When dealing with household appliances, issues can arise that disrupt daily routines. Understanding the inner workings of your equipment can greatly aid in identifying problems and restoring functionality. This resource is designed to provide insights and instructions for addressing common concerns, ensuring your device operates efficiently once more.

Effective maintenance is essential for longevity and optimal performance. Regular checks and timely interventions can prevent minor glitches from escalating into significant failures. By familiarizing yourself with essential procedures, you can take proactive steps to enhance the durability of your appliance.

In the following sections, you’ll discover detailed guidance on troubleshooting techniques, potential fixes, and tips for ongoing care. Whether you’re facing a minor hiccup or a more challenging situation, this information will empower you to tackle issues confidently and restore your appliance to peak condition.

Understanding Whirlpool WED7500GW0 Features

This section delves into the distinctive functionalities and advantages of a popular dryer model, showcasing how these elements contribute to efficient laundry care. From advanced drying cycles to user-friendly interfaces, this appliance is designed to enhance the laundry experience while ensuring optimal performance.

Key Features

- Multiple Drying Cycles: Offers a variety of settings tailored for different fabric types, ensuring that each load is dried appropriately.

- Moisture Sensor Technology: Automatically detects moisture levels and adjusts drying time accordingly, preventing over-drying and saving energy.

- Energy Efficiency: Engineered to consume less power while maintaining high drying performance, which can lead to lower utility bills.

- Large Capacity Drum: Accommodates bulky items like bedding and towels, allowing for fewer loads and time savings.

- Steam Options: Reduces wrinkles and freshens clothes, making it easier to maintain a crisp appearance without ironing.

User-Friendly Features

- Digital Controls: Intuitive interface with clear displays for easy navigation through settings and cycles.

- Delay Start Feature: Allows users to schedule drying cycles to begin at a more convenient time, enhancing flexibility.

- End-of-Cycle Signal: Alerts users when the drying cycle is complete, ensuring that laundry is promptly attended to.

- Lint Filter Indicator: Notifies when the lint filter needs cleaning, promoting safe and efficient operation.

Common Issues with Whirlpool Dryers

Many users encounter various challenges with their drying appliances, which can affect performance and efficiency. Understanding these common problems can help in identifying the source of issues and taking appropriate action to resolve them.

One frequent complaint involves inadequate drying. This can be caused by clogged venting systems, which restrict airflow, or by overloading the drum, preventing proper heat distribution. Another prevalent issue is unusual noises during operation, often resulting from worn drum rollers or a malfunctioning belt.

Temperature irregularities are also a concern, with some units failing to heat up adequately while others may overheat. These issues may stem from faulty heating elements or thermostats. Additionally, electrical problems, such as tripped breakers or damaged cords, can hinder the unit’s functionality, leading to complete failure to start.

Lastly, persistent error codes may appear on digital displays, indicating specific malfunctions. Consulting the user guide or online resources can provide insights into troubleshooting these alerts effectively.

Tools Needed for Repair Process

To effectively address any issues that may arise with your appliance, having the right equipment is essential. Proper tools not only ensure safety but also enhance efficiency and accuracy during the task. Below is a list of necessary items that will aid in successfully tackling common challenges.

Essential Hand Tools

Start with a good set of hand tools, including screwdrivers of various sizes, pliers, and wrenches. These items will help you access internal components and make adjustments as needed. A sturdy utility knife can also come in handy for cutting through any packaging or insulation materials.

Diagnostic Equipment

In addition to hand tools, consider having diagnostic equipment at your disposal. A multimeter is crucial for checking electrical connections and ensuring components are functioning correctly. Furthermore, a voltage tester can provide additional safety by confirming that circuits are not live before you begin any work.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to diagnosing common issues that may arise with your appliance. By following these steps, you can identify problems and determine potential solutions, ensuring optimal performance.

Identifying Common Problems

Start by observing any unusual behaviors or error codes. Here are some typical issues to consider:

- Appliance not starting

- Unusual noises during operation

- Inadequate drying or washing results

- Door not sealing properly

Troubleshooting Steps

Follow these steps to narrow down the issue:

- Check Power Supply:

- Ensure the appliance is plugged in securely.

- Verify the circuit breaker hasn’t tripped.

- Inspect Door and Latches:

- Make sure the door closes tightly.

- Examine the latches for damage or obstruction.

- Examine Hoses and Filters:

- Look for kinks or clogs in water hoses.

- Clean or replace filters if necessary.

- Run Diagnostic Test:

- Refer to your appliance’s instructions for initiating a self-diagnostic mode.

- Note any error codes displayed for further research.

By systematically following these steps, you can effectively identify and address various issues, ensuring your appliance operates smoothly and efficiently.

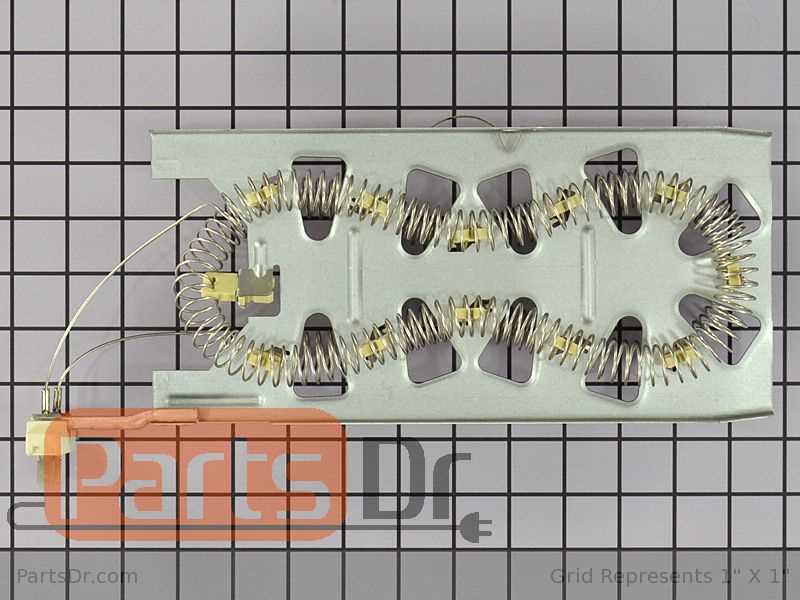

Replacing the Heating Element

When your appliance fails to generate sufficient heat, it may be time to consider a component replacement. This process can enhance the efficiency and performance of your unit, ensuring that it operates effectively. The heating element is crucial for proper functionality, and addressing any issues promptly can prevent further complications.

Tools and Materials Required:

- Multimeter

- Replacement heating element

- Screwdriver set

- Wire connectors

- Safety gloves

Before beginning, ensure that the appliance is disconnected from the power source to avoid any accidents. Utilize a multimeter to test the existing element for continuity. If there is no reading, it indicates that the element is faulty and needs to be replaced.

Steps to Replace the Heating Element:

- Remove the access panel to gain access to the heating element.

- Carefully disconnect the wires attached to the faulty element, noting their positions for reinstallation.

- Unscrew the old element from its mounting.

- Install the new heating element by reversing the removal steps.

- Reconnect the wires, ensuring they are secured properly.

- Replace the access panel and restore power to the appliance.

After the installation, run a test cycle to confirm that the new element is functioning as expected. If any issues persist, further investigation may be required to identify underlying problems.

How to Fix Drum Problems

Drum issues in laundry appliances can lead to frustrating experiences, often affecting performance and efficiency. Addressing these challenges requires a systematic approach to identify the underlying causes and implement effective solutions. By following a few steps, you can restore proper functionality and enhance the longevity of your appliance.

First, check for any unusual noises during operation, which might indicate loose parts or worn bearings. Inspect the drum for any visible damage, such as dents or cracks, that could hinder its movement. If the drum does not spin at all, examine the drive belt for signs of wear or detachment.

Next, ensure that the load is balanced. Overloading can lead to excessive strain on the drum and motor. If the appliance shakes excessively, redistribute the laundry to maintain even weight distribution. Additionally, verify that the leveling feet are properly adjusted to prevent vibrations.

If the drum is not draining effectively, examine the drain pump and hose for clogs. Clearing any blockages can significantly improve performance. In cases of persistent problems, consult the technical specifications for guidance on more complex issues, such as motor malfunctions or electronic control failures.

Lastly, regular maintenance, such as cleaning the lint filter and checking for debris, can prevent many drum-related issues. By staying proactive, you can ensure smoother operation and extend the lifespan of your appliance.

Cleaning the Lint Filter Efficiently

Maintaining the lint filter is essential for optimal dryer performance and safety. Regular cleaning not only enhances efficiency but also prevents potential hazards associated with lint buildup. By implementing a simple cleaning routine, users can ensure their appliance operates smoothly and prolong its lifespan.

Step-by-Step Cleaning Process

Follow these steps to clean the lint filter effectively:

| Step | Description |

|---|---|

| 1 | Remove the lint filter from its slot, typically located on the door or the top of the dryer. |

| 2 | Gently brush off the lint using your fingers or a soft brush. Avoid using sharp objects that could damage the filter. |

| 3 | Rinse the filter under warm water to eliminate any remaining debris. Ensure it is thoroughly dry before reinserting. |

| 4 | Regularly inspect the filter for wear and tear, replacing it if necessary to maintain efficiency. |

Additional Tips for Maintenance

For optimal results, consider the following recommendations:

- Clean the lint filter after every use to prevent buildup.

- Check the venting system periodically to ensure it is clear of obstructions.

- Schedule a professional inspection annually for thorough maintenance.

Addressing Electrical Failures

Electrical malfunctions can significantly impact the performance of household appliances, leading to frustration and inconvenience. Understanding the common causes of these issues and how to troubleshoot them is essential for restoring functionality. This section provides insights into identifying symptoms of electrical failures and offers guidance for resolution.

Common Symptoms of Electrical Issues

Several indicators may suggest an electrical problem. These include unexpected shutdowns, failure to start, or unusual noises during operation. Additionally, flickering lights or tripped circuit breakers may be linked to appliance malfunctions. Recognizing these signs early can prevent further complications and facilitate timely intervention.

Troubleshooting Steps

To effectively address electrical issues, start by checking the power source and connections. Ensure that the appliance is plugged in securely and that there are no damaged cords. Inspect circuit breakers for any tripped switches and reset them if necessary. If problems persist, consider examining internal components, such as fuses or wiring, but exercise caution and refer to professional guidance when needed.

Inspecting and Replacing Belts

Proper maintenance of your appliance often involves checking and replacing various components, including belts. These essential parts play a crucial role in the machine’s operation, facilitating movement and ensuring efficiency. Regular inspection can prevent more significant issues, extending the life of your device and enhancing its performance.

Identifying Belt Issues

Begin by disconnecting the appliance from the power source to ensure safety. Open the access panel to reach the belts. Look for signs of wear such as cracks, fraying, or stretching. A damaged belt may cause unusual noises or poor functionality. If any irregularities are detected, it’s crucial to replace the belt promptly to avoid further complications.

Replacing the Belt

To replace a worn belt, carefully remove the old one from its pulleys. Take note of the belt routing to ensure proper installation of the new part. Position the new belt around the pulleys, making sure it sits securely. Once installed, reassemble the access panel and reconnect the power. Test the appliance to confirm that it operates smoothly and efficiently.

Understanding Error Codes Explained

Error codes serve as vital indicators for diagnosing issues within appliances. These codes offer insights into specific malfunctions, allowing users to identify problems quickly and efficiently. By comprehending these signals, one can take appropriate actions to resolve concerns, ensuring optimal performance of the device.

Common Error Codes and Their Meanings

Each appliance is equipped with a unique set of error codes. For instance, a code indicating a temperature sensor malfunction may suggest a need for immediate attention. Recognizing these messages empowers users to troubleshoot effectively. Familiarizing oneself with common codes can streamline the process of identifying underlying issues.

Troubleshooting Steps

When encountering an error code, it’s essential to follow a systematic approach. Begin by noting the displayed code and consulting available resources for its meaning. Next, consider the suggested corrective measures, which may include resetting the unit or inspecting specific components. Documenting the steps taken can be beneficial for future reference or if professional assistance is required.

In summary, understanding error codes can significantly enhance one’s ability to manage appliance performance. By recognizing these signals and implementing troubleshooting techniques, users can maintain their equipment more effectively.

Preventative Maintenance Tips

Maintaining your appliance regularly can significantly enhance its efficiency and prolong its lifespan. Implementing simple yet effective practices can help you avoid potential issues and ensure optimal performance. By dedicating a little time each month to these tasks, you can keep your device running smoothly.

Regular Cleaning

Cleaning the interior and exterior of your appliance is essential. Dust, lint, and spills can accumulate and hinder functionality. Use a damp cloth and mild detergent to wipe down surfaces. Pay special attention to areas that are often overlooked, such as vents and filters. Regularly removing debris helps maintain airflow and efficiency.

Check Hoses and Connections

Inspecting hoses and connections periodically is crucial for preventing leaks and ensuring safe operation. Look for signs of wear, such as cracks or bulges, and replace any damaged components promptly. Ensuring that all connections are tight can also help avoid water damage and improve performance. Taking these small steps can save you from larger problems down the road.

When to Call a Professional Technician

Knowing when to seek help from an expert is crucial for maintaining the functionality of your appliances. While some issues can be resolved through DIY approaches, there are specific situations where professional assistance is essential to ensure safety and effectiveness.

- Persistent Problems: If an issue continues after multiple attempts to fix it, it’s time to consult a technician.

- Strange Noises or Smells: Unusual sounds or odors can indicate serious underlying issues that require expert evaluation.

- Electrical Issues: Any signs of electrical problems, such as flickering lights or tripped breakers, should be addressed by a qualified professional.

- Complex Repairs: Tasks that involve disassembling components or require specialized tools are best left to those with the right expertise.

- Safety Concerns: If you feel uncertain about any aspect of the repair process, prioritizing safety by contacting a professional is wise.

By recognizing these indicators, you can make informed decisions about when to involve a trained technician, ensuring the longevity and proper functioning of your equipment.