Maintaining precision devices is crucial for ensuring their longevity and optimal performance. This section delves into the essential practices and procedures required to keep your equipment in top condition. By understanding the intricacies of these tools, users can enhance their efficiency and tackle various tasks with confidence.

Regular upkeep not only prevents common issues but also extends the lifespan of your instruments. Knowledge of various components and their functions empowers users to perform basic troubleshooting and minor adjustments independently. With the right approach, users can avoid costly repairs and maintain smooth operation.

In the following sections, we will explore detailed guidance on addressing common concerns, along with practical tips for effective maintenance. Emphasizing safety and proper handling, this guide aims to equip users with the necessary skills to manage their devices effectively.

This section provides a comprehensive introduction to a versatile handheld instrument widely used in various crafting and repair tasks. Known for its adaptability, this device is favored by hobbyists and professionals alike for its ability to perform multiple functions with interchangeable attachments.

| Feature | Description |

|---|---|

| Speed Settings | Variable speed control allows users to adjust the rotation for different applications. |

| Attachments | A wide range of accessories enables cutting, sanding, polishing, and engraving. |

| Ergonomics | Designed for comfort, making it easy to handle for extended periods. |

| Portability | Lightweight construction facilitates easy transport and usage in various locations. |

Common Issues and Solutions

When working with precision devices, various challenges can arise, impacting performance and efficiency. Understanding these common problems and their solutions can help maintain functionality and extend the lifespan of your equipment.

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive heat can lead to component failure. | Ensure adequate ventilation and allow for cooling breaks during use. |

| Noise | Unusual sounds may indicate wear or damage. | Inspect moving parts for wear and replace if necessary. |

| Inconsistent Performance | Fluctuations in speed or power can hinder effectiveness. | Check for debris in the mechanism and clean thoroughly. |

| Stalling | Sudden stops can disrupt workflow and cause frustration. | Examine power supply and connections for any issues. |

Essential Tools for Repairs

When it comes to fixing precision instruments, having the right equipment is crucial for achieving optimal results. This section highlights the necessary items that every enthusiast should have on hand to ensure effective maintenance and enhancement of their devices.

Basic Equipment

First and foremost, a quality set of hand-held implements is indispensable. These include items like screwdrivers, pliers, and wrenches, which allow for easy access to various components. Additionally, a reliable cutting instrument can facilitate the separation of parts when needed.

Safety Gear

Ensuring safety during the maintenance process cannot be overlooked. Protective eyewear is essential to shield the eyes from debris, while gloves can provide grip and prevent injury. Utilizing these basic safety measures contributes to a smoother and more secure working experience.

Step-by-Step Repair Process

This section outlines a comprehensive approach to fixing common issues encountered with precision devices. By following a structured method, users can effectively troubleshoot and restore functionality to their equipment.

1. Identify the Problem: Begin by assessing the symptoms. Take note of any unusual sounds, performance issues, or visible damage. This initial step is crucial for determining the appropriate course of action.

2. Gather Necessary Tools: Assemble all required instruments and components before starting the process. Having everything on hand minimizes interruptions and allows for a smoother workflow.

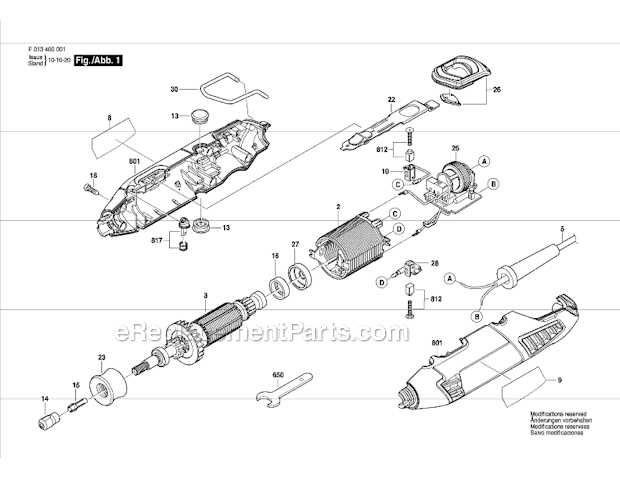

3. Disassemble the Unit: Carefully take apart the device to access internal components. Ensure that all parts are organized and accounted for to avoid confusion during reassembly.

4. Inspect Components: Examine each element for wear, breakage, or other signs of malfunction. Pay special attention to electrical connections, gears, and any moving parts that may require lubrication or replacement.

5. Make Repairs: Based on the inspection, perform the necessary fixes. This could involve replacing damaged parts, tightening loose connections, or applying appropriate lubricants to enhance performance.

6. Reassemble the Unit: Once repairs are completed, carefully reassemble the device, ensuring that all components are properly aligned and secured. Refer to any diagrams or notes made during disassembly.

7. Test Functionality: After reassembly, conduct a thorough test to confirm that the device operates as intended. Monitor for any lingering issues and address them as needed.

8. Final Cleanup: Clean the workspace and dispose of any waste materials responsibly. A tidy environment promotes safety and readiness for future tasks.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended life of your equipment. By implementing simple maintenance practices, you can significantly enhance performance and minimize the need for future repairs. Below are key recommendations to keep your device in optimal condition.

Regular Cleaning

Cleaning your equipment after each use is crucial. Dust and debris can accumulate, affecting functionality. Use a soft brush or a compressed air canister to remove any particles. Make sure to check and clean the air vents regularly to prevent overheating.

Lubrication

Applying the right lubricant to moving parts helps reduce friction and wear. Follow manufacturer guidelines for the appropriate type and frequency of lubrication. This practice not only improves efficiency but also extends the lifespan of the internal components.

| Maintenance Task | Frequency | Recommended Action |

|---|---|---|

| Cleaning | After each use | Use a soft brush or compressed air |

| Lubrication | Monthly | Apply suitable lubricant to moving parts |

| Inspection | Every three months | Check for wear and tear on components |

Identifying Parts and Components

Understanding the various elements of an equipment is crucial for effective maintenance and troubleshooting. Each part plays a specific role, contributing to the overall functionality and performance of the device. By recognizing these components, users can make informed decisions when addressing issues or performing upgrades.

Components typically include the housing, which encases the internal mechanisms, and the motor, responsible for powering the device. Additionally, attachments and accessories enhance versatility, allowing for a range of applications. Recognizing these key parts not only facilitates repairs but also improves the user’s ability to utilize the equipment to its full potential.

It’s important to familiarize oneself with the layout and function of each component. For example, understanding how the power switch operates or the significance of various attachments can significantly impact the user experience. Effective identification of these elements streamlines the process of maintenance and enhances operational efficiency.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. By following proper guidelines, individuals can create a secure environment while handling equipment.

- Always wear protective gear, such as goggles and gloves, to safeguard against debris and sharp edges.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust particles.

- Keep your workspace organized to minimize the risk of tripping or accidentally knocking over tools.

- Ensure that the device is unplugged or powered down before beginning any service.

- Use the right equipment for the job to prevent unnecessary strain and potential injury.

Adhering to these precautions not only enhances personal safety but also contributes to more effective and efficient maintenance work.

Troubleshooting Electrical Problems

Addressing electrical issues can significantly enhance the performance of your device. By systematically examining various components, you can identify common malfunctions and implement effective solutions to restore functionality.

Common Symptoms of Electrical Issues

- Device fails to turn on

- Unusual noises during operation

- Intermittent power supply

- Excessive heat generation

Steps to Diagnose Electrical Malfunctions

- Check the power source and ensure it is functioning correctly.

- Inspect all cables and connections for any signs of damage.

- Test the fuse or circuit breaker for any disruptions.

- Examine internal components for wear or burn marks.

Replacement Parts and Upgrades

Maintaining the functionality of your equipment often requires the use of new components and enhancements. Upgrading parts not only improves performance but can also extend the lifespan of the device. Understanding the options available for replacements and enhancements is crucial for optimizing usage.

Common replacement components include brushes, motors, and bearings, which are essential for ensuring smooth operation. When considering upgrades, look for improved attachments or enhanced power settings that can elevate your project’s capabilities. Investing in high-quality parts can lead to significant improvements in efficiency and effectiveness.

Before purchasing replacements, it is advisable to consult compatibility charts and specifications to ensure proper fit. Many suppliers offer kits that include multiple components for a complete overhaul, making the upgrade process more accessible. By regularly updating parts, users can achieve superior results and enjoy a seamless experience.

Tools for Disassembly and Assembly

To effectively separate and reassemble various components, having the right instruments is essential. A well-equipped workspace facilitates the process, ensuring efficiency and minimizing the risk of damage to delicate parts.

Screwdrivers are fundamental for loosening and tightening screws. Various sizes and types, such as flathead and Phillips, should be at hand to accommodate different fasteners. Additionally, a wrench set can assist in handling nuts and bolts securely.

For accessing tight spaces, needle-nose pliers are invaluable. They provide grip and precision when manipulating small components. Furthermore, cutters may be necessary for removing any wires or connections safely.

Using a torque wrench helps ensure that screws are fastened to the correct specifications, preventing over-tightening which could lead to damage. Lastly, keeping a magnifying glass nearby aids in examining intricate details and ensuring everything is in order before completing the assembly.

Customer Support Resources

When faced with challenges regarding your equipment, accessing reliable assistance is crucial. Various avenues exist for customers to seek help, ensuring that issues can be addressed effectively and efficiently.

Online Support Platforms: Many manufacturers provide comprehensive online resources, including FAQs, troubleshooting guides, and instructional videos. These tools can offer immediate solutions and step-by-step instructions to help users resolve common problems.

Customer Service Contacts: Direct communication with customer service representatives is often available through phone, email, or live chat. These professionals can provide personalized assistance tailored to specific issues, ensuring a quicker resolution.

Community Forums: Engaging with other users through community forums can be beneficial. These platforms allow individuals to share experiences, tips, and solutions, fostering a supportive environment for problem-solving.

Authorized Service Centers: For more complex concerns, reaching out to certified service centers may be necessary. These facilities are equipped with trained technicians who can diagnose and repair equipment efficiently, providing peace of mind for customers.

Community Forums and Advice

Online communities offer a wealth of knowledge and support for individuals looking to enhance their understanding of various devices and their maintenance. Engaging with fellow enthusiasts can provide valuable insights, troubleshooting tips, and shared experiences that can guide you in resolving issues effectively.

Participating in these forums allows users to:

- Share personal experiences and solutions.

- Ask questions and receive prompt responses from knowledgeable members.

- Access tutorials and guides created by experienced users.

- Discuss common challenges and find collective solutions.

When seeking advice, consider the following tips to maximize your experience:

- Be specific about the issues you are facing to receive targeted advice.

- Search through existing threads to find relevant information before posting new questions.

- Contribute to discussions by sharing your own tips and solutions.

- Respect the community guidelines to maintain a positive environment.