Maintaining your lawn equipment is essential for ensuring its longevity and optimal performance. Understanding the intricacies of these machines can save you both time and money, allowing you to tackle any issues that may arise with confidence. A well-functioning device not only enhances the aesthetic appeal of your outdoor space but also contributes to the health of your lawn.

In this section, we will explore various techniques and insights for troubleshooting and servicing your essential gardening tool. From identifying common problems to implementing effective solutions, our comprehensive guide will equip you with the knowledge needed to keep your equipment running smoothly. Whether you’re a seasoned gardener or just starting out, knowing how to maintain your tools can make all the difference.

With a focus on practical advice and step-by-step instructions, this resource aims to demystify the maintenance process. You’ll discover how simple repairs can extend the life of your machine and improve its efficiency. Let’s dive into the details and empower you to take control of your gardening tasks!

Common Issues with Craftsman Push Mowers

Many users encounter similar challenges when using their lawn maintenance equipment. Understanding these common problems can help in troubleshooting and restoring functionality effectively. From performance drops to starting difficulties, identifying the root causes is essential for seamless operation.

One frequent issue involves difficulty starting the engine. This can be attributed to a clogged air filter, old fuel, or spark plug problems. Ensuring these components are clean and in good condition can often resolve the issue.

Another prevalent concern is the machine not cutting evenly. This can result from dull blades, improper height settings, or debris buildup underneath the deck. Regular maintenance of the cutting elements and proper adjustments can enhance cutting performance.

Moreover, vibrations during use can indicate loose parts or worn-out components. Checking bolts and fasteners for tightness can help mitigate excessive shaking, ensuring a smoother operation.

Lastly, frequent stalling may occur due to fuel supply issues or overheating. Inspecting the fuel system and allowing adequate cooling time between uses can prevent these interruptions.

Tools Needed for Basic Repairs

Having the right equipment is essential for effective maintenance and troubleshooting of outdoor machinery. A well-equipped toolkit not only simplifies the process but also enhances the overall efficiency of your tasks. Below are the fundamental tools that can aid in performing essential fixes.

Wrenches: A set of adjustable wrenches and socket sets is crucial for loosening and tightening various nuts and bolts. Ensure you have multiple sizes to accommodate different components.

Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and securing screws in various parts. A magnetic screwdriver can help prevent screws from falling into hard-to-reach areas.

Pliers: Needle-nose and standard pliers are invaluable for gripping, bending, and cutting wires or small components. They can also assist in removing stuck parts.

Blades and Cutting Tools: A sharp utility knife or blade can be used for cutting through materials like plastic or rope, making it easier to access internal mechanisms.

Cleaning Supplies: A brush and a cloth are vital for keeping surfaces clean and free from debris. Proper maintenance helps ensure longevity and optimal performance.

Safety Gear: Always prioritize safety by wearing gloves and goggles. Protecting yourself while working on machinery is paramount to avoid injuries.

Equipping yourself with these essential tools will facilitate smoother maintenance processes and ensure that you can tackle various tasks with confidence.

Step-by-Step Maintenance Guide

Regular upkeep of your outdoor equipment is essential to ensure longevity and optimal performance. Following a systematic approach to maintenance not only enhances functionality but also helps prevent potential issues in the future. This guide provides straightforward steps to keep your machine in excellent condition.

Essential Tools and Supplies

- Wrench set

- Screwdriver

- Oil and filter

- Air filter

- Fuel stabilizer

- Spark plug

- Cleaning brush

Maintenance Steps

- Check the Oil Level:

- Ensure the engine is cool.

- Remove the dipstick, wipe it clean, and reinsert.

- Check the level; add oil if necessary.

- Inspect the Air Filter:

- Remove the filter from its housing.

- Clean or replace it if it appears dirty or damaged.

- Sharpen the Blade:

- Disconnect the spark plug for safety.

- Remove the blade and sharpen it using a file or grinder.

- Reattach the blade securely.

- Check the Spark Plug:

- Inspect for wear and carbon buildup.

- Replace if necessary.

- Clean the Undercarriage:

- Use a cleaning brush to remove debris.

- Ensure no grass clippings are stuck.

- Fuel System Maintenance:

- Empty old fuel if it has been sitting for months.

- Add fresh fuel with stabilizer.

By adhering to these maintenance steps, you can significantly extend the life of your equipment and maintain its efficiency. Regular attention to these details will lead to a smoother operation and enhance your overall experience.

How to Change the Oil

Maintaining optimal performance of your equipment involves regular oil changes. This essential task helps ensure that the engine runs smoothly and extends its lifespan. Here’s a simple guide to help you through the process effectively.

Gather Your Materials

Before starting, make sure you have the necessary items: a suitable oil container, a funnel, a wrench, and fresh lubricant. Additionally, keep some rags handy for any spills.

Draining the Old Oil

Begin by locating the oil drain plug, usually found at the base of the engine. Use the wrench to loosen and remove the plug, allowing the used oil to flow into your container. Ensure that the area is clean to prevent contamination. Once the oil has fully drained, replace the drain plug securely.

Next, use the funnel to pour the new oil into the designated fill tube. Refer to your specific model’s guidelines to determine the correct type and quantity of lubricant required. After filling, check the oil level with the dipstick, if available, to ensure it’s at the proper mark.

Regular oil changes not only improve efficiency but also reduce wear and tear, making this maintenance task a vital part of caring for your equipment.

Troubleshooting Starting Problems

Experiencing difficulty in starting your equipment can be frustrating. Several factors can contribute to this issue, ranging from fuel quality to mechanical failures. Understanding common problems and their solutions can help you get back to work efficiently.

- Check Fuel Quality:

- Ensure that the fuel is fresh and free of contaminants.

- Consider replacing stale fuel if it has been stored for an extended period.

- Inspect the Battery:

- Verify that the battery is charged and in good condition.

- Look for any signs of corrosion on the terminals.

- Examine the Spark Plug:

- Remove the spark plug and check for wear or carbon buildup.

- Replace it if necessary to ensure a strong ignition.

- Evaluate the Air Filter:

- Inspect the air filter for dirt or blockages.

- Clean or replace it to allow proper airflow.

- Inspect the Starter Mechanism:

- Check for any mechanical obstructions that may hinder the starter.

- Ensure all components are functioning properly without any damage.

By systematically examining these areas, you can identify and resolve the starting issues more effectively, ensuring reliable performance for your equipment.

Blade Sharpening Techniques

Maintaining the sharpness of cutting tools is essential for optimal performance and longevity. A well-honed edge ensures cleaner cuts, reduces strain on the engine, and promotes healthier growth of grass or plants. This section explores various methods for sharpening blades effectively, ensuring they remain in peak condition.

One of the most common techniques involves using a sharpening stone. Begin by removing the blade from the equipment and securing it in a vice. Hold the stone at a consistent angle, typically around 30 degrees, and glide it along the cutting edge in smooth, even strokes. This method allows for precise control over the sharpening process, resulting in a razor-sharp finish.

Another popular approach is employing a file. Similar to the stone technique, this requires a steady hand and the correct angle. Use a flat file for a straight edge or a round file for curved blades. Always sharpen in one direction, moving away from the cutting edge, to avoid dulling the blade further.

For those seeking convenience, electric sharpeners are available. These tools can quickly restore the blade’s edge but should be used with caution to prevent overheating, which can damage the metal. Always follow the manufacturer’s instructions for best results.

Regardless of the method chosen, it is crucial to regularly check the blade’s balance after sharpening. An imbalanced blade can lead to uneven cuts and additional wear on the equipment. A simple test involves suspending the blade from a central point; it should remain level. If it tilts, adjustments may be necessary.

In summary, keeping blades sharp not only enhances performance but also prolongs the lifespan of your tools. By using the appropriate sharpening techniques, anyone can achieve the desired results and ensure efficient operation.

Replacing Spark Plugs Effectively

Ensuring optimal performance in small engine equipment often hinges on the proper maintenance of essential components. One such element is the spark plug, which plays a critical role in the ignition process. Replacing these plugs can lead to improved efficiency and reliability, making it a vital task for any equipment owner.

Before you begin the replacement process, gather the necessary tools, including a spark plug socket, a ratchet, and a gap gauge. Start by locating the spark plug, which is typically found on the engine’s cylinder head. Disconnect the spark plug wire to prevent accidental ignition during the procedure.

Using the spark plug socket, carefully remove the old plug by turning it counterclockwise. Once removed, inspect it for signs of wear or damage. A worn plug may exhibit discoloration, buildup, or cracks, indicating that it needs replacement.

Next, prepare the new plug by checking the gap using the gap gauge. Adjust it if necessary, ensuring it meets the manufacturer’s specifications. This step is crucial, as the correct gap ensures optimal combustion and engine performance.

Install the new spark plug by threading it in by hand initially to avoid cross-threading. Once it is hand-tight, use the ratchet to secure it snugly, but be careful not to overtighten, as this can cause damage to the engine.

Finally, reattach the spark plug wire, ensuring a secure connection. Regularly replacing spark plugs can lead to smoother operation and prolonged engine life, making it a simple yet effective maintenance task.

Adjusting the Cutting Height

Achieving the desired grass length is crucial for maintaining a healthy lawn. Proper height adjustment not only enhances the appearance of your yard but also promotes optimal growth and resilience. This section will guide you through the steps necessary to modify the cutting height effectively.

Step 1: Gather Your Tools

Step 2: Locate the Adjustment Mechanism

Find the adjustment system, which is usually situated near the wheels or on the cutting deck. It may feature a series of notches or a simple lever for quick changes. Understanding this component is essential for making accurate modifications.

Step 3: Adjust the Height

Once you’ve located the mechanism, determine your preferred cutting height. Most systems allow for multiple settings. If using a lever, simply move it to your desired position. For notched systems, release the locking mechanism and shift to the appropriate notch, ensuring it is securely in place.

Step 4: Test the Adjustment

After making the necessary changes, it’s important to test the setting. Perform a quick pass over a small area of your lawn. Observe how the grass is cut and make further adjustments if needed to achieve the ideal height.

Step 5: Regular Maintenance

Finally, remember that grass height may need to be adjusted periodically due to seasonal changes or varying growth rates. Regular checks will help maintain the health and aesthetics of your lawn.

Winterizing Your Push Mower

Preparing your lawn care equipment for the cold months is essential to ensure its longevity and performance. Proper maintenance during this period can prevent damage and save you time and money in the spring. Here are key steps to follow for a successful winterization process.

- Clean the Equipment:

- Remove grass clippings and debris from the cutting deck and undercarriage.

- Wipe down surfaces with a damp cloth to prevent rust.

- Drain or Stabilize Fuel:

- If you use a fuel stabilizer, add it to the tank and run the engine for a few minutes.

- Alternatively, you can completely drain the fuel system if no stabilizer is used.

- Change the Oil:

- Warm up the engine slightly and then drain the old oil.

- Replace it with fresh oil to keep internal components lubricated.

- Check the Blades:

- Inspect the cutting blades for wear and sharpen if necessary.

- Consider removing the blades for a thorough cleaning and maintenance.

- Store Properly:

- Find a dry, cool place for storage, away from direct sunlight.

- Consider covering the equipment to protect it from dust and moisture.

By following these steps, you can ensure that your lawn maintenance equipment is ready to tackle the tasks ahead when the weather warms up again.

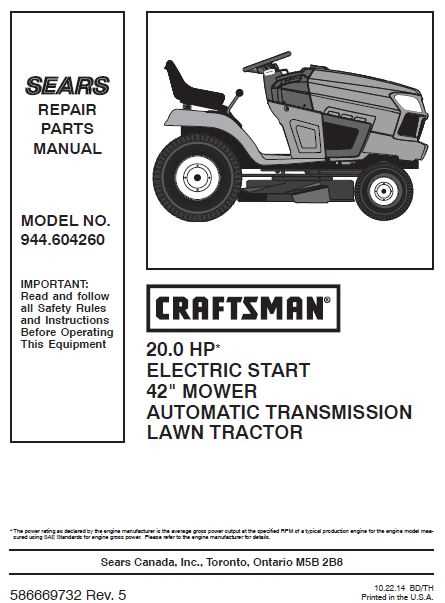

Finding Replacement Parts Online

Locating suitable components for your outdoor equipment has become more accessible thanks to various online platforms. Whether you need a specific item for maintenance or a complete overhaul, the internet provides a vast selection of options to cater to your needs. This guide will help you navigate the process of sourcing the right pieces efficiently.

Utilizing Reputable Websites

Start by exploring well-known e-commerce sites that specialize in gardening and outdoor tools. These platforms typically have extensive catalogs featuring a range of parts, allowing you to filter results based on compatibility and specifications. User reviews can also guide you in selecting quality items that fit your machinery.

Checking Manufacturer Resources

Another effective strategy is to visit the official website of the equipment’s manufacturer. Many companies offer a dedicated section for spare parts, ensuring you find genuine products designed for your model. Additionally, some sites provide diagrams and part numbers to simplify the identification process.