Ensuring the longevity and optimal performance of your air pistol requires a thorough understanding of its components and functionality. Regular upkeep is essential to maintain efficiency and accuracy, and this section provides essential insights into handling common issues that may arise.

By exploring various techniques and methodologies for addressing typical malfunctions, you will gain the necessary skills to effectively troubleshoot and restore your device. Whether you are dealing with minor adjustments or more complex challenges, this guide will empower you to confidently manage repairs.

Investing time in understanding the mechanics of your air weapon not only enhances its performance but also enriches your overall experience. With the right knowledge and tools, you can ensure that your equipment remains in peak condition for countless enjoyable sessions.

Crosman 600 Overview

This section provides a comprehensive examination of a renowned air pistol, known for its innovative design and historical significance in the world of shooting sports. Originally introduced in the mid-20th century, this firearm has become a beloved choice among enthusiasts for its unique features and reliable performance.

Featuring a distinctive semi-automatic mechanism, this model allows for rapid successive shots, making it a popular option for both casual practice and competitive shooting. The design emphasizes user-friendliness, with easy handling and a comfortable grip that enhances accuracy and control.

Additionally, the inclusion of a unique magazine system allows for straightforward reloading, minimizing downtime during use. Collectors appreciate this model not only for its functionality but also for its aesthetic appeal, as it showcases a classic look that pays homage to its era of origin.

In summary, this air pistol stands out as a remarkable piece of craftsmanship, combining historical relevance with modern shooting capabilities, making it a sought-after item for both collectors and shooters alike.

Common Issues with Crosman 600

Air pistols can encounter various challenges that affect their performance and reliability. Understanding these issues can help enthusiasts maintain optimal functionality and enhance their shooting experience.

1. Air Leaks: One of the most prevalent problems involves leaks within the pneumatic system. Over time, seals and O-rings may deteriorate, leading to a loss of pressure and decreased efficiency. Regular inspections can help identify these leaks before they become significant.

2. Feed Mechanism Jamming: The feeding mechanism is crucial for consistent operation. Dirt or debris can obstruct this system, resulting in misfeeds or complete stoppages. Ensuring that the loading area remains clean is essential for uninterrupted shooting.

3. Inconsistent Velocity: Variations in firing speed can occur due to a range of factors, including temperature fluctuations or poor lubrication. These inconsistencies can impact accuracy and performance, making it vital to monitor the conditions and maintain proper care.

4. Trigger Malfunction: Issues with the trigger mechanism can lead to failure in firing or an unexpected release. Regular maintenance and adjustments can often resolve these concerns, ensuring a smooth and predictable shooting experience.

5. Barrel Blockage: Obstructions within the barrel can result in reduced accuracy and potential safety hazards. Regular cleaning and checks can prevent this problem, ensuring that the projectile travels unobstructed for optimal performance.

Tools Required for Repairs

When undertaking maintenance tasks for your air pistol, having the right tools is essential for a successful and efficient process. This section outlines the necessary instruments to ensure that your project goes smoothly and effectively.

Essential Tools

- Precision Screwdrivers: Various sizes to accommodate different screw types.

- Hex Keys: Useful for accessing internal components securely.

- Wrenches: Necessary for tightening and loosening nuts and bolts.

- Lubricant: Ensures smooth operation of moving parts.

- Cleaning Brushes: Helps in maintaining cleanliness and functionality.

Additional Accessories

- Safety Goggles: Protects eyes during disassembly and assembly.

- Work Gloves: Provides grip and protects hands from sharp edges.

- Magnifying Glass: Aids in inspecting small components for damage.

- Multimeter: Useful for checking electrical connections if applicable.

By gathering these tools, you will be well-prepared to handle various tasks, enhancing both your efficiency and the longevity of your equipment.

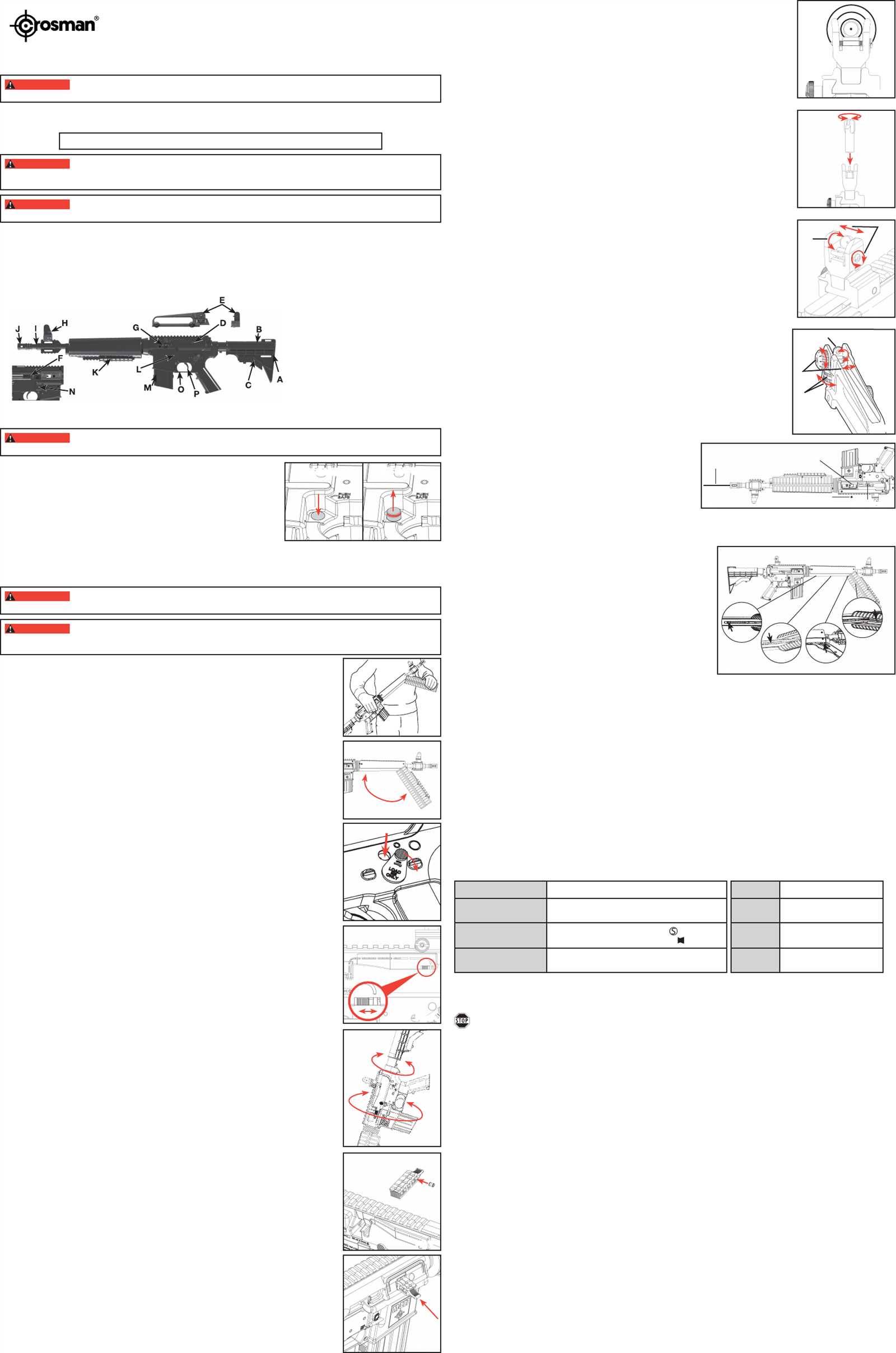

Step-by-Step Disassembly Guide

This section provides a comprehensive guide for safely taking apart a specific type of air-powered device. Understanding the disassembly process is essential for maintenance and troubleshooting, ensuring that you can access internal components for inspection and repairs. Follow the steps carefully to avoid damage and ensure a smooth reassembly.

Tools Required

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove screws holding the casing |

| Pliers | To grip and pull components |

| Cleaning Cloth | To clean parts during disassembly |

| Container | To keep small parts organized |

Disassembly Steps

Begin by ensuring that the device is unloaded and safe to handle. Start by removing any external attachments or accessories. Next, identify and unscrew the screws located on the exterior casing. Carefully lift the casing away, taking note of any clips or latches that may need to be released. As you proceed, pay attention to the arrangement of internal components, and consider documenting their positions to facilitate reassembly. Remove each part systematically, placing them in the designated container to prevent loss.

Inspecting Key Components

Regular evaluation of essential parts is crucial for maintaining optimal performance in any mechanical device. Identifying wear, damage, or misalignment can significantly enhance functionality and extend lifespan. Thorough inspection helps ensure all components work harmoniously, preventing costly repairs and downtime.

Barrel and Air Seal

The barrel should be free of obstructions and show no signs of corrosion or pitting. An effective air seal is vital for consistent performance; check for cracks or signs of degradation in the seals and o-rings. Replacing worn seals can prevent air leakage and improve power delivery.

Trigger Mechanism

Inspecting the trigger assembly is important for ensuring smooth operation. Look for any signs of stiffness or excessive wear in the moving parts. Cleaning and lubricating the trigger mechanism can enhance responsiveness and improve user experience.

Reassembly Instructions Explained

Reassembling a complex mechanism requires careful attention to detail and a methodical approach. This section provides a clear guide to ensure that each component is correctly placed and functions smoothly. Understanding the sequence of assembly is crucial for restoring the item to its original operational state.

Step-by-Step Assembly Process

Begin by organizing all components to ensure nothing is misplaced. Follow the sequence outlined in the initial disassembly, ensuring each part is correctly aligned with its corresponding counterpart. Pay particular attention to the positioning of springs and seals, as improper placement can lead to malfunction.

Final Checks and Testing

Once reassembly is complete, conduct thorough checks to confirm all parts are secure. Test the functionality of the mechanism to identify any issues. If any irregularities are noticed, disassemble and repeat the assembly process, addressing any misalignments or errors encountered.

Replacing Worn Out Parts

Maintaining optimal performance in your equipment often requires the replacement of degraded components. Identifying and addressing worn-out elements is essential for ensuring functionality and longevity. This section will guide you through the process of swapping out parts that may be hindering performance.

| Part | Signs of Wear | Replacement Tips |

|---|---|---|

| Seals | Leaks or decreased efficiency | Ensure a snug fit; use appropriate lubricant. |

| O-Rings | Cracks or brittleness | Select the correct size; replace regularly. |

| Springs | Weakness or breaks | Choose high-quality materials for replacements. |

| Valves | Sticking or improper sealing | Clean thoroughly; consider upgrading to higher performance versions. |

Following these guidelines will facilitate smooth replacements and enhance overall performance. Regular maintenance not only preserves functionality but also prolongs the lifespan of your device.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for maximizing the lifespan of your air-powered device. By implementing a few straightforward practices, you can ensure optimal performance and reduce the likelihood of issues arising over time.

Routine Inspection

Performing regular checks on your equipment can help identify potential problems before they escalate. Look for any signs of wear or damage, especially in seals and moving parts. Keeping everything clean and free of debris is crucial for smooth operation.

Lubrication

Applying appropriate lubricants to moving components can significantly enhance functionality and prevent rust or corrosion. Use products designed for pneumatic mechanisms to maintain the integrity of the materials. Always follow the manufacturer’s recommendations for the frequency and type of lubrication.

Incorporating these simple maintenance strategies will help ensure your device remains in excellent condition, providing reliable performance for years to come.

How to Troubleshoot Performance Problems

When encountering issues with performance, it is essential to follow a systematic approach to identify and resolve the underlying causes. This section provides a comprehensive guide to effectively diagnose common issues that may affect functionality.

1. Check for Air Leaks: Begin by inspecting all seals and connections. Air leaks can significantly impact efficiency. Use a simple method, such as applying soapy water to joints; if bubbles form, you have identified a leak.

2. Inspect the Power Source: Ensure that the power source is functioning correctly. Check for adequate charge or supply, as insufficient power can lead to diminished performance.

3. Clean and Maintain Components: Regular maintenance is crucial. Accumulation of dirt and debris can hinder operation. Disassemble necessary parts and clean them thoroughly, ensuring all mechanisms move freely.

4. Examine the Mechanism: Look closely at the internal components for wear or damage. Worn-out parts may need replacement. Pay attention to springs, seals, and any moving parts that could affect overall performance.

5. Test for Consistency: After making adjustments, conduct a series of tests to evaluate performance. This will help determine if issues persist or if further action is necessary. Consistency in operation is key to ensuring reliability.

By following these steps, you can effectively troubleshoot and enhance the overall functionality of your device, ensuring a smoother and more efficient experience.

Cleaning and Lubrication Techniques

Maintaining the performance and longevity of your air pistol requires regular cleaning and proper lubrication. These essential practices help to prevent malfunctions and ensure smooth operation. This section outlines effective methods and tips for keeping your device in optimal condition.

Cleaning Steps

- Disassemble the Device: Carefully take apart the main components, ensuring that you keep track of each part.

- Remove Residue: Use a soft cloth or brush to eliminate any dirt, dust, or lubricant buildup from the barrel and other surfaces.

- Use Appropriate Solvents: Choose a suitable cleaner designed for air pistols. Apply it to a cloth and wipe down the internal mechanisms.

- Inspect O-Rings: Check for wear or damage. Replace them if necessary to maintain airtight seals.

Lubrication Techniques

- Select the Right Lubricant: Opt for high-quality, non-toxic oil that is safe for use with your air pistol.

- Apply Sparingly: Use a small amount of lubricant on moving parts, ensuring not to over-saturate.

- Wipe Off Excess: After application, gently wipe away any surplus to prevent attracting dirt.

- Frequency: Regularly check and reapply lubricant based on usage frequency and environmental conditions.

Safety Precautions During Repair

Ensuring safety while working on devices is crucial to prevent accidents and injuries. Adhering to specific guidelines not only protects the individual but also preserves the integrity of the equipment being serviced.

General Safety Guidelines

- Always work in a well-ventilated area to avoid inhaling harmful fumes.

- Use personal protective equipment (PPE) such as gloves and safety goggles.

- Keep a first aid kit accessible in case of emergencies.

Device Handling Practices

- Disconnect any power source before starting the procedure.

- Ensure tools are in good condition to avoid malfunctions during use.

- Follow the specific instructions for handling fragile components to prevent damage.

Frequently Asked Questions

This section aims to address common inquiries and concerns related to the maintenance and troubleshooting of air-powered devices. Here, you will find valuable insights that can assist you in understanding various aspects of functionality, care, and potential issues.

What should I do if my device is not firing?

If the device fails to operate, first check the power source and ensure it is properly charged or loaded. Inspect for any obstructions in the mechanism that may prevent operation.

How can I improve the accuracy of my air-powered device?

Enhancing precision often involves regular maintenance, including cleaning the barrel and ensuring all components are correctly aligned. Additionally, using quality ammunition can significantly affect performance.

What maintenance tasks are essential for longevity?

Routine cleaning and lubrication of moving parts are crucial. Regularly inspect seals and O-rings for wear and replace them as necessary to maintain optimal performance.

Are there any specific troubleshooting steps I should follow?

Yes, if you encounter issues, start by reviewing the user guidelines for troubleshooting advice. Many problems can be resolved by checking the air supply and inspecting for loose components.

Can I use aftermarket accessories with my device?

While some aftermarket accessories may be compatible, it is advisable to use components specifically designed for your model to ensure proper functionality and safety.