In the world of outdoor equipment, efficient functioning is crucial for accomplishing tasks with ease. Understanding how to maintain and troubleshoot these machines can significantly enhance their longevity and performance. This section aims to provide comprehensive insights into the common issues that may arise, along with practical solutions.

Regular upkeep not only ensures optimal operation but also prevents potential breakdowns. Familiarity with the components and mechanisms involved can empower users to address minor complications independently. With the right knowledge, individuals can navigate challenges effectively, leading to successful usage and minimal downtime.

This guide will cover essential techniques and tips, making it a valuable resource for anyone looking to enhance their skills in managing outdoor machinery. Whether you’re a seasoned user or a newcomer, the information presented here will serve as a practical reference for handling various scenarios that may occur.

When engaging in maintenance or troubleshooting tasks, ensuring a safe environment is crucial. Proper safety measures can prevent accidents and injuries, making the process smoother and more efficient.

Here are essential safety guidelines to follow:

- Always disconnect power sources before starting any work.

- Wear appropriate personal protective equipment, such as gloves and safety goggles.

- Keep the workspace tidy and free from obstructions to avoid trips and falls.

- Use tools that are in good condition and designed for the specific task.

- Follow manufacturer instructions and guidelines when handling equipment.

By adhering to these precautions, you can significantly reduce risks associated with maintenance activities.

Tools Needed for Repairs

Having the right equipment is essential for any maintenance task, ensuring efficiency and effectiveness. Proper tools not only simplify the process but also enhance safety, allowing for precise handling and manipulation of components.

Some of the basic items required include a reliable set of wrenches for loosening and tightening fasteners, along with a selection of screwdrivers to accommodate various screw types. Additionally, a sturdy hammer may be necessary for tapping stubborn parts into place.

For electrical issues, a multimeter is crucial for diagnosing voltage and continuity problems, while pliers can aid in gripping and cutting wires. A good-quality socket set can also make removing bolts and nuts much easier, especially in tight spaces.

Lastly, don’t forget about safety gear, such as gloves and safety glasses, which protect against debris and sharp edges during the process. Investing in quality tools will pay off in the long run by facilitating smoother and safer repair work.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing issues that may arise with your equipment. Following these detailed steps will help restore functionality effectively and efficiently, ensuring optimal performance once again.

Preparation

Before starting the process, gather the necessary tools and materials:

- Safety goggles

- Gloves

- Wrenches

- Screwdrivers

- Replacement parts

- Lubricants

Disassembly and Inspection

Begin the procedure by disassembling the unit carefully:

- Ensure the machine is unplugged to prevent accidents.

- Remove any protective covers to access internal components.

- Inspect each part for signs of wear, damage, or malfunction.

- Document any issues for reference during reassembly.

By following these steps, you can efficiently diagnose and resolve the problems encountered with your machinery, enhancing its longevity and performance.

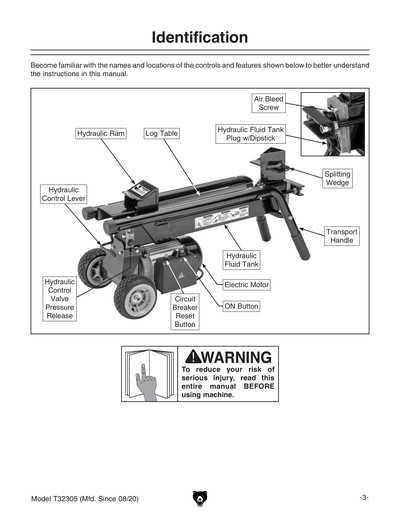

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in various machinery by utilizing pressurized fluid to transfer energy and perform work efficiently. This technology is widely employed across multiple applications, providing the necessary force to accomplish tasks that would be challenging with mechanical means alone. By harnessing the properties of fluids, these systems offer both power and precision in operation.

Basic Components of Hydraulic Systems

At the core of hydraulic mechanisms are several key components that work in concert to facilitate movement and control. Understanding these parts is essential for anyone looking to maintain or troubleshoot such systems.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates flow and pressure of the hydraulic fluid |

| Hydraulic Cylinder | Converts fluid power into linear motion |

| Valves | Control the direction and flow of the fluid |

| Hydraulic Fluid | Transmits power throughout the system |

Working Principle

The operation of hydraulic systems is based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. This principle allows for the amplification of force, making it possible to lift or move heavy objects with relatively little effort. By strategically manipulating the pressure and flow within the system, operators can achieve precise control over the equipment’s movement.

Replacing Worn Components

Maintaining optimal performance requires timely substitution of deteriorated parts within any machinery. Identifying components that have lost their effectiveness is essential for ensuring smooth operation and prolonging the lifespan of the equipment. Regular inspections can help catch issues before they lead to more significant problems.

Identifying Worn Parts

To begin the process, visually inspect the equipment for any signs of wear or damage. Common indicators include unusual noises, decreased efficiency, or visible deterioration. Pay close attention to moving elements, seals, and fasteners, as these are often the first to show signs of aging.

Steps for Replacement

Once worn components are identified, proceed with their removal and replacement. Start by disconnecting the power source to ensure safety. Use the appropriate tools to detach the old parts carefully, and install new ones according to manufacturer specifications. After replacement, conduct a thorough test to confirm that the machinery operates correctly and efficiently.

Troubleshooting Performance Issues

Addressing operational challenges is crucial for maintaining optimal functionality in any machinery. When devices fail to perform as expected, it is essential to identify the root causes and implement effective solutions. This section outlines common problems and their remedies to ensure reliable operation.

Common Symptoms and Causes

- Insufficient Power: Check the power source and connections to ensure consistent energy supply.

- Overheating: Inspect ventilation and coolant levels to prevent overheating issues.

- Slow Operation: Assess the hydraulic fluid levels and replace any worn components that may impede performance.

- Noise and Vibration: Examine for loose parts or debris that could contribute to unusual sounds or movement.

Effective Solutions

- Verify and secure all electrical connections to eliminate power-related issues.

- Regularly change hydraulic fluid and maintain proper levels to ensure smooth operation.

- Conduct routine inspections of components to detect wear and replace them as needed.

- Ensure that the device is kept clean and free from debris to avoid operational disruptions.

When to Seek Professional Help

Knowing when to consult an expert can save time, effort, and potentially costly mistakes. While many minor issues can be handled independently, certain circumstances require the expertise of a trained professional. Recognizing these situations is crucial for effective troubleshooting and maintenance.

Signs Indicating Professional Assistance is Needed

Several indicators suggest that it may be time to reach out to a skilled technician:

| Indicator | Description |

|---|---|

| Frequent Breakdowns | Repeated malfunctions may indicate underlying issues that need specialized attention. |

| Unusual Noises | Strange sounds during operation often signal significant problems that require expert diagnosis. |

| Performance Decline | A noticeable decrease in efficiency suggests that components may be failing or misaligned. |

Benefits of Professional Intervention

Engaging a qualified technician offers numerous advantages, including:

- Accurate diagnosis of complex issues

- Access to specialized tools and equipment

- Expertise in handling repairs safely and effectively