This section focuses on the essential practices for maintaining and troubleshooting vital components of pool systems. Understanding the intricacies of these devices ensures their longevity and optimal performance.

Proper upkeep of your aquatic apparatus not only enhances functionality but also contributes to a safe and enjoyable swimming environment. By following systematic guidelines, users can address common issues and implement effective solutions, ultimately prolonging the lifespan of their equipment.

In this guide, you will find comprehensive instructions and helpful insights aimed at empowering users to take control of their maintenance routines. Emphasizing preventive care and timely interventions can lead to significant improvements in the efficiency and reliability of your system.

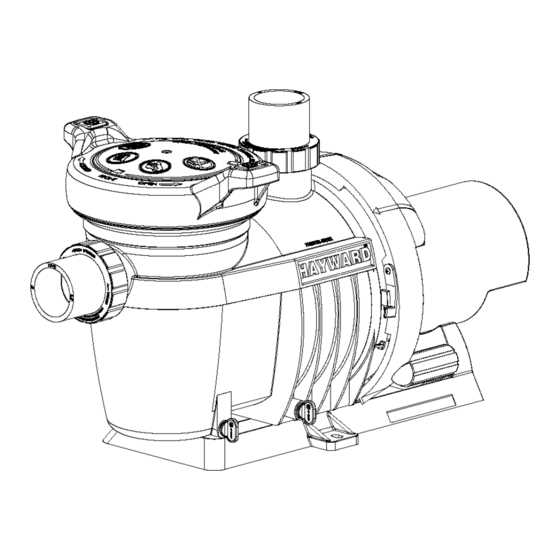

Overview of Hayward Super Pump

This section provides a comprehensive examination of a popular water circulation device, highlighting its features, functionality, and common applications. Designed for efficiency and reliability, this equipment plays a crucial role in maintaining clean and safe water in various settings.

The device is recognized for its robust construction and ease of use. It is equipped with advanced technologies that enhance its performance and energy efficiency, making it a favored choice among users.

| Feature | Description |

|---|---|

| Efficiency | Optimized design for reduced energy consumption |

| Durability | Made from high-quality materials to withstand harsh conditions |

| Maintenance | User-friendly access for simple upkeep and servicing |

| Performance | Reliable operation for various water systems |

Common Issues with Super Pump

Understanding frequent challenges associated with water circulation units can enhance maintenance and longevity. Users often encounter specific problems that, if addressed promptly, can prevent further complications.

- Inadequate Flow Rate: Insufficient water movement may result from blockages in the intake or debris in the filtration system.

- Noisy Operation: Excessive noise can indicate mechanical wear, misalignment, or air entering the system.

- Leakage: Fluid leaks around seals or fittings can suggest deterioration or improper installation.

- Electrical Issues: Problems with the motor or power supply can cause intermittent operation or complete failure.

- Overheating: Overheating may occur due to prolonged use without proper cooling or restricted airflow.

Identifying these issues early allows for effective troubleshooting and reduces the need for significant repairs. Regular inspections and timely interventions can ensure optimal performance.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right instruments is crucial for efficiency and effectiveness. Proper tools facilitate the process and ensure that each step is performed correctly, minimizing the risk of further complications.

Essential Hand Tools

Basic hand tools are fundamental for any task. These include screwdrivers, wrenches, and pliers. Each of these items serves a unique purpose, allowing for adjustments, disassemblies, and installations as needed. It is advisable to have a variety of sizes and types to accommodate different components.

Specialized Equipment

In addition to standard hand tools, certain specialized equipment may be required for specific tasks. This can include multimeters for electrical diagnostics and sealant applicators for ensuring proper sealing of joints. Utilizing the right tools will enhance the quality of the work and prolong the lifespan of the unit.

Step-by-Step Repair Process

This section outlines a comprehensive procedure for addressing common issues associated with pool circulation systems. Following these steps will help ensure effective troubleshooting and restoration of functionality.

Preparation and Safety Measures

Before beginning any work, it is crucial to gather necessary tools and materials. Ensure that the system is completely powered down to prevent any electrical hazards. Wear appropriate safety gear, including gloves and goggles, to protect against potential injuries during the process.

Troubleshooting and Component Inspection

Start by examining the various components for signs of wear or damage. Check for leaks, unusual noises, or any malfunctioning parts. Carefully document your findings, as this will assist in identifying the root cause of the issue and guide you in the subsequent steps of the restoration process.

Maintaining Optimal Performance

Ensuring the best functionality of your equipment is crucial for longevity and efficiency. Regular maintenance not only extends the lifespan of the unit but also enhances its operational effectiveness. Implementing a consistent care routine can prevent common issues and optimize performance.

Start by routinely inspecting all components for wear and tear. Cleaning filters and other parts regularly will help maintain a steady flow and prevent blockages. Additionally, checking fluid levels and ensuring they meet the required specifications can greatly influence overall performance.

Monitoring for unusual noises or vibrations during operation can provide early warning signs of potential problems. Addressing these issues promptly can prevent more significant malfunctions down the line. It is also advisable to refer to specific guidelines related to your model for best practices and troubleshooting tips.

Finally, consider scheduling professional evaluations periodically. Expert insights can identify underlying issues that may not be immediately apparent, ensuring your system runs smoothly and efficiently for years to come.

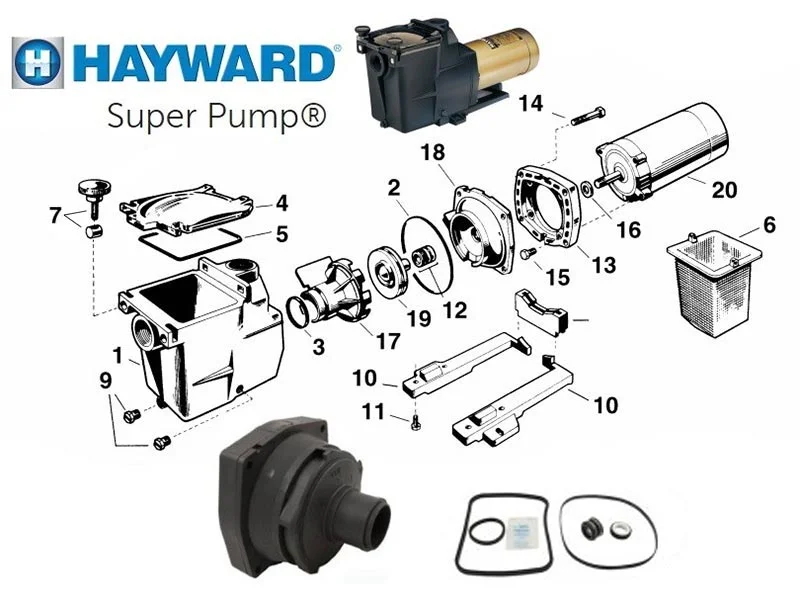

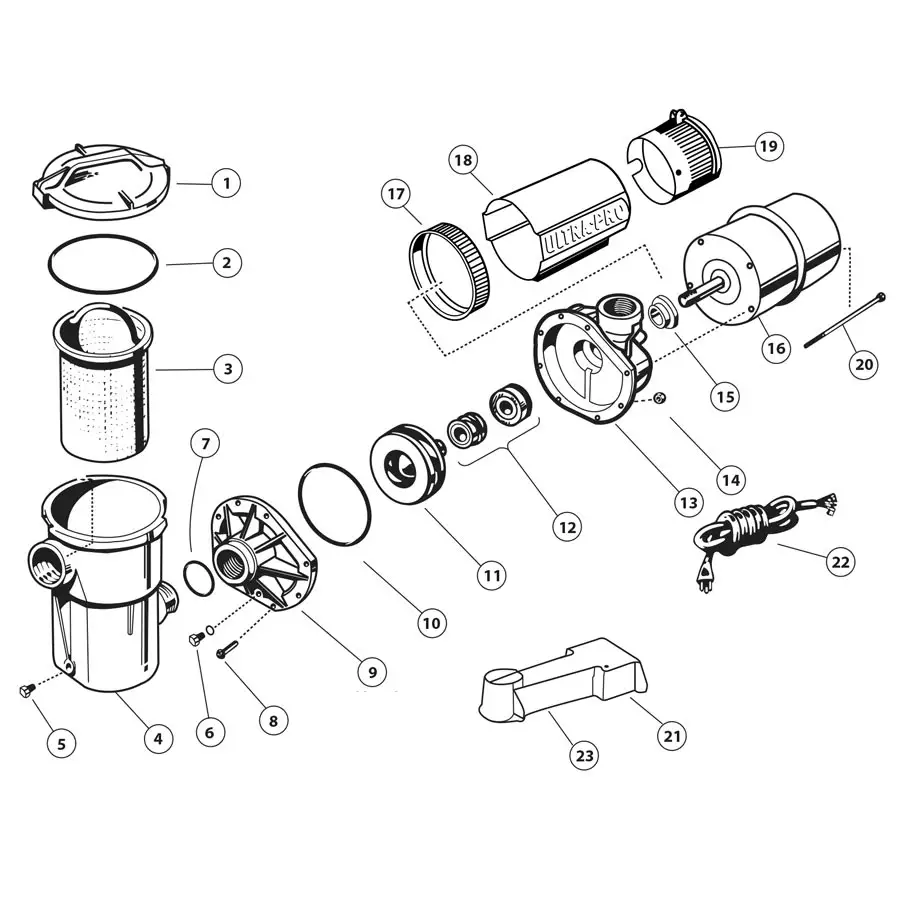

Understanding Pump Components

Grasping the elements that comprise a fluid-moving device is essential for effective maintenance and optimal functionality. Each component plays a vital role in ensuring the seamless operation of the entire system.

The following table outlines the key elements and their functions:

| Component | Function |

|---|---|

| Motor | Drives the entire system, converting electrical energy into mechanical energy. |

| Impeller | Generates flow by transferring energy to the fluid, allowing it to move efficiently. |

| Volute | Helps in directing the flow from the impeller to the discharge pipe, increasing pressure. |

| Diffuser | Slows down the fluid’s speed, converting kinetic energy into pressure energy. |

| Seal | Prevents leakage of fluids and maintains pressure within the system. |

| Strainer | Filters debris and particles from the fluid before it enters the main assembly. |

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining the efficiency of your water circulation system. This section outlines common electrical faults and provides practical steps to diagnose and correct them.

Common Symptoms of Electrical Issues

- Inconsistent power supply

- Frequent tripping of circuit breakers

- Unusual noises or vibrations

- Overheating components

Steps to Diagnose Electrical Issues

- Check the power source for voltage stability.

- Inspect all wiring for signs of damage or wear.

- Examine connections to ensure they are secure.

- Test individual components for functionality.

By systematically addressing these aspects, you can effectively troubleshoot and rectify electrical problems in your system.

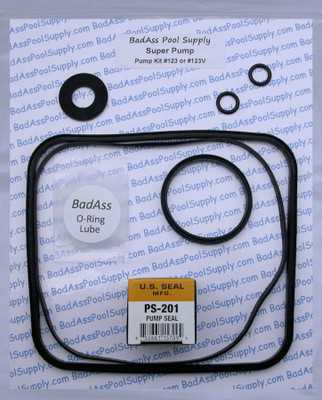

Replacing Seals and O-Rings

Maintaining optimal performance in your equipment often requires the replacement of essential components such as seals and O-rings. These elements play a crucial role in preventing leaks and ensuring that the machinery operates efficiently. Regular checks and timely replacements can save you from more significant issues down the line.

Here’s a step-by-step guide to assist you in the process:

- Gather Necessary Tools: Make sure you have the right tools on hand, including a wrench, pliers, and a seal removal tool.

- Turn Off Power: Always ensure that the device is powered down to avoid any accidents during maintenance.

- Remove the Housing: Carefully detach the housing to access the internal components. This may involve loosening screws or bolts.

- Extract Old Seals and O-Rings: Use your seal removal tool to carefully pry out the worn seals and O-rings. Take care not to damage surrounding areas.

- Clean the Surfaces: Before installing new components, clean the surfaces to remove any debris or residue.

- Install New Components: Place the new seals and O-rings in their respective slots, ensuring a snug fit to prevent any leaks.

- Reassemble the Housing: Carefully put the housing back in place and secure it with screws or bolts.

- Test the Equipment: Once reassembled, power on the machinery and check for any leaks to ensure everything is functioning correctly.

By following these steps, you can effectively replace seals and O-rings, ensuring the longevity and reliability of your device.

Cleaning the Filter System

Regular maintenance of the filtration apparatus is essential for optimal performance and longevity. A clean system ensures efficient operation, preventing debris buildup that can hinder functionality.

Steps to Clean the Filter

Begin by turning off the power supply to the unit. Next, carefully remove the filter from its housing, ensuring no residual water remains. Rinse the filter under a steady stream of water to dislodge any accumulated particles. For thorough cleaning, a soft brush can be utilized to remove stubborn debris. Once clean, allow the filter to dry completely before reinstallation.

Maintaining Filter Efficiency

To enhance the longevity of the filtration system, regularly inspect the filter for wear and tear. Replace any damaged components promptly. Additionally, schedule routine cleaning every few weeks, especially during peak usage seasons, to maintain optimal flow rates and prevent clogging.

Winterizing Your Pump

Preparing your equipment for colder months is essential to ensure its longevity and proper functioning. This process involves several crucial steps to prevent damage caused by freezing temperatures and to maintain optimal performance for the next season.

Step-by-Step Preparation

Begin by shutting down the system and disconnecting it from any power sources. Drain all water from the unit to prevent freezing and cracking. It is advisable to use a wet/dry vacuum to remove any residual moisture.

Protective Measures

Consider adding antifreeze specifically designed for your type of system, ensuring it is compatible with the materials used. Cover the equipment with a weatherproof cover to shield it from harsh elements during the off-season.

Following these guidelines will help extend the lifespan of your equipment and ensure it is ready for use when warmer temperatures return. Proper care is key to avoiding costly repairs in the future.

Identifying Leaks and Fixing Them

Recognizing and addressing fluid escape issues is crucial for maintaining optimal functionality of your system. Early detection can prevent further complications and ensure longevity.

Common Signs of Leakage

Several indicators can suggest the presence of a leak. Monitoring these signs can help identify the problem early:

- Unusual wet spots near the equipment

- Increased water bills

- Reduced performance or pressure

Steps to Diagnose and Repair

Follow these steps to effectively troubleshoot and resolve leakage issues:

| Step | Description |

|---|---|

| 1 | Inspect all connections and seals for signs of wear or damage. |

| 2 | Check hoses and fittings for cracks or loose attachments. |

| 3 | Apply appropriate sealants to minor leaks after cleaning the area. |

| 4 | Replace any compromised components as necessary. |

Regular maintenance and prompt attention to leaks can significantly enhance performance and reduce repair costs.

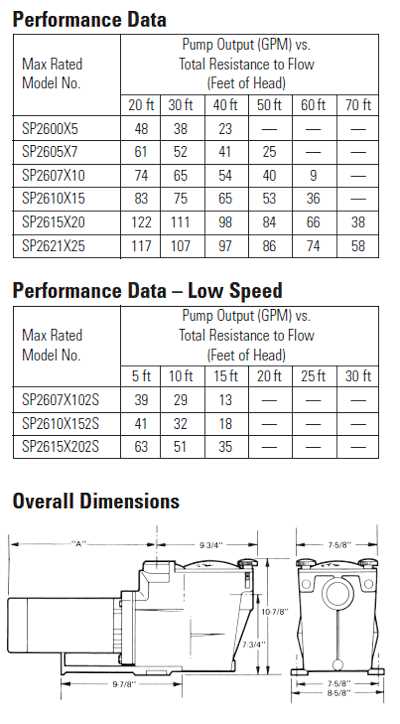

Checking and Adjusting Pressure

This section focuses on the importance of monitoring and fine-tuning the system’s pressure to ensure optimal performance and efficiency. Proper pressure levels are crucial for the effective operation of various components involved in the circulation and filtration process.

To begin, identify the pressure gauge located on the filtration unit. Observe the reading while the system is operating. It is essential to compare this measurement with the manufacturer’s recommended pressure range. If the pressure deviates from the ideal range, adjustments will be necessary.

To adjust the pressure, first, turn off the system to ensure safety. Next, check for any obstructions in the filter or pipes that may be causing increased resistance. Clean or replace any clogged components. Once cleared, restart the system and monitor the gauge again. If the pressure remains too high or too low, further adjustments may be needed, such as altering the valve settings or checking the level of water in the reservoir.

Regular checks and adjustments help maintain efficiency and prolong the lifespan of the equipment. Establish a routine to monitor these levels consistently to prevent potential issues before they arise.

When to Call a Professional

Understanding when to seek expert assistance can significantly impact the longevity and performance of your equipment. While many maintenance tasks can be handled independently, certain situations may require specialized knowledge and tools.

Unusual Noises or Vibration: If you notice unfamiliar sounds or excessive vibration during operation, it may indicate underlying issues that need professional evaluation. Ignoring these signs could lead to more severe damage.

Leaks or Unusual Fluids: The presence of liquid where it shouldn’t be can signal serious problems. If you detect leaks or any unusual substances, it’s advisable to consult a technician to prevent further complications.

Persistent Performance Issues: If your system consistently fails to meet expected performance standards despite routine maintenance, a professional inspection may be necessary to identify hidden faults and ensure optimal functionality.

Electrical Concerns: Any electrical irregularities, such as flickering lights or tripped breakers, should be addressed by a qualified expert to avoid safety hazards and potential damage to your system.

Ultimately, recognizing the right time to call for help can save you time, effort, and expense in the long run.