In the world of agricultural operations, the efficiency and longevity of heavy-duty machinery play a crucial role in ensuring optimal productivity. Understanding the intricacies of these powerful machines is essential for any operator seeking to maximize performance and minimize downtime. This section delves into comprehensive strategies and detailed insights to facilitate the upkeep of vital equipment.

Every piece of machinery comes with its own set of challenges, requiring specific knowledge and skills for effective troubleshooting and upkeep. From basic adjustments to complex overhauls, having access to structured information can empower users to tackle issues confidently. By familiarizing oneself with the essential components and their functions, operators can foster a proactive approach to maintenance.

Furthermore, regular attention to the health of machinery not only enhances operational efficiency but also significantly extends its lifespan. Emphasizing the importance of preventative measures, this guide aims to equip users with the necessary tools to handle a variety of maintenance tasks, ensuring that equipment remains in peak condition throughout its service life.

Understanding Deutz Tractors

In the realm of agricultural machinery, certain brands have established a reputation for reliability and performance. This segment explores the nuances of one such manufacturer, emphasizing the engineering excellence and innovative designs that set their equipment apart. By delving into the features, functionalities, and maintenance practices, users can gain a comprehensive understanding of these powerful machines.

| Feature | Description |

|---|---|

| Engine Performance | Equipped with advanced engine technology, these machines deliver optimal power while ensuring fuel efficiency. |

| Durability | Constructed with high-quality materials, they are built to withstand rigorous working conditions. |

| User-Friendly Design | Intuitive controls and ergonomic seating enhance operator comfort and ease of use. |

| Versatility | Adaptable for various tasks, they can be fitted with a range of attachments to suit different agricultural needs. |

| Serviceability | Designed for easy maintenance, ensuring minimal downtime and prolonged lifespan. |

Understanding these aspects not only aids in selecting the right machinery for specific tasks but also empowers users to maintain and operate their equipment effectively. Knowledge of the components and systems involved can significantly enhance overall productivity in the field.

Common Issues in Deutz Tractors

When operating agricultural machinery, various challenges may arise, impacting performance and efficiency. Understanding these frequent problems is essential for maintaining optimal functionality and ensuring longevity. Below are some of the most prevalent concerns faced by users.

Mechanical Malfunctions

- Engine Overheating

- Transmission Failures

- Hydraulic System Leaks

Electrical Problems

- Battery Drainage

- Faulty Wiring Connections

- Malfunctioning Alternators

Identifying and addressing these issues promptly can prevent more significant complications and enhance operational efficiency.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. A well-equipped workspace not only enhances efficiency but also ensures safety during the process. Below is a guide to some fundamental instruments that are essential for successful interventions.

Basic Hand Tools

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are necessary for loosening and tightening fasteners.

- Wrenches: Both adjustable and fixed wrenches are important for securing nuts and bolts.

- Pliers: These are useful for gripping, twisting, and cutting wires or small components.

- Hammer: A solid hammer is essential for driving nails or adjusting parts that may be misaligned.

Specialized Instruments

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing damage.

- Multimeter: A vital tool for diagnosing electrical issues and checking voltage and continuity.

- Diagnostic Scanner: Useful for reading error codes and understanding performance issues in modern machinery.

- Oil Filter Wrench: Specifically designed to remove oil filters without causing damage.

Equipping yourself with these essential tools will greatly enhance your capability to address various tasks, ensuring that everything runs smoothly and efficiently.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring the optimal performance and longevity of your agricultural machinery. By following a structured maintenance routine, you can prevent issues before they arise and keep your equipment running smoothly.

1. Regular Inspection: Begin with a thorough visual examination of all components. Check for any signs of wear, leaks, or damage. Regular inspections help identify potential problems early, allowing for timely interventions.

2. Cleaning: Keep all parts clean and free from debris. Use appropriate cleaning agents to remove dirt and grease, especially in areas prone to build-up. A clean machine operates more efficiently and reduces wear on moving parts.

3. Fluid Levels: Regularly check and maintain the fluid levels, including oil, coolant, and hydraulic fluids. Ensuring that these fluids are at optimal levels is crucial for the proper functioning of your equipment.

4. Filter Changes: Replace filters according to the manufacturer’s recommendations. Clean or replace air, fuel, and oil filters regularly to ensure that your machine is running at peak performance.

5. Component Lubrication: Lubricate moving parts as necessary. Using the correct lubricant for each component will minimize friction and extend the life of the machinery.

6. Tire Maintenance: Inspect tires for proper inflation and wear. Maintaining the right tire pressure ensures better traction and fuel efficiency, while also extending the life of the tires.

7. Battery Care: Check battery terminals for corrosion and ensure that the battery is charged. Regular maintenance of the electrical system is essential for reliable starts and operation.

8. Seasonal Preparation: Before changing seasons, conduct a thorough check to prepare your equipment for varying conditions. This includes inspecting belts, hoses, and other critical components that may be affected by temperature fluctuations.

By adhering to this maintenance guide, you can enhance the reliability and efficiency of your machinery, ultimately leading to improved productivity and reduced operational costs.

Engine Troubleshooting Tips

Identifying and resolving issues within a power unit is crucial for maintaining optimal performance and extending its lifespan. By understanding common symptoms and their potential causes, operators can efficiently address malfunctions and ensure smooth operation.

Common Symptoms and Their Causes

Unusual noises, poor performance, and irregular starting are frequent indicators of underlying problems. For instance, if a persistent knocking sound is heard, it could be a sign of insufficient lubrication or worn components. Similarly, a lack of power may suggest fuel delivery issues or air intake blockages. Regular observation of these symptoms can lead to timely interventions.

Basic Diagnostic Steps

To effectively troubleshoot, begin with a systematic approach. Start by checking fluid levels, including oil and coolant, as low levels can lead to overheating or component damage. Next, inspect electrical connections for corrosion or loose wires, which can disrupt functionality. Additionally, examining filters for clogs is essential, as dirty filters can restrict airflow and fuel supply, resulting in performance declines.

In conclusion, a proactive approach to identifying and rectifying issues in a power unit can significantly enhance reliability and efficiency. By following these guidelines, operators can ensure their machinery remains in peak condition.

Hydraulic System Diagnostics

The hydraulic system plays a crucial role in the functionality of various machinery, ensuring efficient operation and control. Diagnosing issues within this system requires a systematic approach, utilizing specific techniques to identify malfunctions and ensure optimal performance. By understanding the components and their interactions, operators can effectively troubleshoot and maintain hydraulic efficiency.

Common Issues and Symptoms

Several typical problems may arise within hydraulic systems, often manifesting through noticeable symptoms. Recognizing these indicators is essential for timely intervention and resolution.

| Symptom | Possible Cause |

|---|---|

| Unresponsive controls | Low fluid levels or air in the system |

| Overheating | Contaminated fluid or excessive load |

| Leakage | Worn seals or damaged hoses |

| Erratic movement | Faulty valves or blockages |

Diagnostic Techniques

To accurately diagnose issues, several techniques can be employed. Monitoring pressure levels, checking fluid quality, and inspecting for leaks are foundational steps in the assessment process. Additionally, utilizing diagnostic tools such as pressure gauges and flow meters can provide valuable insights into the system’s performance, enabling informed decisions regarding maintenance and repairs.

Electrical Components Overview

This section provides a comprehensive understanding of the various electrical elements that play a crucial role in machinery operations. These components are essential for ensuring optimal performance and reliability, making it vital to comprehend their functions and maintenance needs.

Key Electrical Elements

- Batteries: Serve as the primary power source, providing the necessary energy to start the engine and operate electrical systems.

- Alternators: Generate electrical power while the machine is running, ensuring the battery remains charged and supporting other electrical functions.

- Fuses: Protect circuits from overload by breaking the connection when excessive current flows.

- Wiring Harness: A collection of wires that connect various electrical components, facilitating communication and power distribution.

- Relays: Act as switches that control high-current circuits using a low-current signal, enhancing safety and efficiency.

Common Issues and Maintenance

- Regularly check battery terminals for corrosion and ensure a tight connection.

- Inspect wiring for wear and damage to prevent short circuits.

- Test fuses periodically to ensure they are functional and replace any that are blown.

- Keep alternators clean and secure to maintain effective power generation.

- Monitor relays for proper operation, replacing any that show signs of failure.

Understanding these components not only aids in troubleshooting but also enhances overall efficiency and longevity of the equipment.

Transmission Problems and Solutions

Addressing issues within the gear shifting system is crucial for optimal performance and longevity of machinery. Various malfunctions can disrupt the seamless operation, leading to inefficiencies. Understanding these common challenges and their solutions can help ensure smooth functionality.

| Problem | Symptoms | Solutions |

|---|---|---|

| Slipping Gears | Unexpected loss of power, difficulty maintaining speed | Check fluid levels, inspect for leaks, and replace worn components |

| Unresponsive Shifting | Difficulty in changing gears, grinding noises | Examine the linkage, adjust or replace as necessary |

| Overheating | Burning smell, unusual sounds | Inspect fluid condition, ensure proper cooling systems are functioning |

| Fluid Leaks | Puddles under machinery, low fluid levels | Identify leak sources, seal and replace damaged parts |

Regular maintenance and prompt attention to these issues can prevent major failures and enhance the overall efficiency of your equipment.

Routine Service Intervals Explained

Regular maintenance is crucial for ensuring optimal performance and longevity of machinery. Understanding the recommended timelines for various servicing tasks helps operators to maintain efficiency and prevent unexpected breakdowns. Adhering to these intervals not only enhances productivity but also safeguards the investment in equipment.

Importance of Scheduled Maintenance

Scheduled upkeep allows for the identification of potential issues before they escalate into significant problems. This proactive approach minimizes downtime and repair costs, ensuring that equipment operates smoothly. Additionally, following a maintenance schedule can improve fuel efficiency and overall performance.

Typical Service Intervals

| Service Task | Frequency |

|---|---|

| Oil Change | Every 100 hours |

| Filter Replacement | Every 200 hours |

| Fluid Levels Check | Every 50 hours |

| Belts and Hoses Inspection | Every 500 hours |

| Battery Maintenance | Every 6 months |

By following these recommended service intervals, operators can ensure that their equipment remains in peak condition, ready to tackle the demands of any job.

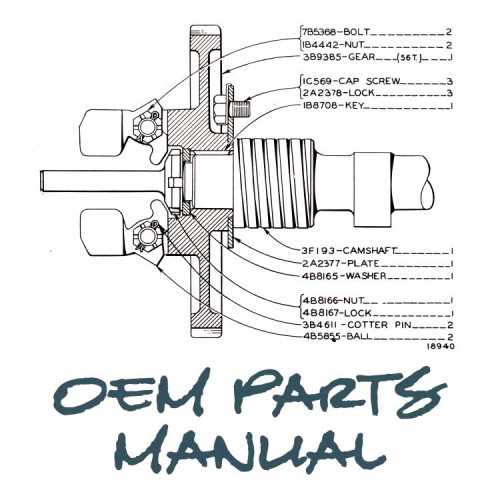

Parts Replacement Procedures

This section outlines essential guidelines for the efficient substitution of components within your machinery. Following a systematic approach ensures optimal performance and longevity of the equipment.

Begin by identifying the specific part that requires replacement. Consult the schematic diagrams if available, as they provide valuable insights into the assembly and positioning of each component. Ensure you have the correct replacement part, compatible with your machine’s specifications.

Before starting the process, gather the necessary tools and safety equipment. Disconnect the power source to prevent any accidental activation during the procedure. If applicable, drain any fluids to avoid spills and ensure a clean working environment.

Carefully remove the old component, taking note of how it is secured. Documenting the disassembly can be beneficial for reassembly. Once the part is removed, inspect surrounding areas for wear or damage, as these might need attention before installing the new piece.

Install the new component by following the reverse order of removal. Ensure that all fasteners are tightened to the manufacturer’s specifications and that any seals or gaskets are properly seated to prevent leaks. After installation, recheck all connections and refill any necessary fluids.

Finally, restore the power supply and perform a test run to verify that everything is functioning as intended. Regular maintenance checks after replacement will help prolong the lifespan of the new part and enhance overall operational efficiency.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, adhering to safety measures is paramount. Proper precautions not only protect the individual performing the work but also ensure the longevity of the equipment. Understanding potential hazards and implementing effective strategies can significantly reduce the risk of accidents.

Personal Protective Equipment (PPE) is essential when engaging in maintenance activities. Always wear appropriate gear such as gloves, goggles, and sturdy footwear. This equipment acts as a barrier against potential injuries caused by sharp objects, harmful substances, or falling debris.

Furthermore, it is crucial to maintain a clean and organized workspace. Clutter can lead to accidents, so keeping tools and parts in designated areas minimizes risks. Ensure that all materials are stored safely and that spills are cleaned promptly to prevent slips and falls.

Awareness of Surroundings is another vital aspect of safety. Before beginning any task, assess the area for potential hazards, including uneven surfaces or electrical cords. Being mindful of your environment allows for better decision-making and can help avoid unforeseen dangers.

Additionally, proper training is indispensable. Familiarize yourself with the equipment and its operational guidelines. Understanding how each component functions will empower you to work more safely and effectively. If uncertain about any procedure, consulting a knowledgeable individual can provide clarity and enhance safety.

Finally, never overlook the importance of emergency preparedness. Have a first aid kit readily accessible and know the location of emergency exits. Being prepared for unexpected situations ensures a swift response and can mitigate the effects of accidents when they occur.

Finding Genuine Replacement Parts

Ensuring optimal performance and longevity of your equipment often hinges on sourcing authentic components. Utilizing original parts not only guarantees compatibility but also enhances reliability, ultimately saving time and resources in the long run.

Why Choose Authentic Components?

- Quality Assurance: Genuine parts undergo rigorous testing to meet industry standards.

- Compatibility: Original components are designed specifically for your machinery, ensuring seamless integration.

- Performance: Authentic parts maintain the efficiency and effectiveness of your equipment.

- Warranty Protection: Using genuine components often safeguards any existing warranties on your machinery.

Where to Find Original Parts

- Authorized Dealers: Start with certified retailers who specialize in your brand.

- Manufacturer’s Website: Check the official site for a list of approved vendors and online stores.

- Online Marketplaces: Look for platforms that specifically list OEM components.

- Local Distributors: Visit local suppliers who stock original items and provide expert guidance.

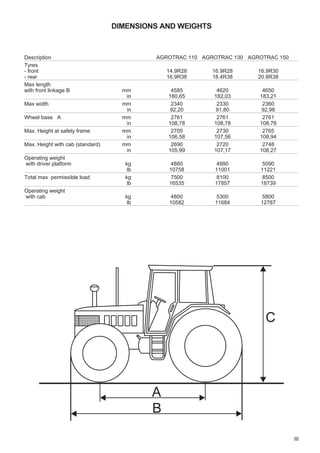

Upgrading Your Deutz Tractor

Enhancing the performance and efficiency of your agricultural machine can significantly improve productivity and longevity. This section provides insights on how to effectively elevate your equipment through various modifications and upgrades.

Consider these essential areas for enhancement:

- Engine Performance: Upgrading components such as air filters, fuel injectors, and exhaust systems can lead to better power output and fuel efficiency.

- Transmission Improvements: Consider installing a higher performance gearbox or a more efficient hydraulic system for smoother operation and increased speed.

- Suspension Enhancements: Upgrading the suspension can improve stability and handling, especially when working on uneven terrain.

- Cab Comfort: Adding ergonomic seats, climate control systems, and soundproofing can enhance operator comfort during long working hours.

- Technology Integration: Implementing GPS systems, precision farming tools, and modern monitoring solutions can optimize operations and resource management.

To achieve these upgrades, it is crucial to source high-quality parts and consult with professionals to ensure compatibility and proper installation. Regular maintenance after upgrades will help in sustaining the performance and reliability of your enhanced machinery.