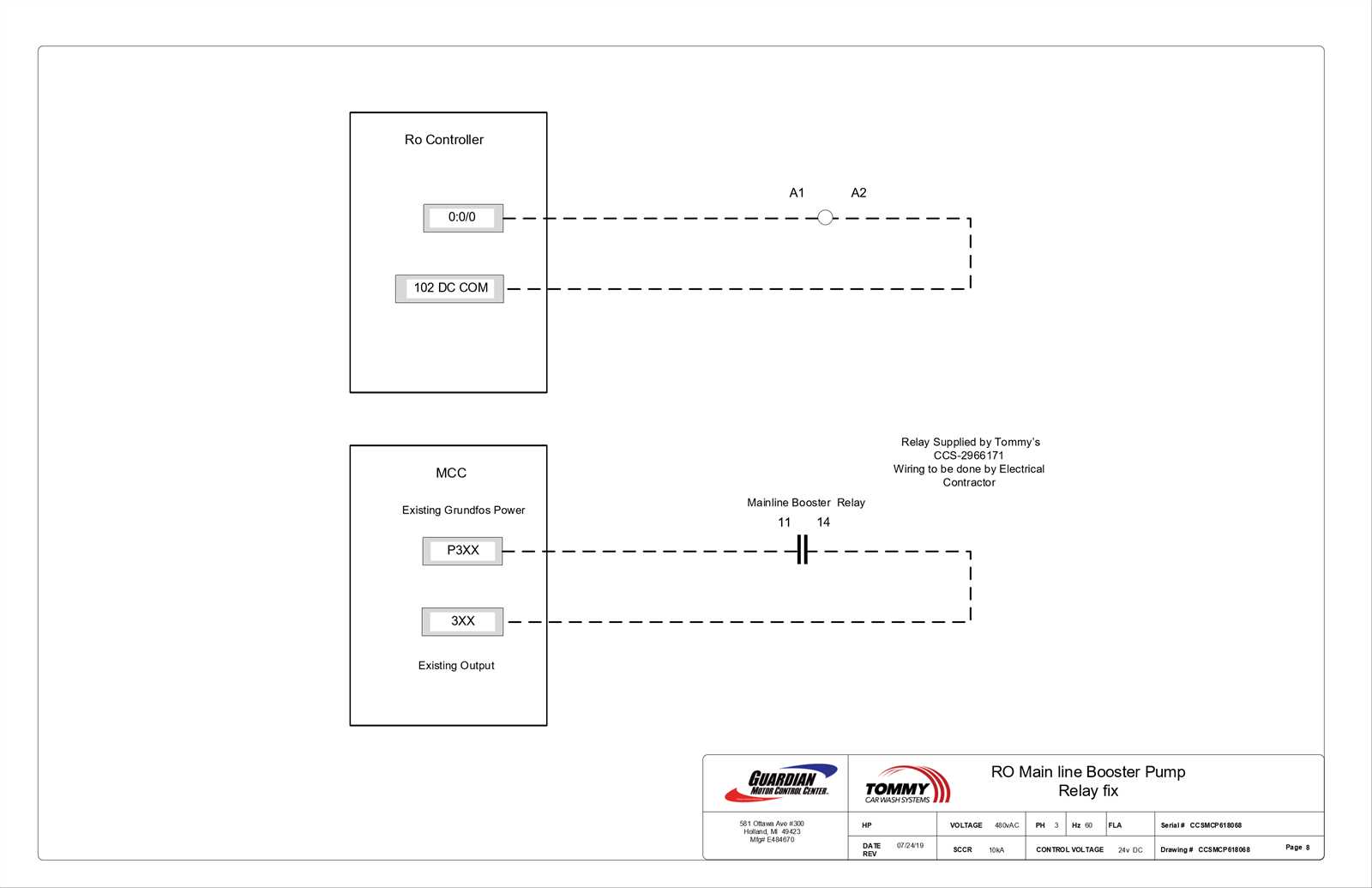

- Power supply issues

- Faulty electrical connections

- Mechanical obstructions within the system

- Leaks:

- Worn seals or gaskets

- Corrosion of housing materials

- Improper assembly or tightening of components

Identifying and addressing these issues promptly can significantly improve system performance and reliability. Regular maintenance and monitoring are key to preventing such problems from escalating.

Essential Tools for Repair

When it comes to maintaining and fixing various mechanical systems, having the right instruments at your disposal is crucial. A well-equipped toolkit not only streamlines the process but also enhances efficiency and safety. Understanding which items are necessary will empower you to tackle issues confidently.

Basic Hand Tools

Every toolkit should include a selection of fundamental hand instruments. Screwdrivers, wrenches, and pliers form the backbone of any maintenance task. Ensure you have various sizes and types to accommodate different fasteners and components. Adjustable wrenches are particularly useful for dealing with nuts and bolts of varying dimensions.

Specialized Equipment

In addition to standard tools, certain specialized equipment can significantly aid in addressing specific challenges. Multimeters are essential for diagnosing electrical issues, while torque wrenches ensure proper fastening of components. Having a pipe cutter or tension gauge can also prove invaluable in particular situations, allowing for precise adjustments and repairs.

Step-by-Step Repair Process

This section outlines a systematic approach to addressing issues with fluid circulation equipment. By following these steps, you can effectively diagnose and resolve common malfunctions, ensuring optimal performance and longevity of the unit.

- Preparation

- Gather necessary tools and materials.

- Ensure safety equipment is available.

- Read through the specific guidelines for the equipment.

- Initial Assessment

- Check for visible signs of damage.

- Listen for unusual noises during operation.

- Observe fluid flow and pressure readings.

- Disassembly

- Power down the unit and disconnect from the power source.

- Carefully remove any housing or covers.

- Document the assembly for easier reinstallation.

- Inspection

- Examine internal components for wear or blockage.

- Check seals and gaskets for integrity.

- Test electrical connections and components.

- Replacement

- Replace damaged or worn parts as needed.

- Use compatible components to ensure proper functionality.

- Ensure all new parts are installed correctly.

- Reassembly

- Reattach any housing or covers securely.

- Double-check all connections and seals.

- Document the process for future reference.

- Testing

- Reconnect the power source and turn on the unit.

- Monitor for proper operation and any abnormal signs.

- Ensure fluid circulation meets specified parameters.

By adhering to this detailed process, you can effectively restore functionality and enhance the reliability of your fluid handling equipment.

Safety Precautions During Maintenance

When conducting servicing activities, ensuring safety is of paramount importance. Adopting proper precautions minimizes the risk of accidents and injuries, fostering a secure environment for both personnel and equipment. This section outlines essential guidelines that should be adhered to during maintenance tasks.

General Safety Guidelines

Before initiating any servicing procedures, it is crucial to familiarize oneself with the specific equipment and its operational parameters. Always ensure that the system is powered down and disconnected from any electrical sources to prevent unintentional activation.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, such as gloves, goggles, and helmets, to protect against hazards. |

| Work Area Organization | Keep the workspace tidy and free of obstacles to avoid trips and falls. |

| Emergency Procedures | Familiarize yourself with emergency protocols and the location of first aid kits. |

| Tool Inspection | Regularly check tools for damage to ensure they are safe to use. |

Electrical Safety Considerations

Pay special attention to electrical safety measures. Confirm that all circuits are de-energized before beginning any work. Utilize insulated tools and follow lockout/tagout procedures to ensure that the equipment cannot be accidentally re-energized during maintenance.

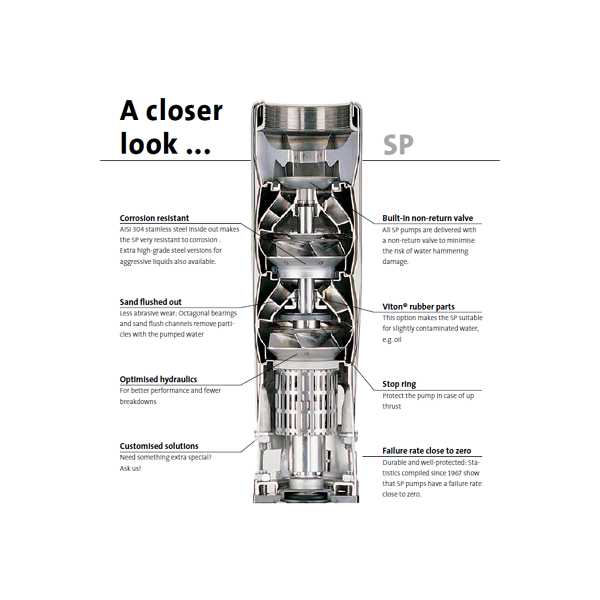

Identifying Pump Components

Understanding the various elements of a hydraulic device is crucial for effective troubleshooting and maintenance. Each component plays a specific role in ensuring the system operates smoothly, and recognizing these parts can help in diagnosing issues and enhancing performance.

Typically, these devices consist of several key elements, including the motor, impeller, volute casing, and seals. The motor serves as the driving force, converting electrical energy into mechanical motion. The impeller is responsible for moving the fluid, while the volute casing guides the flow and maintains pressure. Seals are vital for preventing leaks and ensuring the integrity of the system.

Additionally, auxiliary components such as bearings, sensors, and control systems play important roles in enhancing efficiency and providing feedback. Familiarity with these parts allows for a more comprehensive understanding of the entire assembly and its functionality.

Replacing Worn-Out Parts

When machinery experiences wear and tear, it is crucial to address the issue promptly to ensure optimal performance and longevity. Identifying and substituting degraded components can significantly enhance efficiency and prevent further complications. This section outlines the essential steps for effectively replacing these critical elements.

Identifying Damaged Components

Before proceeding with any replacements, it is vital to conduct a thorough inspection of the equipment. Look for signs of wear, such as cracks, leaks, or unusual noises. Pay attention to the functionality of each part; if something appears off, it may be time for a change. Documenting your findings will help in sourcing the appropriate replacements.

Steps for Replacement

Once the faulty components are identified, the following steps should be taken:

- Gather Necessary Tools: Ensure you have all the required tools and replacement parts on hand.

- Power Down: Always disconnect the power supply before starting any work to ensure safety.

- Remove the Old Parts: Carefully detach the worn-out components, taking note of how they were installed.

- Install New Parts: Place the new elements in the correct position, ensuring a secure fit.

- Test Functionality: Once everything is reassembled, restore power and run a test to confirm proper operation.

By following these guidelines, one can effectively replace outdated components, enhancing overall efficiency and reliability.

Testing Pump Performance After Repair

Evaluating the efficiency of a fluid transfer device after maintenance is crucial to ensure optimal operation. This process not only verifies the success of the service conducted but also confirms that the equipment meets the required standards for flow rate and pressure. Proper assessment helps identify any lingering issues and guarantees reliable performance moving forward.

Key Testing Parameters

Several critical factors should be measured during the evaluation phase. These include flow rate, pressure, power consumption, and noise levels. Each parameter provides insight into the operational integrity of the unit. Accurate measurements can help diagnose potential problems, ensuring that everything functions smoothly.

Procedure for Performance Testing

The testing process typically involves setting up the system under normal operating conditions. Begin by establishing baseline measurements before initiating the device. Monitor all relevant parameters closely and compare the results to manufacturer specifications. Any deviations should be documented for further analysis and corrective actions.

Preventive Maintenance Tips

Ensuring optimal performance and longevity of your equipment requires regular attention and care. By implementing a routine of preventive upkeep, you can minimize the risk of failures and enhance operational efficiency. This section outlines essential practices to keep your systems running smoothly.

- Regular Inspections: Schedule frequent checks to identify signs of wear or damage early. Look for leaks, unusual noises, or vibrations.

- Clean Components: Maintain cleanliness by removing debris and buildup from critical parts. This can prevent clogs and overheating.

- Lubrication: Ensure that moving parts are adequately lubricated to reduce friction and wear. Follow the manufacturer’s recommendations for the appropriate type and frequency.

- Check Electrical Connections: Inspect wiring and connections for corrosion or looseness. Tighten any loose connections and replace corroded wires as needed.

- Monitor Performance: Keep track of operational data to identify trends or deviations. This can help pinpoint issues before they escalate.

- Replace Wear Parts: Be proactive in replacing components that are prone to wear. Having a schedule for these replacements can save time and prevent downtime.

By following these guidelines, you can significantly extend the life of your machinery and ensure consistent performance. Regular attention to maintenance will pay off in reduced repair costs and improved reliability.

When to Seek Professional Help

Identifying the right moment to call in experts can significantly influence the outcome of a situation involving mechanical systems. Often, certain signs indicate that specialized assistance is necessary to ensure optimal functioning and prevent further complications. Recognizing these signals is crucial for maintaining efficiency and safety.

Common Signs Indicating the Need for Expertise

Several indicators suggest that it may be time to consult with a professional. These can range from unusual noises to performance issues that cannot be resolved through basic troubleshooting. Understanding these symptoms can help prevent more extensive damage and costly repairs.

| Indicator | Description |

|---|---|

| Unusual Noises | Any strange sounds, such as grinding or rattling, could signify internal issues. |

| Persistent Leaks | Ongoing leakage may point to seal failures or other critical problems. |

| Inconsistent Performance | Irregular operation, including fluctuations in output, often requires expert evaluation. |

| Frequent Breakdowns | Regular malfunctions indicate underlying issues that need professional assessment. |

Benefits of Seeking Professional Assistance

Engaging with trained technicians not only resolves immediate problems but also provides long-term advantages. Professionals possess the necessary tools, knowledge, and experience to address complex challenges effectively. Their insights can lead to enhanced performance, prolonged lifespan, and ultimately, significant cost savings over time.