When it comes to ensuring the longevity and performance of your automobile, understanding its intricate components is essential. This section delves into the various aspects of upkeep and troubleshooting, providing essential insights for both novice and seasoned enthusiasts. Knowledge in this area not only enhances the driving experience but also empowers owners to tackle issues proactively.

From basic inspections to more complex interventions, a thorough comprehension of your vehicle’s systems can lead to significant savings and improved reliability. Whether you are addressing minor irregularities or undertaking substantial modifications, having access to detailed information can make all the difference. This guide serves as a valuable resource for those looking to deepen their understanding and skills.

Throughout this exploration, readers will find step-by-step instructions, practical tips, and troubleshooting advice tailored to a specific model. By following these guidelines, you will be equipped to maintain your vehicle with confidence, ensuring it remains in peak condition for years to come. Embrace the opportunity to learn and take charge of your automobile’s health.

Overview of Volvo 740 Repair Manual

This section provides a comprehensive guide for maintaining and troubleshooting a specific model of a well-known automotive brand. The aim is to equip owners with the essential knowledge and tools necessary for effective vehicle upkeep. From routine inspections to complex diagnostics, this guide serves as a valuable resource for enhancing the longevity and performance of the automobile.

The following table outlines key components and their respective maintenance practices:

| Component | Maintenance Practice | Frequency |

|---|---|---|

| Engine | Oil change | Every 5,000 miles |

| Brakes | Pad replacement | As needed |

| Transmission | Fluid check | Every 30,000 miles |

| Cooling System | Coolant flush | Every 50,000 miles |

| Battery | Terminal cleaning | Twice a year |

By adhering to these guidelines, vehicle owners can ensure optimal functionality and reduce the likelihood of unforeseen issues. This resource is designed to empower users with the knowledge needed for effective vehicle management.

Common Issues with Volvo 740

Many owners encounter specific challenges that can affect the performance and reliability of their vehicles. Understanding these common problems can help in proactive maintenance and ensure longevity. This section highlights prevalent concerns that enthusiasts and users should be aware of, along with potential solutions.

Engine and Performance

One of the most frequent areas of concern involves the engine. Symptoms such as rough idling or stalling can arise from various factors, including fuel delivery issues or ignition system failures. Regular inspections and timely replacements of worn components can mitigate these problems.

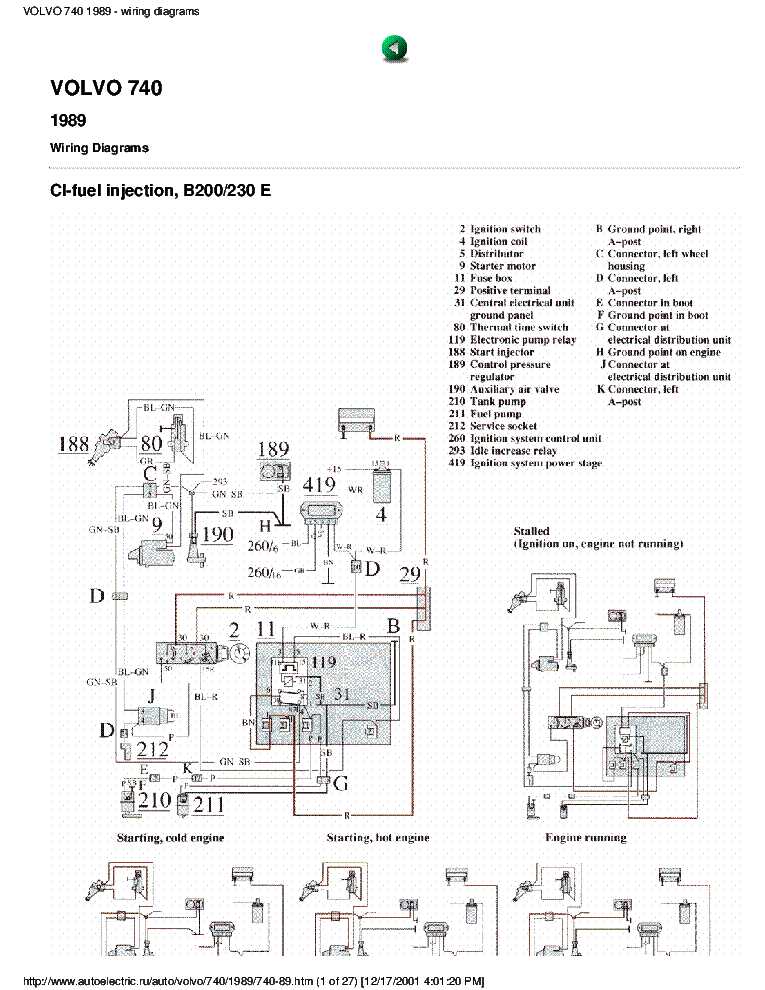

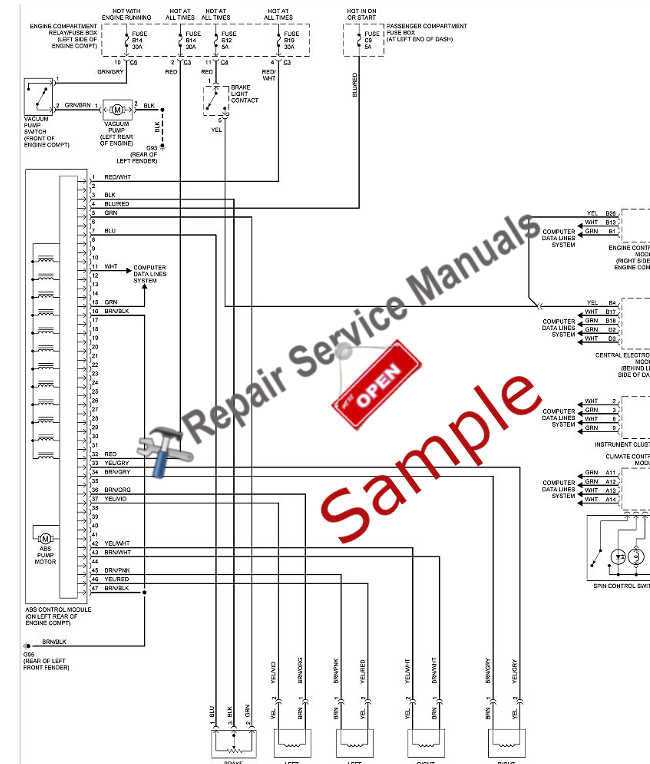

Electrical System

The electrical system can also present difficulties, with issues ranging from dead batteries to malfunctioning lights. Understanding the wiring and potential short circuits can aid in diagnosing these faults effectively.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Rough idling | Engine vibrations, stalling | Check spark plugs, fuel injectors |

| Electrical failures | Non-functioning lights, dead battery | Inspect fuses, wiring connections |

| Transmission problems | Slipping gears, delayed engagement | Fluid change, inspect transmission filter |

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance task. A well-equipped workshop ensures that you can handle various challenges efficiently and effectively. Different tools serve unique purposes, enabling you to address issues ranging from minor adjustments to major overhauls.

First and foremost, a comprehensive set of hand tools is indispensable. Wrenches, sockets, and screwdrivers in various sizes allow for the loosening and tightening of components with ease. Additionally, pliers and cutters can aid in manipulating wires and hoses as needed.

Power tools, such as drills and impact wrenches, can significantly speed up the process and reduce physical strain. These devices come in handy for more demanding tasks, where manual effort may fall short.

Don’t overlook the importance of diagnostic tools. A code reader or scanner can provide insight into any electronic issues, making it easier to pinpoint problems before proceeding with repairs. A multimeter is also valuable for checking electrical systems and connections.

Finally, safety equipment should not be neglected. Protective eyewear, gloves, and ear protection are essential for ensuring your well-being while working. With the right set of tools and safety measures in place, you’ll be well-prepared to tackle any mechanical challenge that comes your way.

Engine Maintenance Procedures

Proper care of the engine is crucial for ensuring optimal performance and longevity of any vehicle. Regular maintenance activities not only enhance efficiency but also prevent potential issues that could lead to costly repairs. Understanding the fundamental procedures can empower owners to take proactive steps in keeping their engines running smoothly.

1. Regular Oil Changes: One of the most essential tasks is to change the engine oil and filter at recommended intervals. Clean oil lubricates moving parts, reduces friction, and helps dissipate heat. Always use the correct oil type as specified by the manufacturer.

2. Coolant System Checks: Maintaining the coolant system is vital for preventing overheating. Regularly inspect coolant levels and the condition of hoses and connections. Flushing the system periodically can help remove deposits and ensure efficient heat transfer.

3. Air Filter Replacement: A clean air filter is essential for optimal airflow to the engine. Inspect the air filter regularly and replace it as needed to maintain proper combustion and improve fuel efficiency.

4. Spark Plug Maintenance: Spark plugs play a critical role in engine ignition. Regularly check their condition and replace them according to the service schedule. Worn or fouled spark plugs can lead to misfires and reduced performance.

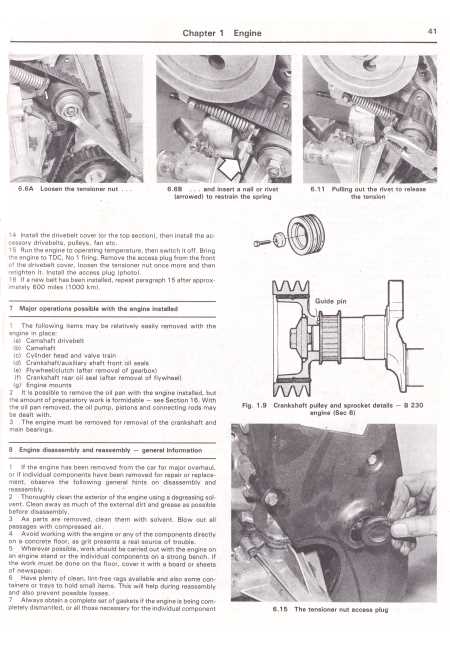

5. Timing Belt Inspection: The timing belt is vital for synchronizing engine components. Inspect it for wear and replace it at the manufacturer-recommended intervals to prevent catastrophic engine failure.

6. Battery Care: Ensure the battery terminals are clean and tight. Regularly check the battery’s charge level and replace it when necessary to avoid starting issues.

By adhering to these fundamental maintenance procedures, vehicle owners can significantly extend the lifespan of their engines while ensuring reliable performance on the road.

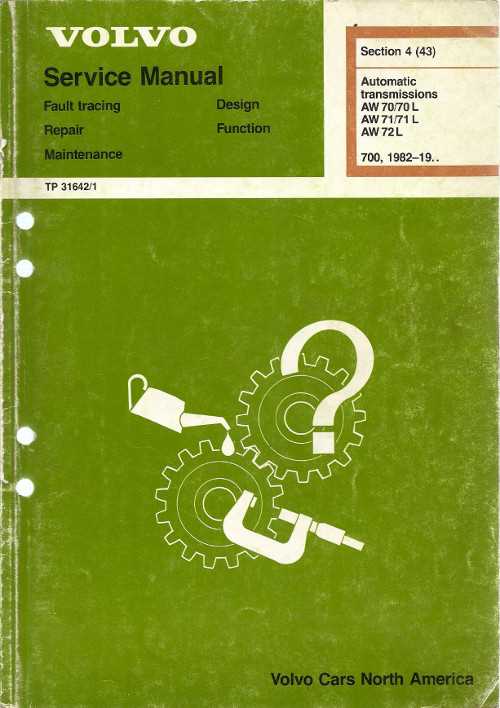

Transmission Troubleshooting Tips

Addressing issues related to the shifting system is crucial for maintaining optimal vehicle performance. Recognizing the symptoms of malfunction early can save time and resources, ensuring a smoother ride. This section offers practical advice for diagnosing and resolving common concerns that may arise with the shifting mechanism.

Common Symptoms of Transmission Issues

- Slipping gears during acceleration

- Delayed or rough shifting

- Unusual noises, such as grinding or whining

- Fluid leaks under the vehicle

- Warning lights illuminated on the dashboard

Troubleshooting Steps

- Check Fluid Levels: Inspect the transmission fluid to ensure it is at the correct level and in good condition. Low or dirty fluid can lead to shifting problems.

- Inspect for Leaks: Examine the ground beneath the vehicle and the transmission casing for any signs of fluid leakage.

- Examine the Filter: A clogged filter can restrict fluid flow. Replace the filter if it appears dirty or worn.

- Scan for Error Codes: Use an OBD-II scanner to check for any diagnostic trouble codes that may indicate specific issues.

- Test Drive: Take the vehicle for a test drive to replicate the problem and observe any unusual behavior in real-time.

By following these troubleshooting tips, you can effectively identify and address potential issues with the transmission, ensuring your vehicle continues to operate smoothly and efficiently.

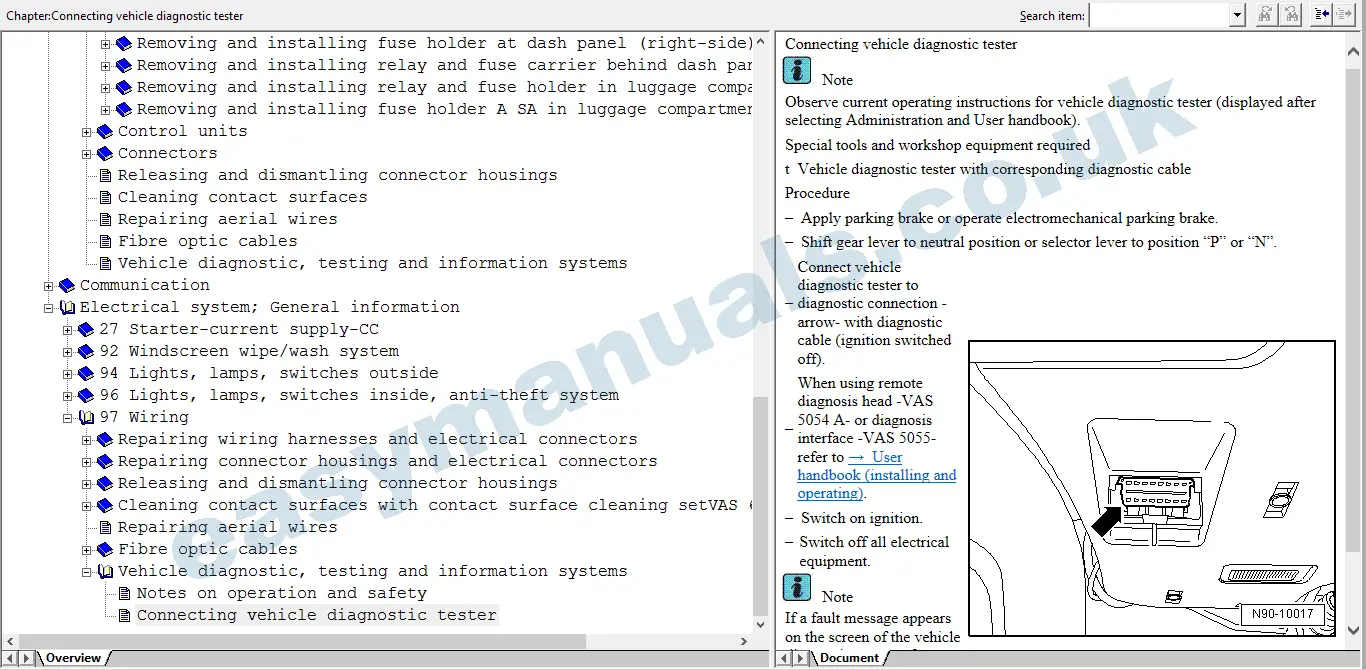

Electrical System Diagnostics

Diagnosing the electrical system of a vehicle is crucial for ensuring optimal performance and reliability. This process involves identifying faults, understanding the circuitry, and utilizing appropriate tools to analyze various components. Effective diagnostics can save time and prevent further complications by addressing issues promptly.

Key areas to focus on during the diagnostic process include:

- Power Distribution

- Ground Connections

- Wiring Integrity

- Component Functionality

The following steps outline a systematic approach to troubleshooting:

- Visual Inspection: Begin with a thorough visual check for damaged wires, loose connections, or corrosion.

- Check Power Supply: Use a multimeter to verify that voltage is present at key points in the system.

- Ground Testing: Ensure that all ground connections are secure and free from rust or dirt.

- Component Testing: Individually test components such as switches, sensors, and relays to confirm proper operation.

- Use Diagnostic Tools: Employ specialized diagnostic equipment to read error codes and monitor system performance.

By following these steps, one can effectively isolate and address electrical issues, ensuring the vehicle operates smoothly and efficiently.

Suspension and Steering Repairs

Maintaining the integrity of the suspension and steering systems is crucial for ensuring a smooth and safe driving experience. These components work together to provide stability, handling, and comfort, making their upkeep essential for vehicle performance. Understanding common issues and their solutions can help in prolonging the lifespan of these systems.

Here are some typical problems that may arise and their respective signs:

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Worn Shock Absorbers | Excessive bouncing, loss of control | Replace shock absorbers |

| Loose Steering Components | Play in the steering wheel, misalignment | Tighten or replace affected parts |

| Uneven Tire Wear | Visible tread wear patterns | Check alignment and suspension components |

| Clunking Noises | Noise when going over bumps | Inspect bushings and mounts |

Regular inspections and timely interventions can prevent more severe issues from developing. Ensuring that all parts function correctly not only enhances safety but also improves the overall driving experience.

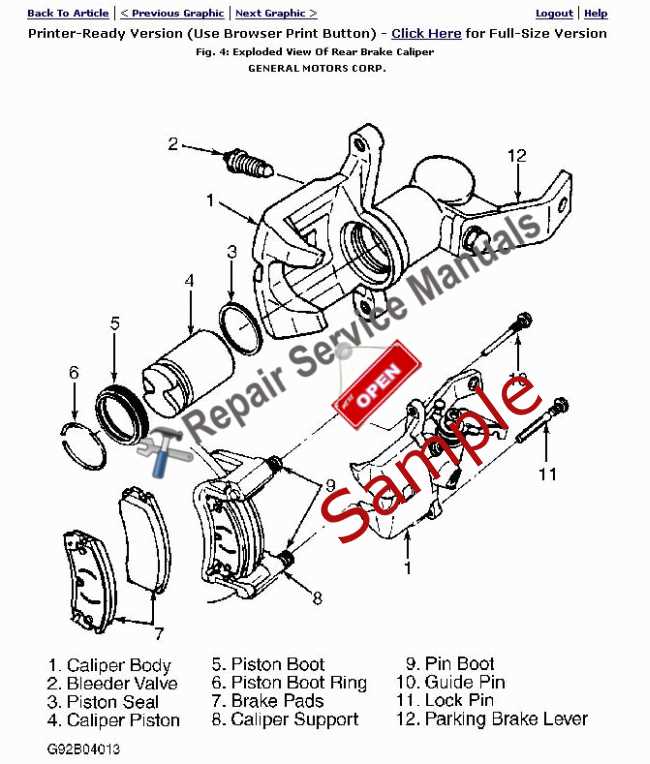

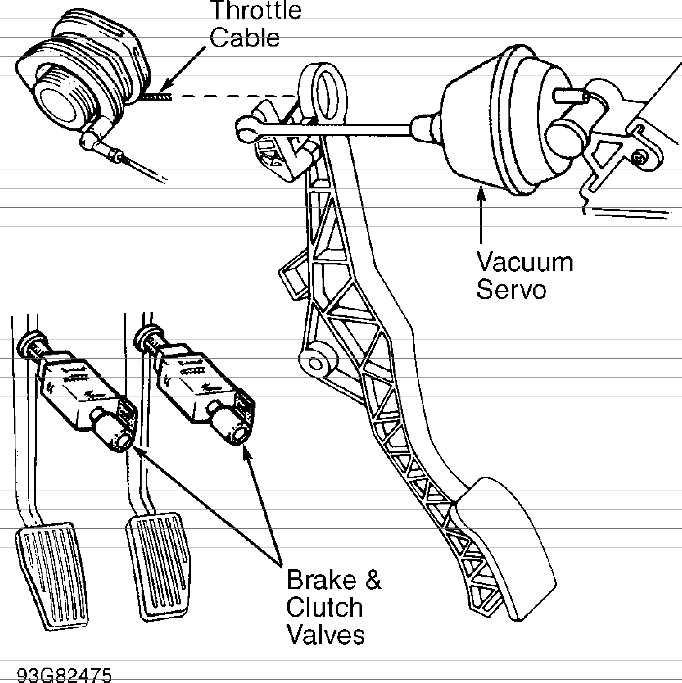

Brake System Maintenance Guide

Ensuring the optimal performance of the braking mechanism is crucial for vehicle safety. Regular upkeep and timely interventions can enhance braking efficiency, prolong component life, and prevent potential malfunctions. This guide outlines essential practices for maintaining the braking system effectively.

The primary components requiring attention include brake pads, rotors, fluid, and calipers. Each part plays a significant role in the overall functionality, and neglecting any can lead to reduced performance or hazardous situations.

| Component | Maintenance Tips | Signs of Wear |

|---|---|---|

| Brake Pads | Inspect thickness regularly; replace if less than 3mm. | Squeaking noise, reduced stopping power. |

| Rotors | Check for warping; replace if grooves are visible. | Vibration during braking, pulsating pedal. |

| Brake Fluid | Change every 2 years; check for contamination. | Discoloration, low fluid level. |

| Calipers | Inspect for leaks and proper operation; lubricate moving parts. | Uneven wear on pads, sticking brakes. |

By following these guidelines, vehicle owners can ensure their braking system remains in excellent condition, providing safety and reliability on the road.

Cooling System Inspection Techniques

Regular examination of the cooling system is crucial for maintaining optimal engine performance and preventing overheating issues. Implementing systematic inspection techniques ensures that any potential problems are identified early, facilitating timely interventions and enhancing the longevity of the vehicle.

Visual Inspection

The initial step in assessing the cooling system involves a thorough visual check. Look for signs of leaks, corrosion, and wear around hoses, clamps, and the radiator. Pay special attention to the coolant reservoir and connections for any discoloration or residue, which can indicate fluid loss.

Pressure Testing

Utilizing a pressure tester can reveal hidden leaks within the cooling system. By pressurizing the system, technicians can monitor for drops in pressure that signify potential leaks. This method helps ensure the integrity of the hoses, radiator, and gaskets, allowing for an effective assessment of the entire cooling assembly.

| Inspection Technique | Description |

|---|---|

| Visual Inspection | Check for leaks, corrosion, and damage in components. |

| Pressure Testing | Identify hidden leaks by pressurizing the system. |

| Temperature Checks | Monitor coolant temperatures to ensure efficient operation. |

| Coolant Condition Analysis | Examine coolant for clarity and proper pH levels. |

Interior Components and Fixes

This section delves into the various elements that make up the interior of your vehicle and offers solutions to common issues that may arise. Understanding these components is essential for maintaining comfort and functionality within the cabin. From upholstery to electronic systems, addressing wear and tear can significantly enhance your driving experience.

Upholstery and Seating Issues

Over time, the upholstery and seating can experience fading, tearing, or general wear. Regular cleaning and conditioning of leather or fabric can prevent premature aging. For small tears, using fabric adhesive or patches can be effective, while complete seat covers offer a fresh look for more extensive damage. Additionally, adjusting seat mechanisms ensures comfort and safety during drives.

Dashboard and Control Panel Repairs

The dashboard houses critical controls and displays that can become faulty or unresponsive. Start by checking fuses and connections if you notice any issues. For cosmetic repairs, consider using specialized cleaners for scratches and scuffs. If gauges malfunction, replacement parts may be necessary, and consulting the vehicle’s documentation can guide you through proper installation.

Exterior Bodywork Repair Steps

Maintaining the integrity of the vehicle’s exterior is crucial for both aesthetics and functionality. Addressing damage or wear can enhance its longevity and appearance. The following steps outline the process for restoring the outer shell effectively.

- Assessment:

Begin by thoroughly examining the body for dents, scratches, and rust. Identify areas requiring attention and document the extent of the damage.

- Gather Materials:

Collect necessary tools and supplies, including:

- Sandpaper (various grits)

- Body filler

- Primer

- Paint

- Clear coat

- Masking tape

- Protective gear (gloves, mask)

- Preparation:

Clean the affected areas to remove dirt and grease. Use masking tape to cover adjacent surfaces, protecting them from dust and paint.

- Repairing Dents:

For minor dents, apply gentle pressure from behind the panel if accessible. Alternatively, use a suction cup or a specialized tool to pull the dent out. For deeper damage, body filler can be applied.

- Filling and Sanding:

Apply body filler to the repaired area as needed. Allow it to cure fully, then sand it down smoothly to match the surrounding surface.

- Priming:

Once the surface is even, apply a primer to enhance paint adhesion. Allow the primer to dry according to manufacturer instructions.

- Painting:

Using an appropriate paint, apply several thin coats, allowing each coat to dry. This will ensure an even finish and better durability.

- Finishing Touches:

Once the paint is dry, apply a clear coat to protect the color and provide a glossy finish. Allow it to cure completely.

- Final Inspection:

Inspect the repaired areas closely for any imperfections. Touch up as needed to ensure a seamless appearance.

Following these systematic steps will help restore the exterior to its original condition, ensuring both functionality and visual appeal.

Preventive Maintenance Best Practices

Regular upkeep is essential for ensuring the longevity and reliability of any vehicle. By implementing a series of proactive measures, owners can significantly reduce the risk of unexpected breakdowns and costly repairs. This section outlines key practices that contribute to optimal performance and safety.

Routine Inspections

Conducting frequent inspections is crucial for identifying potential issues before they escalate. Focus on essential components such as the brakes, tires, and fluid levels. Regularly checking belts and hoses can also prevent failures. Establish a checklist to ensure no critical area is overlooked during these evaluations.

Scheduled Maintenance

Adhering to a regular maintenance schedule, as outlined by the manufacturer, is vital. This includes oil changes, filter replacements, and fluid flushes at recommended intervals. Staying on top of these tasks not only enhances vehicle performance but also helps maintain warranty coverage and resale value.