Ensuring the longevity and optimal performance of vital machinery components requires a thorough understanding of their upkeep and revitalization techniques. This section delves into essential practices that can significantly enhance the durability and efficiency of your vehicle’s drivetrain elements.

By following systematic approaches to troubleshoot and address common issues, enthusiasts and professionals alike can achieve remarkable results. Through a combination of regular assessments, strategic interventions, and informed replacements, you can maintain peak functionality and prevent costly breakdowns.

Understanding the intricate workings of these systems is crucial. With detailed insights into specific components and their interactions, you’ll be better equipped to tackle challenges effectively. This guide aims to empower you with knowledge that can transform your approach to preserving and restoring critical machinery elements.

Axle Overview

This section provides a comprehensive look at a specific type of drivetrain component commonly found in various vehicles. Understanding its structure, functionality, and key features is essential for anyone involved in vehicle performance and reliability.

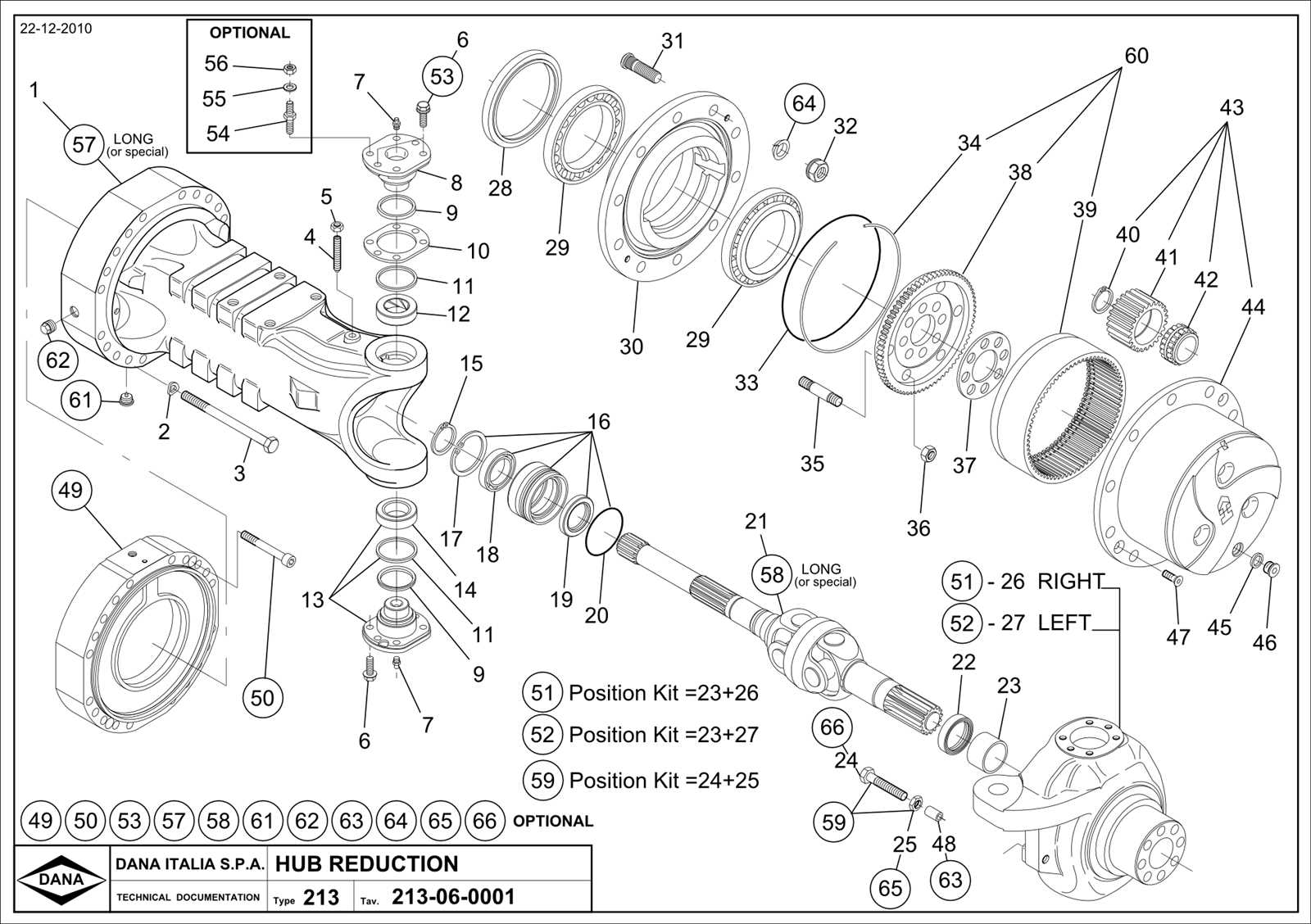

Design and Composition: The component is engineered to support significant loads while ensuring smooth rotation and power transfer. Typically, it consists of a robust housing, precision gears, and high-strength bearings, all designed to withstand rigorous conditions.

Functionality: This unit plays a crucial role in distributing torque from the engine to the wheels. Its design allows for effective navigation through diverse terrains, making it vital for both on-road and off-road applications.

Performance Characteristics: Key attributes include load capacity, gear ratio options, and ease of integration with different vehicle systems. Regular checks on these features can enhance overall efficiency and longevity.

In summary, a thorough understanding of this drivetrain element is paramount for achieving optimal vehicle performance and reliability.

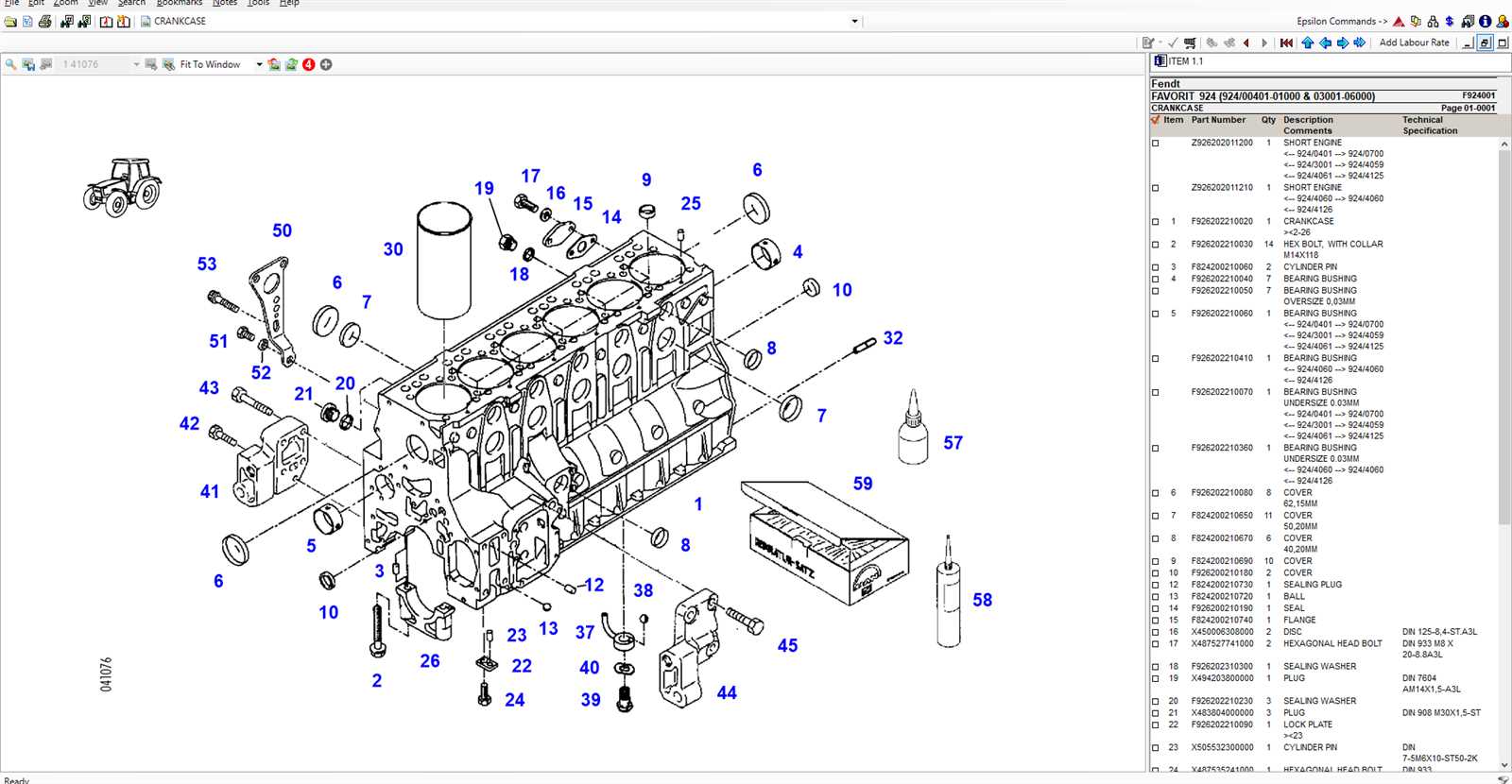

Understanding the Dana 213 Design

The engineering behind this particular drive component exemplifies a blend of functionality and resilience. Its configuration has been meticulously crafted to support heavy loads while ensuring smooth operation across various terrains. This design is a testament to innovative thinking in automotive technology, addressing both performance and durability.

Key features of this assembly include a robust housing that protects internal mechanisms, as well as precision-crafted gears that facilitate efficient power transfer. The integration of advanced materials enhances its strength, making it suitable for demanding applications. Additionally, the thoughtful arrangement of components contributes to reduced friction, which ultimately leads to improved efficiency and longevity.

Understanding the structural elements and their interplay is essential for anyone looking to grasp the overall functionality. This system’s layout not only supports operational demands but also simplifies the process of inspection and troubleshooting. Recognizing these design principles can significantly enhance one’s ability to maintain optimal performance.

Common Issues with Dana 213

In the realm of heavy-duty vehicles, certain components may encounter frequent challenges that can affect their performance and reliability. Understanding these typical problems is crucial for ensuring longevity and optimal functionality. Below, we explore some prevalent concerns that users may face with these crucial parts.

Wear and Tear: Over time, components can experience significant wear, leading to decreased efficiency. This issue often arises from inadequate lubrication or prolonged use under heavy loads. Regular checks are essential to identify early signs of degradation.

Sealing Failures: Seals play a vital role in maintaining fluid integrity. Common issues include leaks caused by deterioration or improper installation. Addressing these leaks promptly can prevent further damage and costly repairs.

Noisy Operation: Unusual noises during operation often signal underlying problems, such as misalignment or damaged gears. These sounds can indicate a need for immediate attention to avoid catastrophic failure.

Vibration Problems: Excessive vibrations can be a symptom of imbalance or worn-out components. This not only affects performance but can also lead to additional strain on related systems. Regular inspections can help identify the root causes.

Heating Issues: Overheating is another critical concern that can stem from inadequate lubrication or excessive load. Monitoring operating temperatures is vital to prevent potential breakdowns and extend the lifespan of the equipment.

By being aware of these common challenges, operators can take proactive measures to maintain the efficiency and reliability of their vehicles, ultimately reducing downtime and repair costs.

Symptoms of Axle Failure

Recognizing the signs of component malfunction is crucial for ensuring the longevity and performance of any vehicle. Various symptoms can indicate underlying issues that, if not addressed promptly, may lead to significant complications. Being aware of these indicators can help in timely interventions and prevent further damage.

Unusual Noises: One of the most common signs of impending trouble is the presence of strange sounds during operation. Clicking, grinding, or whining noises can suggest wear or damage to internal parts.

Vibration or Shaking: If the vehicle experiences unexpected vibrations, especially during acceleration or turning, it may indicate an imbalance or a fault within the system. This sensation can be a clear warning sign that requires immediate attention.

Fluid Leaks: Spotting fluid leaks underneath the vehicle is another symptom that should not be overlooked. Transmission or differential fluid leaking can compromise performance and lead to more severe issues if left unchecked.

Difficulty in Steering: A noticeable change in steering responsiveness or difficulty in maneuvering can signal problems with the connecting components. This may affect overall control and safety while driving.

Uneven Tire Wear: Inspecting the tires regularly can reveal uneven wear patterns. This discrepancy often points to alignment issues or problems with the underlying mechanisms, indicating that a closer inspection is necessary.

Prompt recognition of these signs is vital for maintaining vehicle safety and performance. Regular assessments and addressing issues early can save time and money in the long run.

Essential Tools for Maintenance

Having the right equipment is crucial for effective upkeep and troubleshooting of any mechanical system. A well-equipped toolkit ensures that tasks can be performed efficiently and safely, minimizing downtime and potential damage.

Basic Hand Tools

- Wrenches: Various sizes for loosening and tightening nuts and bolts.

- Screwdrivers: Flathead and Phillips for different types of screws.

- Pliers: Useful for gripping and bending materials.

- Socket Set: For better leverage and access to hard-to-reach fasteners.

Specialized Equipment

- Torque Wrench: Ensures proper fastening with specific torque settings.

- Jack Stands: Essential for safely supporting loads during work.

- Fluid Pumps: Helpful for transferring lubricants and fluids without spills.

- Inspection Mirrors: Aid in visual checks of tight or obscured areas.

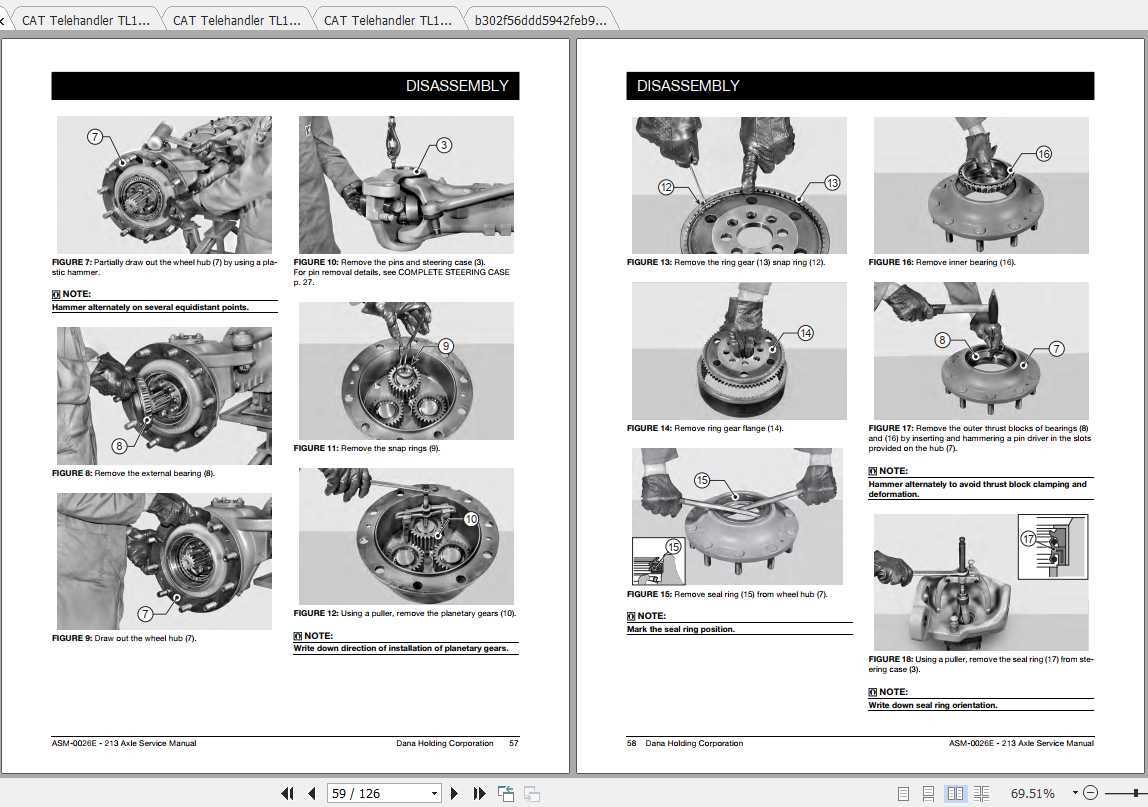

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal functionality and longevity of your equipment. By following these organized steps, you can effectively manage performance and address any potential issues proactively.

Preparation and Initial Inspection

Before starting, gather the necessary tools and materials. Conduct a thorough inspection of all components, looking for signs of wear or damage. This preliminary assessment is crucial for identifying areas that require attention.

Routine Upkeep Procedures

Establish a schedule for regular checks and servicing. Focus on lubricating moving parts, tightening connections, and replacing any worn components. Consistency in these tasks will help prevent major complications in the future.

Lubrication and Fluid Requirements

Proper lubrication and fluid management are critical for ensuring smooth operation, longevity, and efficiency. Utilizing the appropriate types of oils and fluids helps minimize friction, prevents overheating, and reduces wear.

- Use recommended oil grades to support efficient operation across varied conditions and temperatures.

- Regularly inspect fluid levels to avoid potential issues that may arise from insufficient lubrication.

- Ensure that all seals are intact to prevent fluid leaks, which can compromise performance.

- Check for contamination or debris within the lubricant, as these can impact the performance and health of moving parts.

For optimal outcomes, follow a consistent lu

Inspection Procedures for Longevity

Regular checks are essential to ensure that all moving parts continue to operate smoothly over time. A proactive approach can greatly reduce the risk of unexpected breakdowns and extend the life of mechanical components. This section covers key inspection points to help you maintain optimal performance and avoid costly repairs.

Key Areas to Examine

Focus on assessing structural elements for signs of wear, including cracks, corrosion, or any unusual noises during operation.

Repair Techniques for Damaged Parts

Properly addressing wear and damage in mechanical components is essential for ensuring smooth operation and extending the equipment’s lifespan. Repair approaches can vary depending on the extent of the deterioration, making it vital to understand suitable techniques for effective restoration.

- Inspection and Assessment: Begin by thoroughly examining each component to identify cracks, wear, or other signs of strain. Accurate assessment will guide the choice of suitable restoration methods.

- Enhanced Gears: Opt for high-quality gears designed to withstand increased loads and higher torque demands. These upgrades reduce the risk of wear, ensuring smoother operation under stress.

- Improved Bearings: Replacing standard bearings with high-performance alternatives can reduce friction and extend component life. Look for models with better load capacity and heat resistance.

- Upgraded Seals: Quality seals provide enhanced protection against contaminants, improving the longevity of internal parts by preventing moisture, dust, and debris from causing damage.

- Stronger Housings: Reinforced housings are essential for vehicles subject

Safety Precautions During Repairs

Proper precautions ensure a secure work environment, minimizing risks when handling various components and tools. Awareness of potential hazards, use of the correct protective gear, and adherence to safety guidelines play critical roles in safeguarding against injuries.

Precaution Description Wear Protective Gear Use gloves, safety goggles, and durable clothing to shield yourself from sharp edges, flying debris, or unexpected leaks during the process. Ensure Proper Ventilation Perform work in a well-ventilated area to avoid inhaling potentially harmful fumes from chemicals or lubricants. Use Appropriate Tools Only utilize tools specifically designed for each task to prevent slips, damage, or accidental injury. Inspect tools before use to ensure

When to Seek Professional Help

There are times when handling complex vehicle component issues requires a professional touch. Recognizing these instances can help prevent further damage and ensure safe, optimal performance.

Signs of Persistent Issues

If you notice recurring issues that persist despite attempts to troubleshoot, it may indicate a deeper underlying problem. Persistent symptoms, such as unusual noises, vibrations, or inconsistencies in performance, often require specialized tools and expertise for accurate diagnosis

Upgrading Components for Performance

Enhancing the performance of vehicle components often requires strategic upgrades that optimize strength, durability, and efficiency. Each improvement has the potential to elevate how well the system handles challenging conditions and delivers reliable results.