In today’s demanding transportation industry, ensuring the longevity and efficiency of long-haul trucks is essential for both productivity and safety. This section delves into the key aspects of vehicle upkeep, providing invaluable insights for operators and technicians alike. By understanding core components and common challenges, drivers and fleet managers can better manage essential maintenance tasks and address issues effectively as they arise.

Throughout this guide, you’ll discover detailed approaches to diagnostics, practical maintenance techniques, and step-by-step procedures for addressing a variety of common concerns. From engine functionality to electrical systems, we’ll cover essential areas, ensuring every vehicle is equipped to perform at its best. The goal here is not only to extend the vehicle’s life but also to foster a safer and more cost-effective operation for the long run.

Whether you’re an experienced technician or a driver with basic mechanical knowledge, this resource will provide you with the tools and insights to enhance

Freightliner Cascadia Repair Manual Overview

This section provides a comprehensive guide aimed at understanding essential procedures and detailed instructions for maintaining and servicing a well-known line of commercial trucks. Offering practical insights, this resource serves as a valuable tool for owners and technicians alike, covering everything from diagnostic steps to component replacement.

Core Areas of Maintenance

Within this guide, users will find clear and concise directions on major upkeep areas. Emphasis is placed on regular inspection, diagnostics, and part renewal practices, all intended to maximize the lifespan and efficiency of the vehicle. Each segment of the manual addresses specific systems, ensuring that troubleshooting is straightforward and accessible.

Technical Specifications and Resources

The manual also includes technical specifications and resources essential for understanding the vehicle’s core systems. Readers can expect to find detailed information on electrical diagrams, torque requirements, and recommended service intervals, enabling efficient and safe procedures. Designed for both novice and experienced technicians, this

Engine Maintenance Essentials for Cascadia

Regular attention to the engine’s upkeep is vital to ensure long-lasting performance and reliability. Consistent care and preventive measures help avoid unexpected breakdowns, promoting smoother operations over extended periods. By focusing on routine checks and timely interventions, operators can maximize engine efficiency and extend its lifespan.

One of the fundamental aspects of maintaining any engine is keeping a close watch on fluid levels. Engine oil, coolant, and transmission fluids should be monitored regularly to prevent overheating and ensure optimal functioning of critical parts. Keeping these fluids topped off and replacing them at recommended intervals helps reduce wear and tear on key components.

Filtration systems, including air and fuel filters, play a significant role in protecting the engine from contaminants. Clean air and fuel filters are essential for efficient combustion, preventing debris and particles from entering the engine. Replacing filters on time improves fuel efficiency and reduces the risk of engine damage caused by clogs or buildup.

Another crucial area to focus on is the condition of belts and hoses. These components endur

Understanding the Cascadia Transmission System

The transmission mechanism in commercial vehicles plays a critical role in translating engine power into motion, directly impacting the vehicle’s performance and efficiency. This section provides an in-depth look at the main components and operational principles of this system, which is essential for both smooth acceleration and optimal fuel usage during long hauls.

Transmission systems in heavy-duty vehicles incorporate complex gear ratios and control mechanisms designed to handle high torque demands. These systems generally include a variety of modes to accommodate different driving conditions, balancing power output and fuel consumption effectively.

| Component |

Description |

| Clutch |

Responsible for engaging and disengaging the power between the engine and gearbox, allowing for smooth gear shifts and minimizing wear on the system. |

Gearbox

Cooling System Troubleshooting Tips

Maintaining a functional cooling system is essential to ensure the engine operates within optimal temperature ranges. Diagnosing and addressing issues early can prevent overheating and other potential complications. Below, explore practical strategies for identifying and resolving common cooling system issues, with a focus on enhancing performance and reliability.

Identify Signs of Cooling System Problems

- Temperature Fluctuations: Sudden increases in engine temperature or fluctuating temperature levels can indicate an issue within the cooling components.

- Fluid Leaks: Look for any visible signs of coolant leakage beneath the vehicle, especially around the radiator, hoses, or the reservoir.

- Unusual Noises: Grinding or squealing sounds near the cooling fan or pump might suggest a need for inspection.

Steps for Troubleshooting the Cooling System

- Check Coolant Levels: Regularly inspect the coolant reservoir to ensure fluid

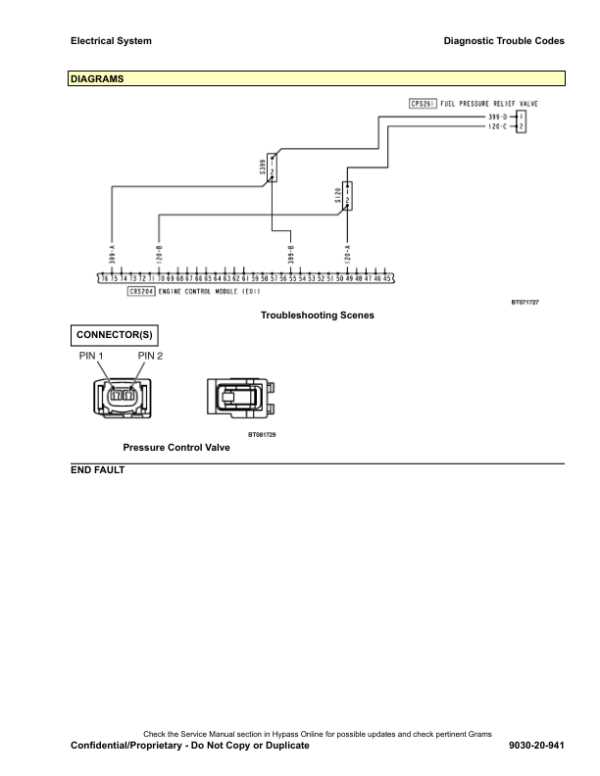

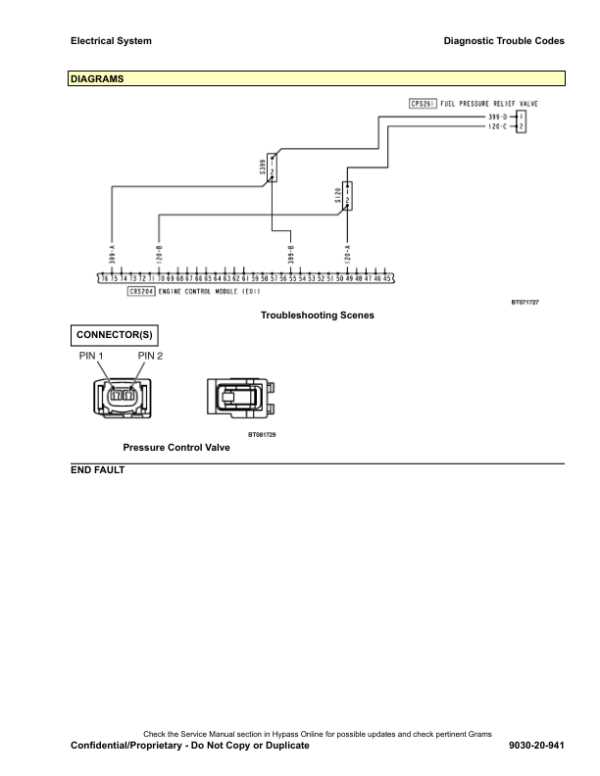

Electrical System Diagnostics and Repair

Identifying and resolving issues within a vehicle’s electrical network demands a systematic approach. This section outlines the essential techniques for diagnosing malfunctions, ensuring functionality, and restoring connections to maintain performance. Addressing electrical challenges efficiently minimizes potential downtime and extends operational reliability.

Common Issues and Symptoms

Many electrical problems stem from faulty connections, damaged wiring, or failing components. Typical symptoms include intermittent power loss, dim or flickering lights, and unresponsive controls. Systematic testing and targeted checks can reveal the underlying causes, helping pinpoint exact areas requiring attention.

| Component |

Potential Issues |

Testing Method |

| Battery |

Low voltage, poor connections |

Fuel System Maintenance Guide

Maintaining the fuel system is crucial for ensuring optimal performance and longevity of your vehicle. Regular inspection and servicing of various components can help prevent costly repairs and ensure smooth operation. This guide outlines essential practices for keeping the fuel delivery system in top condition.

Regular Inspection

Routine examination of the fuel system should be conducted to identify potential issues before they escalate. Check for any signs of leaks, wear, or damage in fuel lines and connections. It is also essential to inspect the fuel filter and replace it according to the manufacturer’s recommendations to avoid clogging and reduce strain on the fuel pump.

Fuel Quality Management

The quality of fuel used can significantly impact engine performance. Always utilize high-quality fuel that meets specified standards. Consider adding a fuel stabilizer to prevent degradation during extended periods of inactivity. Regularly clean the fuel injectors to ensure optimal spray patterns and efficient combustion, promoting better fuel economy and reduced emissions.

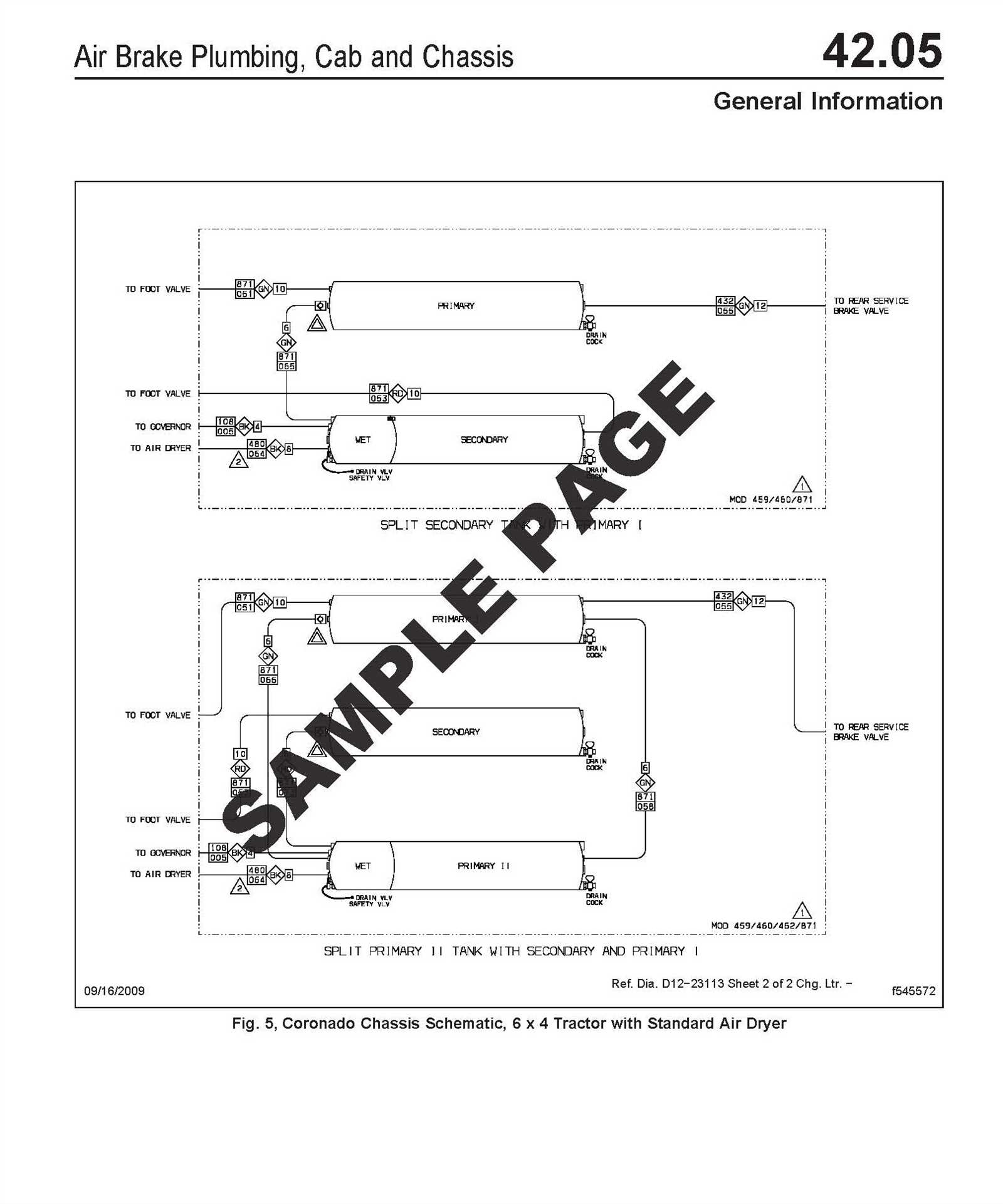

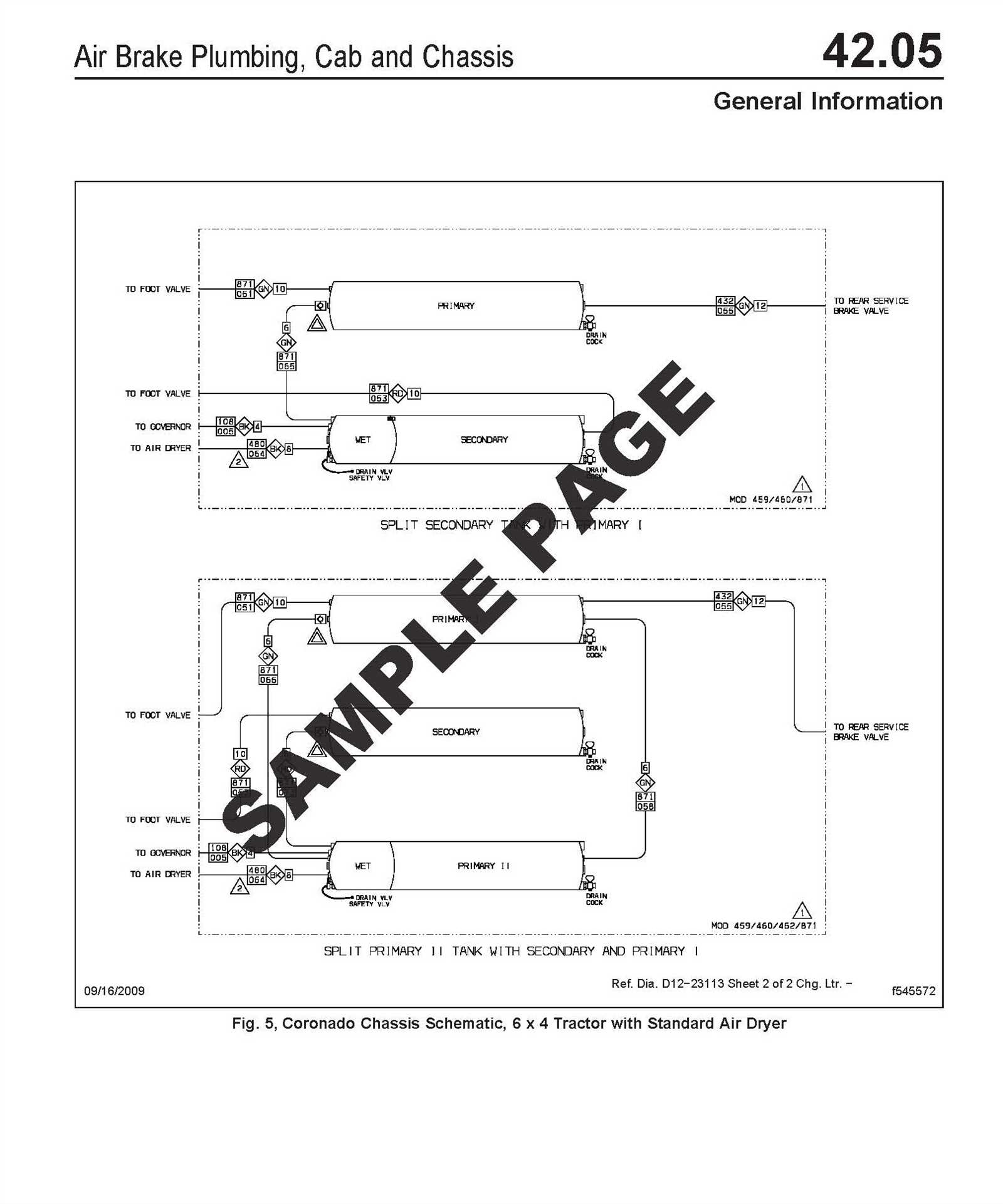

Brake System Components and Repairs

The braking mechanism is crucial for ensuring safety and control in any heavy-duty vehicle. Understanding its various elements and how to maintain them effectively is essential for optimal performance. This section delves into the primary components of the braking system, common issues that may arise, and the necessary steps to address them.

Key elements of the braking system include the brake pads, rotors, calipers, master cylinder, and brake lines. Each component plays a vital role in the overall functionality, contributing to the vehicle’s ability to stop efficiently. Regular inspection and maintenance are imperative to prevent wear and tear that can lead to performance degradation.

| Component |

Common Issues |

Maintenance Tips |

| Brake Pads |

Worn pads can reduce braking efficiency |

Inspect and replace regularly |

| Rotors |

Warping can cause vibrations |

Resurface or replace if damaged |

| Calipers |

Leaking fluid can affect braking |

Check seals and replace if necessary |

| Master Cylinder |

Loss of pressure can lead to brake failure |

Inspect for leaks and ensure proper fluid levels |

| Brake Lines |

Corrosion can lead to leaks |

Regularly check for wear and replace damaged sections |

In conclusion, maintaining the braking system is essential for vehicle safety and reliability. By being aware of each component’s function and common issues, operators can ensure timely interventions and maintain optimal braking performance.

Cabin Interior Repairs and Upgrades

Maintaining and enhancing the interior space of a commercial vehicle is crucial for driver comfort and functionality. Whether addressing wear and tear or looking to modernize the cabin, various options are available to improve both aesthetics and usability. This section explores common tasks and upgrades that can significantly impact the overall experience within the vehicle.

Key areas to consider when focusing on the interior include:

- Seating: Upgrading seats for better ergonomics and support can reduce fatigue during long hauls.

- Dashboard Modifications: Installing advanced displays and controls can enhance the driver’s interface with the vehicle.

- Soundproofing: Adding sound-dampening materials can minimize road noise, creating a more serene environment.

- Storage Solutions: Implementing custom storage options can maximize space and improve organization within the cabin.

When undertaking these enhancements, it’s essential to consider both functionality and style to create a balanced and efficient interior. This can involve:

- Assessing the current condition of seats, controls, and storage spaces.

- Researching suitable aftermarket products that fit your vehicle’s specifications.

- Consulting with professionals if extensive modifications are planned.

- Budgeting for materials and labor to ensure a successful upgrade.

Ultimately, investing in the interior of the vehicle not only improves comfort for the driver but can also increase the overall value of the asset.

Steering and Suspension Maintenance

Regular upkeep of steering and suspension systems is crucial for the overall performance and safety of any heavy-duty vehicle. Proper maintenance ensures stability, enhances handling, and prolongs the lifespan of various components, contributing to a smoother driving experience.

Key Components to Inspect

- Steering linkage

- Shock absorbers and struts

- Ball joints

- Sway bar links

- Control arms

- Tie rod ends

Maintenance Procedures

- Check for wear and tear on all steering and suspension components regularly.

- Inspect the fluid levels in the steering system and replace as necessary.

- Ensure that all bolts and nuts are tightened to manufacturer specifications.

- Replace any worn-out parts promptly to avoid further damage.

- Consider periodic alignments to maintain optimal handling and tire life.

By adhering to these practices, you can maintain the integrity of the steering and suspension systems, ensuring safer and more efficient operation of the vehicle.

Common Issues with Cascadia Electronics

The electronic systems in heavy-duty vehicles are critical for performance and safety. However, various challenges can arise, leading to potential disruptions in functionality. This section will delve into typical problems encountered in the electronic systems of these vehicles, helping owners and technicians identify and address issues effectively.

Typical Electronic Malfunctions

- Dashboard Warning Lights: Frequent illumination of warning indicators without an apparent cause can signal underlying electronic faults.

- Communication Failures: Issues with data transmission between control modules can result in poor vehicle performance or diagnostic trouble codes.

- Power Supply Problems: Inconsistent power delivery to various components may lead to sporadic functionality or complete failures.

- Sensor Failures: Malfunctioning sensors can produce inaccurate readings, affecting systems such as braking and fuel management.

Prevention and Troubleshooting

- Regular Diagnostics: Conducting frequent checks using specialized diagnostic tools can help identify issues before they escalate.

- Wiring Inspection: Regularly inspecting wiring and connectors for damage or corrosion can prevent many electronic problems.

- Software Updates: Keeping the vehicle’s software up to date can resolve known bugs and enhance overall system performance.

- Component Replacement: Timely replacement of faulty components can help maintain optimal functioning of electronic systems.

Preventative Maintenance Practices for Longevity

Implementing effective preventative maintenance practices is crucial for extending the lifespan and enhancing the performance of heavy-duty vehicles. By focusing on routine inspections and timely interventions, operators can mitigate potential issues and ensure optimal functionality over time.

- Regular Inspections: Conduct thorough inspections of all critical components, including the engine, transmission, and braking systems. This proactive approach helps identify wear and tear before they escalate into significant problems.

- Fluid Checks and Changes: Monitor and maintain fluid levels, such as oil, coolant, and brake fluid. Regular fluid changes are essential to prevent overheating and maintain the overall efficiency of the vehicle.

- Tire Maintenance: Check tire pressure and tread depth frequently. Properly inflated and well-maintained tires enhance fuel efficiency and provide better handling, contributing to safer operation.

- Brake System Care: Inspect brake pads, rotors, and lines regularly. Address any signs of wear promptly to ensure the safety and reliability of the vehicle.

- Battery Maintenance: Keep battery terminals clean and check the charge regularly. A well-maintained battery is vital for reliable starting and electrical system performance.

- Scheduling Professional Services: Plan periodic visits to certified technicians for comprehensive evaluations. Professional insights can uncover hidden issues and provide tailored solutions for maintenance.

By integrating these preventative measures into the maintenance routine, operators can significantly enhance the durability and reliability of their vehicles, ensuring they remain in peak condition for years to come.

|