In the realm of machinery, understanding the intricacies of upkeep is essential for optimal performance and longevity. This segment delves into the vital aspects of ensuring that your equipment remains in peak condition, offering insights into common issues and their solutions.

By familiarizing yourself with the operational dynamics and troubleshooting techniques, you can effectively enhance the functionality of your device. This resource serves as a practical tool, enabling users to navigate through various maintenance scenarios with confidence and clarity.

Equipping yourself with knowledge about preventative measures and repair tactics not only fosters a deeper appreciation for the technology but also empowers you to address challenges proactively. Embrace the journey of mastering your equipment’s needs for a more seamless experience.

This section provides a comprehensive overview of a popular portable power source. Understanding its key features, specifications, and overall functionality is essential for both new users and those seeking to optimize their experience.

| Feature | Description |

|---|---|

| Power Output | Delivers a substantial amount of energy, suitable for various applications. |

| Fuel Type | Operates on gasoline, making it convenient for outdoor use. |

| Portability | Designed with wheels and a handle for easy transportation. |

| Runtime | Offers extended usage time on a full tank, ideal for prolonged tasks. |

| Noise Level | Engine design minimizes noise, enhancing user comfort. |

Common Issues and Troubleshooting

When operating portable power units, users may encounter various challenges that can affect performance and reliability. Understanding these common issues can help in diagnosing and resolving problems effectively, ensuring the equipment functions optimally.

Starting Difficulties

One frequent concern is difficulty in starting the device. This can stem from issues such as insufficient fuel, stale gasoline, or a discharged battery. Checking the fuel level and ensuring fresh gasoline is used can often remedy this situation. Additionally, inspecting the battery connections and charging can help in restoring functionality.

Unusual Noises

Another issue may involve abnormal sounds during operation, which could indicate mechanical problems or loose components. It’s important to examine all parts for signs of wear or damage. Tightening loose screws and bolts may alleviate these sounds, while any severe irregularities should be addressed by a qualified technician to prevent further damage.

Essential Tools for Repairs

Having the right instruments on hand is crucial for effectively addressing issues and ensuring optimal performance. This section outlines the fundamental implements that will aid in troubleshooting and maintenance tasks.

Utilizing appropriate tools can significantly enhance efficiency and accuracy during the process. Below is a list of indispensable items for any maintenance endeavor:

| Tool | Purpose |

|---|---|

| Socket Set | Ideal for loosening and tightening various fasteners. |

| Screwdrivers | Essential for adjusting and securing screws of different sizes. |

| Pliers | Useful for gripping, twisting, and cutting wire. |

| Multimeter | Perfect for measuring voltage, current, and resistance. |

| Wrench | Facilitates turning nuts and bolts with precision. |

Equipping yourself with these vital tools will empower you to tackle various challenges effectively, ensuring longevity and reliability in performance.

Step-by-Step Repair Procedures

This section provides detailed guidelines for addressing common issues encountered with portable power units. By following these systematic approaches, users can effectively troubleshoot and restore functionality, ensuring optimal performance of the equipment.

Preparation and Safety Measures

Before commencing any work, ensure the device is disconnected from its power source. Utilize appropriate safety gear, including gloves and goggles, to protect yourself from potential hazards. Familiarize yourself with the basic components and layout of the unit to streamline the repair process.

Troubleshooting Techniques

Begin by identifying the symptoms exhibited by the unit. Common problems may include failure to start, unusual noises, or power inconsistencies. Systematically check connections, fuel levels, and electrical components. Document each step to facilitate future reference and ensure no critical aspect is overlooked.

Once the issue is identified, proceed with the necessary replacements or adjustments. Maintain organization by keeping track of screws and parts removed during disassembly. After repairs, conduct thorough testing to confirm that the device operates as intended.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of any equipment. Regular maintenance not only enhances functionality but also prevents potential issues that could arise over time. Following a structured approach to care can significantly extend the lifespan of your device.

Routine Inspections: Conduct frequent checks to identify any wear and tear. Look for signs of damage or deterioration in components, as early detection can prevent more significant problems.

Cleaning: Keep the exterior and interior parts clean. Dust and debris can obstruct airflow and cause overheating. Regular cleaning helps maintain optimal performance.

Fluid Levels: Regularly check and replenish necessary fluids. This includes oil and fuel, which are vital for smooth operation. Ensuring proper levels can prevent engine wear and improve efficiency.

Storage Conditions: Store the equipment in a dry, sheltered location when not in use. This protects it from environmental factors that can lead to rust and corrosion.

Consult the Manufacturer: Always refer to the manufacturer’s guidelines for specific maintenance instructions. Adhering to these recommendations will help ensure your device remains in peak condition.

Understanding Electrical Components

The functionality of any power generation system relies heavily on its electrical elements. These components play a crucial role in converting energy into usable power, ensuring the smooth operation of the entire system. Understanding how these parts work together is essential for effective troubleshooting and maintenance.

Key Components

Central to any electrical setup are the generator, circuit breakers, and control panels. The generator is responsible for producing electrical energy, while circuit breakers protect the system from overloads by interrupting the flow of electricity in case of faults. Control panels allow users to monitor and manage the system’s performance, providing vital information about its operational status.

Importance of Maintenance

Regular upkeep of these electrical components is necessary to ensure longevity and efficiency. Neglecting maintenance can lead to failures and decreased performance. By routinely checking connections, replacing worn parts, and ensuring proper functionality, users can prevent significant issues and prolong the life of their electrical system.

Fuel System Troubleshooting

Addressing issues within the fuel delivery system is crucial for ensuring optimal performance. Recognizing symptoms and understanding their causes can significantly enhance troubleshooting efficiency. This section will guide you through common challenges related to fuel flow, contamination, and delivery.

1. Inspecting Fuel Flow: Begin by checking the fuel lines for any blockages or leaks. A clear flow is essential for proper operation. If the lines appear damaged, consider replacing them to prevent further complications.

2. Examining the Fuel Filter: A clogged filter can restrict fuel delivery, leading to poor performance. Regularly inspect and replace the filter as needed to maintain a clean supply.

3. Evaluating Fuel Quality: Poor-quality fuel can introduce contaminants into the system. Always use fresh fuel and store it in a clean container to minimize the risk of impurities affecting performance.

4. Checking the Fuel Pump: Ensure the fuel pump is functioning correctly. Listen for unusual sounds that may indicate wear or malfunction. If issues persist, consider testing or replacing the pump.

By systematically examining these components, you can effectively diagnose and resolve fuel system issues, ultimately leading to improved functionality.

Engine Maintenance and Care

Proper upkeep of your power equipment’s motor is essential for optimal performance and longevity. Regular attention ensures that the engine operates smoothly and efficiently, minimizing the risk of unforeseen issues.

Here are key practices to consider for maintaining your engine:

- Regular Inspections: Check the engine components frequently for any signs of wear or damage.

- Oil Changes: Replace the oil at recommended intervals to keep the engine lubricated and functioning properly.

- Air Filter Maintenance: Clean or replace the air filter as needed to ensure proper airflow and prevent dirt from entering the engine.

- Fuel System Care: Use high-quality fuel and consider adding a fuel stabilizer to prevent degradation.

- Spark Plug Checks: Inspect and replace spark plugs regularly to ensure efficient ignition and performance.

By adhering to these maintenance practices, you can enhance the reliability of your engine and extend its operational life.

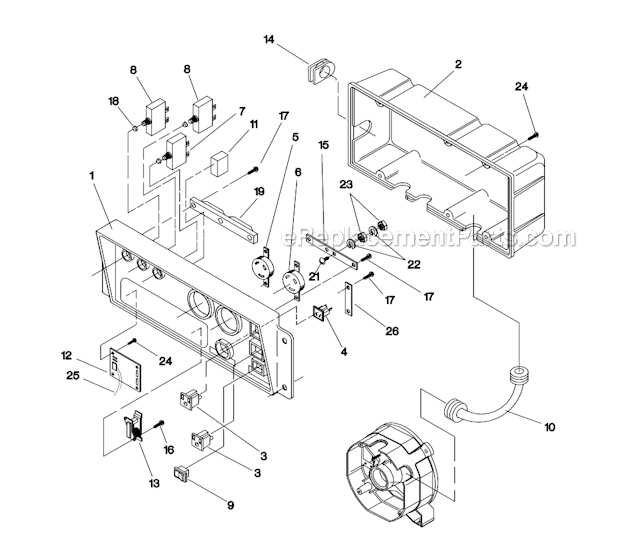

Replacing Worn Parts Effectively

Maintaining optimal performance of your equipment requires timely replacement of components that have shown signs of wear. Identifying and addressing these issues early can prevent further damage and extend the lifespan of the machine.

Begin by assessing the condition of various parts regularly. Look for signs such as cracks, excessive wear, or unusual noises that may indicate that a component is nearing the end of its usable life. Once identified, sourcing high-quality replacement parts is crucial; always choose components that match the specifications of your equipment for proper functionality.

When performing the replacement, ensure that you have the right tools at hand and follow appropriate safety protocols. Carefully remove the worn part, taking note of its orientation and how it fits within the assembly. Install the new component with precision, ensuring a secure fit to avoid any operational issues.

Finally, after replacing the worn parts, conduct a thorough inspection to confirm that everything is functioning correctly. Regular maintenance checks will help you catch potential problems early, allowing for timely interventions that keep your equipment running smoothly.

Safety Precautions During Repairs

When conducting maintenance on equipment, ensuring safety is paramount. Proper precautions help prevent accidents and injuries, ensuring a secure working environment. Following established guidelines can significantly reduce risks associated with servicing machinery.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and masks.

- Ensure the work area is well-ventilated to avoid inhaling harmful fumes.

- Disconnect the power source before beginning any work to prevent electrical shock.

- Keep tools organized and within reach to avoid unnecessary movement and distractions.

- Read the safety information provided by the manufacturer before starting any procedures.

In addition to these basic precautions, it’s essential to be aware of potential hazards specific to the task at hand. Each piece of equipment may have unique risks that require careful consideration.

- Check for leaks or spills that may create slippery surfaces.

- Use appropriate lifting techniques to avoid strain when handling heavy components.

- Be cautious of hot surfaces or components that can cause burns.

- Keep a first aid kit accessible in case of emergencies.

By adhering to these safety measures, you can create a safer environment while performing necessary tasks. This vigilance not only protects you but also ensures the longevity and reliability of the machinery.

Finding Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its functionality and performance. Whether you are looking for specific items or general replacements, understanding where to search can streamline the process.

Online Resources

The internet offers a plethora of options for sourcing parts. Many websites specialize in providing a wide range of components. Here are some popular options:

- Manufacturer’s official website

- Dedicated parts suppliers

- Online marketplaces

Local Retailers

Visiting local stores can also be beneficial. Engaging with local suppliers provides the advantage of immediate availability. Consider the following:

- Home improvement stores

- Specialized hardware shops

- Authorized service centers

Contacting Customer Support

When seeking assistance for your equipment, reaching out to customer support is essential. Their knowledgeable representatives are equipped to help resolve any issues you may encounter and provide guidance tailored to your needs.

Here are the steps to effectively contact customer service:

- Gather relevant information about your product, including the model number and purchase details.

- Prepare a list of specific questions or issues you wish to address.

- Check the official website for support options, including phone numbers, email addresses, or live chat services.

When communicating with the support team, consider the following tips:

- Be clear and concise about your problem.

- Stay patient and courteous, as representatives are there to assist you.

- Take notes during the conversation for future reference.

Utilizing these strategies will enhance your experience and lead to quicker resolutions.