Systematic Servicing: Periodic service tasks focus on cleaning, testing, and adjusting specific parts. These tasks are scheduled based on hours of operation or cycles

Understanding Material Types in A320 Repairs

When addressing the complexities of aircraft maintenance, it is essential to recognize the various materials utilized in aircraft construction and their respective applications. Each substance plays a critical role in ensuring that the aircraft meets safety standards, performance expectations, and longevity requirements. The choice of materials can significantly influence the efficacy and durability of interventions carried out on the aircraft.

Categories of Materials

The materials employed in aircraft frameworks can generally be categorized into metals, composites, and plastics. Metals, such as aluminum and titanium, are favored for their strength-to-weight ratios and resistance to fatigue. They are often used in components that require high structural integrity. On the other hand, composites, which include carbon fiber and glass fiber, provide excellent performance characteristics, including weight savings and enhanced aerodynamic properties. These materials are particularly beneficial in areas where reducing weight is critical for fuel efficiency and overall performance.

Material Selection Considerations

Choosing the right material for any specific application requires careful consideration of factors such as environmental exposure, load-bearing requirements, and compatibility with existing materials. Corrosion resistance is another vital aspect, as certain materials can degrade when exposed to harsh conditions. Thus, a thorough understanding of these different types of materials and their properties is paramount for effective interventions on the aircraft.

Structural Damage Classification Methods

Classifying damage to aircraft components is essential for ensuring safety and integrity during operations. Different techniques and criteria are employed to identify and categorize various forms of deterioration, allowing maintenance teams to assess the extent of issues and prioritize interventions effectively.

Visual Inspection Techniques

Visual examination is a primary approach for assessing damage. Inspectors utilize various tools and methodologies to detect visible flaws, such as cracks, dents, and corrosion. This method often serves as the first line of defense, helping to quickly identify areas requiring further investigation.

Non-Destructive Testing (NDT)

Non-destructive testing methods are crucial for evaluating material integrity without causing harm. Techniques like ultrasonic testing, radiography, and magnetic particle inspections allow for an in-depth analysis of hidden defects. By utilizing these advanced technologies, maintenance personnel can detect subsurface issues that might not be visible through standard visual inspection.

Approved Repair Procedures and Standards

This section outlines the accepted methods and benchmarks that guide the rectification of aircraft components. Following these guidelines ensures that the processes meet regulatory and safety requirements, thereby maintaining airworthiness and operational efficiency.

Key Procedures

- Documentation of defects and damages.

- Assessment of affected areas to determine necessary actions.

- Selection of appropriate techniques and materials for restoration.

- Implementation of repairs according to established protocols.

- Final inspection to verify compliance with industry standards.

Standards and Regulations

Adherence to recognized standards is crucial for ensuring the integrity of modifications. The following regulations are typically referenced:

- FAA regulations that dictate maintenance practices.

- Manufacturer guidelines for specific techniques and materials.

- International safety standards that provide a framework for quality assurance.

Regular updates and training in these procedures help personnel stay current with evolving practices and technologies.

Safety Protocols in Structural Maintenance

Ensuring the integrity of aviation frameworks necessitates strict adherence to safety measures. These protocols are designed to mitigate risks associated with inspections and modifications, safeguarding personnel and equipment throughout the process.

Risk Assessment and Planning

Conducting a thorough risk assessment is essential before commencing any maintenance activities. This involves identifying potential hazards and formulating a detailed action plan that outlines necessary precautions. Proper planning helps in allocating resources effectively and minimizes the likelihood of accidents.

Personal Protective Equipment (PPE)

Utilizing personal protective equipment is crucial in maintaining safety during maintenance tasks. Workers must be equipped with appropriate gear, including helmets, gloves, and eye protection, to defend against environmental hazards. Regular training on the correct use of PPE enhances awareness and promotes a culture of safety.

Detailed Repair Documentation Requirements

This section outlines the essential criteria for comprehensive documentation when addressing the restoration and maintenance of aircraft structures. Accurate and thorough documentation is crucial to ensure safety, compliance, and operational efficiency throughout the process.

Documentation Scope: Every project requires a precise definition of the scope, including the components involved and the nature of the tasks to be executed. Clear specifications help in understanding the extent of the intervention necessary for each situation.

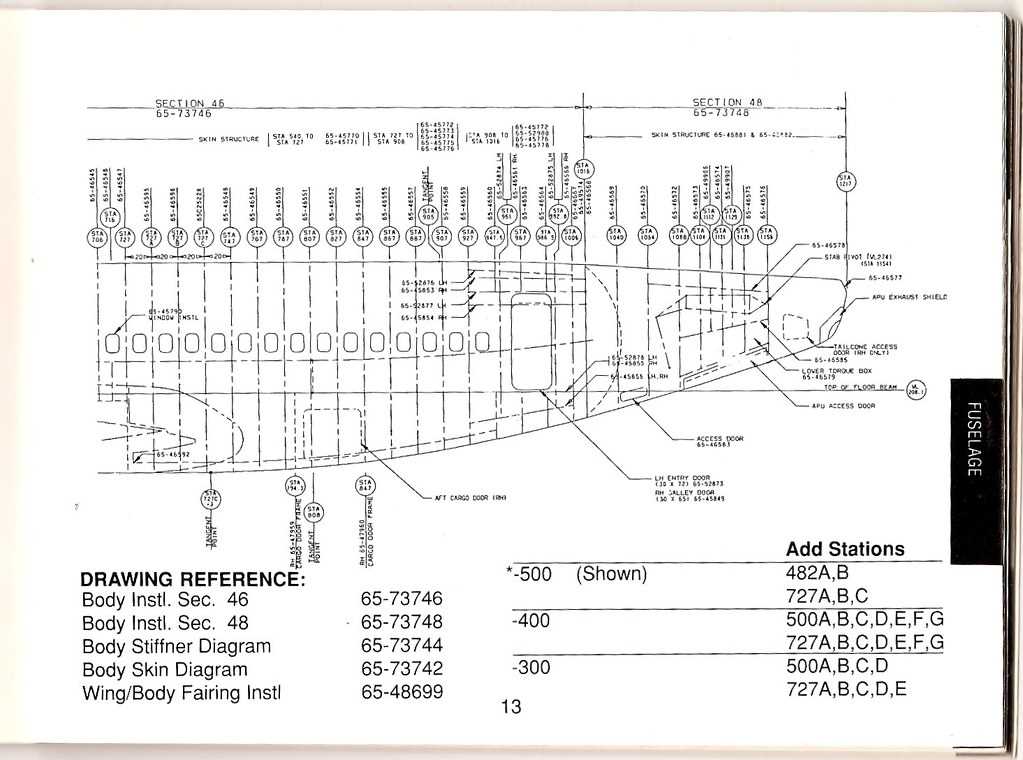

Technical Data: Detailed technical information should accompany each task, including diagrams, specifications, and relevant instructions. This data serves as a reference point for personnel to adhere to standard practices and achieve the desired outcomes.

Verification and Validation: It is imperative to establish protocols for verifying and validating the completed work. This includes checklists and sign-off procedures to confirm that all tasks have been executed in accordance with regulatory standards and internal guidelines.

Record Keeping: Maintaining organized records of all activities is vital for future reference. This includes documenting the initial condition, procedures followed, and final outcomes. Such records support ongoing assessments and facilitate audits by regulatory bodies.

Training and Competency: Personnel involved in these processes must possess the necessary skills and training. Documentation should reflect the qualifications required for each role, ensuring that only competent individuals are engaged in sensitive operations.

Assessing Damage Severity and Impact

Evaluating the extent and implications of harm to an aircraft is a critical step in ensuring safety and operational readiness. Understanding the level of damage allows for informed decision-making regarding necessary actions and potential consequences. This process involves examining the affected areas, determining the nature of the impairment, and assessing how it may influence the overall functionality of the aircraft.

Evaluation Criteria

The assessment of damage encompasses various factors, including the type of material affected, the size of the damage, and its location. Each criterion plays a significant role in determining the severity of the incident. Here are some key factors to consider:

| Factor |

Description |

| Material Type |

Different materials exhibit varying degrees of resilience and failure modes, influencing the assessment process. |

| Damage Size |

The larger the damaged area, the more significant the potential impact on structural integrity and performance. |

| Location |

Certain areas are more critical than others; damage in essential zones requires immediate attention. |

Impact Analysis

Following the evaluation of the damage, it is essential to analyze the potential impact on the aircraft’s operational capabilities. This includes assessing any effects on safety, performance, and regulatory compliance. A comprehensive understanding of these aspects ensures that necessary measures can be implemented to maintain the aircraft’s reliability and efficiency.

Preventive Measures to Reduce Structural Wear

To ensure longevity and reliability of aircraft components, it is essential to implement effective strategies aimed at minimizing deterioration. Proactive practices not only enhance performance but also significantly decrease the likelihood of costly interventions.

Regular Inspections: Conducting frequent examinations of critical parts helps in early identification of potential issues. Utilizing advanced inspection techniques, such as ultrasonic testing and visual assessments, allows for timely interventions before wear progresses.

Maintenance Schedules: Establishing a rigorous maintenance routine, based on manufacturer guidelines, ensures that all components are regularly serviced and any signs of fatigue or damage are addressed promptly. This includes checking fasteners, joints, and other key areas that may be prone to wear.

Environmental Considerations: Protecting aircraft from harsh weather conditions is vital. Utilizing covers or hangars during extreme conditions can shield surfaces from corrosive elements, thereby extending their lifespan.

Material Selection: Choosing high-quality materials with superior resistance to wear can make a significant difference. Utilizing advanced composites and alloys designed to withstand stress and fatigue will enhance durability and performance.

Training and Awareness: Ensuring that all personnel involved in maintenance and operations are adequately trained increases the effectiveness of preventive measures. Awareness programs regarding the importance of proper handling and maintenance practices can foster a culture of diligence and care.

Documentation: Keeping detailed records of inspections, maintenance activities, and any modifications helps in tracking wear patterns and identifying areas that require increased attention. This data-driven approach allows for informed decision-making regarding maintenance and operational practices.